How to set up a Porsche GT3 for the âPorsche Mobil 1 ... - Loctite

How to set up a Porsche GT3 for the âPorsche Mobil 1 ... - Loctite

How to set up a Porsche GT3 for the âPorsche Mobil 1 ... - Loctite

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

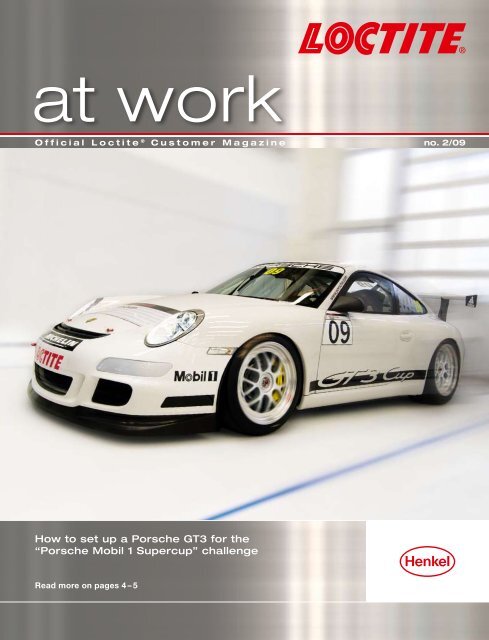

Official <strong>Loctite</strong> ® Cus<strong>to</strong>mer Magazineno. 2/09<strong>How</strong> <strong>to</strong> <strong>set</strong> <strong>up</strong> a <strong>Porsche</strong> <strong>GT3</strong> <strong>for</strong> <strong>the</strong>“<strong>Porsche</strong> <strong>Mobil</strong> 1 S<strong>up</strong>erc<strong>up</strong>” challengeRead more on pages 4 – 5

10Leadingin Health & SafetyOur contribution <strong>to</strong> your safety at work.Read more about this <strong>to</strong>pic on page 10.at work | no. 2/09

Edi<strong>to</strong>rial | 3Cédric BerthodVice President<strong>Loctite</strong> Industrial Gro<strong>up</strong>Henkel AdhesiveTechnologies EMEADear Readers,Welcome on board. Once again, we are going <strong>to</strong> take you on a trip behind <strong>the</strong> scenes of some <strong>the</strong> world’s mostfamous and successful companies. In this second issue of our cus<strong>to</strong>mer magazine at work, we will take you <strong>to</strong><strong>the</strong> desert, where <strong>the</strong> iconic <strong>Porsche</strong> 911 raced down <strong>the</strong> track in Bahrain’s scorching heat. Ano<strong>the</strong>r destinationis Scotland, where Terex ® produces a mining truck of gigantic dimensions. The journey will also take you <strong>to</strong> Italy,where Gessi, <strong>the</strong> exclusive interior design manufacturer opened its fac<strong>to</strong>ry gates <strong>for</strong> us.What is it that powerful race cars, luxurious bathroom fittings and monstrous mining trucks have in common?They all rely on a technology without which modern life as we know it would be unthinkable, but which remainsinvisible <strong>for</strong> most people: adhesive technology. “This is <strong>the</strong> golden age of glue” writes <strong>the</strong> American author BruceSterling and continues: “During <strong>the</strong> past 30 years, <strong>the</strong>re has been a silent revolution in adhesion.” In this issue, wegive a voice <strong>to</strong> that silent revolution and open <strong>the</strong> door <strong>to</strong> our engineers in Munich and Dublin. They'll share <strong>the</strong>irinsights and experiences as a part of Sterling’s silent revolution.In our trend report, we follow <strong>up</strong> on this <strong>the</strong>me, taking an in-depth look at <strong>the</strong> his<strong>to</strong>ry of maintenance, a <strong>to</strong>picclosely linked <strong>to</strong> <strong>the</strong> development of sealants, adhesives and threadlockers.Yours sincerely,Cédric Berthod4 6 14 18Contents4 14Highlight: <strong>Porsche</strong> Mo<strong>to</strong>rsportTake a look behind <strong>the</strong> scenes of <strong>Porsche</strong>Mo<strong>to</strong>rsport and discover exciting details about<strong>the</strong> <strong>Porsche</strong> 911 <strong>GT3</strong> C<strong>up</strong> car.6 18Reliability Report 3: Terex ®100 <strong>to</strong>n trucks exerting <strong>up</strong> <strong>to</strong> 1000 horsepower.We are paying a visit <strong>to</strong> <strong>the</strong> site where <strong>the</strong>segiants are manufactured.10 22RD&E InsightsEnvironmentally compatible threadlockers<strong>set</strong> new standards in Health & Safety andsustainability.12 23Integrated SolutionsDeveloping adhesive <strong>for</strong>mulations tailored <strong>to</strong><strong>the</strong> needs of a wide variety of industries. One ofHenkel’s core competencies.Trend ReportMaintenance and repair. The future economicpath.Reliability Report 4: GessiLuxury bathroom design "Made in Italy".Manufactured by experts skilled in <strong>the</strong> fineart of technology.Handy HintsInsights online – let us bring you closer <strong>to</strong> ourtechnologies and help you find <strong>the</strong> right <strong>Loctite</strong> ®product faster and easier.OutlookSome of <strong>the</strong> <strong>to</strong>pics <strong>for</strong> <strong>the</strong> next issue of <strong>Loctite</strong> ®at work.at work | no. 2/09

