Indian Welding Journal - The Indian Institute of Welding

Indian Welding Journal - The Indian Institute of Welding

Indian Welding Journal - The Indian Institute of Welding

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

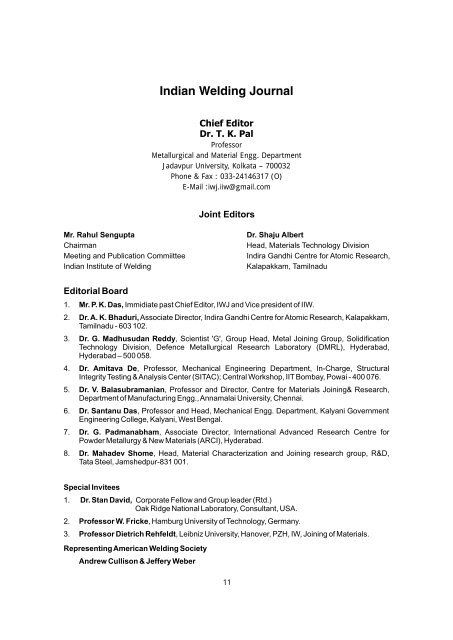

<strong>Indian</strong> <strong>Welding</strong> <strong>Journal</strong>Chief EditorDr. T. K. PalPr<strong>of</strong>essorMetallurgical and Material Engg. DepartmentJadavpur University, Kolkata – 700032Phone & Fax : 033-24146317 (O)E-Mail :iwj.iiw@gmail.comJoint EditorsMr. Rahul SenguptaChairmanMeeting and Publication Commiittee<strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Welding</strong>Dr. Shaju AlbertHead, Materials Technology DivisionIndira Gandhi Centre for Atomic Research,Kalapakkam, TamilnaduEditorial Board1. Mr. P. K. Das, Immidiate past Chief Editor, IWJ and Vice president <strong>of</strong> IIW.2. Dr. A. K. Bhaduri, Associate Director, Indira Gandhi Centre for Atomic Research, Kalapakkam,Tamilnadu - 603 102.3. Dr. G. Madhusudan Reddy, Scientist 'G', Group Head, Metal Joining Group, SolidificationTechnology Division, Defence Metallurgical Research Laboratory (DMRL), Hyderabad,Hyderabad – 500 058.4. Dr. Amitava De, Pr<strong>of</strong>essor, Mechanical Engineering Department, In-Charge, StructuralIntegrity Testing & Analysis Center (SITAC); Central Workshop, IIT Bombay, Powai - 400 076.5. Dr. V. Balasubramanian, Pr<strong>of</strong>essor and Director, Centre for Materials Joining& Research,Department <strong>of</strong> Manufacturing Engg., Annamalai University, Chennai.6. Dr. Santanu Das, Pr<strong>of</strong>essor and Head, Mechanical Engg. Department, Kalyani GovernmentEngineering College, Kalyani, West Bengal.7. Dr. G. Padmanabham, Associate Director, International Advanced Research Centre forPowder Metallurgy & New Materials (ARCI), Hyderabad.8. Dr. Mahadev Shome, Head, Material Characterization and Joining research group, R&D,Tata Steel, Jamshedpur-831 001.Special Invitees1. Dr. Stan David, Corporate Fellow and Group leader (Rtd.)Oak Ridge National Laboratory, Consultant, USA.2. Pr<strong>of</strong>essor W. Fricke, Hamburg University <strong>of</strong> Technology, Germany.3. Pr<strong>of</strong>essor Dietrich Rehfeldt, Leibniz University, Hanover, PZH, IW, Joining <strong>of</strong> Materials.Representing American <strong>Welding</strong> SocietyAndrew Cullison & Jeffery Weber11

EDITORIALEDITORIALFirst <strong>of</strong> all I would like to thank council members <strong>of</strong> <strong>The</strong> <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Welding</strong> for giving me the opportunity to actas Chief Editor <strong>of</strong> <strong>Indian</strong> <strong>Welding</strong> <strong>Journal</strong> from January issue.You will agree that the economic growth <strong>of</strong> India over the period has changed her position and has involved changes inher industrial structure. <strong>The</strong>se changes greatly affect the status <strong>of</strong> welding engineering and technology in the presentindustrial society. <strong>The</strong> <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Welding</strong> has also decided to restructure itself to adopt to these newenvironments.We have come round an eventful year for the <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Welding</strong> as well as <strong>Indian</strong> <strong>Welding</strong> <strong>Journal</strong>. Ourthinstitute hosted the prestigious event “64 Annual Assembly & International Conference <strong>of</strong> theInternational <strong>Institute</strong> <strong>of</strong> welding, Chennai, India, July 17-22, 2011”, being held for the first time in ourcountry and our annual assembly "NWS 2011" during December 16-18, 2011 at Bhilai.IWJ provides a forum for the multidisciplinary subjects within joining <strong>of</strong> materials and helped to encouragedevelopments and information exchange <strong>of</strong> important work within the field. In this issue, there are three awardedtechnical papers which would be <strong>of</strong> interest to both welding and material engineers.We have the pleasure to put on records our compliments to Dr. R. S. Parmar, who made valuable contribution towelding technology and the institute, for being chosen to receive the “Life time achievement award” andMr. P. K. Das, immediate past Chief Editor and Vice President <strong>of</strong> our institute, for being promoted the journal a new lookidea and making them available for advertisement and sponsorship.IWJ is proud to welcome the new board members, who are recognized for their significant contribution towards thegrowth <strong>of</strong> welding technology. It is my hope that the new editorial board will play an important role and with thesupport from related organizations, contribute to the prosperity and welfare <strong>of</strong> human being and <strong>of</strong> global society.<strong>The</strong> January issue <strong>of</strong> the journal is coming out during mid February. Late receipt <strong>of</strong> materials for publication has causedthis delay which we sincerely regret. <strong>The</strong> cooperation and ideas from all members shall continue to make the journalmore valuable in future.Before we end, we from IWJ wish all our readers, home and abroad, a very Happy, Prosperous and eventful 2012.T. K. PalChief-EditorEmail: iwj.iiw@gmail.com13

