High-yield purification of an organic solvent-tolerant ... - INBIOSIS

High-yield purification of an organic solvent-tolerant ... - INBIOSIS

High-yield purification of an organic solvent-tolerant ... - INBIOSIS

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

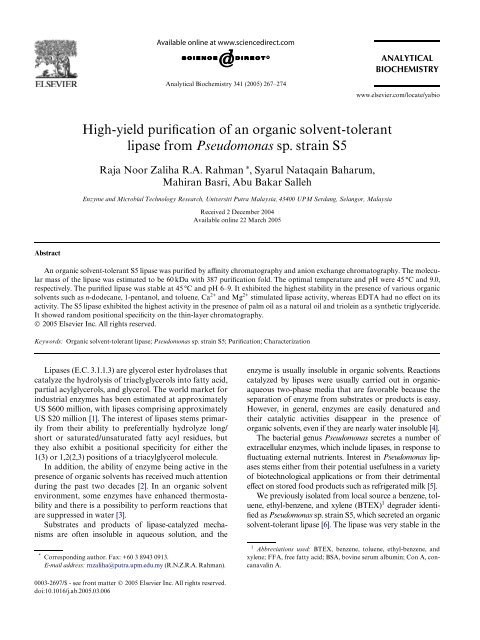

ANALYTICALBIOCHEMISTRYAnalytical Biochemistry 341 (2005) 267–274www.elsevier.com/locate/yabio<strong>High</strong>-<strong>yield</strong> puriWcation <strong>of</strong> <strong>an</strong> org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>tlipase from Pseudomonas sp. strain S5Raja Noor Zaliha R.A. Rahm<strong>an</strong> ¤ , Syarul Nataqain Baharum,Mahir<strong>an</strong> Basri, Abu Bakar SallehEnzyme <strong>an</strong>d Microbial Technology Research, Universiti Putra Malaysia, 43400 UPM Serd<strong>an</strong>g, Sel<strong>an</strong>gor, MalaysiaReceived 2 December 2004Available online 22 March 2005AbstractAn org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>t S5 lipase was puriWed by aYnity chromatography <strong>an</strong>d <strong>an</strong>ion exch<strong>an</strong>ge chromatography. The molecularmass <strong>of</strong> the lipase was estimated to be 60 kDa with 387 puriWcation fold. The optimal temperature <strong>an</strong>d pH were 45 °C <strong>an</strong>d 9.0,respectively. The puriWed lipase was stable at 45 °C <strong>an</strong>d pH 6–9. It exhibited the highest stability in the presence <strong>of</strong> various org<strong>an</strong>ic<strong>solvent</strong>s such as n-dodec<strong>an</strong>e, 1-pent<strong>an</strong>ol, <strong>an</strong>d toluene. Ca 2+ <strong>an</strong>d Mg 2+ stimulated lipase activity, whereas EDTA had no eVect on itsactivity. The S5 lipase exhibited the highest activity in the presence <strong>of</strong> palm oil as a natural oil <strong>an</strong>d triolein as a synthetic triglyceride.It showed r<strong>an</strong>dom positional speciWcity on the thin-layer chromatography.© 2005 Elsevier Inc. All rights reserved.Keywords: Org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>t lipase; Pseudomonas sp. strain S5; PuriWcation; CharacterizationLipases (E.C. 3.1.1.3) are glycerol ester hydrolases thatcatalyze the hydrolysis <strong>of</strong> triaclyglycerols into fatty acid,partial acylglycerols, <strong>an</strong>d glycerol. The world market forindustrial enzymes has been estimated at approximatelyUS $600 million, with lipases comprising approximatelyUS $20 million [1]. The interest <strong>of</strong> lipases stems primarilyfrom their ability to preferentially hydrolyze long/short or saturated/unsaturated fatty acyl residues, butthey also exhibit a positional speciWcity for either the1(3) or 1,2(2,3) positions <strong>of</strong> a triacylglycerol molecule.In addition, the ability <strong>of</strong> enzyme being active in thepresence <strong>of</strong> org<strong>an</strong>ic <strong>solvent</strong>s has received much attentionduring the past two decades [2]. In <strong>an</strong> org<strong>an</strong>ic <strong>solvent</strong>environment, some enzymes have enh<strong>an</strong>ced thermostability<strong>an</strong>d there is a possibility to perform reactions thatare suppressed in water [3].Substrates <strong>an</strong>d products <strong>of</strong> lipase-catalyzed mech<strong>an</strong>ismsare <strong>of</strong>ten insoluble in aqueous solution, <strong>an</strong>d the* Corresponding author. Fax: +60 3 8943 0913.E-mail address: rnzaliha@putra.upm.edu.my (R.N.Z.R.A. Rahm<strong>an</strong>).enzyme is usually insoluble in org<strong>an</strong>ic <strong>solvent</strong>s. Reactionscatalyzed by lipases were usually carried out in org<strong>an</strong>icaqueoustwo-phase media that are favorable because theseparation <strong>of</strong> enzyme from substrates or products is easy.However, in general, enzymes are easily denatured <strong>an</strong>dtheir catalytic activities disappear in the presence <strong>of</strong>org<strong>an</strong>ic <strong>solvent</strong>s, even if they are nearly water insoluble [4].The bacterial genus Pseudomonas secretes a number <strong>of</strong>extracellular enzymes, which include lipases, in response toXuctuating external nutrients. Interest in Pseudomonas lipasesstems either from their potential usefulness in a variety<strong>of</strong> biotechnological applications or from their detrimentaleVect on stored food products such as refrigerated milk [5].We previously isolated from local source a benzene, toluene,ethyl-benzene, <strong>an</strong>d xylene (BTEX) 1 degrader identi-Wed as Pseudomonas sp. strain S5, which secreted <strong>an</strong> org<strong>an</strong>ic<strong>solvent</strong>-toler<strong>an</strong>t lipase [6]. The lipase was very stable in the1 Abbreviations used: BTEX, benzene, toluene, ethyl-benzene, <strong>an</strong>dxylene; FFA, free fatty acid; BSA, bovine serum albumin; Con A, conc<strong>an</strong>avalinA.0003-2697/$ - see front matter © 2005 Elsevier Inc. All rights reserved.doi:10.1016/j.ab.2005.03.006