4 | HighlightWinning <strong>to</strong>ge<strong>the</strong>r<strong>Loctite</strong> ® and <strong>Porsche</strong> Mo<strong>to</strong>rsport start <strong>the</strong>ir technical partnership at full throttle<strong>Porsche</strong> Mo<strong>to</strong>rsportand Henkel:a winning teamPartner status:Official TechnologyPartner <strong>to</strong> <strong>the</strong> <strong>Porsche</strong><strong>Mobil</strong> 1 S<strong>up</strong>erc<strong>up</strong>.Official Partner <strong>to</strong><strong>Porsche</strong> Mo<strong>to</strong>rsportFirst participation:2009Main technicalapplications:Engine, Transmission,Differential.Threadlocking:<strong>Loctite</strong> ® 243,<strong>Loctite</strong> ® 270Flange Sealing:<strong>Loctite</strong> ® 574,<strong>Loctite</strong> ® 5188Cleaning:<strong>Loctite</strong> ® 7063On a race circuit in Bahrain, a parade of tiny dotswhizzes by in <strong>the</strong> blistering heat. The icons on parade are<strong>the</strong> cars that make <strong>up</strong> <strong>the</strong> field of <strong>the</strong> <strong>Porsche</strong> 911 <strong>GT3</strong><strong>Mobil</strong> 1 S<strong>up</strong>erc<strong>up</strong>. The <strong>Porsche</strong> 911 is a legendary vehicleand a physical symbol of brand awareness rivalled only bya select few. It is one of <strong>the</strong> few products that have becomea globally recognizable symbol, like Coca-Cola.<strong>How</strong>ever, what is not as well known as <strong>the</strong> elegant, curvedshape of <strong>the</strong> 911 <strong>GT3</strong> that just raced by under <strong>the</strong> burningdesert sun is this "minor" detail: <strong>the</strong> construction of <strong>the</strong> carrelies on modern adhesive technology. In order <strong>to</strong> drawattention <strong>to</strong> this fact, <strong>Porsche</strong> and Henkel, with its strong<strong>Loctite</strong> brand, have engaged in a partnership <strong>to</strong> s<strong>up</strong>port<strong>the</strong> <strong>Porsche</strong> <strong>Mobil</strong> 1 S<strong>up</strong>erc<strong>up</strong>.The S<strong>up</strong>erc<strong>up</strong> competition is <strong>the</strong> overture <strong>to</strong> Formula 1,<strong>the</strong> most popular mo<strong>to</strong>rsport event in <strong>the</strong> world. <strong>Porsche</strong><strong>Mobil</strong> 1 S<strong>up</strong>erc<strong>up</strong> races are held on every Sunday be<strong>for</strong>ea Formula 1 race. After <strong>the</strong> opening event in <strong>the</strong> Kingdomof Bahrain this spring, ten more races in different Europeancountries are scheduled throughout <strong>the</strong> course of <strong>the</strong>year.The <strong>Porsche</strong> 911 <strong>GT3</strong> C<strong>up</strong> cars, which only weigh1130 kg, boast engines with 420 bhp and a <strong>to</strong>p speed of290 kilometres per hour. This lightweight co nstruction ismade possible using alternative materials like aluminiumand composites, which is where adhesives come in<strong>to</strong>play. Since aluminium and composites don’t lend <strong>the</strong>mselves<strong>to</strong> <strong>the</strong>rmal welding, alternative solutions needed<strong>to</strong> be found.<strong>Porsche</strong> and <strong>Loctite</strong> ® engineers worked <strong>to</strong>ge<strong>the</strong>r <strong>to</strong> findexactly those solutions, in <strong>the</strong> race car as well as in <strong>the</strong>series model 911 <strong>GT3</strong>. <strong>Loctite</strong> ® products are used in <strong>the</strong>construction of <strong>the</strong> engine, <strong>the</strong> gearbox and differential.<strong>Porsche</strong> relies on <strong>the</strong> proven <strong>Loctite</strong> ® durability when itcomes <strong>to</strong> threadlocking and flange sealing, ensuringreliability of <strong>the</strong>se vehicles even under extreme conditionslike <strong>the</strong> heat of Bahrain. <strong>Loctite</strong> ® 243 is used <strong>to</strong> securebolts on <strong>the</strong> gearbox clamping plate, <strong>the</strong> fixing bolts of<strong>the</strong> oil spray tube inside <strong>the</strong> gearbox and fixing bolts of<strong>the</strong> sequential gear shift system. While <strong>Loctite</strong> ® 574, afast curing gasketing product, seals <strong>the</strong> two-part gearboxhousing.The fixing bolts of <strong>the</strong> differential housing, <strong>the</strong> stud boltsof <strong>the</strong> gearbox housing as well as <strong>the</strong> fixing bolts of <strong>the</strong> oilpump housing and <strong>the</strong> bolts of <strong>the</strong> mounting frame of apinion wheel shaft are secured with <strong>Loctite</strong> ® 270. <strong>Loctite</strong> ®products are also used <strong>for</strong> component manufacturing:<strong>Loctite</strong> ® 270 <strong>for</strong> <strong>the</strong> tappet pins on<strong>to</strong> <strong>the</strong> wheel hub, and<strong>Loctite</strong> ® 243 <strong>for</strong> <strong>the</strong> heat protection shield mounted <strong>to</strong><strong>the</strong> brake caliper protecting electronic sensors from <strong>the</strong>brake heat.<strong>Loctite</strong> ® is heavily used in <strong>the</strong> manufacturing of <strong>the</strong>vehicles, but it plays a part in <strong>the</strong>ir maintenance, <strong>to</strong>o. At<strong>the</strong> beginning of <strong>the</strong> season in March, all 14 cars takingpart in <strong>the</strong> S<strong>up</strong>erc<strong>up</strong> were provided with a full <strong>set</strong> of<strong>Loctite</strong> ® threadlocking, gasketing and cleaning products.The cooperation between <strong>the</strong> two companies goes a lotfur<strong>the</strong>r than that, however. Engineers of <strong>the</strong> two firms arein constant contact and <strong>Porsche</strong>’s demands often spurinnovation in <strong>the</strong> <strong>Loctite</strong> ® labs in Dublin and Munich.at work | no. 2/09

Highlight| 5Bernd Homberg is <strong>the</strong> <strong>Loctite</strong> ® Sales Engineer responsible<strong>for</strong> <strong>the</strong> cooperation with <strong>Porsche</strong> Mo<strong>to</strong>rsports. “It can goboth ways: ei<strong>the</strong>r we have a new product and approach<strong>the</strong> <strong>Porsche</strong> engineers, <strong>the</strong>y test it and check whe<strong>the</strong>r it’shelpful <strong>for</strong> <strong>the</strong>m. Or, <strong>Porsche</strong> hits on a problem that canbe solved with adhesive technology and <strong>the</strong>y turn <strong>to</strong> us<strong>for</strong> assistance”. He explains <strong>the</strong> way <strong>the</strong> partners work<strong>to</strong>ge<strong>the</strong>r. “At <strong>the</strong> moment, <strong>Porsche</strong> is testing <strong>Loctite</strong> ® 5188as a gasket <strong>for</strong> <strong>the</strong> differential housing. When <strong>the</strong>y werelooking <strong>for</strong> a way <strong>to</strong> attach a s<strong>to</strong>pper <strong>to</strong> <strong>the</strong> tank we wereable <strong>to</strong> solve <strong>the</strong> problem with high temperature resistanttwo-component epoxy adhesive <strong>Loctite</strong> ® Hysol 9492,” hecontinues.This commitment <strong>to</strong> <strong>the</strong> high-end of innovation and qualityrepresents only two of <strong>the</strong> values that Henkel and <strong>Porsche</strong>share. The fact that both firms are family businesses thatmaintain long-term relationships with <strong>the</strong>ir employees isone of <strong>the</strong> similarities in company culture that facilitatescommunication.Both companies are used <strong>to</strong> being consultants as well asmanufacturers. <strong>Loctite</strong> ® provides its cus<strong>to</strong>mers with hightechsolutions and individual s<strong>up</strong>port. <strong>Porsche</strong> actuallystarted as an engineering consulting company and hasretained that feature until <strong>to</strong>day.One of <strong>the</strong> interesting features of what <strong>the</strong> Americanauthor Bruce Sterling calls <strong>the</strong> “silent revolution in adhesivechemistry” is <strong>the</strong> fact that adhesive technology doesn’talways receive a great deal of attention in academia.Groundbreaking research and innovative ideas are oftena result of business needs and take place in companiesra<strong>the</strong>r than natural science faculties. Henkel is trying <strong>to</strong>remedy this situation, however, and is making its longyears of experience and extensive know-how available<strong>to</strong> universities in a number of cooperation projects. As aprofessional partner <strong>to</strong> young engineers and a products<strong>up</strong>plier <strong>to</strong> <strong>the</strong>ir racing teams, <strong>Loctite</strong> ® has been part of“Formula Student” <strong>for</strong> several years.Threadlocker <strong>Loctite</strong> ® 2700:Health & Safety countsFlange sealant <strong>Loctite</strong> ® 574:fast cure speedThreadlocker <strong>Loctite</strong> ® 270:high strength <strong>for</strong> extreme loadsThreadlocker <strong>Loctite</strong> ® 243:vibration resistant, removable assemblyHigh-speed engineering <strong>for</strong> professionalsThe Bahrain s<strong>to</strong>ry of <strong>the</strong> German driver René Rast makes abundantly clear how crucial good engineering and maintenanceis <strong>to</strong> succeeding in <strong>the</strong> S<strong>up</strong>erc<strong>up</strong>. Ten minutes be<strong>for</strong>e <strong>the</strong> start of <strong>the</strong> race, René Rast wanted <strong>to</strong> drive out of <strong>the</strong> garage,but suddenly <strong>the</strong>re was a loud crack! His chances of making it <strong>to</strong> <strong>the</strong> grid in time didn’t look good. One of <strong>the</strong> two driveshafts had gone. Seven mechanics instantly swarmed <strong>the</strong> car and managed <strong>to</strong> do <strong>the</strong> impossible: within only 8 minutesand 23 seconds <strong>the</strong>y had replaced <strong>the</strong> shaft, using threadlocker <strong>Loctite</strong> ® 243 <strong>to</strong> secure <strong>the</strong> six bolts holding <strong>the</strong> shaft<strong>to</strong> <strong>the</strong> gearbox. “The change of <strong>the</strong> drive shaft was done in just over eight minutes”, says engineer Frank Funke, proudof his team Veltins MRS Racing, in an interview with racecam.de. “I owed this result <strong>to</strong> my boys”, a grateful Rast saidafter <strong>the</strong> race. He came in second, beaten only by Bleekemolen. Richard Westbrooke, S<strong>up</strong>erc<strong>up</strong> winner in 2005 and2006, achieved a third place on his comeback <strong>to</strong> <strong>the</strong> S<strong>up</strong>erc<strong>up</strong>.at work | no. 2/09