IIW NEWSIIW NEWSNATIONAL WELDING SEMINAR – 2011HELD AT BHILAIREPORT FROM IIW BHILAI BRANCH<strong>The</strong> National <strong>Welding</strong> Seminar – 2011 (NWS-2011) wasorganized by the Bhilai Branch <strong>of</strong> the <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong>welding in association with Bhilai Steel Plant (SAIL)during December 15th – 17th, 2011 and this was thethird occasion the branch hosted this mega event after agap <strong>of</strong> five years. <strong>The</strong> theme <strong>of</strong> the seminar was“<strong>Welding</strong> Science & Technology in InfrastructureIndustries”. While the Inaugural session held at KalaMandir Auditorium, the technical sessions andconcluding session were held at Bhilai Niwas, both withinthe Bhilai Steel Plant township. Around 225 delegateswere drawn from a variety <strong>of</strong> fields like EducationalInstitutions, R & D, Industrial Consumables,Manufacturer etc. Altogether 40 papers were acceptedand 36 papers were presented during the seminar on awide range <strong>of</strong> topics.<strong>The</strong> Chief Guest Shri Pankaj Goutam, Chief ExecutiveOfficer <strong>of</strong> Bhilai Steel Plant and Chief Patron <strong>of</strong> BhilaiBranch <strong>of</strong> IIW, underlined the rising importance <strong>of</strong>welding in the infrastructure Industry and stressed theneed for constant updation <strong>of</strong> knowledge related to allaspects <strong>of</strong> welding. In the same vein Shri R. Ravi,President (IIW-INDIA) while enumerating the role <strong>of</strong>IIW in keeping the industry informed and guided in thelatest development taking place in the field.Other speakers including President IIW – Bhilai BranchShri P.K. Singh, ED (Works) BSP and Secretary General <strong>of</strong>IIW-INDIA Shri Parimal Biswas also stressed theimportance <strong>of</strong> such events for better applicability <strong>of</strong>welding as a Science & Technology.At the outset, Shri Debasish Thakur, Chairman (IIW-Bhilai Branch) and GM (Utility) BSP, welcomed thedignitaries, distinguished guests & delegates and briefedthe gathering about the Seminar and the action rolebeing played by the Bhilai Branch in spreading theobjective <strong>of</strong> IIW-INDIA.To commemorate the event a souvenir & CD, containingall the selected Technical Papers <strong>of</strong> NWS-2011, werereleased by the dignitaries.During Inaugural Session, various welding Awards,institutionalized by IIW-India, were ceremoniously givenaway for the papers presented during the last weldingseminar by the IIW-India president Shri R. Ravi & Chiefguest Shri Pankaj Goutam that also includes the bestwelding Engineer and best welders awards. <strong>The</strong>prestigious Life Time Achievement Award for year 2010-11 was given away to Dr. R. S. Paramar, Ex. Pr<strong>of</strong>. <strong>of</strong> IIT,Delhi.<strong>The</strong> two prominent memorial lectures viz Keith HartleyMemorial lecture & Dr. Placid Rodriguez Memorial lecturewere delivered by Dr. T. K. Pal, Pr<strong>of</strong>. <strong>of</strong> JadavpurUniversity & Dr. G. D. Janaki Ram, Pr<strong>of</strong>. <strong>of</strong> IIT, Madras ontopics 'Development <strong>of</strong> welding technology forauto-motive industries' & 'Emerging concepts inwelding research, respectively.Coming to Technical Sessions about 36 papers werepresented in two parallel run sessions. <strong>The</strong> sessionswere chaired by S/Shri N. K. Sarkar, V. S. Galgali, H. V.Sharma, C. K. Datta, P. K. Das, Dr. G. L. Datta, A. B.Purang, Dr. Madhusudan Reddy, H. K. Sethi & S. N. Singhall prominent persons in their chosen field <strong>of</strong>pr<strong>of</strong>essions.<strong>The</strong> papers covered the wide spectrum right fromResearch, New application, New developments,Economy & Health concern related to various aspect <strong>of</strong>welding.<strong>The</strong> speakers were all experts in their particular areasand did a splendid job in compiling their thought &research into their papers.Each paper was judged by 3 persons including thesession chairman and 2 delegates from audience. <strong>The</strong>seevaluation sheets have been handed over to Dr. ShajuAlbert, Chairman, Technical Committee (IIW-INDIA) fordeclaring the results.15

