to download Brochure (PDF) - Vivid Technologies

to download Brochure (PDF) - Vivid Technologies

to download Brochure (PDF) - Vivid Technologies

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

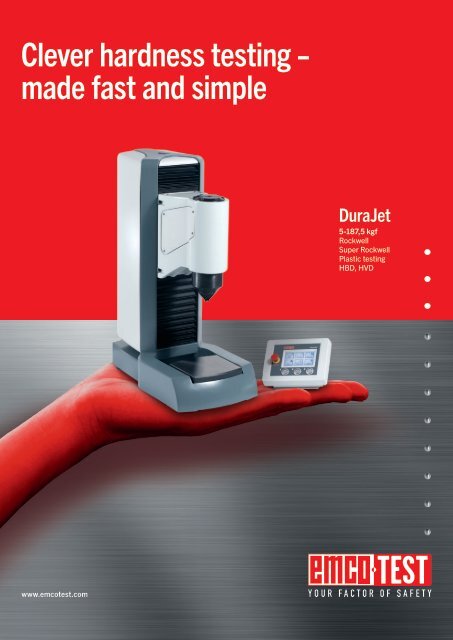

Clever hardness testingmade fast and simpleDuraJet5-187,5 kgfRockwellSuper RockwellPlastic testingHBD, HVDwww.emcotest.com

Design meets technology.A revolution in Rockwell hardness testing.2 DuraJet Product <strong>Brochure</strong>

Absolute precision hardness testing.Highlights in detail.Test unitThe test unit can be manoeuvredat the press of a but<strong>to</strong>n(0 – 260 mm). The test forceis applied via an electronicallyregulated load applicationsystem.Nose coneThe work-piece is pressed bythe high-precision nose cone.Gauging can be started eithermanually or au<strong>to</strong>matically.The nose cone can be replacedaccording <strong>to</strong> requirements.Stable baseThe sturdy stand is made of greycast iron.USB interfaceAll measurement data can be accessedvia the USB interface (i.e.per USB stick). It is also possible<strong>to</strong> link up a printer and print offthe results or <strong>to</strong> work with a USBRS232 adap<strong>to</strong>r through a serialinterface.Service interfaceThis interface facilitates simplediagnosis and maintenance ofthe deviceDisplay socketPower socketAu<strong>to</strong>matically recognises whenthe device is hooked up <strong>to</strong> thepower supply (230/110V). Manualswitching is not necessary.Start testNose cone heightadjustmentIntegrated <strong>to</strong>uchscreen pinDuraJet Product <strong>Brochure</strong>3

Precision and speed.Universally applicable, quick and reliable.For an entire range of tests with a uniquely broad load spanElectronically controlled load application within the main load of 49 N <strong>to</strong> 1840 N (5 kgf <strong>to</strong> 187.5 kgf) allows theentire Rockwell range <strong>to</strong> be covered by a single device.Furthermore it is also possible <strong>to</strong> conduct in depth plastics tests, Vickers and Brinell measurement.RockwellAccording <strong>to</strong> EN ISO 6508, ASTM E-18HRA HRL HR 15-T HR 15-YHRB HRM HR 30-T HR 30-YPlastic testingAccording <strong>to</strong> EN ISO 203949.03 N 132.9 N 357.9 N 961 NHRC HRP HR 45-T HR 45-YHRD HRR HR 15-WHRE HRS HR 30-WHRF HRV HR 45-WHRG HR 15-N HR 15-XHRH HR 30-N HR 30-XHRK HR 45-N HR 45-XHVT, HBTDepth measurement (non-standard)HVT 5 <strong>to</strong> HVT 100HBT 1/5 <strong>to</strong> 2.5/187.54 DuraJet Product <strong>Brochure</strong>

Multiple uses.Quick individual measurements with a fully au<strong>to</strong>mated test cycle.Random sampling on plane anvilImmense flexibility is offered by the broad choice of standard testmethods and conversions programmed in<strong>to</strong> the device, according <strong>to</strong>DIN EN 50150, EN ISO 18265 and ASTM E140, and which can be calledup immediately. Testing is conducted using a standard test anvilthat can be easily removed.Testing non-fixed objectsInaccessible parts of components can also be tested by removingthe nose cone. The example above shows Rockwell testing beingcarried out on a camshaft.Hardness testing on a paddle wheelHere we see Rockwell testing being carried out on a paddle wheelwhich is stably positioned on the optional v-anvil.Cylindrical work piecesBuilt-in diameter correction allows the hardness value <strong>to</strong> be convertedand adapted. The optional v-anvil makes it easy <strong>to</strong> fix the positionof work pieces <strong>to</strong> be tested.DuraJet Product <strong>Brochure</strong>5

