Kverneland CLF Cultivator - Agriquip

Kverneland CLF Cultivator - Agriquip

Kverneland CLF Cultivator - Agriquip

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

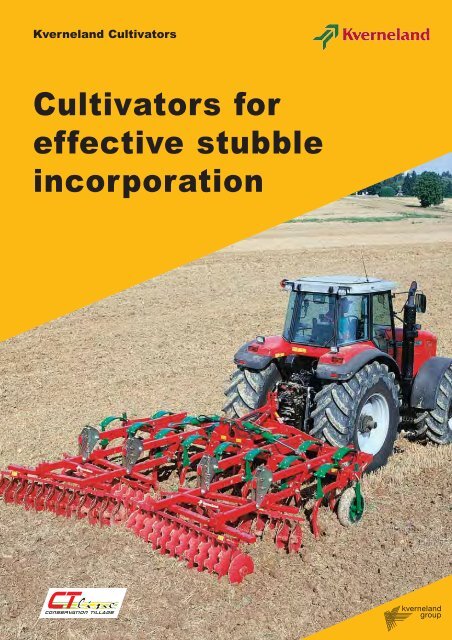

<strong>Kverneland</strong> <strong>Cultivator</strong>s<strong>Cultivator</strong>s foreffective stubbleincorporation

Stubble cultivation with <strong>Kverneland</strong>Incorporation, mixing, levelling and consolidation<strong>Kverneland</strong> offer a wide range of cultivators, ensuring the optimum choiceof stubble cultivation implements to suit your soil conditions.Important features for the optimum cultivator are: Frame with optimum under-beam clearance High performance Large inter-tine spacing Type of tines Type of wing shares2 Manoeuvrability

Fast and shallow, re-compactionand level finish, that’s how stubblecultivation should be!The stubble cultivation, especiallywithin a no-tillage or minimum tillagecultivation program to conserve soilstructure and moisture, is anoperation which requires greatconsideration. Stubble cultivation willbe the basis of success or failure ofthe following crops.Interruption of the "green bridge"For efficient farming, stubblecultivation has to be carried withgreater care the closer the croppingsequence is repeated.The transmission of root diseasesor weed problems from one cropto the next needs to be prevented.If the period between two cropsbecomes shorter the interruption ofthe "green bridge" will be necessaryto ensure soil hygiene.Volunteers germination andstraw decompositionmanage this effectively, an additionaloperation of mulching might becomenecessary.Supporting the soil structureCultivation should be carried outas quickly as possible after harvestin order to benefit from the stablecrumb structure. Cut stubblecontinues to draw the moisture fromthe soil so it is important to fullyexpose the rootto the air and improve moistureretention.Shallow, an average working depth of5 -10 cm is the ideal cultivation depthto ensure that all volunteer and weedseeds are germinated and not buried.Stubble cultivation should recompactthe work in order to ensure that allseeds have the optimum soil contactand accelerate emergence.Stubble cultivation also has toensure a quick and even emergenceof volunteers prior to spraying off ora second pass of the cultivator toclean the seedbed. Strawdecomposition should also beaccelerated as any diseases aretransferred by straw. Effectivechopping and even distribution of thestraw by the combine is the idealstarting point. If the combine does notA fine level seed bed improves soilclosure and a weatherproof finish,reducing slug damage and preservingmoisture. Straw decomposition isalso accelerated since a largerquantity of straw gets in contact withthe soil bacteria through effectivemixing.3

<strong>Kverneland</strong> <strong>CLF</strong><strong>Cultivator</strong>for fast and effective stubble cultivationat working depths of 5 to 15 cmThe <strong>Kverneland</strong> <strong>CLF</strong> is the ideal tool for shallow optimum mixingstubble cultivation. The special design of the "Turbo-tine"ensures excellent mixing of soil and crop residues.In Autumn cultivations the results prior to ploughing areexcellent.4