INDIAN WELDING JOURNAL Volume 45 No.1 January 2012<strong>The</strong> sumptuous lunches & dinners assisted by culturalprogrammes at night have only helped in assimilatingthese technical contents easily.Valedictory function was presided over by Dr. R. S.Parmar and concluding remarks was summed up by ShriParimal Biswas on behalf <strong>of</strong> the council.<strong>The</strong> proceedings <strong>of</strong> the entire activity were conducted byShri G. M. Arun Kumar, DGM (MARS); Mrs. ManjuHaridas, AGM (ERS); Shri V. K. Ogale, Sr. Mgr. (RMP-1)and Shri Umesh Malayath, Jr. Mgr. (CAS) while the vote<strong>of</strong> thanks was proposed by Shri Ajay Bedi, HonySecretary (IIW-Bhilai Branch).During the seminar, the 280th Council Meeting andAnnual Members Assembly were also held.<strong>The</strong> work <strong>of</strong> various committees, formed to make theevent a grand success, was highly acknowledged thatalso includes S/Shri S. K. Bansal, H. K. Sahu, R. K.Bisare, M. R. K. Sariff and D. Anand.REPORT OF THE BWE & BW COMPETITIONS,2011<strong>The</strong> National Level Competitions for the Best Weldersand Best <strong>Welding</strong> Engineer <strong>of</strong> the year, 2011-12 was heldat the <strong>Welding</strong> Reclamation Shop <strong>of</strong> the Bhilai SteelPlant, Bhilai on 13th December, 2011 and was conductedby Mr. N. K. Sarkar.Out <strong>of</strong> 11 branches, only 7 branches viz. Baroda, Bhilai,Chennai, Jamshedpur, Kolkata, Mumbai andVisakhapatnam participated in this year's competition,there were only five candidates in each category.IIW Mumbai Branch assisted by Mr. S. C. Mitra and Mr. T.K. Mitra both from Kolkata branch and Mr. S. C. Tutejafrom Bhilai.Mr. Biswajeet Paul <strong>of</strong> L&T Ltd., Mumbai was declared asthe Best <strong>Welding</strong> Engineer. He was given an AWARD <strong>of</strong>Rs. 7,000/- in cash and a certificate. He was registered asa free delegate for the NWS.Mr. Roque Fernandes <strong>of</strong> Don Bosco Maritime Academy,Mumbai was declared as the Best Welder in theStructural (Plate) <strong>Welding</strong> category and Mr. VinodKumar, R. Parmar <strong>of</strong> L&T, Baroda was declared as theBest Welder in the Pipe <strong>Welding</strong> category. Each <strong>of</strong> themwas given an Award <strong>of</strong> Rs.5000/- in cash and acertificate.All the Awards sponsored by ELCA Laboratories, Thane,Maharashtra were given to the winners during theInauguration ceremony at the National <strong>Welding</strong> Seminarheld at Bhilai on 15th December, 2011.IIW MES AB:A total number <strong>of</strong> 372 candidates assessed under thisscheme at various ITI in Gujarat under the activeleadership <strong>of</strong> Mr. R. R. Vishawakarma, Gujarat StateCoordinator & Authorised AssessorBRANCH ACTIVITY REPORTREPORT FROM BANGALORE BRANCH1. Program on “Advances in <strong>Welding</strong> & Testing”jointly conducted on 17th Nov 2011 by <strong>Indian</strong>Society for Non-Destructive Testing [ISNT], Societyfor <strong>Indian</strong> Aerospace SIATI Blr, where-in PadmashriDr. C. G. Krishnadas Nair was facilitated; and theBranch Chairman, Mr. N. Ramesh Rao delivered theKey-Note Address.2. Program on “Copper <strong>Welding</strong>, Brazing &Soldering” was conducted on 25th Nov 2011jointly with <strong>Indian</strong> Copper Development Centre,where-in the Branch Chairman Mr. N. Ramesh Raopresented a paper on “Considerations in implementingCopper <strong>Welding</strong> Procedures” .3. <strong>The</strong> Branch Committee members visited Mysore &Dharwad Regional Centres for Skill Development forpromoting <strong>Welding</strong> Training Programs; this wasarranged by the Branch Hony Secry Mr SV Dilipan.4. <strong>The</strong> Branch Committee members visited AdvancedSimulator Training Facility for Skill Development forpromoting <strong>Welding</strong> Training Programs; this wasarranged by the Branch Hony. Secy. Mr. S. V. Dilipan16

IIW NEWSREPORT FROM BARODA BRANCHI. One-day SeminarOrganised Seminar on "<strong>Welding</strong> in PressureVessels Industries" - as 13th Foundation DayCelebration, held on 15th October 2011 at HotelSurya Palace.<strong>The</strong> Seminar was inaugurated by lighting the lampby Chief Guest Mr. R. K. Batra & other dignitariespresent on dias. On this occasion, the Souvenircovering technical papers, advertises & IIWinformations etc., was released by Chief Guest.<strong>The</strong> Chief Guest Mr. R. K. Batra, Exe. Director(Project & Construction, Engineers India Ltd ) in hisinaugural speech emphasized on the need <strong>of</strong>welding knowledge sharing to various pr<strong>of</strong>essionalsin the construction industries and training to thewelding inspectors as well as welders to improveupon the skill and performance to achieve the bestquality standards.<strong>The</strong> Convenor <strong>of</strong> the seminar was Mr. D. C. Mehtaand the technical session was chaired by Mr. R. R.Chhari. <strong>The</strong> Seminar received overwhelmingresponse from various advertisers & sponsors.<strong>The</strong> Seminar was Sponsored by M/s Vijay Tanks andVessels (Baroda) and by M/s Satkul Enterprises Ltd,(Ahmedabad).II. Technical Lectures :Following Technical Lectures were organized :1. “Comparison between ASME and ENrequirements for Welders and <strong>Welding</strong>Procedure Qualification” by Mr. MahendraShiroya (QMOS-LeveIII Inspector) and Mr. SunitKumar (PED Inspector) from M/S. Bureau Veritas(India) Pvt. Ltd., Baroda, on 14th July 2011 at HotelRevival Lords INN. near Sayaji Garden, Vadodara.67 Participants attended.2. “<strong>Welding</strong> <strong>of</strong> Nickel and High Alloy Steels”Presented by Dr. K. Manfred Rostek, TechnicalDirector, Selectarc Industries, France, on 14thDecember 2011 at Hotel Surya Palace. 85Participants attended.3. “Seam less flux/metal cored wires suitablefor pipe line, <strong>of</strong>fshore & shipbuildingapplications” Presented by Mr. Martin Schnirch,Sales Director & Mr. Andreas Holzner, Head <strong>of</strong>Quality and Application Management DrahtzugStein wire & welding (German Company).III. Workshop Training :Following workshop training programmes wereconducted1. WPS/PQR workshop from 17th to 18th December2011 at Hotel Sayaji, Vadodara. Total 26participants attended the workshop. <strong>The</strong> workshopconducted was to educate the welding engineerson the different aspects <strong>of</strong> preparing WPS/PQR asper ASME Section IX Code requirements. At the end<strong>of</strong> the workshop participants were given casestudies to prepare the WPS on their own andpresent it to all.<strong>The</strong> Convenor <strong>of</strong> the programme was Mr. KashyapBhatt, supported by Mr. Vijay Patel, Mr. R. R. Chhariand Mr. B. S. Kandpal as faculties and evaluationteam members.2. NDT Level II (Visual Testing) course from 23rd to25th December 2011 at Hotel Nidra, Vadodara. <strong>The</strong>training for NDT Level II (Visual Testing) wasorganized as per ASNT recommended Practice-SNT-TC-1A : 2006. Total 18 Participants attended theTraining Programme.<strong>The</strong> Convenor <strong>of</strong> the programme was Mr. KashyapBhatt.3. 47th IWE/IWT Certification Programme throughTransition Route from 22nd to 26th November 2011at GETRI, Baroda. 19 participants attended theprogramme.17