6 | Reliability Report 3Hard workSiberia, minus 50 °C. A giant truck rumbles along <strong>the</strong> gravel of <strong>the</strong> coal mines, with <strong>the</strong>powerful determination of an angry rhino. The giant used in <strong>the</strong> Siberian mines wasmanufactured in Scotland, just like its twin bro<strong>the</strong>r doing hard work in copper minesunder <strong>the</strong> blazing Mexican sun.The fac<strong>to</strong>ry in Scotland Ready <strong>for</strong> delivery A wheel as big as a man Wheel suspension of a 100 <strong>to</strong>n truckat work | no. 2/09

Reliability Report 3| 7These trucks, used <strong>for</strong> heavy mining work in some of <strong>the</strong> world'smost treacherous areas, are produced by <strong>the</strong> American companyTerex ® . Vehicles exposed <strong>to</strong> <strong>the</strong> full <strong>for</strong>ce of extreme climates and loadsrely on high-end technology in combination with solid engineering <strong>to</strong> get<strong>the</strong> job done. This is where <strong>Loctite</strong> ® products make an impact, and <strong>the</strong>two companies have a long standing business relationship.22 bolts are secured with <strong>Loctite</strong> ® 648at work | no. 2/09

8 | Reliability Report 3Terex ® markets more than 50 brands covering a broad range of equipment<strong>for</strong> <strong>the</strong> construction, infrastructure, quarrying, recycling, surface mining,shipping, transportation, refining, utility and maintenance industries. Henkelhad <strong>the</strong> chance <strong>to</strong> send a film crew <strong>to</strong> <strong>the</strong> Terex ® plant in Glasgow, Scotland<strong>to</strong> see <strong>Loctite</strong> ® products in action.The enormous power <strong>the</strong> Terex ® machines wield requires <strong>the</strong> reliability that<strong>Loctite</strong> ® adhesives and sealants can ensure. Locating studs – locked withhigh strength anaerobic compound <strong>Loctite</strong> ® 648 – allow easy and fastfixturing of <strong>the</strong> differential, a crucial construction part exposed <strong>to</strong> strong<strong>for</strong>ces. The rigid flanges of <strong>the</strong> differential housing are sealed with <strong>Loctite</strong> ®518. Besides instant seal, <strong>Loctite</strong> ® 518 guarantees <strong>the</strong> reliable long-termper<strong>for</strong>mance because <strong>the</strong>re is no gasket relaxation, and correct clamp loadis maintained throughout <strong>the</strong> life of <strong>the</strong> assembly. This is a perfect exampleof how <strong>Loctite</strong> ® products provide optimisation in production.A wheelas big as a manInspiring strong feelings<strong>How</strong> do you measure a company’s appeal? Is it <strong>the</strong> level of brand awareness?The market position? Cus<strong>to</strong>mer loyalty?There is ano<strong>the</strong>r way of doing it, by asking a simple question: whoseproducts will inspire more excitement in a conversation amongst schoolchildren? Applying that measure, even <strong>Porsche</strong> and Ferrari will have hardtime competing with Terex ® . The American firm is <strong>the</strong> manufacturer of <strong>the</strong>biggest digger and <strong>the</strong> strongest crane in <strong>the</strong> world.The list of awe-inspiring products from Terex ® doesn’t s<strong>to</strong>p here. At <strong>the</strong>Scottish location, gigantic coal-mining trucks and o<strong>the</strong>r heavy dutyapplications are assembled. To get an idea of how big <strong>the</strong>se trucksreally are, just picture a wheel that is as tall as a grown man. Terex ®produces seven different models of <strong>the</strong>se trucks, with loadingcapacities <strong>up</strong> <strong>to</strong> 100 <strong>to</strong>ns.Attention <strong>to</strong> detail and emphasis on good craftsmanship are <strong>the</strong>attributes that Terex ® and <strong>Loctite</strong> ® engineers share. “Jackie is alwaysjust a phone call away,” says Steven Macholecki, a s<strong>up</strong>ervisor at<strong>the</strong> Scottish Terex ® plant in a video documenting <strong>the</strong> use of <strong>Loctite</strong> ® inproduction. Jackie is Jackie Marshall, <strong>the</strong> <strong>Loctite</strong> ® sales engineer responsible<strong>for</strong> Terex ® in Glasgow.Marshall spends at least one day a week at <strong>the</strong> plant in Glasgow, and<strong>the</strong> cooperation with <strong>the</strong> Terex ® engineers seems <strong>to</strong> be working well <strong>for</strong>both parties. “I’m involved in finding adhesive and sealant solutions <strong>for</strong> newdesigns, but I’m also <strong>the</strong>re when <strong>the</strong>y encounter maintenance problems,”he explains.at work | no. 2/09