268 Org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>t lipase from Pseudomonas / R.N.Z.R.A. Rahm<strong>an</strong> et al. / Anal. Biochem. 341 (2005) 267–274presence <strong>of</strong> various org<strong>an</strong>ic <strong>solvent</strong>s such as n-hex<strong>an</strong>e,cyclohex<strong>an</strong>e, toluene, <strong>an</strong>d 1-oct<strong>an</strong>ol. In this article, wereport the puriWcation <strong>an</strong>d characterization <strong>of</strong> org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>tlipase secreted by Pseudomonas sp. strain S5.Materials <strong>an</strong>d methodsCulture conditionPseudomonas sp. strain S5, which secreted org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>tlipase, was used in this study [6].CultivationThe culture was grown at 37 °C for 48 h in themedium prepared by optimizing the previously usedmedium for lipase production [6]. In the cultivation procedure,6% <strong>of</strong> inoculum was inoculated into a 250 mlblue cap bottle containing 50 ml <strong>of</strong> the medium.Preparation <strong>of</strong> culture supernat<strong>an</strong>tThe culture supernat<strong>an</strong>t was prepared by removingthe cells in the culture by centrifugation at 12,000g for20 min at 4 °C.Measurement <strong>of</strong> lipase activityDetermination <strong>of</strong> liberated free fatty acid (FFA) wasmeasured by the modiWed method <strong>of</strong> Kwon <strong>an</strong>d Rhee [7].Olive oil was used as a substrate. The reaction mixture,consisting <strong>of</strong> 1.0 ml <strong>of</strong> crude enzyme, 2.5 ml olive oil emulsion,<strong>an</strong>d 0.02 ml <strong>of</strong> 20 mmol CaCl 2·2H 2 O, was incubatedfor 30 min with shaking at 200 rpm at 37 °C. Then thereaction was stopped by adding 1.0 ml <strong>of</strong> 6 N HCl <strong>an</strong>d5.0 ml isooct<strong>an</strong>e. The upper layer (4 ml) was pipetted outinto a test tube, <strong>an</strong>d 1.0 ml cupric acetate pyridine wasadded. The FFA dissolved in isooct<strong>an</strong>e was determinedby measuring the absorbency <strong>of</strong> isooct<strong>an</strong>e solution at715 nm. Lipase activity was determined by measuring theamount <strong>of</strong> FFA from the st<strong>an</strong>dard curves <strong>of</strong> oleic acid.One unit <strong>of</strong> lipase activity is deWned as the amount <strong>of</strong>enzyme that liberated 1 μmol FFA in 1 min at 37 °C.Determination <strong>of</strong> protein concentrationsThe protein concentrations in this study were determinedby the method <strong>of</strong> Bradford [8] using bovine serumalbumin (BSA, Sigma Chemical, St. Louis, MO, USA) asa st<strong>an</strong>dard.Con A–Sepharose column chromatographyThe enzyme solution was loaded onto the column(1.6 cm diameter, 20.0 cm height) <strong>of</strong> conc<strong>an</strong>avalin A(Con A)–Sepharose (Amersham–Pharmacia Biotech,Uppsala, Sweden) preequilibrated with 25 mM Tris–HClbuVer (pH 7.5). The column was washed with 5£ <strong>of</strong> columnbed volume <strong>of</strong> the equilibration buVer. The proteinsbound to the aYnity gel were eluted by increasing theconcentration <strong>of</strong> methyl α-D-glucoside from 0.1 to 0.5 Mwith a step gradient in 100 ml <strong>of</strong> 25 mM Tris–HCl buVer(pH 7.5) <strong>an</strong>d 100 ml <strong>of</strong> the same buVer containing methylα-D-glucoside. Fractions (approximately 5 ml <strong>of</strong> each)that exhibited lipase activity in the gradient region <strong>of</strong> themethyl α-D-glucoside concentration were collected. Theenzyme solution was then dialyzed overnight againstbuVer containing methyl α-D-glucoside.DEAE–Sephacel column chromatographyThe enzyme solution from the previous column wasloaded onto a column (1.6 cm diameter, 10.0 cm height)<strong>of</strong> DEAE–Sephacel (Amersham–Pharmacia Biotech)preequilibrated with 25 mM Tris–HCl buVer (pH 7.5).The column was washed with 100 ml <strong>of</strong> the equilibrationbuVer. The proteins bound to the <strong>an</strong>ion exch<strong>an</strong>ge gelwere eluted by increasing the concentration <strong>of</strong> NaCl in25 mM Tris–HCl buVer (pH 7.5) from 0.1 to 0.5 M with alinear gradient using 50 ml <strong>of</strong> 25 mM Tris–HCl buVer(pH 7.5) <strong>an</strong>d 50 ml <strong>of</strong> the same buVer containing NaCl.Fractions (approximately 2 ml <strong>of</strong> each) that exhibitedlipase activity in the gradient region <strong>of</strong> the NaCl concentrationwere collected. The enzyme solution was dialyzedovernight against buVer containing NaCl.Determination <strong>of</strong> the purity <strong>an</strong>d molecular mass <strong>of</strong> puriWedS5 lipase by SDS–PAGEThe solution containing puriWed S5 lipase <strong>an</strong>dsample buVer solution was heated in a boiling waterbath for 3 min. The sample was run in a stacking gelcontaining 4.35%(w/v) polyacrylamide <strong>an</strong>d 0.3%(w/v)N,N-methylene-bis(acrylamide) <strong>an</strong>d in a separating gelcontaining 14.8%(w/v) polyacrylamide <strong>an</strong>d 0.2%(w/v)N, N-methylene-bis(acrylamide) under the conditionsdeveloped by Laemmli [9]. The protein was stained bysilver staining.Org<strong>an</strong>ic <strong>solvent</strong> stability <strong>of</strong> the enzymeThe stability <strong>of</strong> the puriWed lipase in the org<strong>an</strong>ic <strong>solvent</strong>was investigated by the method as described byOgino et al. [10] with slight modiWcation. The puriWed S5lipase-containing 25 mM Tris–HCl (pH 7.5) was Wltersterilizedwith a cellulose acetate membr<strong>an</strong>e Wlter (0.2 μmpore size). Then 1 ml <strong>of</strong> <strong>an</strong> org<strong>an</strong>ic <strong>solvent</strong> was added to3ml <strong>of</strong> the Wltrate in a vial bottle, <strong>an</strong>d the mixture wasincubated at 37 °C with shaking at 150 rpm for 2 h. Theremaining lipase activity was measured by the methodby Kwon <strong>an</strong>d Rhee [7] as described above.

