Ductile iron pipe solutions for highly aggressive soils - Saint-Gobain ...

Ductile iron pipe solutions for highly aggressive soils - Saint-Gobain ...

Ductile iron pipe solutions for highly aggressive soils - Saint-Gobain ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

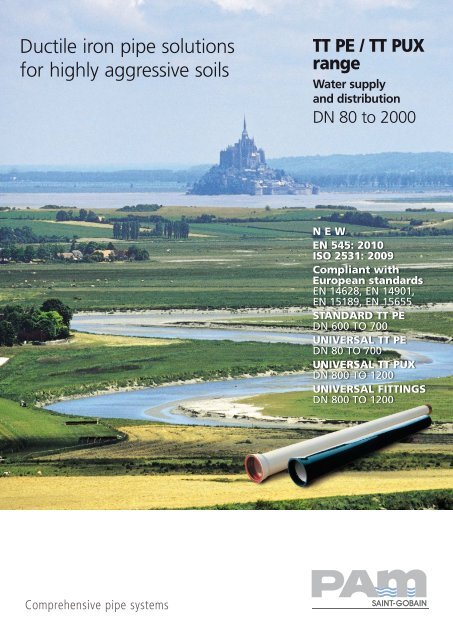

<strong>Ductile</strong> <strong>iron</strong> <strong>pipe</strong> <strong>solutions</strong><strong>for</strong> <strong>highly</strong> <strong>aggressive</strong> <strong>soils</strong>TT PE / TT PUXrangeWater supplyand distributionDN 80 to 2000N E WEN 545: 2010ISO 2531: 2009Compliant withEuropean standardsEN 14628, EN 14901,EN 15189, EN 15655STANDARD TT PEDN 600 TO 700UNIVERSAL TT PEDN 80 TO 700UNIVERSAL TT PUXDN 800 TO 1200UNIVERSAL FITTINGSDN 800 TO 1200Comprehensive <strong>pipe</strong> systems

contents Mont <strong>Saint</strong>-Michel is known all over the world <strong>for</strong>its architecture and the natural beauty of the site.It has been listed as a UNESCO world heritage sitesince 1979.For decades, <strong>Saint</strong>-<strong>Gobain</strong> PAM has been using thesurrounding salt marshes as a test bed <strong>for</strong> its newcoatings, including the TT range of coatings.The polders surrounding the mount are aparticularly corrosive env<strong>iron</strong>ment. Resistivity ofthe soil in the salt marshes near Mont-<strong>Saint</strong>-Michel is almost 100 Ω.cm, making the locationan excellent natural test facility in which to assessthe per<strong>for</strong>mances of ductile <strong>iron</strong> <strong>pipe</strong> coatings.

introduction

2/3Buried <strong>pipe</strong>s are subjected to various loads and aggressions, including soil and backfillcorrosivity. Standard version of <strong>Saint</strong>-<strong>Gobain</strong> PAM <strong>pipe</strong>s feature either a conventional zinccoating or the new ZINALIUM coating, which provide a sufficient level of corrosion resistance<strong>for</strong> most situations. However, the <strong>soils</strong>'s corrosivity must be assessed to determine whetherspecial protective measures and high per<strong>for</strong>mance coatings are required. <strong>Saint</strong>-<strong>Gobain</strong>PAM engineering teams carry out soil analyses on customers' request.General corrosion indicatorsGeneral corrosion indicators are determined with a detailed map which indicates: spots are wet and unaerated, there<strong>for</strong>e likely to be more corrosive, other low areas rich in humic acids and bacteria, and often polluted,Pollution and specific corrosion indicatorsUsing plans (available from public authorities), the following are determined: waste, or by sewage, mainly from households, structures, electric traction systems, plants, etc.).fThis survey indicates the various strata crossed and provides in<strong>for</strong>mation on the nature ofthe soil and its natural corrosivity

4/5> Low risk:> High risk:> Very high risk:

Active protections Passive protectionsTT PE DN 80 to 700 DN 800 to 1200 DN 1400 to 2000Pipes / Standard TT PE / EN 14628 TT PUX / EN 15189 TT PUX / EN 15189Fittings / Standard Epoxy / EN 14901 Epoxy / EN 14901 Polyurethane / EN 15655MaterialPolyethylenePolyurethaneEPOXYSpecifications− − CH −