INDIAN WELDING JOURNAL Volume 45 No.1 January 2012IV. Awareness <strong>of</strong> IIW Activities (Promoting<strong>Welding</strong> Science & Technology)Presentation <strong>of</strong> IIW India activities (specialemphasis on AMIIW exam and Membership) wereconducted by Dr. Vishvesh J. Badheka, Hon. JointSecretary <strong>of</strong> IIW Baroda Branch and in Industriesby Mr. B. S. Kandpal at following academic and R &D institutes:1. Mechanical Eng Dept; U V Patel College <strong>of</strong> Eng &Technology, Ganpat University, Mehsana. Morethan 80 students <strong>of</strong> Final & Pre final yearMechanical and M.Tech (Advance Mfg. Technology)students were attended. Presentation was <strong>of</strong> about1 hr. followed by 30 min. questions answers.2. ITER-INDIA, IPR, Gandhinagar; 20 Scientist/Engineers <strong>of</strong> ITER India were attended. Mr. MukeshJindal <strong>of</strong> ITER INDIA who is already member <strong>of</strong> IIWBaroda, is nodal person to promote IIW activities.3. Diploma Mechanical Engineering (Polytechnic) andM.E (<strong>Welding</strong> Technology) <strong>of</strong> <strong>The</strong> M. S. University <strong>of</strong>Baroda.4. Diploma Fabrication Technology and DiplomaMechanical Engineering at Government Polytechnic,Bhavnagar on 3rd December 20115. Electrical Research and Development Association(ERDA), on 14th December 2011.V. Best <strong>Welding</strong> Engineer And Best WelderCompetition -2011Best Welder and Best welding Engineer competitionwas held at M/S Avadh Industries – Makarpura on11th November 2011. <strong>The</strong> competition wasconducted and examined by Mr. Jayesh Patel,Mr. Kashyap Bhatt, Mr. D. V. Acharya and Mr. B. S.Kandpal.<strong>The</strong>re were 4 participants from different industriesfor Best <strong>Welding</strong> Engineer Competition and 2participants for Best Welder (Pipe & Plate)competition. Written Tests and Viva were conductedfor the Best <strong>Welding</strong> Engineers and for the welderscategory practical test coupon welding and vivawere conducted. <strong>The</strong> following candidates weredeclared winners after the evaluation procedure forthe branch level competition :Mr. Tushar Koradia - L&T Ranoli – Best weldingEngineerMr. Mukesh R Valand – Inox India – Best welder forstructural <strong>Welding</strong>Mr. Vinodkumar R Parmar – L&T Ranoli – Bestwelder for Pipe <strong>Welding</strong>.<strong>The</strong> Winners <strong>of</strong> the branch level participated in theNational Level Competition held at Jamshedpurfrom 13th to 15th December 2011. Results are verypleasing for Baroda Branch.Mr. Vinodkumar R. Parmar declared Winner <strong>of</strong> theBest Welder competition; while Mr. Tushar Koradiawas declared as runner up <strong>of</strong> the Best weldingEngineer competition.VI. Industrial Visits :Industrial Visit was made to M/s Hindustan DorrOliver, Ahmedabad on 1st October 2011. A total 20members visited the HDO.REPORT FROM CHENNAI BRANCHI. IWE/IWT ANB Programme during 11th to15th October 2011<strong>The</strong> forty fifth Certification Programme (IWE, IWT)<strong>of</strong> International <strong>Institute</strong> <strong>of</strong> <strong>Welding</strong> was held from11th to 15th October, 2011, at the lecture hall <strong>of</strong> theISNT Chennai Chapter. Six participants attended theprogramme.II. Best Welder/Best <strong>Welding</strong> Engineer Contests<strong>The</strong> contests for the Best Welder (Structural andPipe <strong>Welding</strong>) and Best <strong>Welding</strong> Engineer were held18

INDIAN WELDING JOURNAL Volume 45 No.1 January 2012Chennai Branch, on the occasion <strong>of</strong> hissuperannuation. Shri R. Natarajan, Director, RPGinaugurated the programme. Around 60participants attended the workshop and benefited.Eminent speakers from IGCAR/Kalpakkamdelivered the technical lectures on following topics.1. “QA Experiences in Reprocessing Projects”by– Dr. B. Venkatraman2. “J-Rod Campaign to DFRP – Experiences”by Shri P. Ram KumarSri. T. V. Prabhu Hony. Secretary, IIW ChennaiBranch co-ordinated the entire event.REPORT FROM IIW DELHI BRANCHI. A one day workshop on “Advances in Arc<strong>Welding</strong> Technology” was organized atNorthern India Engg. College, New Delhi on 16thNovember, 2011. About 100 delegates fromvarious Engineering Colleges in the regionattended the program. <strong>The</strong> lectures were deliveredby Dr. R. S. Paramar, Dr. C. K. Datta, Mr. J. R.Prasher and Mr. Vivek Vasudeva. A lively discussiontook place between the speakers and the delegatesat the end <strong>of</strong> the Technical Sessions. Certificate <strong>of</strong>participation was given to all the attendingdelegates in the valedictory session.II. <strong>The</strong> Branch Seminar <strong>of</strong> IIW - Delhi Branch has beenannounced to be held on 11th February, 2012 atIndia International Center, Max Mueller Marg, NewDelhi. <strong>The</strong> theme <strong>of</strong> the seminar is “EmergingTrends in <strong>Welding</strong> Industry.”REPORT FROM KOLKATA BRANCH<strong>The</strong> branch will organise a one day Workshop on"Advancement in <strong>Welding</strong> Technology" at <strong>The</strong>Institution <strong>of</strong> Chemical Engineer's Hall, JadavpurUniversity on 25th February, 2012. As a programme, thebranch is planning to celebrate Foundation Day <strong>of</strong> the<strong>Institute</strong> in a dignified manner on 21st February, 2012.REPORT FROM VIZAG BRANCH<strong>The</strong> <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Welding</strong>, Visakhapatnam Branchorganized a lecture on “Advanced <strong>Welding</strong>Processes” and “Emerging <strong>Welding</strong> Processes”held at the Executive Director (Projects &Commissioning) Conference Hall on 19th December2011 from 10.30 am to 1.30 pm. <strong>The</strong> programme waswell attended by IIW members, Vizag Steel Engineers,M. N. Dastur & Co. (P) Ltd., Engineers and other IndustryEngineers.Lecture was delivered by the Eminent Pr<strong>of</strong> Dr. R. S.Paramar and started with welcome address by Sri A. K.Bose, Vice Chairman.Mr. M. Saibabu, Hony. Secretary, Vizag Branch informedthe gathering about the IIW activities, particularlycourses <strong>of</strong>fered by ANB and the advantages <strong>of</strong> theANBCC.Mr. Venkat R D, the Jt. Secretary <strong>of</strong> the IIW, VizagBranch, proposed a Vote <strong>of</strong> Thanks.20