Org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>t lipase from Pseudomonas / R.N.Z.R.A. Rahm<strong>an</strong> et al. / Anal. Biochem. 341 (2005) 267–274 269EVect <strong>of</strong> pH <strong>an</strong>d pH stability <strong>of</strong> the S5 lipaseThe eVect <strong>of</strong> pH on the S5 lipase activity was investigatedby the method using olive oil as a substrate. VariousbuVer systems (pH 4.0–12.0) at 25 mM were added toolive oil to perform olive oil emulsion. Then the enzymewas assayed at diVerent pH values at 37 °C for 30 minwith shaking at 200 rpm. For pH stability studies, 200 μl<strong>of</strong> puriWed enzyme solution was mixed with 800 μl <strong>of</strong>25 mM buVer at speciWc pH. The mixture was incubatedat 37 °C for 30 min, <strong>an</strong>d the residual activity was determined.BuVer systems were used at a concentration <strong>of</strong>25 mM: glycine–HCl buVer (pH 4.0–5.0), sodium hydrogenphosphate–NaOH buVer (pH 5.0–7.0), Tris–HClbuVer (pH 7.0–9.0), disodium hydrogen orthophosphate–NaOHbuVer (pH 9.0–11.0), <strong>an</strong>d glycine–NaOHbuVer (pH 10.0–12.0).EVect <strong>of</strong> temperature on activity <strong>an</strong>d thermostability <strong>of</strong> S5lipaseThe eVect <strong>of</strong> temperature on lipase activity wasstudied by carrying out the enzyme reaction at diVerenttemperatures in the r<strong>an</strong>ge <strong>of</strong> 30–55 °C at pH 9.0using Tris–HCl buVer (25 mM). The reaction was carriedout for 0 <strong>an</strong>d 30 min. The thermostability <strong>of</strong>lipase was tested at various temperatures, r<strong>an</strong>gingfrom 37 to 45 °C, for diVerent time intervals, r<strong>an</strong>gingfrom 0 to 6 h. At each time interval, 500 μl sampleswere pippeted out <strong>an</strong>d immediately frozen prior tobeing assayed.Substrate speciWcityTo determine the eVect <strong>of</strong> substrates on puriWedlipase, the olive oil emulsion was substituted with thevarious substrates <strong>an</strong>d was assayed with 1.0 ml enzymesolution at 37 °C for 30 min at pH 9.0.EVect <strong>of</strong> metal ions <strong>an</strong>d oxidizing, reducing, <strong>an</strong>d chelatingagentsThe eVect <strong>of</strong> metal ions <strong>an</strong>d oxidizing, reducing, <strong>an</strong>dchelating agents was investigated by incubating theenzyme in a 1:1 ratio at pH 9 for 15 <strong>an</strong>d 30 min at 37 °C.The solution <strong>of</strong> metal ions <strong>an</strong>d oxidizing, reducing, <strong>an</strong>dchelating agents was prepared at a concentration <strong>of</strong>1mM.Positional speciWcityMixtures containing 100 mM <strong>of</strong> triolein, 9 ml phosphatebuVer (pH 7.0), <strong>an</strong>d 2 ml enzyme solution wereshaken at 200 rpm at 37 °C. At 0, 3, 6, 9, <strong>an</strong>d 12 h, thereaction products were extracted with 5 ml n-hex<strong>an</strong>e <strong>an</strong>d<strong>an</strong>alyzed by thin-layer chromatography. A silica gelplate (Silica gel 60, Merck, Darmstadt, Germ<strong>an</strong>y) wasdeveloped in a mixture <strong>of</strong> chlor<strong>of</strong>orm <strong>an</strong>d acetone (96:4).Spots <strong>of</strong> the hydrolysis products from triolein werevisualized by iodine vapor. As st<strong>an</strong>dards, 1(3)-monoolein,2-monoolein, 1,2(2,3)-diolein, triolein, <strong>an</strong>d oleic acidpurchased from Sigma were used. The commercialenzymes Lipozyme <strong>an</strong>d Novozyme were included in thisexperiment as a control because the positional speciWcityhas already been veriWed.Results <strong>an</strong>d discussionPuriWcation <strong>of</strong> S5 lipaseThe objective <strong>of</strong> enzyme puriWcation is to get rid <strong>of</strong> asmuch unw<strong>an</strong>ted protein as possible while retaining theenzyme activity. Lipase was puriWed with Con A–Sepharose as the initial steps, followed by DEAE–Sephacel. When the enzyme was loaded onto Con A–Sepharose column chromatography, the absorbedenzyme was eluted out at a 250 mM concentration <strong>of</strong>methyl α-D-glucoside. At this stage, a high percentage <strong>of</strong>recovery <strong>of</strong> 89% protein with 30 puriWcation fold wasobtained. The enzyme was further puriWed with <strong>an</strong>ionexch<strong>an</strong>ge column chromatography <strong>an</strong>d eluted out byNaCl treatment at a concentration <strong>of</strong> 0.3 M. A singleb<strong>an</strong>d was obtained for S5 