Reliability Report 3| 9Long-life, reliablegasketing solutionGlobally, Terex ® is a well-known name when it comes <strong>to</strong>equipment <strong>for</strong> <strong>the</strong> construction, infrastructure, quarrying,recycling, surface mining, shipping, transportation, refining,utility, and maintenance industries. Among its portfolio is animpressive range of heavy duty vehicles including cranes,dumpers, excava<strong>to</strong>rs, digger derricks and rollers, as wellas both rigid and articulated trucks.“The company has built a reputation <strong>for</strong> providing highquality products that do <strong>the</strong>ir jobs with efficiency,” explainsDavid Brown, Technical S<strong>up</strong>port Engineer at <strong>the</strong> Terex ®base in Mo<strong>the</strong>rwell, Scotland. “The differential flangemust be sealed in a way <strong>to</strong> ensure long-term reliability byeliminating leak paths.”Terex ® already used a number of <strong>Loctite</strong> ® products on itsvehicles <strong>for</strong> a variety of applications, so it was natural <strong>to</strong>call in <strong>the</strong> local Henkel sales engineer, Jackie Marshall, <strong>to</strong>recommend a solution.“The answer was <strong>to</strong> use a liquid gasketing product,” statesDavid. “It was recommended that <strong>Loctite</strong> ® 518 was trialled<strong>for</strong> <strong>the</strong> purpose – and this provided <strong>the</strong> solution we wereseeking.”vehicle differentials, but also on gearbox, axle and engineflanges such as timing covers. It provides an instant sealagainst low pressures, fills gaps <strong>up</strong> <strong>to</strong> 0.25 mm, and iseffective at temperatures ranging from -55 °C <strong>to</strong> +150 °C.The size of <strong>the</strong> flange surface meant that applicationtechniques needed <strong>to</strong> be taken in<strong>to</strong> consideration. “Weare talking about a two-inch wide film on a three-footdiameter flange,” declares David. “With such an area <strong>to</strong>cover, normal application methods – such as <strong>the</strong> use of astandard dispensing gun – were not really suitable. Again,Henkel through its <strong>Loctite</strong> ® products was able <strong>to</strong> help.”That help came in <strong>the</strong> <strong>for</strong>m of <strong>the</strong> <strong>Loctite</strong> ® Trax Roller.This is a roller (similar <strong>to</strong> <strong>the</strong> one used <strong>for</strong> painting) that isattached <strong>to</strong> a dispensing gun, allowing <strong>the</strong> gasket material<strong>to</strong> be applied quickly with a very even film over <strong>the</strong> wholearea.“Since we have put this solution in<strong>to</strong> practice, we havenever experienced any problems with leakage," concludesDavid.Reliabilityat workCus<strong>to</strong>mer:Terex ® ,ScotlandTask:Provide a long-lastingseal on a three-footdiameter rigid flange at<strong>the</strong> rear axle differential.Products:<strong>Loctite</strong> ® 518<strong>Loctite</strong> ® 648Liquid anaerobic gaskets con<strong>for</strong>m <strong>to</strong>tally <strong>to</strong> <strong>the</strong> flangesurface, filling all gaps and irregularities. Bolts, flange, andgasket act as a unit, sharing operational stresses. <strong>Loctite</strong> ®518 is designed <strong>for</strong> sealing rigid flange faces – not only onSource: Terex ® case studyThe rear axle shaft ready <strong>for</strong> fur<strong>the</strong>rprocessingCleaning <strong>the</strong> flange of <strong>the</strong> rear axledifferential with <strong>Loctite</strong> ® 7063Sealing <strong>the</strong> flange of <strong>the</strong> rear axledifferential with <strong>Loctite</strong> ® 518Differential is ready <strong>for</strong> assembly22 bolts holding <strong>the</strong> differential <strong>to</strong> <strong>the</strong>rear axle are retained with <strong>Loctite</strong> ®648Transmission and wheel suspension areassembledRear axle ready <strong>for</strong> <strong>the</strong> next assemblystepTransmission assembly in a 100 <strong>to</strong>ntruckat work | no. 2/09

10 | RD&E InsightsReliabilityat workBenefits• Medium andhigh strengththreadlockers• Outstandingper<strong>for</strong>mance• Added benefi<strong>to</strong>f enhancedocc<strong>up</strong>ational H&S• No hazard symbols• No risk phrases• No safety phrases• No declarable CMRsDefining sustainabilityEnvironmental awareness has come a long way. Once<strong>the</strong> domain of bearded men wearing Birkens<strong>to</strong>ck sandals,<strong>the</strong>y have now arrived in corporate boardrooms all over<strong>the</strong> world. Sustainability has become a buzz word in <strong>the</strong>business community. What exactly does sustainabilitymean <strong>to</strong> you, though?That is <strong>the</strong> question that Henkel Product Manager ErikEdelmann and his team asked <strong>the</strong>ir industrial cus<strong>to</strong>mers.“For most cus<strong>to</strong>mers it is ra<strong>the</strong>r difficult <strong>to</strong> clearly definesustainability. The term generally encompasses energyand climate, materials and waste, water consumption,health and safety, as well as social progress. <strong>How</strong>ever, <strong>the</strong>primary focus is clearly on occ<strong>up</strong>ational health and safetyand environmental responsibility,” says Edelmann.A clean sheetThis was not an entirely new challenge <strong>for</strong> Henkel, as <strong>the</strong>company has always placed great importance on nonhazardoussubstances and minimal eco-<strong>to</strong>xicity in <strong>the</strong>more than one hundred years of its his<strong>to</strong>ry. With <strong>the</strong> newthreadlockers <strong>Loctite</strong> ® 2400 and <strong>Loctite</strong> ® 2700, Henkel hasbroken new ground in occ<strong>up</strong>ational health and safety. Themedium strength threadlockers <strong>Loctite</strong> ® 2400 and <strong>the</strong> highstrength threadlocker <strong>Loctite</strong> ® 2700 are a leap <strong>for</strong>ward,because <strong>the</strong>y both have a “white” MSDS (Material SafetyData Sheet).Never sacrifice per<strong>for</strong>manceAs usual, <strong>the</strong> Henkel specialists in <strong>the</strong> Dublin Technologycentre were working <strong>to</strong>ge<strong>the</strong>r very closely with <strong>the</strong>ircus<strong>to</strong>mers during <strong>the</strong> development process. “In <strong>the</strong> caseof <strong>Loctite</strong> ® 2400 and <strong>Loctite</strong> ® 2700, we were collaboratingwith two large cus<strong>to</strong>mers in France,” says Edelmann. Hisprofessional background is in chemical engineering, atraining which greatly facilitated <strong>the</strong> communication withleading developer David Condron in Dublin. “The cus<strong>to</strong>mers<strong>to</strong>ok a very cautious approach and insisted that not even<strong>the</strong> decomposition products should be hazardous,” saysCondron.Not willing <strong>to</strong> sacrifice per<strong>for</strong>mance, Condron and hiscolleagues worked <strong>for</strong> more than a year on <strong>the</strong> projectand finally made it happen: <strong>the</strong>y developed products thatretained <strong>the</strong> cus<strong>to</strong>mary high <strong>Loctite</strong> ® per<strong>for</strong>mance with a“white” health and safety bill.“We were lucky <strong>to</strong> have <strong>the</strong> chance <strong>to</strong> cooperate withhighly sophisticated and demanding cus<strong>to</strong>mers,” saysEdelmann.“A white MSDS means that according <strong>to</strong> <strong>the</strong> <strong>to</strong>ughregulations of (EC) No. 1907/2006 - ISO 11014-1 boththreadlockers do not carry any hazard symbols, risk or safetyphrases. In addition, <strong>the</strong>y do not contain any declarableCMRs (Carcinogenic, Mutagenic and Reproductive <strong>to</strong>xins),”explains Edelmann and continues: “You will be surprised<strong>to</strong> see that your ordinary dishwashing agent or all- purposecleaner carries more hazard symbols than <strong>the</strong>se industrialproducts.”RD&E InsightsThe evolution of new adhesivesDavid CondronSenior Chemist, Product Development Europe,Dublin, Irelandat work | no. 2/09

RD&E Insights| 11The medical officers in France <strong>to</strong>ok a personal interestin <strong>the</strong> project and gave direct feedback on <strong>the</strong> variouspro<strong>to</strong>types. By meeting <strong>the</strong> cus<strong>to</strong>mer’s needs, <strong>Loctite</strong> ®engineers <strong>set</strong> a new standard in <strong>the</strong> realm of industrialthreadlocking. “I have <strong>to</strong> say that we are proud of thisachievement and <strong>the</strong> fact that we were able <strong>to</strong> reaffirmHenkel’s position as a technological industry leader,”Condron stated at <strong>the</strong> end of <strong>the</strong> interview.Because safety matters: <strong>Loctite</strong> ® threadlockerswith a “white” health and safety billQuality and responsibility have always been important issuesat Henkel. Continuously striving <strong>to</strong> improve <strong>the</strong> Health & Safety ofits products, <strong>the</strong> company breaks new ground with <strong>the</strong> medium strengththreadlocker <strong>Loctite</strong> ® 2400 and high strength threadlocker <strong>Loctite</strong> ® 2700. The<strong>set</strong>wo products retain <strong>the</strong> same outstanding level of per<strong>for</strong>mance cus<strong>to</strong>mers have come<strong>to</strong> trust, with <strong>the</strong> essential added benefit of enhanced occ<strong>up</strong>ational health and safety:®• <strong>Loctite</strong> 2400 and <strong>Loctite</strong> ® 2700 require no hazard symbols, no risk phrases and nosafety phrases on Material Safety Data Sheet complying with <strong>the</strong> <strong>to</strong>ugh EU regulations• They do not contain any declarable CMRs (Carcinogenic, Mutagenic and Reproductive<strong>to</strong>xins)• They do not require any entries in sections 2, 3, 15 and 16 of <strong>the</strong> MSDS according <strong>to</strong>(EC) No. 1907/2006 - ISO 11014-1No compromise on per<strong>for</strong>manceMedium strength threadlocker <strong>Loctite</strong> ® 2400 is fluorescent blue with a viscosity of3000 mPa·s and a shear strength on steel of 9 N/mm 2 . The high strength <strong>Loctite</strong> ® 2700 isfluorescent green, has a viscosity of 500 mPa·s and a shear strength of 18 N/mm 2 . Oncecured, both products offer excellent resistance against most industrial chemicals. Theyachieve good <strong>the</strong>rmal resistance, withstanding continuous operating temperatures <strong>up</strong> <strong>to</strong>150 °C.at work | no. 2/09