LIFETIME ACHIEVEMENT AWARDLIFETIME ACHIEVEMENT AWARDSPr<strong>of</strong>. R. S. Parmar was honoured by <strong>The</strong> <strong>Institute</strong> with the Lifetime Achievement Awardat the National <strong>Welding</strong> Seminar, Bhilai held in December 2011Dr. R S Parmar is B.E. Mechanical Engineering fromPunjab University; M.E.Hons. (Production Engg.) fromUniversity <strong>of</strong> Roorkee, and Ph.D. (<strong>Welding</strong>) from IIT,Kharagpur. He has an experience <strong>of</strong> more than 44 yearsin Teaching and Research in different subjects <strong>of</strong> Mech.Engg. particularly related to Production Engineering. Heserved at REC, Srinagar (Kashmir) for 14 years and atIIT, Delhi for 21 years. After retirement from IIT, Delhi heJoined Netaji Subhas <strong>Institute</strong> <strong>of</strong> Technology, New Delhi,where he served in the Department <strong>of</strong> ManufacturingProcesses and Automation Engineering till Sept., 2002and was also Dean Administration for 3 years (1999-2002) there.He coordinated a Collaborative Project for 5 years onUnderwater <strong>Welding</strong> between IIT Delhi and Cranfield<strong>Institute</strong> <strong>of</strong> Technology, Cranfield (UK). He also served asa Visiting Pr<strong>of</strong>essor for one year at Brunel University,Uxbridge, London (UK).Pr<strong>of</strong>. Parmar has authored 2 books on <strong>Welding</strong>, and onebook on Manufacturing viz.,1. WELDING PROCESSES AND TECHNOLOGY, and2. WELDING ENGINEERING AND TECHNOLOGY3. MANUFACTURING PROCESSES AND AUTOMATIONand has published more than 100 Technical Papers in theNational and International <strong>Journal</strong>s, conferences, andSeminars. He has guided 13 Ph.D. (2 Iranians and 11<strong>Indian</strong> Research Scholars), 27 M.Tech. and more than 50B.Tech. Projects on Production Engineering in generaland <strong>Welding</strong> in Particular.He is a Life Fellow <strong>of</strong> the <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Welding</strong> and<strong>The</strong> Institution <strong>of</strong> Engineers (India) and a Life Member <strong>of</strong><strong>Indian</strong> Society <strong>of</strong> Mechanical Engineers and <strong>Indian</strong>Society <strong>of</strong> Technical Education.He is a recipient <strong>of</strong> Gold Medal from University <strong>of</strong>Roorkee, K. F. Antia Memorial Prize and Col. G. N. BajpaiAward (Twice) from the Institution <strong>of</strong> Engineers (India)and Keith Hartley Memorial Award (1996) <strong>of</strong> <strong>The</strong> <strong>Indian</strong><strong>Institute</strong> <strong>of</strong> <strong>Welding</strong>. He is also a Joint winner <strong>of</strong> McKAY-HELM AWARD (1998) <strong>of</strong> American <strong>Welding</strong> Society,Miami, USA for their paper published in <strong>Welding</strong> <strong>Journal</strong><strong>of</strong> Oct., 1997.Dr. Parmar joined IIW in 1972 as a Member and is now aLIFE FELLOW for the past about 15 years. He has beenvery active with IIW Delhi Branch which he joined in1978 as an EXECUTIVE COMMITTEE MEMBER. In itslong association <strong>of</strong> about 27 years with IIW Delhi he hasserved in every capacity viz., Member, Treasurer,Secretary, Vice Chairman, and Chairman. He has beenelected as Chairman 6 times and is still active inorganizing workshops and seminars in Delhi. During histenure as Chairman, IIW Delhi the <strong>Institute</strong> acquired itspermanent premises at 705 A, Jaina Tower-I, JanakpuriDistrict Centre, Janakpuri, New Delhi - 110 058. He hasbeen actively involved in organising Branch Seminars,Short Courses, and One Day Workshops at differentvenues in and around Delhi.21