6/7Tramways - TT PE and TT PUX offer the ideal <strong>solutions</strong> External coatingLocationZINALIUMRangeZn 200 g/mZnAl 85-15 400 g/m 2 2 TT, PE or PUXAbove the water tableAPPROVEDIn the water tableAPPROVEDAcidic <strong>soils</strong>PROHIBITEDPROHIBITEDAPPROVEDMixed <strong>soils</strong>APPROVEDCAUTION!APPROVEDSoils containing refuse,ash, slag or pollutionresulting from solid orliquid industrial wastePROHIBITED PROHIBITED APPROVEDStray currents PROHIBITED PROHIBITED APPROVEDAvailable in the PAMrange

8/9

10/11 Annular coextrusionLateral extrusionAppearance of the TT-PEcoating <strong>for</strong> DN 1234512345Appearance of the TT-PEcoating <strong>for</strong> DN > DN 80 to 100 DN 125 to 250 DN 300 to 450 DN 500 to 700Thickness NB:1 mm = 1000 μmBeware of imitations!Lateral extruded TT PE <strong>pipe</strong>s should not be confused with <strong>pipe</strong>s covered withself-adhesive strips of PE material.Lateral extrusion ensures that <strong>pipe</strong>s are continuously protected and the PElayers fully welded.Only PE coatings applied by annular coextrusion or lateral extrusion complywith the European standard EN 14628.

N° Parameter Requirement1 2 3 4 5 6 7 8 9 Property Standard RequirementFluidity value Density Property Standard RequirementSoftening point Saponification value Viscosity

12/13 Metallic zinc Bituminous varnish <strong>Ductile</strong> <strong>iron</strong>Cement mortar<strong>Ductile</strong> <strong>iron</strong>Metallic zinc High density polyethyleneDN 80 to 300Joints protected by an elastomer sleeveDN 350 to 700Joints protected by a heat-shrink collar

14/15 Red epoxy <strong>Ductile</strong> <strong>iron</strong>Cement mortar<strong>Ductile</strong> <strong>iron</strong>Polyurethane

In countries with hot climates (in particular certain African and Middle Eastern countries).<strong>Saint</strong>-<strong>Gobain</strong> PAM can provide TT PUX <strong>pipe</strong>s <strong>for</strong> DN to .Contact our sales engineers <strong>for</strong> more detailed specifications relating to these complementaryproducts, and the situations in which it is better to choose the TT PUX range.

16/17Barrel Socket SpigotAverage thickness (μm) Minimum thickness (μm) Material NB : 1 mm = 1000 μmN° Parameter Requirement1 1 2 3 4 5 6 7 8

N° Parameter Requirement1 Applying powder usinga spray gun2 3 4 5 Applying powder bydipping in a fluidized bed6≥7 ≥8 ≥

18/19

DVGWSAINT-GOBAINCANALISATIONe1Ø BØ DIPLuEN 545Ø DESTANDARD TTC40EN 14628ePLuPLu2 3Ø BØ DIeØ DEØ BØ DIØ DEPUXISO 2531EN 545EN 15189PUXISO 2531EN 545EN 151891DN L Class enominal DE DI P B TT Coating Min. thickweight type coating 80 PE 100 PE 125 PE 150 PE 200 PE 250 PE 300 PE 350 PE 400 PE 450 PE 500 PE 600 PE 700 PE 2800 900 1000 1100 1200 31400 1500 1600 1800 2000

DVGWSAINT-GOBAINCANALISATION20/21e1e4Ø BØ DIPLuK9UNIVERSAL STANDARD TTEN 545ISO 2531EN 14628eeØ DEPLuPLu5 6ISO 2531ISO 2531EN 545EN 545EN 15189EN 15189Ø BØ DIØ DEØ BØ DIØ DEcc4DN L Class e*nominal DE DI P B Bead TT Coating Min. thickweight type coating 80 100 PE 125 PE 150 PE 200 PE 250 PE 300 PE 350 PE 400 PE 450 PE 500 PE 600 PE 700 PE 5800 900 1000 1200 61400 1500 1600 1800 2000 * : PAM internal specifications. Pipe wall thickness may be higher than the values specified in ISO 2531:2009 orEN 545:2010 in order to garantee the PFA, PMA and PEA values given in tables pages 24 and 25 of the anchored joints.