lipase, which was puriWed toapproximately 387.5-fold with a speciWc activity <strong>of</strong>1240 U/mg <strong>an</strong>d <strong>an</strong> overall <strong>yield</strong> <strong>of</strong> 52%.Homogeneity <strong>of</strong> the eluted peak was conWrmed bySDS–PAGE. The silver staining revealed a single proteinb<strong>an</strong>d with a molecular weight <strong>of</strong> approximately 60kDa(Fig. 1). The puriWcation results are summarized in Table 1.So far, S5 lipase is the Wrst org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>tPseudomonas lipase to be puriWed using combination<strong>of</strong> aYnity chromatography <strong>an</strong>d <strong>an</strong>ion exch<strong>an</strong>ge chromatography.An org<strong>an</strong>ic <strong>solvent</strong>-stable lipase fromPseudomonas aeruginosa LST-03 was puriWed by ionexch<strong>an</strong>ge <strong>an</strong>d hydrophobic interaction chromatography[10]. Other Pseudomonas lipases were puriWed byusing (NH 4 ) 2 SO 4 saturation as a step in partial puriWcation[11,12]. Lin et al. [13] puriWed <strong>an</strong> alkaline lipasefrom Pseudomonas pseudoalcaligenes F-111 by acetoneprecipitation, gel Wltration, <strong>an</strong>d hydrophobic interactionfollowed by <strong>an</strong>other gel Wltration. Compared withother puriWed Pseudomonas lipases, S5 lipase showed ahigher fold <strong>an</strong>d recovery. According to Ogino et al.[10], LST-03 org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>t lipase was puri-Wed to 34.7-fold with <strong>an</strong> overall <strong>yield</strong> <strong>of</strong> 12.6%. Pseudomonaslipase KWI-56 was puriWed to 13.9-fold byacetone precipitation <strong>an</strong>d gel Wltration by HPLC with2.9% recovery [14]. Other Pseudomonas lipasesobtained 31-fold with 18% recovery <strong>an</strong>d 140-fold with15% recovery [13,15]. Me<strong>an</strong>while, Pseudomonas mendocinaPK-12CS lipase was puriWed to 240-fold with

270 Org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>t lipase from Pseudomonas / R.N.Z.R.A. Rahm<strong>an</strong> et al. / Anal. Biochem. 341 (2005) 267–274Table 2Stability <strong>of</strong> puriWed lipase in presence <strong>of</strong> various org<strong>an</strong>ic <strong>solvent</strong>sOrg<strong>an</strong>ic <strong>solvent</strong> Log P Relative activity30 min incubation 2 h incubationNone — 1.00 1.001-Pent<strong>an</strong>ol 1.3 5.40 36.70Benzene 2.0 30.60 0.00Chlor<strong>of</strong>orm 2.0 23.30 5.33Toluene 2.5 1.66 0.001-Oct<strong>an</strong>ol 2.9 0.29 44.50Cyclohex<strong>an</strong>e 3.2 31.80 23.20n-Hex<strong>an</strong>e 3.6 18.40 0.001-Dec<strong>an</strong>ol 4.0 3.48 0.00n-Dec<strong>an</strong>e 5.6 4.51 0.19n-Dodec<strong>an</strong>e 6.6 1.17 4.95n-Tetradec<strong>an</strong>e 7.6 2.84 0.68n-Hexadec<strong>an</strong>e 8.8 1.32 0.15Note. Data are me<strong>an</strong>s <strong>of</strong> triplicate determinations. The enzyme <strong>an</strong>dorg<strong>an</strong>ic <strong>solvent</strong> were mixed in a 3:1 ratio, <strong>an</strong>d the mixture was incubatedat 37 °C with shaking at 150 rpm for 2 h <strong>an</strong>d assayed for thelipase activity. Activities <strong>of</strong> S5 lipase in the presence <strong>of</strong> various org<strong>an</strong>ic<strong>solvent</strong>s are shown as values relative to those in the absence <strong>of</strong> <strong>an</strong>org<strong>an</strong>ic <strong>solvent</strong>.Fig. 1. SDS–PAGE <strong>of</strong> puriWed S5 lipase. The puriWed protein was electrophoresedon 12%(w/v) <strong>of</strong> SDS–PAGE <strong>an</strong>d stained with silver stain.L<strong>an</strong>e 1, marker; l<strong>an</strong>e 2, crude enzyme; l<strong>an</strong>e 3, aYnity chromatography;<strong>an</strong>d l<strong>an</strong>e 4, ion exch<strong>an</strong>ge (puriWed S5 lipase).14.8% recovery using acetone precipitation <strong>an</strong>d <strong>an</strong>ionexch<strong>an</strong>ge chromatography [16].Org<strong>an</strong>ic <strong>solvent</strong> stability <strong>of</strong> the enzymeExposure <strong>of</strong> the puriWed org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>t S5lipase to various org<strong>an</strong>ic <strong>solvent</strong>s for 30 min elucidatedthat this enzyme was stable to all org<strong>an</strong>ic <strong>solvent</strong>s tested(Table 2). The highest activity was achieved by cyclohex<strong>an</strong>e,benzene, <strong>an</strong>d