INDIAN WELDING JOURNAL Volume 45 No.1 January 2012KEITH HARTLEY MEMORIAL AWARD 2011Every alternate year an eminent welding pr<strong>of</strong>essional <strong>of</strong> the country is selected for delivering theKeith Hartley Memorial Award at the National <strong>Welding</strong> Seminar. IWJ complimentsPr<strong>of</strong>. T. K. Pal for being chosen to deliver the Prestigious Lecture this year at the NWS - 2011Dr. T. K. Pal obtained his B. E. in Metallurgy fromBurdwan University in 1975 and subsequentlycompleted M.Tech in Mechanical Shaping and HeatTreatment. After six month exposure in a privatefoundry, he joined as a Senior Research Fellow atMaterial Science Centre <strong>of</strong> I.I.T., Kharagpur. Hejoined as Lecturer, Department <strong>of</strong> MetallurgicalEngineering, Jadavpur University in 1981 andcompleted his Ph.D (Engineering) from I.I.T.Kharagpur in 1987. He became Head, MetallurgicalEngineering Department, Jadavpur Universityduring 1995 - 1997.During the last 30 years, he had been activelyengaged in Teaching, Research, Training Coursesand Consultancy Services related to weldingtechnology. He had already completed fifteenresearch projects sponsored by different CentralGovernment funding authorities such as DST, CSIR,Ministry <strong>of</strong> Steel, Naval Research Board (NRB),DRDO, UGC, AICTE and Private Industries like TataSteel and BOC Ltd. Two Research projectssponsored by Ministry <strong>of</strong> Steel and Tata Steel andone research project sponsored by CSIR are ongoing.He has guided 19 students for their Ph.Dthesis and published about 110 papers in Nationaland International <strong>Journal</strong>s and Proceedings. He is afounder <strong>of</strong> <strong>Welding</strong> Technology Centre at JadavpurUniversity which was established in 2002. He isCourse Director <strong>of</strong> Six module based Post DiplomaCourse in <strong>Welding</strong> Technology and Short termCourse on "<strong>Welding</strong> Inspection and Testing".He was Controller <strong>of</strong> Associate Membershipexamination <strong>of</strong> <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Welding</strong> duringthe period from 1991 to 1999 and Chairman <strong>of</strong> IIW<strong>of</strong> Kolkata branch during 1999 - 2000. He hasreceived many awards for his contribution in thefield <strong>of</strong> welding Technology.He is a fellow member <strong>of</strong> the <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong><strong>Welding</strong>, life member <strong>of</strong> the <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong>Metals. <strong>The</strong> Institution <strong>of</strong> Engineers (India) and<strong>The</strong> <strong>Indian</strong> Society for Non-Destructive Testing.He is at present Pr<strong>of</strong>essor and Coordinator, <strong>Welding</strong>Technology Centre, Metallurgical and MaterialEngg. Department, Jadavpur University and alsoTechnical Advisor <strong>of</strong> two private industries.22

PROF. PLACID RODRIGUES AWARDPLACID RODRIGUES MEMORIAL AWARD 2011Every year an eminent <strong>Welding</strong> Engineer and Scientist below 45 years <strong>of</strong> age is selected for delivering thePr<strong>of</strong>. Placid Rodrigues Award. This year IWJ congratulates Dr. Janaki Ram for being selected to deliverthe prestigious lecture this year.Dr. Janaki Ram obtained his masters and doctoral degrees in metallurgical engineering from IITMadras. He specializes in welding technology. From 1998 to 2005, he was in DRDO, working onindigenous development and airworthiness certification <strong>of</strong> a number <strong>of</strong> aerospace materials andcomponents. In 2005, he went to Utah State University, USA, for his post-doctoral work in the field <strong>of</strong>additive manufacturing technologies. In 2008, he returned to India to begin a faculty position in theDepartment <strong>of</strong> Metallurgical and Materials Engineering, IIT Madras. Since then, Dr. Janaki Ram has beenteaching welding processes, welding metallurgy and additive manufacturing courses at IIT Madras. Dr.Janaki Ram has been actively involved in welding research for more than a decade. His researchaddresses both fundamental and applied aspects <strong>of</strong> welding. He has published more than 75 papers invarious international journals and conferences.23

INDIAN WELDING JOURNAL Volume 45 No.1 January 2012List <strong>of</strong> Award Holders for the year 2011Sl. Award Name Award Sponsorers Sponsors Awarded To Subject Of <strong>The</strong> Award PaperNo. Amount RepresentativeIf Attending1 Life TimeAchievement Silver IIWAward 2010-11 Salver Head Office Dr. R. S. Parmar2 Keith HeartleyMemorial Silver M/s.GEE LtdLecture-2011 Medalion Mumbai Dr. T. K. Pal3 Pr<strong>of</strong>. Placid Rs.10,000/- IIW-Chennai Branch President-IIW Dr.G.D.Janaki Ram,RodriguezAsst. Pr<strong>of</strong>essor, Dept. <strong>of</strong>MemorialMetallurgical and MaterialsLecture-2011Engg. <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong>Technology, Chennai-600 0364 Minati Trophy Mr. R. R. Bhattacharjee, President, IIW-India Best Performing BranchBhattacharjee Fellow Of <strong>The</strong> <strong>Institute</strong> IIW-India Kolkata Branch For <strong>The</strong> Year 2010-11Memorial Award for<strong>of</strong> IndiaExcellence -20115. Esab India Award Rs.20,000/- Esab India Ltd. Ms. Girish Kumar Padhy, Diffusible Hydrogen Measurement(Best Technical Chennai V. Ramasubbu, SK Albert in Steel Welds using anpaper across N. Murugesan and Electrochemical Hydrogenall categories) C. Ramesh <strong>of</strong> Material SensorJoining Section,IGCAR, Kalpakkam6. I.T. Mirchandani Rs. 10,000/- Ador <strong>Welding</strong> Ltd. M/s. P. Venkataramana & Dissimilar Metal Gas TunstenMemorial Research Mumbai G. Madhusudan Reddy Arc Weldments <strong>of</strong> MaragingAward <strong>of</strong> Mahatma Gandhi Steel and Medium Alloy<strong>Institute</strong> <strong>of</strong> Technology Medium Carbon Steel effectGandipet and Defence <strong>of</strong> Post weld head treatmentsMetallurgical ResearchLaboratory, KanchanbaghHyderabad7. H.D. Govindraj Rs.10,000/- Weldcraft Pvt. Ltd. M/s. G. Madhusudhan Reddy Dissimilar Metal FrictionMemorial Research Bangalore and P. Vankata Ramana <strong>of</strong> <strong>Welding</strong> <strong>of</strong> Maraging SteelAward Defence Metallurgical with Nickel as an interResearch Laboratory, layer.Kanchanbagh, Hyderabadand Mahatma Gandhi <strong>Institute</strong><strong>of</strong> Technology,Gandipet, Hyderabad8. Sharp Tools Award 1 Rs.6,000/- Sharp Tools Ltd. President - IIW M/s. Aravinda Pai, T.K.Mitra Challenges in <strong>Welding</strong> and(1st best paper in Coimbatore T. Loganathan & Prabhat Fabrication <strong>of</strong> Shell Assemblies<strong>Welding</strong> Fabrication Kumar <strong>of</strong> Bharatiya Nabhikiya <strong>of</strong> 500MWe Prototype Fastand Practices) Vidyut Nigam Limited (Bhavini) Breeder Reactor SteamPrototype Fast Breeder GeneratorsReactor (PFBR) ProjectDept. <strong>of</strong> Atomic EnergyKalpakkam - 603 1029. Sharp Tools Award 2 Rs. 4000/- Sharp Tools Ltd. President - IIW M/s. Satinder Pal Singh, Optimization <strong>of</strong> Groove Design(2nd Best Paper in Coimbatore Amandeep Singh, Sunny & Backing Methods to enhance<strong>Welding</strong> Fabrication Soni, Manadar Gaddu, the Productivity <strong>of</strong> Structuraland Practices) Sanjeev Padvanda, Nishant Tubular Welds <strong>of</strong> JacketShah, A.D. Bhathena, Legs and PilesL.S.Rao, Naresh Dhir andH. T. Naik <strong>of</strong> Larsen &Toubro Ltd., Modular FabricationFacility, Hazira.24

