Araldite AV 4076-1 / Hardener HY 4076 - DanLube

Araldite AV 4076-1 / Hardener HY 4076 - DanLube

Araldite AV 4076-1 / Hardener HY 4076 - DanLube

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Intensiv-Seminar zur Optimierung von Transport- und LogistikverträgenTag 1: Vertragsgestaltung in Transport- und Logistik (20.01.2011)09:3009:3510:1511:0011:1512:00Empfang und Ausgabe der TagungsunterlagenEinführung in das logistikrelevante Recht• Ziele und grundsätzliche Gestaltungs- und Risikobereichebei Logistikverträgen• betriebswirtschaftliche und rechtliche Besonderheitenvon Logistikverträgen / Kontraktlogistik- und Zuruflogistik• Abgrenzung zu Fracht- und SpeditionsverträgenPre Contract Management• Vorstellung der Handlungskomplexe des Pre ContractManagements, insb. das Problem und die Zusatzkostenund -risiken nicht spezialisierter Rechtsabteilungen• Vertragspartnercheck• Arten des Zustandekommens von Logistikrahmen- undEinzelverträgen, Verzahnung der Verträge• Pre Contract Risk ManagementKaffeepauseFortsetzung Pre Contract ManagementLeistungsmodule der Kontraktlogistik14:0014:3015:30Logistik-Outsourcing und ergänzende Vertragstools fürinternationale Logistikverträgeinkl. Transportlogistik, insbesondere mit Blick auf Mittel- undOsteuropaIntensiv-Vertrags-Workshop: Angeleitete Erarbeitung einestypischen Kontraktlogistikvertrages in Kleingruppenund anschließende Ergebnisdiskussion im Zweiparteienspiel• Auf der Basis der Best Practice Vertragscheckliste (Kurzfassung)• Kernpunkte von Logistikverträgen, z. B. Supply Chain bezogeneRegelungen, qualitative/quantitative Änderungen derLeistungsbeziehungen, Vergütungsregelungen, Gestaltungsmöglichkeitenzur Vertragsbeendigung, insb. die zahlreichenRegelungsnotwendigkeiten zur Kündigung inkl. derGestaltungen zur Nach-Kündigungswirkungszeit (PostTermination Tools), SLA-/KPI-Regelungen sowie zahlreicheweitere Punkte – ohne Leistungsstörungen/Haftung/VersicherungKaffeepause• Logistik-Kernfunktionen Transport, Umschlag, Lager15:50Fortsetzung des Intensiv-Vertrags-Workshops• Ergänzende Funktionen (z. B. Wareneingang, Exportabwicklung,Retourenmanagement, IT-Dienstleistungen, Inkasso,Factoring, Call Center, Labelung, Verpackung,Konfektionierung usw. )17:30Ende des ersten Seminartages13:00MittagessenIhre Referenten an diesem Seminartag sind: Univ. Prof. Dr. Sebastian KummerRechtsanwalt Karl-Heinz Gimmler

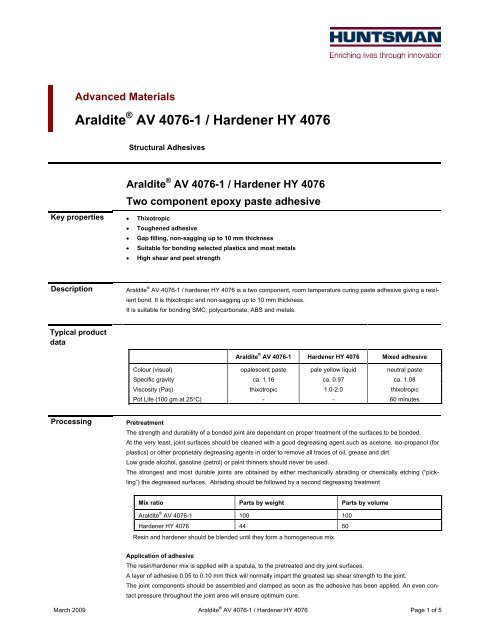

Lap shear strength versus immersion in various media (typical average values)Unless otherwise stated, L.S.S. was determined after immersion for 90 days at 23 C30 days 60 days 90 days Cure: 16 hours at 40°CN/mm 2 0 5 10 15 20 25 30 35As-made valueIMSGasoline (petrol)Ethyl acetateAcetic acid, 10%XyleneLubricating oilParaffinWater at 23°CWater at 60°CWater at 90°CLap shear strength versus tropical weathering(40/92, DIN 50015; typical average values)Cure: 16 hours at 40 CAs made valueAfter 30 daysAfter 60 daysAfter 90 daysN/mm 20 5 10 15 20 25 30`Lap shear strength versus heat ageingCure:16 hours at 40 CAs made value30 days / 70°C60 days / 70°C90 days / 70°CN/mm 20 5 10 15 20 25 30 35March 2009 <strong>Araldite</strong> ® <strong>AV</strong> <strong>4076</strong>-1 / <strong>Hardener</strong> <strong>HY</strong> <strong>4076</strong> Page 4 of 5