12|Integrated SolutionsA perfectcombinationWhat do cars, aeroplanes, syringes, shoes, trucks, water taps, arrows from ancientMongolia, spaceships and tunnel boring machines have in common? The answer is:<strong>the</strong> use of a ubiqui<strong>to</strong>us, yet rarely noticed technology- adhesive engineering. Eventhough <strong>the</strong> use of glue can be traced back <strong>to</strong> <strong>the</strong> Neanderthals, <strong>the</strong> last 30 yearshave seen an enormous increase in its reliability as well as in industrial adhesiveapplications.Stefan FrischApplication TechnologistHenkel Engineering AdhesiveHermann HandwerkerManager European TechnicalService, Henkel MunichAccording <strong>to</strong> Stefan Frisch and Hermann Handwerker from Henkel in Munich, thisis not only a fact normally ignored by <strong>the</strong> layman; even engineers and academicsdon’t give adhesives <strong>the</strong> credit <strong>the</strong>y deserve. “University courses only <strong>to</strong>uch brieflyon adhesives, one of <strong>the</strong> “youngest” joining technologies, if <strong>the</strong>y include <strong>the</strong>m at all,”says Frisch, an application technologist. “A lot of <strong>the</strong> research and <strong>the</strong> innovationresults from companies like Henkel who are trying <strong>to</strong> meet cus<strong>to</strong>mer needs," addsHandwerker.at work | no. 2/09

Integrated Solutions | 13Handwerker, who holds a PhD in chemistry, continues:“After university, I didn’t even think about <strong>the</strong> adhesiveindustry as a possible employer. And I think it’s <strong>the</strong> same<strong>for</strong> most engineers, <strong>to</strong>o; using adhesives is somehow seenas second best, something <strong>to</strong> be avoided,” he explains.This is of course completely unjustified, according <strong>to</strong> Frischand Handwerker, who almost seem like missionaries <strong>for</strong> <strong>the</strong>adhesive cause during this lunch-time interview, <strong>the</strong>ir zealhardly allowing <strong>the</strong>m <strong>to</strong> finish <strong>the</strong>ir meals.Standard or tailor made?They might have a point, as a look around <strong>the</strong> Henkeltest centre in Munich demonstrates. Just behind<strong>the</strong> entrance <strong>the</strong>re is a showcase displaying avariety of items produced with <strong>the</strong> use ofadhesives: Loudspeakers, syringes andinfusion bottles <strong>to</strong> name just a few. Thecentre in Munich is one of <strong>the</strong> placeswhere <strong>Loctite</strong> ® specialists conduct<strong>the</strong> research that Handwerkerand Frisch referred <strong>to</strong> during <strong>the</strong>interview.Frisch points <strong>to</strong> a differentialgear in one of <strong>the</strong> rooms andexplains: “This is a project we’vebeen working on <strong>for</strong> more thana year. A cus<strong>to</strong>mer from <strong>the</strong>au<strong>to</strong>motive industry wanted us<strong>to</strong> find an adhesive solution <strong>for</strong>putting <strong>to</strong>ge<strong>the</strong>r <strong>the</strong> parts of thisdifferential.” This is one of <strong>the</strong> benefitsof working <strong>for</strong> Henkel: Finding andtesting solutions is a service that Henkeloffers as a s<strong>up</strong>port <strong>to</strong> cus<strong>to</strong>mers in <strong>the</strong>irdevelopment process.conditions. Applying <strong>the</strong> products prevents fretting andcorrosion, minimises costly breakdowns and extendsservice life. Appropriate dispensing equipment is available<strong>for</strong> manual as well as o<strong>the</strong>r application jobs in <strong>the</strong> workshop.And should <strong>the</strong>re be problems: <strong>the</strong> local sales engineer isjust a phone call away.Product applications can be found in a wide range ofindustries. Special packages have been developed <strong>for</strong>applications on pump, centrifuge, power plant, shaft and,last but not least, water treatment which by all accounts willbe one of <strong>the</strong> growth industries of <strong>the</strong> 21st century.Is <strong>the</strong>re fur<strong>the</strong>r room <strong>for</strong> development when it comes <strong>to</strong> <strong>the</strong>use of industrial adhesives? Silly question: “Of course <strong>the</strong>reis,” says Handwerker. “This is a relatively new technologyand we have just scratched <strong>the</strong> surface of what’s possible.”This sentence almost exactly echoes a statement madeby his colleague featured in <strong>the</strong> first issue of this magazineabout <strong>the</strong> Tear Down Centre. There, an interdisciplinaryteam of specialists looks at each component of a finishedproduct <strong>to</strong> see whe<strong>the</strong>r <strong>the</strong> value of <strong>the</strong> product can beenhanced or <strong>the</strong> cost of manufacturing can be reduced.All <strong>the</strong>se ef<strong>for</strong>ts help <strong>to</strong> spread <strong>the</strong> word about <strong>the</strong> powerof adhesives and sealants.But finding or creating <strong>the</strong> right product is only <strong>the</strong>first step; <strong>the</strong> second step is applying and dispensing<strong>the</strong> product in <strong>the</strong> right manner. This is <strong>the</strong> area thatFrisch specialises in. “We offer a large variety of standardequipment, both <strong>for</strong> manual and au<strong>to</strong>matic dispensing,” hesays. Again, <strong>the</strong> <strong>Loctite</strong> ® engineers work on a problem until<strong>the</strong>y have come <strong>up</strong> with a solution that will stand <strong>the</strong> finaltest of continuous use on an assembly line or in a fac<strong>to</strong>ryworkshop. “If no combination of standard equipment willdo, we have a team responsible <strong>for</strong> designing tailor-madesolutions,” Frisch continues.One of <strong>the</strong> advantages of being <strong>the</strong> market leader <strong>for</strong> sucha long time is <strong>the</strong> wealth of experience and know-how <strong>the</strong>team in Munich has accumulated. The cus<strong>to</strong>mer gets <strong>the</strong>right product and <strong>the</strong> appropriate dispensing equipment allin one, which leads <strong>to</strong> very user friendly solutions.The omnipresent cus<strong>to</strong>mer need <strong>to</strong> cut costs is very muchon <strong>the</strong> minds of <strong>the</strong> <strong>Loctite</strong> ® crew in Munich. <strong>Loctite</strong> ®adhesives offer benefits not only in manufacturing, butalso <strong>for</strong> maintenance and repair. <strong>Loctite</strong> ® engineers havedeveloped solutions that emphasise prevention ra<strong>the</strong>r thanrepair. A good example <strong>for</strong> this strategy is <strong>the</strong> gearboxand shaft package <strong>the</strong>y have assembled: a range of morethan 20 products developed <strong>to</strong> per<strong>for</strong>m under extremeat work | no. 2/09

