NOVOTEXi 440 Product and Technical Guide - Macsteel

NOVOTEXi 440 Product and Technical Guide - Macsteel

NOVOTEXi 440 Product and Technical Guide - Macsteel

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>NOVOTEXi</strong> <strong>440</strong><strong>Product</strong> & <strong>Technical</strong> <strong>Guide</strong>Edition 1 / 2013T H E M A C S T E E L G R O U P

1<strong>NOVOTEXi</strong> <strong>440</strong>Company products <strong>and</strong> servicesManufacture <strong>and</strong> supply of NOVOTEXI <strong>440</strong> ® concealed-fix steel roof sheetingSupply of rainwater goods <strong>and</strong> roofing accessoriesSupply Purpose made rainwater goodsSupply Flashings in 6m lengths, Louvre vents <strong>and</strong> copingsOn site <strong>and</strong> factory manufactured Bull-nosing <strong>and</strong> Curving<strong>Technical</strong> servicesConcealed-fix roofing profile - NOVOTEXI <strong>440</strong>NOVOTEXI <strong>440</strong> ® (Latin for “New Cover” <strong>440</strong>mm effective cover width) a concealed-fix roofing profile was developed to accommodatehigh winds as a result of greenhouse gases <strong>and</strong> global warming. As our planet becomes more <strong>and</strong> more exposed to the effects of greenhousegases so global warming effects are starting to cause catastrophic weather conditions that in past years had remote occurrences ofone in 50-year cycles. In recent years, it is not unusual to see these harsh weather occurrences happening 3 times in a single year.As a result of these occurrences determining the terrain categories are becoming more <strong>and</strong> more crucial. The Structural Engineer is thekey to ensure that the roof <strong>and</strong> the roof structure can h<strong>and</strong>le the wind pressures. The down time cost as a result of a storm is not an option!Thus performance of roof sheeting systems need to be verified by Structural Engineers at the planning stage. All manufacturers’ of roofingproducts should be tested <strong>and</strong> verified to ensure those systems can accommodate the wind pressures required in the design of the structure.To ensure these tests are ligitimate an independent third party authority must certify the test results e.g.: CSIR or SABS etc.SHEET PROFILEPatent Number: 2004/5204The roofing Profile covers an effective <strong>440</strong>mm <strong>and</strong> is generally roll formed on site mostly from G550 MPa high tensile steel to anypractical length that is manageable by the roofing contractor <strong>and</strong> as low as 2 degrees pitch with no end lapping required.The center rib is designed to move freely to allow the profile to absorb wind gusts. Due to the nature of the rotational mechanism the male<strong>and</strong> female only start to inter-lock at wind pressures of around 1.2kN/m 2 . The center rib may deflect as much as 100mm before windload starts exerting pressures on the cleats. The unique patented rotational inter-locking mechanism is what makes this concealed-fixroofing system vastly different to other concealed-fix roofing systems available in the South African market:FIG 1: Deflection undernegative loadFIG 2: Rotational MechanismOnce inter-locked the roof sheet is able to exp<strong>and</strong> <strong>and</strong> contractfreely <strong>and</strong> cannot unclip between the purlin supports through foottraffic. All residual moisture between the roof sheet <strong>and</strong> theinsulation layer can still evaporate through the inter-lockingmechanism. The roof sheeting has been designed to accommodatethick composite insulation in accordance with SANS 10400XA aswell as various types of insulation board. When using 100mm x12kg/m 3 insulation blanket, no sub-structure is required whenusing NOVOTEXI <strong>440</strong> ® over the purlin.Capacity<strong>Macsteel</strong> Roofing manufactures <strong>and</strong> Patents their own roll forming machines <strong>and</strong> at present have 6 mobile rolling mills. We have facilitiesthat services the market on a National basis. The rolling mills are light <strong>and</strong> compact <strong>and</strong> can be containerized for shipping or trucking tofar reaching destinations.FIG 3: Roll forming on siteT H E M A C S T E E L G R O U P