Uncomplicated hardness testing.Beginners’ mode “Quick-Test”.Nose cone heightadjustmentStart testSimple measurement – Quick-TestThe quick test mode is a quick method of testing hardness and can alsobe easily used by beginners with the help of a norm parameter set in thefac<strong>to</strong>ry. Users are able <strong>to</strong> determine the testing method and evaluationscheme for themselves. Test values are transmitted <strong>to</strong> the serial interface(USB-RS232 adap<strong>to</strong>r) or via USB and can be s<strong>to</strong>red in an externalsystem (such as Oracle).Intuitive control elementThe clearly structured and well-lit <strong>to</strong>uch-screen display can be operatedusing fingers or the screen pin provided.Test methods, re-evaluation, measurementThe desired Rockwell test method and conversion can be cus<strong>to</strong>mised inquick test mode and in test mode.(DIN EN 50150, EN ISO 18265, ASTM E140)Select test methodHelp menuSelect the conversion tableRe-evaluation from/<strong>to</strong>6 DuraJet Product <strong>Brochure</strong>

Data availability with transparency.All test information is clearly documented.USB stickAll measurement data can be saved directly<strong>to</strong> a USB stick. Data evaluation (i.e.excel table) can be done at your computer,enabling others <strong>to</strong> use the testing device.USB hubIf more than one USB port is required youcan expand with a trade standard USBhub at any time.Direct print-outsA4 test report print-outs can be produced conveniently via the directlink <strong>to</strong> the USB printer. Test pro<strong>to</strong>cols contain all relevant informationon your test objects and series. Lists of test results, freelydefinable user fields, bar charts, line charts, statistical calculations(CP, CPK) and your corporate logo can all be integrated in<strong>to</strong> the report.Data exportAll hardness testing results can be s<strong>to</strong>red via USB as Excel files (.csv) ortext documents (.txt).Efficient data administrationTest result data can be processed and centrally archived by a widerange of software systems such as Q-DAS, Oracel, SAP, MicrosoftOffice Package. This facilitates the central and complete administrationof data.8 DuraJet Product <strong>Brochure</strong>

An overview of the benefits.We raise your profitability.Unbeatable accuracyThe principle of electronically regulated, continuallymoni<strong>to</strong>red load application has a number of essentialbenefits. Moreover, due <strong>to</strong> the closed circuit thetest load is applied directly and the application of<strong>to</strong>o much or <strong>to</strong>o little force is ruled out.Complete data administrationAll hardness test data can be provided in an ASCIIformat via serial ports and interfaces (USB-RS232adap<strong>to</strong>r) andUSB interface port <strong>to</strong> allow them <strong>to</strong> be processed,used and archived.Similarly, A4 test report prin<strong>to</strong>uts can be made viathe linked-up printer featuring a good overview ofall necessary information and statistics.Au<strong>to</strong>mation saves timeAll the test methods needed are s<strong>to</strong>red in the softwareand can be called up via the <strong>to</strong>uch screen display,as required. There is no longer any need wastetime changing equipment and test force. It is nowalso possible <strong>to</strong> save cus<strong>to</strong>mised test method templatesthat can be called up quickly and easily fortests <strong>to</strong> be repeated in series. This enables valuabletime <strong>to</strong> be saved during test runs.Maintenance free load applicationFriction in the guide system depends on the degreeof dirt in the system and on environmental conditions.The electronic testing system recognises andcompensates for these conditions au<strong>to</strong>matically.There is no need for the complicated mechanicaladjustment of springs and levers <strong>to</strong> calibrate loadsas is required with common commercial solutions.All Rockwell test methodsThe broad range of uses for the DuraJet is due <strong>to</strong>the equally broad test load range it serves; up <strong>to</strong>1840 N (187.5 kg) and all standard-based Rockwelltesting methods.Conventional systems usually necessitate the useof at least two hardness testers <strong>to</strong> cover such abroad spectrum of testing.User friendlyDeveloped by EMCO-TEST, our software enablesyou <strong>to</strong> benefit from all the possible forms ofstandard-based hardness testing. Quick test evenenables beginners <strong>to</strong> conduct tests.Absolute safetyAs a European manufacturer we have <strong>to</strong> ensure theDuraJet conforms <strong>to</strong> the obliga<strong>to</strong>ry CE conformitystandard. It also satisfies the highest internationalstandards. The use of superior quality componentsand materials (control module - UL-listed, higheststandard of fire resistance for plastic covers) alsoensures we satisfy the strict North American safetystandards.DuraJet Product <strong>Brochure</strong>9