AWARDSList <strong>of</strong> Award Holders for the year 2011 contd...Sl. Award Name Award Sponsorers Sponsors Awarded To Subject Of <strong>The</strong> Award PaperNo. Amount RepresentativeIf Attending10. Panthaki Memorial Rs. 5,000/- Bakshi Chempharma M/s. V.S.N. Venkata Ramana Effect <strong>of</strong> Post Weld HeatAward (<strong>Welding</strong> Equipments Pvt. Ltd. K. Ratna Kumar, G. Madhu- Treatment on Microstructure<strong>of</strong> Non-ferrous Mumbai sudhan Reddy & K. Srinivasa and Corrosion behaviour <strong>of</strong>Metals) Rao <strong>of</strong> Dept. <strong>of</strong> Mechanical Dissimilar AA 2024-AA6061Engg., PVP Siddhartha Insti- GTA Weldstute <strong>of</strong> Technology, KanuruVijayawada, AP11. EWAC Alloys Rs.10,000/- EWAC Alloys Ltd. M/s. Rajesh Sood and Alok Reclamation <strong>of</strong> Work RollAward (Best Paper Mumbai Jha, Reclamation Shop <strong>of</strong> Plate Mill <strong>of</strong> Bhilai Steelin Reclamation and Bhilai Steel Plant, Bhilai Plant12. CEOBSP Award Rs.10,000/- SAIL, Bhilai Steel Plant M/s. Mahendra Pal, Mayank Root Cause Analysis <strong>of</strong>(Best Paper in Bhilai Banjare and Susil Guria <strong>of</strong> Failure in Hot and Cold MixingReclamation and <strong>Indian</strong> Oil Corpn. Ltd. Point in Hydrogen GenerationRepair <strong>Welding</strong> in Inspection Manager, Unit (HGU) due to <strong>The</strong>rmalSteel Plant)Fatigue Phenomenon13. D&H Secheron Rs.10,000/- D&H Secheron Electrodes M/s. G. Madhusudhan Reddy Friction <strong>Welding</strong> <strong>of</strong> MaragingAward (Best Indore & P. Venkata Ramana, Steel to Low Alloy Steelpresented paper) Defence Metallurgical with Nickel as an interlayerResearch Laboratory,Kanchanbagh, Hyderabad.14. Weldman Award Rs. 5,000/- Weldman Synergic Pvt. M/s. B.P.C.Rao, C.Babu Rao, A New methodology for(Second best Ltd., Kolkata S.Thirunavukkarasu, T. Qualification <strong>of</strong> <strong>Welding</strong> Procedurepresented paper) Jayakumar, Baldev Raj for Circumferential ShellAravinda Pai, T.K.Mitra & Welds <strong>of</strong> Steam GeneratorsPandurang Jadhav <strong>of</strong> <strong>of</strong> PFBRMetallurgy & MaterialsGroup, Indira Gandhi Centrefor Atomic Research,Kalpakkam15. Best Welder Rs.5,000/- ELCA Laboratories President - IIW Mr. Roque Fernandez, Don(Plate) Award Thane Bosco Maritime Academy,Mumbai16. Best Welder (Pipe) Rs. 5,000/- ELCA Laboratories President - IIW Mr. Vinod Kumar R. ParmarAward Thane Larsen & Toubro, Baroda17. Best <strong>Welding</strong> Engineer Rs.7,000/- ELCA Laboratories President - IIW Mr. Biswajit Paul,Award Thane Larsen & Toubro Ltd. Mumbai18. Associate Engineers Rs.5,000/- Associate Engineers President - IIW Mr. Hrishikesh Das submitted Effects <strong>of</strong> Friction Stir <strong>Welding</strong>Award (Best M.Tech Baroda the best M.Tech thesis for the parameters on mechanicalthesis submitted for year 2011 under the guidance properties <strong>of</strong> 6063 aluminiumaward <strong>of</strong> degree in <strong>of</strong> Dr. T.K.Pal <strong>of</strong> Jadavpur alloy and HIF GA steelthe previous academic University, Kolkata lap jointyear)19. Weldwell Rs.10,000/- Weldwell Speciality President - IIW Dr. V. Venkateswara Rao Mechanical and MetallurgicalSpeciality Award Pvt. Ltd. submitted the best Ph.D Characteriation <strong>of</strong> Maraging(Best thesis in the Mumbai thesis for the academic Steel to Low Alloy Steelfield <strong>of</strong> welding year 2011 under the Weldmentsguidance <strong>of</strong> Dr. G. Madhu-sudhan Reddy <strong>of</strong> DMRL,Hyderabad and Dr. A.V.SitaramaRaju <strong>of</strong> JNTUH, Hyderabadsubmitted for theaward <strong>of</strong> Ph.D)25