<strong>Kverneland</strong> CLMHeavy-Duty Stubble<strong>Cultivator</strong>The <strong>Kverneland</strong> CLM is a further developmentof the well proven and tested <strong>Kverneland</strong> CLD.It is the ideal stubble cultivation tool forworking depths of 5 to 20 cm.Tine OptionsTo suit different working conditions,the CLM is available with 2 differenttype of tines:- Rigid tines, with shear bolt safetydevice for for use in stone-free soils.- "Auto-reset" tines with the wellproven<strong>Kverneland</strong> leaf spring safety system,for hard and stony conditions.Specially heat-treated tinesThe “Auto-reset” tines are heat-treatedto the same exacting standards as thebeams on <strong>Kverneland</strong> reversibleploughs. These beams are well renownfor their high quality and durability.Cultivation of the full working widthWhichever tine is used, the CLM has a2-piece wing share, 460 mm wide,combined with a reversible doubleheartpoint. These ensure that all the fieldis cultivated over the entire workingwidth of the machine. Each wearingpart can be replaced individually.Robust frameThe 100x100 mm section square beam,made of fine-grained micro-alloyedsteel, guarantees that the CLM isrobust enough to withstand the mostsevere conditions. A semi-mount kit isavailable for the hydraulic foldingmachines.Parallel lifting of the machine isachieved by utilising two hydrauliccylinders fitted to the drawbar and rearwheel frame.Notched hollow discsfollowing the tines, the notched hollowdiscs mix and level the surface. A rearroller consolidates the work to ensurebetter volunteer weed seedgermination. The hollow discs bothcrumble and level the soil. Each set isstaggered to provide better clearancefor trash.The discs are easily adjusted by eitherpin or screw depth control. Perfectlevelling is ensured when using theoptional border discs.Wide choice of rollersThe CLM can be fitted witha wide choice of rear rollers:- 550 mm Cage roller- 400 mm Twin cage roller- 500 mm Tooth packer roller- 550 mm Cracker-Packer rollerEquipment- Edge shares (standard)- Border discs (option)- Depth wheels (option)Zone 1: 2 rows of tinesFull width cutting over the entworking widthLooseningMixingThe notched levelling discs are mounted ontaper roller bearings. They are heightadjustable by pin or screw and arestaggered to avoid blockages.6The 460 mm wing share ensures cultivation over theentire working width. The specially heat treated wearparts can be individually replaced.Carbide faced wearing parts are also available as anoption.

"Auto-reset" tines with <strong>Kverneland</strong> leafspring safety protection for use instony/hard conditions."Shear-Bolt" tine safety protection for use inlight and stone-free soils.ireZone 2: Notched hollow discsCrackingMixingLevellingZone 3: RollerLevellingCrumblingConsolidatingSpecificationsModelWorkingwidthNo. oftinesTransportwidthWeight mountedShear-bolt/Auto-resetWeight semi-mountedShear-bolt/Auto-resetMinimumpowerrequirementCLM 3.03.00 m73.00 m1020 / 1220 kg-75 kW / 100 HPCLM 4.04.00 m94.00 m1330 / 1580 kg-100 kW / 130 HPCLM 4.0 Hydr.4.00 m9*3.00 m1980 / 2230 kg2820 / 3070 kg100 kW / 130 HPCLM 5.0 Hydr.5.00 m11*3.00 m2250 / 2560 kg3090 / 3400 kg120 kW / 160 HPCLM 6.0 Hydr.6.00 m13*3.00 m2590 / 2950 kg3420 / 3800 kg140 kW / 185 HP* Hydraulic folding models7

<strong>Kverneland</strong> CLCChisel <strong>Cultivator</strong>for stubble cultivation or general soilloosening at working depths of 5 to 40cmThe <strong>Kverneland</strong> CLC is a highly versatile implement.Carrying out shallow or deep soil preparation, it is anextremely versatile machine for the majority of your soilworkingrequirements.Specially heat-treated tines and wear parts guarantee longlife and durability. 8

Ample under frame clearance of 870mmThe robust construction together withthe specially heat-treated tines give animpressive under frame clearance of870 mm. This, coupled with a tinespacing of 280 mm ensures themachines performs optimally in trashyconditions.Tine options- Rigid tines, with shear bolt safetydevice for for use in stone-free soils.- "Auto-reset" tines with the well proven<strong>Kverneland</strong> leaf spring safety system,for hard and stony conditions.Specially heat-treated tinesThe "Auto-reset" tines of the CLCcultivators are heat-treated to the sameexacting standards as the beams on the<strong>Kverneland</strong> reversible ploughs. Thesebeams are well renown for their highquality and durability and minimum ofmaintenance requirement. The tines canwithstand sideways movements of upto 20 cm.The CLC has the advantage of the<strong>Kverneland</strong> Non-Stop safety systemproviding exceptional over load protection.Plough pointsEach tine is provided with a<strong>Kverneland</strong> reversible plough point,made of highquality steel, for maximum working life.The point allows the CLC to work at alldepths, even in stony soils, and helpsto eliminate plough pans, encouragingnatural drainage.For shallow stubble cultivation, theCLC can be fitted with 30 cm wingshares, allowing cultivation over theentire working width of the machine ata depths of 5 to 15 cm.All wear parts benefit from the <strong>Kverneland</strong>steel treatment technology which makesthem robust enough to withstand thetoughest conditions.Optional equipment- Single or double notched disc gang500mm (working depth up to 25cm)- Combination disc gang and410 mm cage roller(working depth up to 25cm)- 2-row Finger harrow- 550 mm Cage rollerOriginal Spare PartsThe <strong>Kverneland</strong> Group regards the saleof each machine as the start of a long-termand valuable relationship. To support therelationship, we provide the vital highquality spare part and an efficient sparepart service.You can depend on the <strong>Kverneland</strong> Groupto offer a premium service. It's vital for us!9