14 | Trend ReportMaintenance −<strong>the</strong> invisible power of developmentSince humans first began developing <strong>to</strong>ols, <strong>the</strong>re has always been a need <strong>to</strong> maintain<strong>the</strong>m. The careful maintenance of an economic production process was often anecessity <strong>for</strong> survival, especially in times of scarce and valuable commodities. Theroad <strong>to</strong> implementing modern industrial maintenance was a long one. Given <strong>the</strong>developments ahead of us, we are still at <strong>the</strong> beginning of that road.at work | no. 2/09

Trend Report| 15The his<strong>to</strong>ry of maintenance is also <strong>the</strong> his<strong>to</strong>ry of culture andan allegory <strong>to</strong> <strong>the</strong> industry's conception and philosophy.Effective and efficient maintenance is, more than ever, vital<strong>for</strong> development, particularly in times of financial crises andreduced turnover, increasing costs <strong>for</strong> energy, commoditiesand labour.Today, Maintenance, Repair and Overhaul (MRO) costsmore than € 1,500 bn per year in <strong>the</strong> EU alone, andmore than € 7,000 bn worldwide. Over 50 million jobsare directly related <strong>to</strong> MRO, and 150 million jobs areindirectly related. <strong>How</strong>ever, requirements <strong>for</strong> MRO areincreasing and, especially in times of financial crisisand reduced budgets, are difficult <strong>to</strong> meet. Laws aretightening <strong>the</strong> scope <strong>to</strong> respond <strong>to</strong> <strong>the</strong>se requirements,as well as meeting cus<strong>to</strong>mers’ demands, incorporatingnew technologies, and considering economic and ecologicnecessities. <strong>How</strong>ever, modern industry would not be able<strong>to</strong> work efficiently without <strong>up</strong>-<strong>to</strong>-<strong>the</strong>-minute and innovativemethods of maintaining <strong>to</strong>ols and equipment.The early years of industry − maintenance byaccidentIn <strong>the</strong> early stages of industrial development, breakdownswere commonplace due <strong>to</strong> <strong>the</strong> means of production and,consequently, down-times were high.The symbol of early maintenance was “<strong>the</strong> man with <strong>the</strong>oil can”. And, beside this basic service, one simply had <strong>to</strong>repair <strong>the</strong> damage as it occurred. There were no moni<strong>to</strong>ringsystems available at that time, and <strong>the</strong> analysis of probabilityof failure was in <strong>the</strong> early developmental stages.The trans<strong>for</strong>mation of failure based on preventivemaintenance began with traffic engineering; initially from <strong>the</strong>railways, and later with aviation technology. The immediatedanger <strong>to</strong> human life and <strong>the</strong> difficulties encountered on <strong>the</strong>way <strong>to</strong> carry out maintenance work were <strong>the</strong> driving <strong>for</strong>cesin <strong>the</strong> development of preventive maintenance.Prevention is better than a cure − preventivemaintenanceThe reorientation of preventive maintenance in <strong>the</strong> industrydid not start in Europe or <strong>the</strong> US, but in post-war Japan.In an exemplary manner, industrial production wastrans<strong>for</strong>med after World War II. The simple concept was<strong>to</strong> follow manufacturers’ recommendations about <strong>the</strong>controlled care and maintenance of machines and devices,which was not so usual in <strong>the</strong> 1950s. It was part of <strong>the</strong>Japanese Kaizen philosophy, which means (in this context)“continuous improvement <strong>to</strong>ward <strong>the</strong> better”.Looking in<strong>to</strong> <strong>the</strong> crystal ball − predictivemaintenanceBy <strong>the</strong> 1960s, increasing competitive pressure led <strong>to</strong> asteady improvement and continuity of production plants.Consequently, <strong>the</strong> reliability of equipment and <strong>the</strong> probabilityof error intervals became predictable, depending on loadand production time. This knowledge led <strong>to</strong> <strong>the</strong> increasingquality standards of used materials and manufacturingprocesses. Predictive maintenance was not able <strong>to</strong><strong>for</strong>esee occurrences caused by incidence or failure butthis approach led <strong>to</strong> distinct statistical knowledge, whichwas reused by modern technology and software.at work | no. 2/09

Trend Report| 17structure <strong>to</strong> be moni<strong>to</strong>red, allow a precise data on criticalzones. It also enables Smart Moni<strong>to</strong>ring, which balancesactivities and controls measures.Increase profits through increasedmaintenance efficiency€ 133 mDowntime in a highly-effective plant can cost enormousamounts each minute. A modern power plant, <strong>for</strong> example,produces <strong>up</strong> <strong>to</strong> 1,500 MW from each turbine. Large powerplants, such as Itaipú in South America, have 20 lines.Measured by international energy spot market prices, eachminute of downtime costs <strong>the</strong> plant roughly €1,500. Farmore error-prone in production is <strong>the</strong> au<strong>to</strong>motive industry.Here a line has clock rates of less than a minute. So eachminute of downtime could exceed <strong>the</strong> <strong>to</strong>tal amount of onecar’s gross profit.RFID – smart objects everywhereSmart tagging by RFID technology is ano<strong>the</strong>r approach <strong>to</strong>realise cost-effective maintenance <strong>for</strong> complex industrialmachines and plants. RFID enables <strong>the</strong> implementation ofa smart object from planning <strong>to</strong> construction, assembling,maintenance, disassembly and reassembly. Maintenancewill be much easier with self-moni<strong>to</strong>ring smart objects,which are able <strong>to</strong> s<strong>to</strong>re <strong>the</strong>ir data his<strong>to</strong>ry, <strong>to</strong> communicatewith a CMD, <strong>to</strong> stimulate necessary steps au<strong>to</strong>matically,and <strong>to</strong> lead service teams <strong>to</strong> <strong>the</strong> area where <strong>the</strong> workis required. In this context, <strong>the</strong> concept of ubiqui<strong>to</strong>uscomputing will lead <strong>to</strong> a new approach in dealing with <strong>the</strong>growing complexity of plants and technology.<strong>Mobil</strong>e maintenance communication servicesIn order <strong>to</strong> avoid downtime, <strong>the</strong> 24/7 availability of allrequired service parts has <strong>to</strong> be guaranteed. Successfuland fast operating logistics is a key fac<strong>to</strong>r of efficientmaintenance. Requirement and delivery times will bereduced <strong>to</strong> a minimum through mobile communicationsystems. In connection with RFID technology, specificationsof work pieces, maintenance instructions, technical detailsand construction plans of even <strong>the</strong> most complex systemswill be available at any time and place.The chemistry of maintenanceFor a long time, maintenance has been seen primarily asa matter of material technique, handcraft and physics.With <strong>the</strong> development of complex and sensitive plants,chemistry has increasingly found its way in<strong>to</strong> processes.Today, a maintenance team not using numerous chemicalaids such as lubricants, metalworking fluids, protectingsprays or silicone speciality products is inconceivable.Improving maintenance is imperative <strong>to</strong> cost-effectiveproduction. Given <strong>to</strong> a standard industrial net profit ratio, areduction of 1 % in maintenance costs may have <strong>the</strong> sameeffect a 33 % increase in turnover. Even in times of lowerturnover, <strong>the</strong> demand <strong>to</strong> reduce <strong>the</strong> cost of labour (whichcovers 60 % of MRO spendings) will meet maintenance aswell as all o<strong>the</strong>r aspects of production. There<strong>for</strong>e, <strong>the</strong> smartreplacement of procedures, such as <strong>the</strong> substitution ofwelding by bonding technologies, will be able <strong>to</strong> contributean important share <strong>to</strong> this goal.€ 100 m8 %3 % ROS€ 100 m€ 3 m € 4 m7 % 8 %4 % ROS 4 % ROSMaintenanceefficiency€ 4 mSalesgrowthmilitary-driven development is able <strong>to</strong> provide very usefulin<strong>for</strong>mation. Currently, some US universities are developingKnowledge-based Augmented Reality <strong>for</strong> MaintenanceAssistance. These systems are tentatively using ahead-mounted display <strong>to</strong> explain maintenance in<strong>for</strong>mation,construction plans or sensor data.New materials <strong>for</strong> a new worldIn 1912, <strong>the</strong> Kr<strong>up</strong>p company developed a new kind ofsteel (a mixture of iron, chromium and nickel) with excellentstrength and durability against corrosion. At that time, it wasa significant step <strong>to</strong>ward reliability. Today, new materialswith outstanding properties are available <strong>to</strong> enable newapplications. Plastics, composites and carbon fibre havebeen available <strong>for</strong> some time now and are widely used innumerous industries, from tunnelling <strong>to</strong> aviation. Along with<strong>the</strong>se new materials, new maintenance requirements willbe sent <strong>to</strong> <strong>the</strong> s<strong>up</strong>pliers of MRO.Currently, self-healing products with <strong>the</strong> ability <strong>to</strong> partiallyrepair damages are in development, but are not incommercial use. Ano<strong>the</strong>r approach <strong>to</strong> future maintenanceare <strong>the</strong> amazing capabilities of nano-tech materials with ahigh capability of increasing <strong>the</strong> stability of equipment byimproved components and processes.From <strong>the</strong> out<strong>set</strong>, <strong>the</strong> goal of maintenance has been <strong>to</strong>increase profit by reducing losses in productivity. Plants andproduction of <strong>the</strong> future will have <strong>to</strong> be far more complexthan <strong>the</strong>y are <strong>to</strong>day. Highly sophisticated maintenancetechnologies are part of <strong>the</strong> solution.TurnoverShare of maintenanceReturn on salesProfitProfit increase bySource: MCP GmbHReliabilityat workGlossarybn:billions 1 billion =1,000,000,000m:millions 1 million =1,000,000MW:Megawatt = 1,000,000WattTPM:Total ProductiveMaintenanceCM:Condition Moni<strong>to</strong>ringCMD:Central MaintenanceDatabaseRFID:Radio frequencyidentification bytransponders withintegrated circuitsROS:Return on salesSee, feel, learn − augmented realityAugmented reality deals with <strong>the</strong> combination of real-worldand computer-generated data, where computer graphicsobjects are blended in<strong>to</strong> real footage in real time. Thisat work | no. 2/09