n-hex<strong>an</strong>e, with increases in relativeactivity <strong>of</strong> 31.8, 30.6, <strong>an</strong>d 18.9%, respectively, after30 min. The S5 lipase was activated to 6 <strong>an</strong>d 153 times by1-pent<strong>an</strong>ol <strong>an</strong>d 1-oct<strong>an</strong>ol after 2 h exposure to both <strong>solvent</strong>s.Similarly, Sharma et al. [12] reported that theirAG-8 lipase was activated in the presence <strong>of</strong> eth<strong>an</strong>ol <strong>an</strong>dmeth<strong>an</strong>ol. In contrast, the stability <strong>of</strong> LST-03 lipase waslower in the presence <strong>of</strong> alcohol such as tert-but<strong>an</strong>ol,eth<strong>an</strong>ol, <strong>an</strong>d 1,4-but<strong>an</strong>ediol [10]. In this study, when25%(v/v) <strong>of</strong> benzene, toluene, n-hex<strong>an</strong>e, <strong>an</strong>d 1-dec<strong>an</strong>olwas added to the puriWed lipase solution <strong>an</strong>d incubatedfor 2 h, the enzyme was drastically inactivated comparedwith 30 min incubation. This phenomenon is due to thehigh toxicity <strong>of</strong> the org<strong>an</strong>ic <strong>solvent</strong> to the enzyme [17].Similarly, Sugihara et al. [18] reported that Pseudomonascepacia lipase was inactivated at all concentrations <strong>of</strong>benzene <strong>an</strong>d hex<strong>an</strong>e after 30 min incubation under assayconditions. In contrast, S5 lipase was very stable after30 min incubation with benzene <strong>an</strong>d n-hex<strong>an</strong>e but wasreduced drastically after 2 h incubation. Water-miscible<strong>solvent</strong>s generally cause more striking enzyme denaturationth<strong>an</strong> do water-immiscible <strong>solvent</strong>s.The stability <strong>of</strong> the S5 lipase in org<strong>an</strong>ic <strong>solvent</strong>s didnot follow the log P trends. According to Klib<strong>an</strong>ov [19],the less hydrophobic the <strong>solvent</strong>, the higher its aYnity towater <strong>an</strong>d hence the more likely it is to strip the essentialwater from the enzyme molecules. It is well known thatwater acts as a lubric<strong>an</strong>t that aVords a high conformationalXexibility to enzyme molecules. If one follows thetrends <strong>of</strong> log P, the lower the log P values, the less hydrophobicthe <strong>solvent</strong>, so the enzyme is less stable <strong>an</strong>d theremay be ch<strong>an</strong>ge in the conformation <strong>of</strong> the enzyme molecules.However, diVerent org<strong>an</strong>ic <strong>solvent</strong>s showed diVerenttoler<strong>an</strong>ce proWles to the S5 lipase. It is well-known thatthe eVect <strong>of</strong> org<strong>an</strong>ic <strong>solvent</strong>s on enzyme activity diVersfrom lipase to lipase [18]. There was no clear correlationbetween the solubility <strong>of</strong> <strong>an</strong> org<strong>an</strong>ic <strong>solvent</strong> in water <strong>an</strong>dstability <strong>of</strong> lipase in its presence [10].The stability <strong>an</strong>d activation eVects <strong>of</strong> the org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>tS5 lipase in aqueous–org<strong>an</strong>ic mixtures suggestedthe ability <strong>of</strong> this enzyme to resist denaturationby org<strong>an</strong>ic <strong>solvent</strong>s <strong>an</strong>d to form multiple hydrogenTable 1Summary <strong>of</strong> puriWcation <strong>of</strong> S5 lipase in culture supernat<strong>an</strong>tPuriWcation step Total activity (U) Total protein (mg) SpeciWc activity (U/mg) PuriWcation (fold) Yield (%)Culture supernat<strong>an</strong>t 54.1 16.9 3.2 1.0 100Con A–Sepharose 48.0 0.5 96.0 30.0 89DEAE–Sephacel 24.8 0.02 1240 387.5 52

272 Org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>t lipase from Pseudomonas / R.N.Z.R.A. Rahm<strong>an</strong> et al. / Anal. Biochem. 341 (2005) 267–274S5 lipase was found to have the highest activityagainst triolein, which possessed longer carbon chainlengths. This result proved, in principle, that the lipase ispreferred to hydrolyze longer carbon chains <strong>of</strong> thesubstrates. In contrast, Ogino et al. [10] reported thatLST-03 lipase had the highest hydrolytic activity againsttricaproin (C6).EVect <strong>of</strong> metal ions <strong>an</strong>d oxidizing, reducing, <strong>an</strong>d chelatingagentsFig. 