The Use of Microsilica in Refractory Castables - Elkem

The Use of Microsilica in Refractory Castables - Elkem

The Use of Microsilica in Refractory Castables - Elkem

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

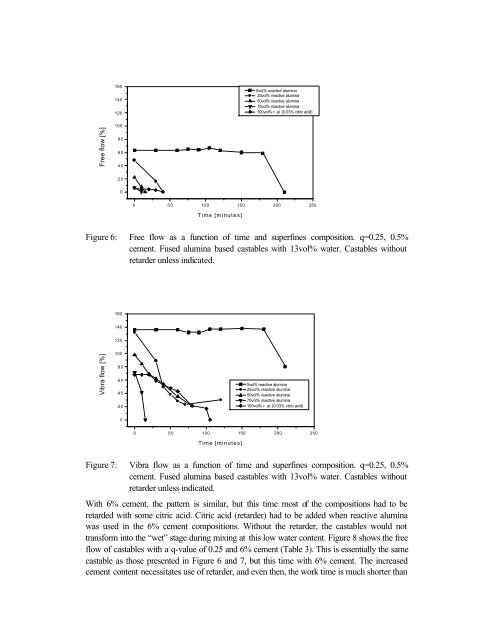

1601401200vol% reactive alum<strong>in</strong>a25vol% reactive alum<strong>in</strong>a50vol% reactive alum<strong>in</strong>a75vol% reactive alum<strong>in</strong>a100vol% r. al. (0.03% citric acid)Free flow [%]1008060402000 50 100 150 200 250Time [m<strong>in</strong>utes]Figure 6: Free flow as a function <strong>of</strong> time and superf<strong>in</strong>es composition. q=0.25, 0.5%cement. Fused alum<strong>in</strong>a based castables with 13vol% water. <strong>Castables</strong> withoutretarder unless <strong>in</strong>dicated.160140120Vibra flow [%]100806040200vol% reactive alum<strong>in</strong>a25vol% reactive alum<strong>in</strong>a50vol% reactive alum<strong>in</strong>a75vol% reactive alum<strong>in</strong>a100vol% r. al. (0.03% citric acid)00 50 100 150 200 250Time [m<strong>in</strong>utes]Figure 7: Vibra flow as a function <strong>of</strong> time and superf<strong>in</strong>es composition. q=0.25, 0.5%cement. Fused alum<strong>in</strong>a based castables with 13vol% water. <strong>Castables</strong> withoutretarder unless <strong>in</strong>dicated.With 6% cement, the pattern is similar, but this time most <strong>of</strong> the compositions had to beretarded with some citric acid. Citric acid (retarder) had to be added when reactive alum<strong>in</strong>awas used <strong>in</strong> the 6% cement compositions. Without the retarder, the castables would nottransform <strong>in</strong>to the “wet” stage dur<strong>in</strong>g mix<strong>in</strong>g at this low water content. Figure 8 shows the freeflow <strong>of</strong> castables with a q-value <strong>of</strong> 0.25 and 6% cement (Table 3). This is essentially the samecastable as those presented <strong>in</strong> Figure 6 and 7, but this time with 6% cement. <strong>The</strong> <strong>in</strong>creasedcement content necessitates use <strong>of</strong> retarder, and even then, the work time is much shorter than