18 | Reliability Report 4The poetryof added valueA slight, but unmistakable scent of vanilla pervades <strong>the</strong> hallway, and <strong>the</strong> attention of<strong>the</strong> visi<strong>to</strong>r is captured by <strong>the</strong> nostalgic beauty of some antique Italian mo<strong>to</strong>rcyclesdecorating <strong>the</strong> room. What seems like <strong>the</strong> entrance <strong>to</strong> an exclusive spa or a fancyhang-out <strong>for</strong> mo<strong>to</strong>rcycle enthusiasts actually leads <strong>to</strong> a showroom <strong>for</strong> water taps andshowerheads. But if you associate water taps and shower heads with <strong>the</strong> appropriateaisle in <strong>the</strong> DIY s<strong>to</strong>re, you need <strong>to</strong> think again.Gessi company headquarters inVercelli, ItalyEntrance <strong>to</strong> Gessi’s showroomDesign meets reliability: RettangoloColour water tapRaw material ready <strong>for</strong> processingat work | no. 2/09

Reliability Report 4| 19Pre-applied coating of water tapsat work | no. 2/09

20 | Reliability Report 4<strong>Loctite</strong> ® 2701 is put <strong>to</strong> use onpassive metal surfacesAssembly of plated parts with <strong>Loctite</strong> ®2701Bagno “Small” is ready <strong>for</strong> use<strong>Loctite</strong> ® 638 is used <strong>for</strong> locking andsealing of threaded parts, even at roomtemperatureReflecting on <strong>the</strong> morality of objectsBoth Gessi’s and Henkel’s company philosophies emphasise <strong>the</strong>importance of beauty. Since its foundation in 1876, Henkel’s missionstatement has remained “<strong>to</strong> produce products <strong>to</strong> make life easier, betterand more beautiful”. Beauty, not just <strong>the</strong> beauty of products, also playsan extremely important role in <strong>the</strong> Gessi philosophy, which sometimesreads like an artistic manifes<strong>to</strong> and dazzles with sentences like <strong>the</strong>se:“The core value of <strong>the</strong> business system is beauty. Beauty does not referexclusively <strong>to</strong> <strong>the</strong> aes<strong>the</strong>tic value of <strong>the</strong> product since it’s a dimensionthat pervades every aspect of <strong>the</strong> business.”The average DIY s<strong>to</strong>re cus<strong>to</strong>mer will probably be as<strong>to</strong>nished <strong>to</strong> learn thata manufacturer of water taps believes that “<strong>the</strong> true added value of abrand is its poetry content and its respect <strong>for</strong> <strong>the</strong> world”. There<strong>for</strong>e, <strong>the</strong>manufacturer hasem barked on a mission <strong>to</strong> create artistic consumergoods, goods that are meant <strong>to</strong> “induce a reflection on <strong>the</strong> morality ofobjects”.Manufacturing beautyGessi, however, doesn’t only talk <strong>the</strong> talk; at <strong>the</strong> plant in SerravalleSesia, it walks <strong>the</strong> walk: “We don’t want <strong>to</strong> compete with low pricemanufacturers in China. We deliver <strong>the</strong> highest quality, both in design andfunctionality and it’s working very well <strong>for</strong> us,” explains Andrea Renna,<strong>the</strong> Quality Assurance Direc<strong>to</strong>r. This is no exaggeration: <strong>the</strong> company’sturnover grew by a stunning 23 % in 2007.Reliabilityat workCus<strong>to</strong>mer:Gessi,ItalyTask:Locking and sealingexclusive sanitaryaccessories <strong>for</strong> a wholelifetime.Products:<strong>Loctite</strong> ® 2701<strong>Loctite</strong> ® 7063<strong>Loctite</strong> ® 638<strong>Loctite</strong> ® 243Gessi’s coloured light taps are a good example of this dedication <strong>to</strong>beauty and functionality. The Rettangolo Color tap lines feature <strong>the</strong>trademark minimalist elegance, relying on geometrical shapes: in thiscase an open rectangle. When water passes through, a temperaturesensitiveLED lights <strong>up</strong> in different colours – blue, purple, or red –according <strong>to</strong> <strong>the</strong> water temperature.<strong>Loctite</strong> ® has been a partner <strong>to</strong> Gessi from <strong>the</strong> very beginning, and <strong>Loctite</strong> ®threadlockers play an important role in <strong>the</strong> manufacturing process of alarge number of Gessi products. “We use <strong>Loctite</strong> ® products <strong>for</strong> everyscrew that needs <strong>to</strong> be secured and watertight,” explains Andrea Renna.Be it <strong>the</strong> extraordinary square showerheads or <strong>the</strong> huge water taps <strong>for</strong>industrial kitchens, <strong>Loctite</strong> ® always plays a vital part in ensuring <strong>the</strong>durability of <strong>the</strong> fittings.Elegant productionThe plant in Serravalle Sesia, which is just across <strong>the</strong> road from <strong>the</strong>showroom, is ano<strong>the</strong>r reflection of <strong>the</strong> company’s emphasis on beautyand design. The production facility resembles a giant lab styled in <strong>the</strong>company colours – orange and black. Every worker wears a shirt or asweater with <strong>the</strong> company logo. The preferred means of transportationwithin <strong>the</strong> plant are bicycles. These are, of course, black and orangeand bear <strong>the</strong> company name as well as <strong>the</strong> name of <strong>the</strong> user or <strong>the</strong>department.at work | no. 2/09