STANDARD TT PE UNIVERSAL TT PE A Flange BPipe coating PE PE Fittings coatings Pipe Bend 1/8 Bend 1/12 Bend 1/16 Bend 1/32 Bend Duckfoot bend Taper Collar 3-Spigot tee Washout tee Level invert tee Cross Flanged socket Flanged spigot Blank flange Reducing flange Non-anchored jointAnchored joint with insertsAnchored joint with beadB- DN 80 to 300 DN 350 to 700STANDARD TT PE

22/23STANDARD TT PUX UNIVERSAL/PAMLOCK TT PUX A Flange BPipe coating Fittings coatings Pipe D Bend 1/8 Bend 1/16 Bend 1/32 Bend Duckfoot bend Taper Collar C 2-Socket tee 3-Socket tee 3-Spigot tee Washout tee Level invert tee Flanged socket Flanged spigot Blank flange Reducing flange Non-anchored jointAnchored jointwith beadBC- DN 80 to 300 DN 350 to 700 DN 800 to 2000STANDARD TT PUX

'DN Class PFA bar PMA bar PEA bar Angular deflection (°)Protection ofTT PE <strong>pipe</strong>s<strong>for</strong> transportSTANDARD TT PESTANDARD TT PE ViUNIVERSAL TT PE Vi*UNIVERSAL TT PE Ve*STANDARD TT PESTANDARD TT PE ViUNIVERSAL TT PE ViUNIVERSAL TT PE VeSTANDARD TT PESTANDARD TT PE ViUNIVERSAL TT PE ViUNIVERSAL TT PE VeSTANDARD TT PESTANDARD TT PE ViUNIVERSAL TT PE ViUNIVERSAL TT PE VeSTANDARD TT PESTANDARD TT PE ViUNIVERSAL TT PE ViUNIVERSAL TT PE Ve80 100 125 150 200 250 300 350 400 450 500 600 700

24/25DN Class PFA bar PMA bar PEA bar Angular deflection (°)STANDARD TT PUXSTANDARD TT PUX VeUNIVERSAL TT PUX Ve*PAMLOCK TT PUX*STANDARD TT PUXSTANDARD TT PUX VeUNIVERSAL TT PUX VePAMLOCK TT PUXSTANDARD TT PUXSTANDARD TT PUX VeUNIVERSAL TT PUX VePAMLOCK TT PUXSTANDARD TT PUXSTANDARD TT PUX VeUNIVERSAL TT PUX VePAMLOCK TT PUXSTANDARD TT PUXSTANDARD TT PUX VeUNIVERSAL TT PUX VePAMLOCK TT PUX800 B B B Protection ofTT PUX <strong>pipe</strong>s<strong>for</strong> transport900 B B B 1000 B B B 1100 B B B 1200 B B B 1400 1500 1600 1800 2000

26/27 STANDARD TTC40Markingson TT PE <strong>pipe</strong>sEN 545EN 14528123456These holes make the sleeveeasier to fit. Handy!1 2 345 6

123 3456 7 891 2 3456789

28/29CPeCPeLuDN 80 100 125 150 200 250 300 350 - 400 450 500 600 7001STANDARD TT <strong>pipe</strong>s UNIVERSAL TT <strong>pipe</strong>s 1221 2345345

30/31 Markingson TT PUX <strong>pipe</strong>sDN 800 900 1000 1100 1200 1400 1500 1600 1800 2000Max. DE 112323

<strong>Saint</strong>-<strong>Gobain</strong> PAM packagesTT range products with great care,to ensure that they are suppliedin perfect conditions.These products should be handledusing appropriate tools.<strong>Saint</strong>-<strong>Gobain</strong> PAM supplies specialhandling hooks designedspecifically <strong>for</strong> the TT product range.Contact us <strong>for</strong> more in<strong>for</strong>mation.

32/33Connecting TT PE <strong>pipe</strong>sConnecting collars, available in sizes DN 80 to 250, can be fitted directly over the HDPEcoating on TT PE <strong>pipe</strong>s. Bolts should be tightened to at least 8 m.daN.For DN 300 to 700 <strong>pipe</strong>s, the PE polyethylenecoating must be removed be<strong>for</strong>e fittingthe collar. The assembly must then becorrosion-protected with a heat-shrinkcollar (or equivalent protection).PAM supplies a range of connectingcollars with rein<strong>for</strong>ced coatings<strong>for</strong> TT products.Depending on the corrosivity risk of the soil, a heatshrinkcollar may be required to provide additional protection to the connection.For further in<strong>for</strong>mation, please contact our sales engineers.