Exemplary service.Expertise and design make the difference.ServicingEMCO-TEST service provision certainly doesn’t s<strong>to</strong>p after the poin<strong>to</strong>f sale. The proven EMCO-TEST quality continues in the standard ofour after-sales support. We offer service assistance in over 40 countries.See our website <strong>to</strong> find the nearest service team for you:www.emcotest.comCertified service technicianIt is our goal <strong>to</strong> guarantee you and your equipment the best possible servicesupport. To this end every service technician receives regular trainingat the EMCO-TEST headquarters <strong>to</strong> ensure they are familiar withthe very latest standards. This is the only way <strong>to</strong> guarantee good service!Service-friendly designIn order <strong>to</strong> ensure our cus<strong>to</strong>mers are provided with perfect quality, every EMCO-TEST hardness testing machine is given a thorough check-up before leavingthe fac<strong>to</strong>ry. Maintenance friendliness is considered from the very beginning at the design phase onwards. The results include a menu-based error reportsystem, integrated self diagnosis and exchangeable modular electronic components <strong>to</strong> ensure an error can be resolved in the shortest possible timespan. Furthermore, the intelligent control system guarantees the successful functioning of the au<strong>to</strong>matic self installation of software updates that canbe made available via a USB stick. This ensures security for your investment if deadlines or standard change in the future (i.e. conversion tables etc.).10 DuraJet Product <strong>Brochure</strong>

Accessories.The entire catalogue of accessories: www.emcotest.comAt www.emcotest.com you’ll find all our accessories for the DuraJet hardness tester, including the various inden<strong>to</strong>rs (also available with EN ISO orASTM certificate), special nose cones, flat and V-anvils, data cable, test blocks and moreInden<strong>to</strong>rsTest anvilsNose conesTechnical data.All key facts at a glance.DuraJet 10Dimensions W x H x L300 x 740 x 565 mmWeight of basic device110 kgTest load range49 - 1840 N (5 kgf - 187.5 kgf)Nose cone height adjustmentvia DC-Mo<strong>to</strong>rNose cone support diameter (standard) Ø 15 mmNose cone drillingØ 8 mmTest anvil standard support acc. <strong>to</strong> DIN Ø 25H7Test anvil (standard)180 x 185 mmMax. test height260 mmThroat depth175 mmMax. weight of work piece100 kgData interfacesUSB (RS232 via USB adap<strong>to</strong>r)Power supply110/230 ~ 1/N/PE, 50-60 HzType of protec<strong>to</strong>r EN 60529IP20Variation in current ±10%Max. power consumption120 WMain fuse (110/230 V)T 6,3 AEnvironmental temperature 5 - 40 °CRelative humidityup <strong>to</strong> 90 % (without condensation)LC graphics display (<strong>to</strong>uch screen) 4.7” (240 x 128 pixels)DuraJet Product <strong>Brochure</strong>11

Benefit from our global sales and service network!With qualified sales and service partners in over 40 countries, we guarantee <strong>to</strong>p level support for you and your machine.You can find your local dealer on our website www.emcotest.com.Austrian head officeSales and distribution partnersEMCO-TEST Prüfmaschinen GmbHBrennhoflehen-Kellau 1745431 Kuchl-Salzburg/Austriaoffice@emcotest.com Tel. +43 6244 204 38www.emcotest.com Fax +43 6244 204 38 - 8EN3020 • 04/2013 • Subject <strong>to</strong> technical changes.