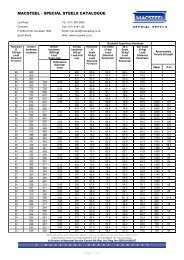

2<strong>NOVOTEXi</strong> <strong>440</strong>Quality of materials used to manufacture NOVOTEXI <strong>440</strong> roof sheeting:DESCRIPTIONGAUGETCT THICKNESSTENSILESTRENGTH MPACOATING MASSMASS PERLINEAR MMASS PER M 2ZINCALUME ® steel 0.47mm G550 AZ150 / AZ200 2.13kg 4.84kgClean COLORBOND steel 0.47mm G550 AZ150 2.13kg 4.84kgZINCALUME ® steel Ultra 0.47mm G550 AZ200 2.13kg 4.84kgZINCALUME ® steel 0.53mm G550 AZ150 / AZ200 2.40kg 5.50kgClean COLORBOND steel 0.53mm G550 AZ150 2.40kg 5.50kgClean COLORBOND Ultra 0.53mm G550 AZ200 2.40kg 5.50kgZINCALUME ® steel 0.80mm G550 AZ150 / AZ200 3.63kg 8.25kgGalv/Chromadek 0.50mm ISQ550 Z275 / Z200 2.43kg 5.52kgPlease see the various literatures available from the suppliers to choose the Colours <strong>and</strong> finishes. Material Warranties must be applied for prior tostarting the project.NB: The lifespan of the roofing material is determined by the coating mass applied eg: AZ150 vs. AZ200.Various web sites: www.bluescopesteel.com, chromadek@arcelormittal.com, www.rheinzink.co.za, www.safalsteel.co.zaRecommended spacings of Purlin supports:It is crucial for the Structural Engineer to determine the effective purlin spacing’s by using the design loads for each fixing cleat system:0,50mm & 0,47mm0,53mmCLIP SIZE SERVICEABILITY LOAD ULTIMATE LOAD40mm x 1.05mm G550 0.50kN/m 2 Note 1 1.65kN/m 2 Note 160mm x 1.05mm G550 0.75kN/m 2 Note 1 2.50kN/m 2 Note 180mm x 1.05mm G550 1.02kN/m 2 Note 2 3.30kN/m 2 Note 280mm x 1.50mm G230 2.10kN/m 2 Note 2 5.10kN/m 2 Note 21. This is an estimated negative load2. This is tested <strong>and</strong> verified• The Structural Engineer based on the above values will determine the end spans <strong>and</strong> intermediate spans based onthe high-pressure zones. He will also indicate what cleats will be required where.• Various configurations e.g.: putting two 60mm cleats side by side can improve the negative load capacity substantially.• If in doubt please consult the manufacturer for further assistance.• A detailed CSIR load test report is available on request.Recommended roof spansSINGLEENDINTER-NALUNSTIFF-ENEDTBA: To be advised <strong>and</strong> confirmed by the Structural EngineerSTIF-FENEDTBA TBA TBA 250 500TBA TBA TBA 250 500Recommended side cladding0,50mm & 0,47mm0,53mmROOFSOVERHANGSINGLE END INTERNAL OVERHANG1800 1200 2200 3002500 2500 3000 600Wind loading performanceThe wind resistance of NOVOTEXI <strong>440</strong> ® concealedfixroofing system underwent a comprehensive testingprogram overseen <strong>and</strong> witnessed by CSIR’s structuralexpert on wind loadings. (A detailed report on thisprogramme, its testing methodology <strong>and</strong> results isavailable on request.) Because of the unique windloading performance of Novotexi <strong>440</strong> ® (involvingactive rotational me-chanism <strong>and</strong> the deflection of thecentre rib), SANS testing requirements were used as aguideline. The system was able to sustain substantialmagnitude negative loads <strong>and</strong> therefore suitable forthe application in high pressure uplift zones derived inthe design process.T H E M A C S T E E L G R O U P