Pipe pulling lengths in horizontal directional bores - in kmDN 0 to 0.4 0.5 0.6 0.7 0.8 0.9 1 1.1 1.2100 125 150 200 250 TT PE <strong>pipe</strong> trainready to be pulledby horizontal directional drilling300 350 400 450 500 600 700 800 to 1000 " There are places where discretion is a paramount"

34/35Sealing chamberAnchoring chamberMetallic mechanicalprotection shellProtective collar

(Attestation de Con<strong>for</strong>mité Sanitaire - ACS)

36/37

SAINT-GOBAIN PAM worldwideALGERIASAINT-GOBAIN PAM ALGERIEZ.I. Sidi Abdelkader-Ben Boulaid - BP 53809000 - BLIDA - AlgeriaPhone: + 213 (0) 25 36 00 60ARGENTINASAINT-GOBAIN PAM ARGENTINABouchard y Enz1836 - LLAVALLOL - BUENOS AIRES - ArgentinaPhone: + 54 11 42 98 9600AUSTRALIASAINT-GOBAIN PAM15 Edgars Road -THOMASTOWN VIC 3074 - AustraliaPhone: + 61 (0) 3 9358 6122AUSTRIASAINT-GOBAIN GUSSROHRVERTRIEBOSTERREICH GmbHGussrohr Vertriebs Österreich - Archenweg, 52A6020 - INNSBRUCK - AustriaPhone: + 43 5123 417 170BELGIUMSAINT-GOBAIN PIPE SYSTEMSRaatshovenstraat, n°2B-3400 - LANDEN - BelgiumPhone: + 32 11 88 01 20BRAZILSAINT-GOBAIN CANALIZACAO LTDAPraia de Botafogo 440 7° andar22250-040 - RIO DE JANEIRO - RJ - BrazilPhone: + 55 21 2128 1677CHILESAINT-GOBAIN PAM CHILEAntillanca Norte 600Parque Industrial Vespucio, Comuna de PudahuelSANTIAGO DE CHILE - ChilePhone: + 562 444 13 00CHINASAINT-GOBAIN PAM CHINA (SHANGAI)1716 Ocean Tower550 Yan'An East Road - SHANGAI 200001 - ChinaPhone: + 86 21 6361 2142SAINT-GOBAIN PAM CHINA (XUZHOU)Jinshanqiao Development ZonePC 221004 - XUZHOU - ChinaPhone: + 86 516 8787 8107SAINT-GOBAIN PAM CHINA (MAANSHAN)Hua Gong Road CihuPC 243052 - MAANSHAN Anhui Province - ChinaPhone: + 86 555 350 8003www.pamline.comSAINT-GOBAIN PAMHead office91, avenue de la Libération54076 NANCY CEDEXFRANCEMarketing Department21, avenue Camille Cavallier54705 PONT-A-MOUSSON CEDEXFRANCEPhone: +33 (0)3 83 80 73 50COLOMBIASAINT-GOBAIN PAM COLOMBIATerminal terrestre de carga de BogotaEtapa 1, Bodega 9, Modulo 3Km 3,5 costado sur autopista - MedellinCOTA CUNDINAMARCA - ColombiaPhone: + 57 (1) 841 5832CZECH REPUBLICSAINT-GOBAIN PAM CZ S.R.O.Polygon House - Doudlebska 5/169914000 PRAHA 4 - Czech RepublicPhone: + 420 246 088 611FINLANDSAINT-GOBAIN PIPE SYSTEMS OYNuijamiestentie 3AFIN-00400 - HELSINKI - FinlandPhone: + 358 207 424 600FRANCE & DOM-TOMSAINT-GOBAIN PAM (HEAD OFFICE)91 Avenue de la Libération54076 NANCY CEDEX - FrancePhone: +33 3 83 95 20 00SAINT-GOBAIN PAM(France Commercial Department)CRD – Chemin de Blénod – B.P. 10954704 PONT A MOUSSON CEDEX - FrancePhone: +33 3 83 80 73 00SAINT-GOBAIN PAM(Europe and International Commercial Departments)21 avenue Camille Cavallier54705 - PONT A MOUSSON CEDEX - FrancePhone: + 33 3 83 80 73 50SAINT-GOBAIN PAM(Local Agency of The Antilles)Rue Alfred Lumière - ZI de Jarry - BP 210497122 - BAIE MAHAULT - GuadeloupePhone: + 33 590 