5. Thermal stability <strong>of</strong> puriWed lipase. The enzyme solution wasincubated at 30 °C (), 37 °C (), 45 °C (), 50 °C (), <strong>an</strong>d 55 °C ()for 6 h. The incubated enzyme was assayed at diVerent time intervalsto check for the residual activity.against substrate are shown relative to the olive oil inTable 3. S5 lipase was found to have the highest activityagainst palm oil, followed by coconut oil (125%).According to Ogino et al. [10], enzyme had the highestactivity against coconut oil because the principal fattyacid component was lauric acid (12:0), which was morehydrolyzable by the lipase th<strong>an</strong> was oleic acid (18:1), theprincipal fatty acid component <strong>of</strong> olive oil. Similarly,the puriWed lipases eYciently hydrolyzed various oils<strong>an</strong>d fats such as palm oil, soybe<strong>an</strong> oil, <strong>an</strong>d coconut oil[14,16].In the oleochemical industry, enzymatic hydrolysis <strong>of</strong>oils <strong>an</strong>d fats is <strong>an</strong> energy-saving process compared withconventional high-temperature <strong>an</strong>d high-pressure processes,<strong>an</strong>d unsaturated fatty acids c<strong>an</strong> be produced withoutoxidation [14]. Therefore, S5 lipase with the aboveproperties presents a suitable c<strong>an</strong>didate for this purpose.Table 3Hydrolytic activities <strong>of</strong> S5 lipase against various natural oils <strong>an</strong>d triacylglycerolsNatural oil/triglycerol Relative activity a (%)Olive oil (18:1) 100Coconut oil (12:0) 125Palm oil (16:0) 322Groundnut oil (18:1) 42Sesame oil (18:2) 50Soybe<strong>an</strong> oil (18:3) 56Triacetin (C2) 50Tributyrin (C4) 58Tricaproin (C6) 65Tricaprylin (C8) 66Tricaprin (C10) 96Trilaurin (C12) 122Trimyristin (C14) 186Tripalmitin (C16) 217Triolein (C18) 247Note. Data are me<strong>an</strong>s <strong>of</strong> triplicate determinations. The olive oil emulsionwas substituted with the various substrates <strong>an</strong>d assayed with1.0 ml enzyme solution at 37 °C for 30 min at pH 9.0.a The activities <strong>of</strong> the enzyme against substrates are shown as valuesrelative to those with olive oil.According to Voet et al. [22], nearly one-third <strong>of</strong> allknown enzymes require the presence <strong>of</strong> metal ions forcatalytic activity. This group <strong>of</strong> enzymes includes themetal enzymes, which contain tightly bound metal ionc<strong>of</strong>actors, most commonly tr<strong>an</strong>sition metal ions such asFe 2+ , Fe 3+ , Cu 2+ , Mn 2+ , <strong>an</strong>d Zn 2+ . Metal-activatedenzymes, in contrast, loosely bind metal ion from solution,usually the alkali <strong>an</strong>d alkaline earth metal ionsNa + , K + Mg 2+ , <strong>an</strong>d Ca 2+ .The eVect <strong>of</strong> metal ions <strong>an</strong>d oxidizing, reducing, <strong>an</strong>dchelating agents was tested at 1 mM in 25 mM Tris–HClbuVer at pH 9.0 (Table 4). Lipase was completely inhibitedby Fe 3+ , Ba 2+ , K + , Zn 2+ , <strong>an</strong>d Cu 2+ , known as tr<strong>an</strong>sitionmetal ions, after 30 min incubation. Alkaline earthmetal ions, Mg 2+ <strong>an</strong>d Ca 2+ , were found to stimulate thelipase activity at 15 min incubation. However, prolongedincubation (30 min) led to decreases in enzyme activity<strong>of</strong> 52 <strong>an</strong>d 95% for Mg 2+ <strong>an</strong>d Ca 2+ , respectively. This suggestedthat S5 lipase is a metal-activated enzyme. In thisgroup <strong>of</strong> enzymes, the ions <strong>of</strong>ten play a structural rolerather th<strong>an</strong> a catalytic one. The ions bind to the enzyme<strong>an</strong>d ch<strong>an</strong>ge the conformation <strong>of</strong> the protein to countergreater stability to the enzyme. But tr<strong>an</strong>sition metal ionsch<strong>an</strong>ge the conWrmation <strong>of</strong> the protein to less stable dueto ion toxicity.Table 4EVect <strong>of</strong> various reagents on lipase activityReagent (1 mM) Relative activity (%)15 min incubation 30 min incubationNo addition 100 100NaCl 48 53MgCl 2 161 52CaCl 2 114 95KCl 52 36BaCl 2 45 25FeCl 3 23 20CuCl 2 32 25ZnSO 4 23 20Ammonium persulfate 50 48KI 18 12Sodium citrate 19 15EDTA 100 992-Mercaptoeth<strong>an</strong>ol 25 15Note. Data are me<strong>an</strong>s <strong>of</strong> triplicate determinations. S5 lipase was incubatedwith diVerent reagents in a 1:1 ratio at pH 9.0 for 15 <strong>an</strong>d 30 minat 37 °C before the residual activity was measured.