Storage<strong>Araldite</strong> ® <strong>AV</strong> <strong>4076</strong>-1 and <strong>Hardener</strong> <strong>HY</strong> <strong>4076</strong> may be stored for up to 6 years and 3 years respectively at room temperatureproved the components are stored in sealed containers. The expiry date is indicated on the label.HandlingPrecautionsCautionOur products are generally quite harmless to handle provided that certain precautions normally taken when handlingchemicals are observed. The uncured materials must not, for instance, be allowed to come into contact with foodstuffsor food utensils, and measures should be taken to prevent the uncured materials from coming in contact withthe skin, since people with particularly sensitive skin may be affected. The wearing of impervious rubber or plasticgloves will normally be necessary; likewise the use of eye protection. The skin should be thoroughly cleansed at theend of each working period by washing with soap and warm water. The use of solvents is to be avoided. Disposablepaper - not cloth towels - should be used to dry the skin. Adequate ventilation of the working area is recommended.These precautions are described in greater detail in the Material Safety Data sheets for the individualproducts and should be referred to for fuller information.Huntsman Advanced Materials warrants only that its products meet the specifications agreed with the buyer. Typical properties,where stated, are to be considered as representative of current production and should not be treated as specifications.The manufacture of materials is the subject of granted patents and patent applications; freedom to operate patented processesis not implied by this publication.Huntsman Advanced Materials(Switzerland) GmbHKlybeckstrasse 2004057 BaselSwitzerlandTel: +41 (0)61 299 11 11Fax: +41 (0)61 299 11 12www.huntsman.com/advanced_materialsEmail: advanced_materials@huntsman.comWhile all the information and recommendations in this publication are, to the best of our knowledge, information and belief,accurate at the date of publication, NOTHING HEREIN IS TO BE CONSTRUED AS A WARRANTY, EXPRESS OROTHERWISE.IN ALL CASES, IT IS THE RESPONSIBILITY OF THE USER TO DETERMINE THE APPLICABILITY OF SUCH INFORMATIONAND RECOMMENDATIONS AND THE SUITABILITY OF ANY PRODUCT FOR ITS OWN PARTICULAR PURPOSE.The behaviour of the products referred to in this publication in manufacturing processes and their suitability in any given end-useenvironment are dependent upon various conditions such as chemical compatibility, temperature, and other variables, which arenot known to Huntsman Advanced Materials. It is the responsibility of the user to evaluate the manufacturing circumstances andthe final product under actual end-use requirements and to adequately advise and warn purchasers and users thereof.Products may be toxic and require special precautions in handling. The user should obtain Safety Data Sheets from HuntsmanAdvanced Materials containing detailed information on toxicity, together with proper shipping, handling and storage procedures,and should comply with all applicable safety and environmental standards.Hazards, toxicity and behaviour of the products may differ when used with other materials and are dependent on manufacturingcircumstances or other processes. Such hazards, toxicity and behaviour should be determined by the user and made known tohandlers, processors and end users.Except where explicitly agreed otherwise, the sale of products referred to in this publication is subject to the general terms andconditions of sale of Huntsman Advanced Materials LLC or of its affiliated companies including without limitation, HuntsmanAdvanced Materials (Europe) BVBA, Huntsman Advanced Materials Americas Inc., and Huntsman Advanced Materials (HongKong) Ltd.Huntsman Advanced Materials is an international business unit of Huntsman Corporation. Huntsman Advanced Materials tradesthrough Huntsman affiliated companies in different countries including but not limited to Huntsman Advanced Materials LLC inthe USA and Huntsman Advanced Materials (Europe) BVBA in Europe.<strong>Araldite</strong> is a registered trademark of Huntsman Corporation or an affiliate thereof.Copyright © 2008 Huntsman Corporation or an affiliate thereof. All rights reserved.March 2009 <strong>Araldite</strong> ® <strong>AV</strong> <strong>4076</strong>-1 / <strong>Hardener</strong> <strong>HY</strong> <strong>4076</strong> Page 5 of 5