26 71 46SAINT-GOBAIN PAM(Local Agency of Indian Ocean)16, Rue Claude Chappe - ZAC 200097420 - LE PORT - Reunion IslandPhone: + 33 262 55 15 34GERMANYSAINT-GOBAIN PAM DEUTSCHLANDSaarbrucker Strasse 5166130 - SAARBRUCKEN - GermanyPhone: + 49 681 87 010GREECESAINT-GOBAIN SOLINOURGEIA5 Klissouras StreetGR 14410 - METAMORFOSI - ATHENS - GreecePhone: + 30 210 28 30 043HONG KONGSAINT-GOBAIN PIPELINESH15/F Hermes Commercial Centre - 4-4A Hillwood RoadTSIM SHA TSUI - KOWLOON - Hong KongPhone: + 852 27 35 78 26INDIASAINT-GOBAIN PAMGrindwell Norton Ltd5th Level, Leela Business Park - Andheri-Kurla RoadMUMBAI - 400059 - IndiaPhone: + 91 22 402 12 121ITALYSAINT-GOBAIN PAM ITALIA SPAVia Romagnoli n°6I-20146 - MILAN - ItalyPhone: + 39 02 42 431JORDANSAINT-GOBAIN PAM REGIONAL OFFICEAbu Zaid Center - Office # 835 Saad Bin Abi Waqqas St, - PO BOX 83100011183 AMMAN - JordanPhone: + 962 6 551 4438MEXICOSAINT-GOBAIN PAM MEXICOHORACIO 1855-502 - Colonia Los Morales - Polanco11510 - MEXICO D.F. - MexicoPhone: + 52 55 5279 1657NETHERLANDSSAINT-GOBAIN PIPE SYSTEMSMarkerkant 10-17NL-1316 - ALMERE - NetherlandsPhone: + 31 36 53 333 44NORWAYSAINT-GOBAIN VAN OG AVLØP ASc/o Maxit - Brobekkveien 84N-0584 - OSLO - NorwayPhone: + 47 23 17 58 60PERUSAINT-GOBAIN PAM PERUAvenida de los Faisanes N° 157 - ChorillosLIMA 09 - PeruPhone: + 511 252 40 34/35POLANDSAINT-GOBAIN CONSTRUCTION PRODUCTS POLSKASP Z.O.OUI. Cybernetyki 21PL-02-677 WARSZAWA - PolandPhone: + 48 22 751 41 72PORTUGALSAINT-GOBAIN PAM PORTUGALEst. Nac. 10 - Lugar de D. Pedro -Apartado 1708P-2691-901 - SANTA IRIA DE AZOIA - PortugalPhone: + 351 218 925 000ROMANIASAINT-GOBAIN CONDUCTES Park - Str. Tipografilor nr. 11-15Sector 1 - Cod 013714BUCURESTI - RomaniaPhone: + 40 21 207 57 25SLOVAKIASAINT-GOBAIN CONSTRUCTIONStara Vajnorska 13983104 - BRATISLAVA - SlovakiaPhone: + 421 265 45 69 61SOUTH AFRICASAINT-GOBAIN PIPELINES SOUTH AFRICA275 Stephenson RoadPretoria Industrial - Gauteng - PO BOX 631PRETORIA 0001 - South AfricaPhone: +24 12 380 46 79SPAINSAINT-GOBAIN PAM ESPANA SAPaseo de la Castellana n°77 - Edificio Ederra - Planta 10E-28046 - MADRID - SpainPhone: + 34 91 397 20 00UNITED ARAB EMIRATESSAINT-GOBAIN PAMPO BOX 47102 - Building N° 1092 - Villa N° 7Muroor Road - ABU DHABI - United Arab EmiratesPhone: + 971 2 448 20 10UNITED KINGDOMSAINT-GOBAIN PAM UKLows Lane - Stanton-by-DaleILLKESTON - DERBYSHIRE - DE7 4QUUnited KingdomPhone: + 44 115 930 5000VIETNAMSAINT-GOBAIN PAM17 Ngo Gia Thieu, Ward 7 - District 3HO CHI MINH CITY - VietnamPhone: +84 8 393 07273 PHOTOS: P. Devanne, Piccaya, Fotolia, <strong>Saint</strong>-<strong>Gobain</strong> PAM. The drawings, illustrations and weights in this document are non-contractual. <strong>Saint</strong>-<strong>Gobain</strong> PAM reserves the right to change product specifications without notice in the interest of improving the Group's products.