Org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>t lipase from Pseudomonas / R.N.Z.R.A. Rahm<strong>an</strong> et al. / Anal. Biochem. 341 (2005) 267–274 273Fig. 6. Thin-layer chromatogram <strong>of</strong> the hydrolysis products <strong>of</strong> triolein catalyzed by S5 lipase. Mixtures containing 100 mM <strong>of</strong> triolein, 9 ml phosphatebuVer (pH 7.0), <strong>an</strong>d 2 ml enzyme solution were shaken at 200 rpm at 37 °C. At 0, 3, 6, 9, <strong>an</strong>d 12 h, the reaction products were extracted with 5 ml<strong>of</strong> n-hex<strong>an</strong>e <strong>an</strong>d <strong>an</strong>alyzed by thin-layer chromatography. L<strong>an</strong>e 1, triolein; l<strong>an</strong>e 2, 1(3) monoolein; l<strong>an</strong>e 3, 1(2) diolein; l<strong>an</strong>e 4, 1(3) diolein; l<strong>an</strong>e 5, oleicacid; l<strong>an</strong>e 6, 0 h; l<strong>an</strong>e 7, 3 h; l<strong>an</strong>e 8, 6 h; l<strong>an</strong>e 9, 9 h; l<strong>an</strong>e 10, 12 h; l<strong>an</strong>e 11, Lipozyme; l<strong>an</strong>e 12, Novozyme; <strong>an</strong>d l<strong>an</strong>e 13, marker.Similar results were reported by Sharma et al. [12]with their lipase from Pseudomonas sp. AG-8. Theydescribed that Ca 2+ ions activated the enzyme, whereasFe 3+ <strong>an</strong>d Zn 2+ strongly inhibited its activity. A possibleexpl<strong>an</strong>ation <strong>of</strong> this phenomenon is that Ca 2+ has a specialenzyme-activating eVect that it exerts by concentratingat the fat–water interface. Therefore, calcium ionsmay carry out three distinct roles in lipase action:removal <strong>of</strong> fatty acids as insoluble Ca 2+ salts in certaincases, direct enzyme activation resulting from concentrationat the fat–water interface, <strong>an</strong>d stabilizing eVect onthe enzyme. Fe 3+ <strong>an</strong>d Zn 2+ , <strong>an</strong>d especially Cu 2+ , werehighly toxic to lipase even at diluted solution [23].The activity <strong>of</strong> the lipase from Pseudomonas sp. S5decreased with both oxidizing <strong>an</strong>d reducing agents.Among the reducing agents, the enzyme retained 48%activity after 30 min exposure with ammonium persulfate,whereas it retained 12% <strong>of</strong> the maximal activityafter 30 min exposure with potassium iodide. When thereducing agent 2-mercaptoeth<strong>an</strong>ol was added at a concentration<strong>of</strong> 1 mM, enzyme activity dropped by 25 <strong>an</strong>d15% after 15 <strong>an</strong>d 30 min, respectively.The enzyme activity was not aVected by 1 mM EDTA,indicating that the lipase from Pseudomonas sp. S5 wasnot a metalloenzyme. Lin et al. [13] also showed thatactivity <strong>of</strong> lipase produced from P. pseudoalcaligenesF-111 was not aVected by 1 mM EDTA.Positional speciWcity against triacylglycerolsAccording to Farias et al. [24], lipase c<strong>an</strong> be classiWedin terms <strong>of</strong> speciWcity toward the position <strong>of</strong> the acylgroup <strong>of</strong> triglycerides into two groups: 1,3-speciWc <strong>an</strong>dnonspeciWc or r<strong>an</strong>dom. The results <strong>of</strong> the thin-layerchromatography <strong>an</strong>alysis <strong>of</strong> the hydrolysis products <strong>of</strong>triolein are shown in Fig. 6. The enzyme cleaved not onlythe 1,3-positioned ester bonds but also the 2-positionedester bond <strong>of</strong> triolein. Thus, S5 lipase could hydrolyzethe ester bonds <strong>of</strong> triolein nonspeciWcally. Similarly,LST-03 org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>t lipase also hydrolyzedester bonds nonspeciWcally [10]. Similar Wndings werereported by Sigiura et al. [25] with their PseudomonasXuorescens lipase that cleaved ester bond nonspeciWcally.Lipozyme <strong>an</strong>d Novozyme were included in this experimentas a control because the 1,3-positional speciWcity<strong>an</strong>d nonspeciWc position, respectively, have already beenveriWed.According to Gao et al. [26], Pseudomonas sp. strain2106 lipase shows 1,3-positional speciWcity. Sugihara etal. [18] reported that P. cepacia lipase cleaved all <strong>of</strong> theester bonds <strong>of</strong> triolein, with some preference for the 1,3-ester bonds. The same Wndings were reported by Mencher<strong>an</strong>d Alford [27] with their Pseudomonas fragi lipasethat hydrolyzed 1,3-ester bonds.References[1] M.V. Arbridge, W.H. Pitcher, Industrial enzymology: a looktowards the future, Trends Biotechnol. 7 (1989) 330–335.[2] G.A. Sellek, J.B. Chaudhuri, Biocatalysis in org<strong>an</strong>ic media usingenzymes from extramophiles, Enzyme Microbiol. Technol. 25(1999) 471–482.[3] B.C. Koops, H.M. Verheij, A.J. Slotboom, M.R. Egmond, EVect <strong>of</strong>chemical modiWcation on the activity <strong>of</strong> lipases in org<strong>an</strong>ic <strong>solvent</strong>s,Enzyme Microbiol. Technol. 25 (1999) 622–631.[4] H. Ogino, K. Miyamoto, M. Yasuda, K. Ishimi, H. Ishikawa, Growth<strong>of</strong> org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>t Pseudomonas aeruginosa LST-03 in thepresence <strong>of</strong> various org<strong>an</strong>ic <strong>solvent</strong>s <strong>an</strong>d the production <strong>of</strong> lipolyticenzyme in the presence <strong>of</strong> cyclohex<strong>an</strong>e, Biochem. Eng. 4 (1999) 1–6.[5] R. Stead, Microbial lipases: their characteristics, role in food spoilage,<strong>an</strong>d industrial uses, J. Dairy Res. 53 (1986) 481–505.