3<strong>NOVOTEXi</strong> <strong>440</strong>Installation Procedure for NOVOTEXI <strong>440</strong>STEP 1Prior to starting the installation we assume that the insulation layeris already installed in place over the purlins. The purpose of theStarter bar is when installing the first sheet from a gable end thatno stitching screws are used to hold this sheet in place, thus thestarter bar holds down the first female lip of the first roof sheet onlyavoiding any perforation. Should the slope have multiple purlinspacing’s it is possible to install 3m lengths at intermittent intervals.This portion is closed up with a barge flashing once the sidecladding is installed. The starter bar is manufactured from eitherGalvanized or Zincalume material <strong>and</strong> is fixed in place with waferhead self-drilling screws. As illustrated the first sheet is hooked overthe starter bar to start the installation process. The starter bar alsoallows the first roof sheet to exp<strong>and</strong> <strong>and</strong> contract freely.FIG 1: Roof sheet hookedover stater barFIG 2: Starter bar fitted overfirst PurlinsSTEP 2Once the first roof sheet is laid flat <strong>and</strong> installed in place square tothe gable, end the fixing cleat must be clipped over the male lip<strong>and</strong> fixed into the purlin with wafer head self drilling screws. Careshould be taken that the fixing cleat is square to the purlin surface.FIG 1: Fixing clear overmale lipFIG 2:Align over PurlinFIG 3:Fasten Cleat to PurlinSTEP 3Taking the next roof sheet <strong>and</strong> holding this sheet at around 90degrees to the first sheet inter-lock the female over the male <strong>and</strong> layflat. Keep in mind there is usually very little tolerance +/-2mmbetween the male <strong>and</strong> female at 90 degrees. Once the sheets areinter-locked <strong>and</strong> laid flat prior to fixing the next cleats in place aneasy check is to feel the lap as illustrated to make sure the sheetsare installed properly, simply by pulling up the sheets will ensurethe lap is closed. Usually the process of pulling up the sheet feelingthe lap <strong>and</strong> securing the next fixing cleat is done simultaneously inone operation.FIG 1: Hold Sheet at 90˚ to engageFIG 2: Make sure sheet is pulled up tightSTEP 4All roofing contractors are to take special note of the following:Because Novotexi <strong>440</strong> ® is cut to length by friction saw during theon site rolling process this causes the female lip to flare for about120mm from the cut-off! The sheet must be closed as illustrated.Great care must be taken to make sure this operation is adhered toby all installation teams. After a section is installed <strong>and</strong> before theinstallation teams leave the site for that day the ends must beclosed as part of work in progress, even if the ends run into guttersthat need to be trimmed off closing is essential. If the structure hasa single span after a gutter <strong>and</strong> short sheets are used where theoverhang is 250mm after the last purlin these ends must be closedwith the closing tools as there is very little material to support thecleat. Bending down <strong>and</strong> bending up of roof sheeting on the eaves<strong>and</strong> ridges is seen as st<strong>and</strong>ard practice on all kinds of roofingsystems <strong>and</strong> the tooling Manufactured specifically for Novotexi<strong>440</strong> ® <strong>Macsteel</strong> supply NOVOTEXI <strong>440</strong> ® to an approved roofingcontractor base in the various provinces that supply variouswarranties after installation. With new contractors not familiar withthe installation of NOVOTEXI <strong>440</strong> ® training is essential <strong>and</strong> isdone under supervision of MacSteel on request. Kicking the roofsheets to get them to engage occurs when the purlin plains are notwithin the required tolerance, this practice will not effect the performanceof the roof sheets however contractors are to wear soft soledshoes when this method is applied. Novotexi <strong>440</strong> ® is designed sothat there is a minimum clearance of 2mm between male <strong>and</strong>female at around 90 degrees.FIG 1: Closing is criticalFIG 2: Make sure sheet is closed on the endsT H E M A C S T E E L G R O U P