Reliability Report 4| 21Assembly of water taps <strong>for</strong> handwashbasins with <strong>Loctite</strong> ® 638Rettangolo Color tap is ready <strong>for</strong> useAssembly of water taps <strong>for</strong> kitchensinks with <strong>Loctite</strong> ® 243Quadro High Tech is ready <strong>for</strong> useEven though Gessi sells its products <strong>to</strong> business and private cus<strong>to</strong>mersall over <strong>the</strong> world, <strong>the</strong> entire production process takes place in <strong>the</strong>Serravalle Sesia plant. Producing in a high-wage region like nor<strong>the</strong>rn Italyis not seen as a liability, but as an integral part of a company philosophywhich emphasises quality and a high standard of human relationships.Modern times haven’t s<strong>to</strong>pped at Gessi’s doorstep, however. The fac<strong>to</strong>ry,which is clean and orderly <strong>to</strong> <strong>the</strong> point of sterility, belying all stereotypicalperception of Italian chaos and laissez faire, employs robots and o<strong>the</strong>radvanced production technology wherever possible. The yellow robotsin <strong>the</strong>ir metal cages with <strong>the</strong>ir graceless, yet effective, movements featureprominently, especially at <strong>the</strong> beginning of <strong>the</strong> assembly line.“We au<strong>to</strong>mate where we can,” says Renna. “But due <strong>to</strong> <strong>the</strong> sophisticationof our products, a lot of work has <strong>to</strong> be done by hand and this willcontinue <strong>to</strong> be <strong>the</strong> case.” While showing us through <strong>the</strong> plant, Rennapoints <strong>to</strong> red <strong>Loctite</strong> ® bottles that can be seen on <strong>to</strong>p of many of <strong>the</strong>work benches inside <strong>the</strong> facility. Gessi handles, soap dispensers ormirrors all rely on <strong>the</strong> per<strong>for</strong>mance of <strong>Loctite</strong> ® 638.Creative solutions<strong>How</strong>ever, <strong>the</strong> collaboration between Henkel and Gessi transcends <strong>the</strong>usual s<strong>up</strong>plier-cus<strong>to</strong>mer relationship. As companies whose successdepends heavily on a continuous process of innovation and <strong>the</strong> ability<strong>to</strong> respond quickly <strong>to</strong> global market demands, Gessi and Henkel haveentered a relationship that can be best described as a <strong>for</strong>m of partnership.Quality Assurance Direc<strong>to</strong>r Renna recalls <strong>the</strong> case of a soap dispenserthat Gessi sold <strong>to</strong> Russia. “Because of <strong>the</strong> temperature differences, <strong>the</strong>regular glue we used gave out and broke <strong>the</strong> glass. We were able <strong>to</strong>solve <strong>the</strong> issue by making use of <strong>the</strong> flexibility built in<strong>to</strong> certain <strong>Loctite</strong> ®products,” says Renna.Andrea Renna,Quality Assurance Direc<strong>to</strong>r,Gessi Spa“Gessi is <strong>the</strong> leader in bathroom and kitchen sanitary ware and accessories.As of <strong>to</strong>day, we are a worldwide reference <strong>for</strong> <strong>the</strong> “Made in Italy” seal asa company whose products are featured in <strong>the</strong> most exclusive hotels,in <strong>the</strong> best wellness spas and on <strong>the</strong> most expensive yachts. Althoughit is a designer product, it is, above all, a quality product.Quality of production, quality of <strong>the</strong> working environment, qualityin <strong>the</strong> way we produce our appliances and <strong>the</strong> way we choose ours<strong>up</strong>pliers.<strong>Loctite</strong> ® is a partner which fully meets our philosophy.”“If <strong>the</strong>re is a challenge where we can assist, we take care of itimmediately,” says Massimigliano Moneta, <strong>Loctite</strong>’s Technical SalesConsultant responsible <strong>for</strong> Gessi. <strong>Loctite</strong> ® maintains a labora<strong>to</strong>ry inMilan and <strong>the</strong> response comes within a matter of days.“Up <strong>to</strong> now, we have always been able <strong>to</strong> find asolution, normally by pointing out an alternativeuse <strong>for</strong> one of <strong>the</strong> products from our range,”says Moneta. Even if that shouldn’t be <strong>the</strong>case at some point in <strong>the</strong> future, <strong>the</strong>re isalways <strong>the</strong> European Technology Centrein Dublin ready <strong>to</strong> take on <strong>the</strong> task offinding a creative adhesive <strong>for</strong> a creativecus<strong>to</strong>mer.at work | no. 2/09

22|Handy HintsThe knowledge <strong>to</strong>olboxWhe<strong>the</strong>r you are designing a new product, or looking <strong>to</strong> keep existing machines running efficiently,<strong>Loctite</strong> ® can help. Discover <strong>the</strong> complete capabilities of <strong>Loctite</strong> ® anaerobic adhesive solutions andinnovations and find <strong>the</strong> right product <strong>for</strong> your application needs. Get connected <strong>to</strong> <strong>Loctite</strong> ® ’s webplat<strong>for</strong>m designed <strong>for</strong> engineers, by engineers: www.loctitesolutions.com/ukSee exciting applicationvideos and share ourcus<strong>to</strong>mers’ experiences.Find your specific product solution <strong>for</strong> yourthreadlocking, thread sealing, retaining andgasketing applications.Order <strong>the</strong> next issue of at work magazine on:www.loctitesolutions.com/ukat work | no. 2/09

Outlook | 23551 <strong>to</strong>ns of grain within 8 hours. That’ s <strong>the</strong> kind of speedthat turned <strong>the</strong> new generation of New Holland combineharvesters in<strong>to</strong> <strong>the</strong> Guinness world record holder.... coming soonJoin us on our trip <strong>to</strong> Zagrebwhere we'll visit Končar ElectricVehicles Inc. Witness <strong>the</strong> production of<strong>the</strong>ses modern low-floor trams, <strong>the</strong>re are overa hundred which reliably serve <strong>the</strong> Zagreb publictransportation system on a daily basis.at work | no. 2/09

ImprintPublisherHenkel AG & Co. KGaAAdhesive TechnologiesHenkelstraße 6740191 DüsseldorfGermanywww.henkel.comEdi<strong>to</strong>rial DepartmentMarketing Department EMEA:Christian ScholzeAndreas EnglBeate SchneiderIsabelle FeixErik EdelmannFrank FischerContactAndreas Engl (Project lead)Phone: +49-211-797-6758Andreas.Engl@henkel.comCreationblösch.partnerWerbeagentur GmbHwww.bloesch-partner.deHenkel LimitedWood Lane EndHemel HempsteadHert<strong>for</strong>dshire HP2 4RQTel. 01442 278100Fax 01442 278071www.loctitesolutions.com/ukwww.loctite.co.uk® designates a trademark of Henkel AG & Co. KGaA or its affiliates, registered in Germany and elsewhere © Henkel AG & Co. KGaA, 2009