Chalon/Saint-Marcel manufacturing plant - AREVA

Chalon/Saint-Marcel manufacturing plant - AREVA

Chalon/Saint-Marcel manufacturing plant - AREVA

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

E Q U I P M E N T<strong>Chalon</strong>/<strong>Saint</strong>-<strong>Marcel</strong><strong>manufacturing</strong> <strong>plant</strong>

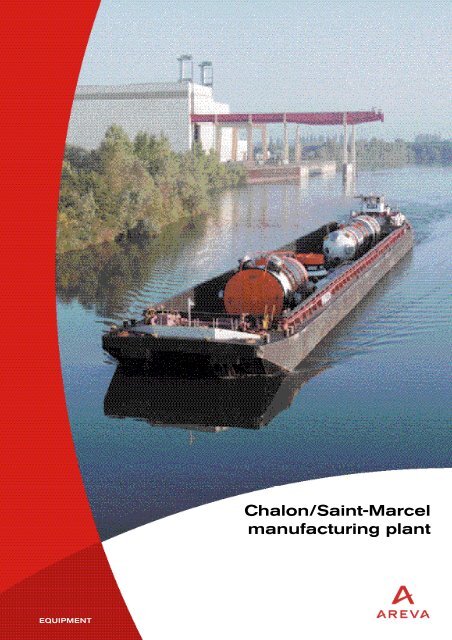

A TRADITIONAL INDUSTRY AT THEFOREFRONT OF NUCLEAR TECHNOLOGY<strong>AREVA</strong> is the world leader in the designand construction of nuclear power<strong>plant</strong>s, the manufacture of heavycomponents, and the supply of nuclearfuel and nuclear services such asmaintenance and inspection.The Equipment Division provides thewidest range of nuclear components andequipment, manufactured at its twofacilities in Jeumont, northern France,and St. <strong>Marcel</strong>, in Burgundy.The St. <strong>Marcel</strong> <strong>plant</strong>, set on 35 ha(87.5 acres) near <strong>Chalon</strong>-sur-Saône, wasestablished in 1973 in a region with along history of specialized metalworkingand mechanical activities to meet thedemand for non-military nuclearrequirements in France.The site offers two advantages:■■excellent facilities for loading andtransporting heavy components on theSaône river,it’s proximity to other group sites.Since its completion in 1975, the<strong>Chalon</strong>/St. <strong>Marcel</strong> facility hasmanufactured all the heavy componentsfor French pressurized water reactors(PWRs) ranging from 900 MW to 1500MW. It has also completed a significantnumber of export contracts that havemade <strong>AREVA</strong> world leader.<strong>Chalon</strong>/St <strong>Marcel</strong> <strong>plant</strong>2

Vessel closure headFacts and figures…■■■■■850 people, 50% of which areengineers, executives and highlyqualified technicians.35 ha site (87.5 acres).39000 m 2 ( 9.6 acres) formanagement, logistics, technicalsupport offices.35800 m 2 (8.85 acres) of workshops,equipped with traveling cranes anddivided into 3 bays.Lifting capacity of the large bay,which is 36m (39 yards) wide andopens onto a dock which links up tothe Saône, exceeds 1000 t and 23 m(25 yards) under hook.…that provide uniquereferencesNearly 600 heavy components (reactorvessels, steam generators, pressurizersand closure heads) have beenmanufactured or are currently beingmanufactured since the <strong>plant</strong> opened in1975:3■■Over 500 of these components are orwill be installed in nuclear power<strong>plant</strong>s in France,Nearly 100 of these components havebeen installed in or are currentlybeing manufactured for <strong>plant</strong>s inBelgium, Great Britain, Korea,People's Republic of China, SouthAfrica, Sweden, Switzerland, Finlandand the United States.

MASTERY OF HEAVY COMPONENTM A N U F A C T U R I N GThe <strong>plant</strong> at <strong>Chalon</strong>/St. <strong>Marcel</strong> is at theheart of the <strong>manufacturing</strong> chain fornuclear steam supply systems (NSSS)supplied by <strong>AREVA</strong>.On the basis of engineering data, the<strong>plant</strong> manufactures reactor vessels,reactor vessel internals, steamgenerators, pressurizers and relatedcomponents such as accumulators,auxiliary heat exchangers andsupporting elements.Other similar components such asreactor vessels for boiling water reactors(BWR) or high temperature reactors(HTR) and other types of steamgenerators can also be manufactured inthe <strong>plant</strong> (for example Once ThroughSteam Generators – OTSG).The basic activities performed at<strong>Chalon</strong>/St. <strong>Marcel</strong> are metalworking andheavy machining. These activities arecarried out in strict compliance withnuclear safety rules.The availability of all of these skills,brought together on a single site andapplied to heavy Nuclear Steam SupplySystem (NSSS) components, allows<strong>Chalon</strong>/St. <strong>Marcel</strong> undeniableadvantages in terms of quality andcompetitiveness.The <strong>plant</strong> is also involved:Vessel upper internals■upstream by adapting the designinput from engineering to theproduction constraints and qualitycontrol requirements,■and downstream by producing stressreports proving the componentresistance to the specified in-serviceconditions.6