<strong>Kverneland</strong> CLCChisel <strong>Cultivator</strong>for reduced operating costsThe reversible point is the same as thoseused on our ploughs.As well as being very inexpensive,they offer unrivalled resistance to wear.10

15-tine <strong>Kverneland</strong> CLC in stubble cultivation configuration: the wing shares make it possibleto carry out shallow stubble cultivation at depths of 5 to 15cm, the discs gang ensuresperfect mixing and levelling. Finally, the cage roller provides the necessary consolidation forvolunteer and weed seed germination.Robust frame constructionThe <strong>Kverneland</strong> CLC is available inworking widths from 2.00 to 5.10 metresand is offered with 2 or 3 rows of tinesand 2 different frame cofigurations:- rigid 2.00 to 3.60m working widthmodels- hydraulic 2 part folding 3.60 to 5.10mmodels.The machine provides a large underframeclearance of 870mm andintercross frame distance of 900mm foroptimum performance in all soil and cropconditions.Front mounting kitThe CLC can be fitted with an optionalfront mounting kit which allows the CLCto be used as a combination cultivator.The CLC utilises the <strong>Kverneland</strong> standardplough point, with all the benefits of the<strong>Kverneland</strong> heat treatment systems. Inaddition to its reduced wear due to its highdurability, it has the advantage of beinginexpensive to replace.SpecificationsWorkingwidthTransportwidthNo. oftinesWeightRigid/Non–StopSinglediscDoublediscRollerCombinationModels with 2 rows of tines:2.00 m2.00 m7405 / 480 kg245 kg460 kg200 kg415 kg2.50 m3.00 m3.60 m3.60 m4.30 m5.10 m2.50 m2.95 m3.60 m2.90 m2.90 m2.90 m9111313*15*19*Models with 3 rows of tines:475 / 575 kg550 / 670 kg650 / 800 kg1050 / 1200 kg1185 / 1350 kg1300 / 1500 kg275 kg305 kg335 kg335 kg490 kg550 kg520 kg580 kg640 kg640 kg920 kg1040 kg230 kg265 kg315 kg315 kg400 kg460 kg475 kg540 kg620 kg620 kg830 kg950 kg2.50 m2.50 m9640 / 740 kg275 kg520 kg230 kg475 kg3.00 m2.95 m11680 / 800 kg305 kg580 kg265 kg540 kg3.60 m3.60 m13715 / 860 kg335 kg640 kg315 kg620 kg* Hydraulic folding modelsPower requirement depends on working depth, 5 - 25 HP / tine.11

Ask for other implements in the<strong>Kverneland</strong> program<strong>Kverneland</strong> Group is one of theleading internationalcompanies developing,producing and distributingagricultural and viticulturalmachinery.The Group’s family of strongbrands allows us to provideprofessional farmers,contractors and dealers witha unique and complete rangeof high quality products for soilpreparation, seeding, grassprocessing, spreading,spraying, vine conditioningand grape harvesting.www.kvernelandgroup.com<strong>Kverneland</strong> ES<strong>Kverneland</strong>CTS Stubble Finisher<strong>Kverneland</strong> - No. 1 in ploughproduction. The complete programconsists of all types and sizes ofploughs from the smallest 2-furrowto the largest 14-furrow.<strong>Kverneland</strong> CTS Stubble Finisherhighspeed stubble cultivation, withuniform mixing of crop residues. Onepass operation to produce a fine, firm,level and weatherproof stale seedbedwhilst carrying out deep loosening, toa maximum of 400mm. The <strong>Kverneland</strong>CTS is available in working widths of3.0, 4,5 and 6,0 m.<strong>Kverneland</strong> Power Harrows andRotary Tillers have gone through aradical development program overrecent years and are now taking anever increasing market share theworld over.<strong>Kverneland</strong> PowerHarrows<strong>Kverneland</strong> Group UK Ltd.Walkers Lane, Lea Green, St. HelensMerseyside WA9 4AF, UKTel: +44 1744 853 200, Fax: +44 1744 853 400<strong>Kverneland</strong> International BVHoofdweg 1278, NL-2153 LR Nieuw-VennepP.O. Box 1000, NL-2150 BA Nieuw-VennepThe NetherlandsTel: +31 252 662 244, Fax: +31 252 687 325<strong>Kverneland</strong> reserves the right to make changes in design and specification or to add new features without obligation on implements purchased before or after such changes are made.AC754921 GB 01/07