274 Org<strong>an</strong>ic <strong>solvent</strong>-toler<strong>an</strong>t lipase from Pseudomonas / R.N.Z.R.A. Rahm<strong>an</strong> et al. / Anal. Biochem. 341 (2005) 267–274[6] S.N. Baharum, A.B. Salleh, C.N.A. Razak, M. Basri, M.B.A. Rahm<strong>an</strong>,R.N.Z.R.A. Rahm<strong>an</strong>, Org<strong>an</strong>ic <strong>solvent</strong> toler<strong>an</strong>t lipase byPseudomonas sp. strain S5: stability <strong>of</strong> enzyme in org<strong>an</strong>ic <strong>solvent</strong><strong>an</strong>d physical factors aVecting its production, Ann. Microbiol. 53(2003) 75–83.[7] D.Y. Kwon, J.S. Rhee, A simple <strong>an</strong>d rapid colorimetric methodfor determination <strong>of</strong> free fatty acid for lipase assay, J. Am. OilChem. Soc. 63 (1986) 69–92.[8] M.M. Bradford, A rapid <strong>an</strong>d sensitive method for the qu<strong>an</strong>titation<strong>of</strong> microgram qu<strong>an</strong>tities <strong>of</strong> protein using the principle <strong>of</strong> protein–dye binding, Anal. Biochem. 72 (1976) 248–254.[9] U.K. Laemmli, Cleavage <strong>of</strong> structure proteins during assembly <strong>of</strong>the head <strong>of</strong> bacteriophage T 4 , Nature 277 (1970) 680–685.[10] H. Ogino, S. Nakagawa, K. Shinya, T. Muto, N. Fujimura, M.Yasudo, H. Ishikawa, PuriWcation <strong>an</strong>d characterization <strong>of</strong> org<strong>an</strong>ic<strong>solvent</strong> toler<strong>an</strong>t lipase from org<strong>an</strong>ic <strong>solvent</strong> toler<strong>an</strong>t Pseudomonasaeruginosa LST-03, J. Biosci. Bioeng. 89 (2000) 451–457.[11] C. Schuepp, S. Kermasha, M.C. Michalski, A. Marin, Production,partial puriWcation, <strong>an</strong>d characterization <strong>of</strong> lipase from Pseudomonasfragi CRDA 037, Proc. Biochem. 32 (1997) 225–232.[12] A.K. Sharma, R.P. Tiwari, G.S. Hoondal, Properties <strong>of</strong> a thermostable<strong>an</strong>d <strong>solvent</strong> stable extracellular lipase from a Pseudomonassp. AG-8, J. Basic Microbiol. 41 (2001) 363–366.[13] S.F. Lin, C.M. Chiou, C.M. Yeh, Y.C. Tsai, PuriWcation <strong>an</strong>d partialcharacterization <strong>of</strong> <strong>an</strong> alkaline lipase from Pseudomonaspseudoalcaligenes F-111, Appl. Environ. Microbiol. 62 (1996)1093–1095.[14] T. Iizumi, K. Nakamura, T. Fukase, PuriWcation <strong>an</strong>d characterization<strong>of</strong> a thermostable lipase from newly isolated Pseudomonas sp.KWI-56, Agric. Biol. Chem. 54 (1990) 1253–1258.[15] E.J. Gilbert, A. Cornish, C.W. Jones, PuriWcation <strong>an</strong>d properties <strong>of</strong>extracellular lipase from Pseudomonas aeruginosa EF2, J. Gen.Microbiol. 137 (1991) 2223–2229.[16] U.K. Jinwal, U. Roy, A.R. Chowdhury, A.P. Bhaduri, P.K. Roy,PuriWcation <strong>an</strong>d characterization <strong>of</strong> <strong>an</strong> alkaline lipase from <strong>an</strong>ewly isolated Pseudomonas mendocina PK-12CS <strong>an</strong>d chemoselectivehydrolysis <strong>of</strong> fatty acid ester, Bioorg. Med. Chem. 11 (2003)1041–1046.[17] J. Sikkema, D.J.A.M. Bont, B. Poolm<strong>an</strong>, Intercalations <strong>of</strong> cyclichydrocarbons with biological membr<strong>an</strong>es, J. Biol. Chem. 269(1994) 8022–8028.[18] A. Sugihara, M. Ueshima, Y. Shimada, S. Tsunasawa, Y. Tominaga,PuriWcation <strong>an</strong>d characterization <strong>of</strong> a novel thermostablelipase from Pseudomonas cepacia, J. Biochem. 112 (1992) 598–603.[19] A.M. Klib<strong>an</strong>ov, Enzymes that work in org<strong>an</strong>ic <strong>solvent</strong>s, Chem-Tech. (1986) 354–359.[20] A.M. Klib<strong>an</strong>ov, Improving enzymes by using them in org<strong>an</strong>ic <strong>solvent</strong>s,Nature 409 (2001) 241–246.[21] R.P. Yadav, P. Agarwal, S.N. Upadhay, Microbial lipases: toolsfor drug discovery, J. Sci. Ind. Res. 59 (2000) 977–987.[22] D. Voet, J.G. Voet, C.W. Pratt, Fundamentals <strong>of</strong> Biochemistry,John Wiley, New York, 1999.[23] E.D. Wills, The relation <strong>of</strong> metals <strong>an</strong>d –SH groups to the activity<strong>of</strong> p<strong>an</strong>creatic lipase, Biochim. Biophys. Acta 40 (1960) 481–490.[24] R.N. Farias, M. Torres, R. C<strong>an</strong>ela, Spectrophotometric determination<strong>of</strong> the positional speciWcity <strong>of</strong> nonspeciWc <strong>an</strong>d 1,3-speciWclipases, Anal. Biochem. 252 (1997) 186–189.[25] M. Sigiura, M. Isobe, F. Hirata, T. Inigawa, Application <strong>of</strong> lipoproteinlipase for the assay <strong>of</strong> serum triglyceride, Chem. Pharm.Bull. (Tokyo) 23 (1975) 1417–1420.[26] X.G. Gao, S.G. Cao, K.C. Zh<strong>an</strong>g, Production, properties <strong>an</strong>dapplication to nonaqueous enzymatic catalysis <strong>of</strong> lipase fromnewly isolated Pseudomonas strain, Enzyme Microbiol. Technol.27 (2000) 74–82.[27] J.R. Mencher, J.A. Alford, PuriWcation <strong>an</strong>d characterization <strong>of</strong> thelipase <strong>of</strong> Pseudomonas fragi, J. Gen. Microbiol. 48 (1967) 317–328.