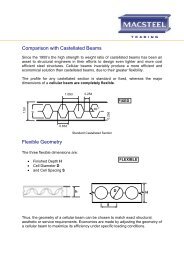

<strong>NOVOTEXi</strong> <strong>440</strong>Fixing Cleats60mm & 80mm Fixing cleatsRecommended Fixings:FIG 1: #10 Wafer Head x 22mmThe fixing cleats are the heart of the system <strong>and</strong> determine the various negative wind load capacities. (Pleaseremember the thickness of the roof sheeting in NOVOTEXI <strong>440</strong> ® does not determine negative wind load capacity)Thickness of roofing material becomes critical when positive point loads are of concern e.g.: When secondarytrades are expected to walk on roofs after installation with additional point loads e.g.; air conditioner units orextractor fans are carried onto the roof.It is st<strong>and</strong>ard practice to walk in the pans or over the purlins when walking on steel roofs40mm x 1.05mm G550 AZ150 Truecore Cleat (2 Pre punched hole centre’s 20mm apart)60mm x 1.05mm G550 AZ150 Truecore Cleat (4 Pre punched hole centre’s 20mm & 50mm apart)80mm x 1.05mm G550 AZ150 Truecore Cleat (4 Pre punched hole centre’s 20mm & 50mm apart)80mm x 1.50mm G230 AZ150 Zincalume Cleat (4 Pre punched hole centre’s 20mm & 50mm apart)Various Tooling <strong>and</strong> equipment supplied by <strong>Macsteel</strong> Roofing4N.B. Also note that when specifying a 80mm or 100mm fixing cleats it is important for the Structural Engineer to specify the appropriatelip-channels or purlin to accommodate fixing the cleat, e.g.: 80mm cleat would require a 60mm or 75mm lip-channel.We strongly recommend that proper attention is given to the selection of fixings usedto fasten the cleats in place <strong>and</strong> which is used to fix the flashings etc.; To fix the cleatsinto steel a #10 x 22mm Wafer Head self drilling screw SANS1273 class 3 coatedmust be used <strong>and</strong> for timber #10 x 45mm Wafer Head type 17 point SANS1273class 3 coated to be used. The material warranties may become void if the incorrectfixings are used. (Especially on Flashings) Please refer to Kare Industries for furtherinformationBending Tool Closing Tool Seaming MachineThese tools may either be rented or purchased from <strong>Macsteel</strong> RoofingBull nosing, natural Curving <strong>and</strong> CrankingNovotexi <strong>440</strong> ® roofing for bull-nosed <strong>and</strong> curved sheeting is rolled with an open female lip. We roll the sheet in this state to allow theroofing contractor to install the sheets without tilting the roof sheets at 90 degrees, thus the sheets are installed horizontally. Once thesheet is inter-locked the castellated portion of the bull nose is aligned <strong>and</strong> closed with the closing tool. On the slope of the sheets everymeter is closed with the closing tool as a temporary measure. After the roof is installed the seaming machine is run along the roof sheetto seam up the sheet. Roof structures that have a radius larger than 38m can be supplied without any castellation <strong>and</strong> the roll formingmill will roll a natural curve during site rolling. With curved structures less than 38m a crank every meter or so has to be cranked toachieve the radius.Closing the Bull nose using the closing tool. Prior to seaming close the sheet every meter or so.Trapezium StiffenerThis was designed to create a walkway on roofs wherethere are secondary trades <strong>and</strong> maintenance crews thatcarry heavy loads exceeding the allowable point loads onthe centre rib. This member is installed under each roofsheet during the installation process between two purlins.After installation the walkway is demarcated on top of theroof sheeting to indicate the safe walking areas.Splicing plateTrapezium stifner intalled under centre ribT H E M A C S T E E L G R O U P

5<strong>NOVOTEXi</strong> <strong>440</strong>Insulation board brackets:These brackets are available in various sizes <strong>and</strong> aresupplied to maintain the spacing’s between the roofsheeting cleats <strong>and</strong> the board.Solar panel brackets:This bracket was recently developed to secure solar panels ontothe Novotexi <strong>440</strong> ® roof sheets without causing any damage orperforation. This bracket creates a base to fit various kinds ofsupporting structures on top of the roofing system without hinderingthe expansion <strong>and</strong> contraction of the roofing system.Available on request.Closures, polyclosures, bending pans <strong>and</strong> flashing brackets:Serrated closures are used under the flashings <strong>and</strong> are supplied in narrow or broad flute. If closures are used it is common practice to fixthe closure into the flute of the roof sheeting <strong>and</strong> then fix the head-wall flashing into the closure <strong>and</strong> not into the roof sheet. Using thismethod water cannot leak into the roof because the perforation is concealed by the flashing. Poly closures are used in conjunction withthe closure as illustrated <strong>and</strong> are supplied in a set of male <strong>and</strong> female. Bending up <strong>and</strong> down of the pans is st<strong>and</strong>ard practice wheninstalling low pitched NOVOTEXI <strong>440</strong> ® <strong>and</strong> is critical to stop water running up the underside of the roof sheeting especially on the eavesends. Flashing brackets are supplied if no closures are used to fix the flashings without perforating the sheets.Serated Closure Broad FluteSerated Closure Narrow FluteFIG1:Poly Closure with flashing bracket FIG2:Pan bending up ridge FIG3:Pan bending down eaves FIG4:Pan bending toolContact usHead Office:Cnr Molecule <strong>and</strong> Helium Roads,Valconia,BrakpanSouth AfricaPostal:P.O. Box 420Brakpan1540South Africa-Tel: +27 11 741-5600Fax: +27 11 813-3693email: info@macroofing.co.zaweb: www.macsteel.co.zaT H E M A C S T E E L G R O U P