Positioning the Civaux 2 reactor vessel(France)Steam Generator Replacement at Tricastin 4 (France)Steam Generator Replacementat Prairie Island (USA)7

CONTINUOUS IMPROVEMENT...Welding of the final reactor vessel weldStainless steel cladding of the vessel shell ring inside surfaceWelding and claddingFully automated large welding gantriesand manipulators, stainless alloycladding machines, etc.Stainless steel cladding of the hot wire TIG-welded EPR tube plate10

MachiningHigh capacity vertical lathes and boringand milling machines.Drilling holes for reactor vessel studsHeat treatmentFurnaces of 600 t and 150 t areequipped with automatic controlsto ensure high quality<strong>manufacturing</strong>.600 t furnaceHydraulic expansionHydraulic expansion processinside cleanliness room11

...OF HIGH PRECISION TECHNIQUESIN CONTINUOUS IMPROVEMENTFinal finishing robotThe <strong>Chalon</strong>/St. <strong>Marcel</strong> factory offersexceptional resources, and is especiallyadapted to <strong>manufacturing</strong> steamgenerators with over 15,000 tubes:■■■■deep drilling machines for tubesheetsof up to 1000 mm thick,twelve-spindle drilling machines fordrilling tube support plates,completely automated broachingmachines for <strong>manufacturing</strong> thevarious tube support plate models,fully automated equipment for tubesupport plate finishing.Broaching of a tube support plateBroached holes in a tube support plate12

Drilling of tube support platesDrilling of a tubesheet13

CLEAN AND SAFE TECHNIQUESControlled access cleanroomsControlled access cleanroomsThe tube installation process (tubing,welding, hydraulic expansion, etc.) forsteam generator <strong>manufacturing</strong> isperformed in pressurized cleanrooms toprevent the introduction of foreignmaterials.Inspection during and after<strong>manufacturing</strong>Forming an essential link in the safetychain, all inspections are based on acomplete range of inspection techniques:linear accelerator, gamma radiographicsources, ultrasonic testing, eddy current,etc.Radiographic inspection with linear acceleratorTubing a steam generator in a cleanroom14

AND CONTINUOUS IMPROVEMENTThe <strong>AREVA</strong> Way process is aContinuous Improvementapproach that aims tointegrate SustainableDevelopment into theoperational management ofour company.<strong>AREVA</strong> Way is a means of structuringour Continuous Improvement approach.It is a reference base that every unit canuse to assess its own performance withregard to our ten SustainableDevelopment commitments, andtherefore determine its objectives for itsown and the group’s improvement.Action plans and the results of these arepresented to general managementduring budgetary sessions.Self-assessment 2003 to 2005 - <strong>Saint</strong>-<strong>Marcel</strong> <strong>plant</strong>16

MEN, WOMEN AND SKILLSRECRUITMENTWith the opening-up ofnumerous internationalmarkets, as well as itssuccesses, the <strong>plant</strong> is todayenjoying a boost that has seenit increase recruitment.40 % of its employees havebeen with the <strong>plant</strong> for underthree years.SAFETYFor the <strong>plant</strong>, the health and safety ofpersonnel – both its own employees andexternal suppliers – are major objectives.17

TRAININGTraining underpins the company’s strongdevelopment and accompanies therenewal of its skills base. We are involvedin bringing young people into theworkplace through an important trainingpolicy, including apprenticeships, shorttermcontracts for young people anduniversity internships.18

CERTIFICATION TO MEET THE CLIENTS'R E Q U I R E M E N T SThe quality system ensures that allproducts comply with applicable codesand standards:■ASME (American Society ofMechanical Engineers) section III,when the client specifies thatAmerican standards be appliedrequiring N and NPT certification.■ ISO 9001■ ISO 14001 (EnvironnementalManagement)■RCC-M (design and constructionrules for mechanical components ofPWR nuclear islands) defined by theAFCEN (French association for thedesign and construction of nuclearpower <strong>plant</strong> materials).■French regulations onpressurized water reactorsmonitored by the French nuclearsafety authorities represented by theBCCN (NSSS Control Office).19

With <strong>manufacturing</strong> facilities in 40 countries and a sales network in more than 100, <strong>AREVA</strong>offers customers reliable technological solutions for CO2-free power generation and electricitytransmission and distribution. We are the world leader in nuclear power and the only companyto cover all industrial activities in this field.Our 58,000 employees are committed to continuous improvement on a daily basis, makingsustainable development the focal point of the group’s industrial strategy.<strong>AREVA</strong>’s businesses help meet the 21st century’s greatest challenges: making energyavailable to all, protecting the planet, and acting responsibly towards future generations.www.areva.comF r a m atome anpAn <strong>AREVA</strong> and Siemens companyUsine de <strong>Chalon</strong> <strong>Saint</strong>-<strong>Marcel</strong> : B.P. 13 - 71380 <strong>Saint</strong>-<strong>Marcel</strong> - FrancePhone: +33 (0)3 85 90 30 00 - Fax: +33 (0)3 85 90 31 31Headquarters: Tour <strong>AREVA</strong> - 92084 Paris La Défense Cedex - FrancePhone: +33 (0)1 47 96 00 00 - Fax: +33 (0)1 47 96 36 36