REPORT ON MES-SDI SCHEMEREPORT ON MES-SDI SCHEME OF DGE&T, GOVT. OF INDIAAs an Assessing Body under DGE&T, Govt. <strong>of</strong> India, IIW-India MAB during the periodOctober to December 2011, received Assessment advises from various RDATs are as follows:Sl. No. Region No. <strong>of</strong> advise Course Name TotalCandidates1 RDAT-Chennai 3 Basic <strong>Welding</strong> Gas / Basic <strong>Welding</strong> Arc 1102 RDAT-Faridabad 8 Basic <strong>Welding</strong> Gas / Basic <strong>Welding</strong> Arc / Basic Fitting Work 2303 RDAT-Hyderabad 6 Basic <strong>Welding</strong> Gas / Basic <strong>Welding</strong> Arc / Basic Fitting Work 1754 RDAT-Kanpur 1 Basic <strong>Welding</strong> Gas / Basic Fitting Work 555 RDAT-Kolkata 5 Basic <strong>Welding</strong> Gas / Basic <strong>Welding</strong> Arc / Basic Fitting Work / Gas Cutting 1306 RDAT-Mumbai 8 Basic <strong>Welding</strong> Gas / Basic <strong>Welding</strong> Arc / Basic Fitting Work 234Out <strong>of</strong> 934 assessment advise received for various courses under fabrication sector, 781 candidates were assessedwith 153 candidates remain absent. Out <strong>of</strong> these 781 candidates, 765 passed and 16 candidates failed.Report on NWTCS programme (National Welders' Training and Certification Scheme)During the period October to December, 2011 altogether 63 candidates had been certified by our AuthorisedExaminers at the following ATIs.934Sl. No. Module Level Name <strong>of</strong> the ATI TotalCandidates1. MMAW Standard (Radiographic) Punj Lloyd, Banmore, MP 31MMAW Standard (Radiographic) Technocon Trg. Inst., Rajarhat, W.B. 102 GTAW Standard WELDTECH (Rishi Laser), Vadodara, Gujarat 12GTAW Standard Zanders Skill Dev. Centre, Mohali, Punjab 53 GMAW Standard Zanders Skill Dev. Centre, Mohali, Punjab 5TOTAL 63Under IIW-India's National Welders Training and Certification programme, during October to December 2011,3-new <strong>Institute</strong>s had applied us for becoming IIW-India's Approved Training <strong>Institute</strong> for conducting NWTCSprogramme. <strong>The</strong>y are1) Deshpande Inst. Of Vocational Training, Karnataka2) <strong>The</strong> <strong>Indian</strong> Steel & Wire Products Ltd., Jamshedpur3) J. K. Centre for Technician's Training, Kanpur27

INDIAN WELDING JOURNAL Volume 45 No.1 January 2012THE INDIAN INSTITUTE OF WELDING(A Member Society <strong>of</strong> <strong>The</strong> International <strong>Institute</strong> <strong>of</strong> <strong>Welding</strong>)Head Quarter & Regd. Office Address:“MAYUR APARTMENTS”, Flat No. 4 B/ N, 3A, Dr. U. N. Brahmachari Streey, Kolkata - 700 017, INDIAPhone: 91 33 2281 3208 | Telefax: 91 33 2287 1350E-mail: indianwelding@vsnl.net | Website: http://www.iiwindia.comAM - IIW Examinations : Summer Session, 2012From June 11 to 14SCHEDULEForenoonAfternoonDate / Day 10:00 A.M. - 1:00 P.M. 2:30 P.M. - 5:30 P.M11.06.2012 1. AME - 01 : Elementary Mathematics 1. AME - 02 : Physics(Monday) 2. AME - 14 : Heat and Mass Transfer 2. AME - 15 : <strong>Welding</strong> and Allied Processes - I3. AME - 19 : Testing and Quality Assurance 3. AME - 21 : <strong>Welding</strong> Applications12.06.2012 1. AME - 04 : General English 1. AME - 06 : Industrial Sociology(Tuesday) 2. AME - 08 : Electrical Engineering and Electronics 2. AME - 09 : Material Science3. AME - 17 : Computation Methods and Computer 3. AME - 18 : Weldment Design and Weld ProcedureProgramming13.06.2012 1. AME - 07 : Strength <strong>of</strong> Materials 1. AME - 05 : Applied Mechanics(Wednesday) 2. AME - 11 : Engineering Drawing 2. AME - 13 : <strong>Welding</strong> Metallurgy - I3. AME - 23 : <strong>Welding</strong> Equipment and Consumables 3. AME - 16 : Engineering Economics14.02.2012 1. AME - 03 : Chemistry 1. AME - 10 : Production Engineering(Thursday) 2. AME - 12 : Engineering Mathematics 2. AME - 22 : <strong>Welding</strong> and Allied Processes - II3. AME - 20 : <strong>Welding</strong> Metallurgy - II 3. AME - 24 : Advanced <strong>Welding</strong> TechnologyLast date for Receipt <strong>of</strong> Enrolment Forms : May 12, 2012AM - IIW Examinations fees w.e.f. 01.06.2011Sl. No Type <strong>of</strong> Fee (Rs.)1. Enrolment Fee 400.002. Examination Fee per subject 350.003. Examination Fee for Part ‘D’ 1,500.00WELDING - For Nation Biulding28

AM - IIWTHE INDIAN INSTITUTE OF WELDING(A Member Society <strong>of</strong> <strong>The</strong> International <strong>Institute</strong> <strong>of</strong> <strong>Welding</strong>)Head Quarter & Regd. Office Address:“MAYUR APARTMENTS”, Flat No. 4 B/ N, 3A, Dr. U. N. Brahmachari Streey, Kolkata - 700 017, INDIAPhone: 91 33 2281 3208 | Telefax: 91 33 2287 1350E-mail: indianwelding@vsnl.net | Website: http://www.iiwindia.comANNOUNCEMENTWinter 2011 AM-IIW Examination will be held during June 11 to 14, 2012 (Monday to Thursday) at different Centres where I.I.W.Branches are located subject to the availability <strong>of</strong> candidates. <strong>The</strong> examination schedule and other related information will be sentto all the enrolled candidates individually as well as to the Branches for information.<strong>The</strong> last date for submission <strong>of</strong> the Registration Form and Enrolment Form for appearing at the examination, which will beavailable from the Prospectus, is May 12, 2012. Details <strong>of</strong> rules, regulations, subjects, course content etc are available in theProspectus, which can be obtained from the IIW Head Office on payment <strong>of</strong> Rs.150/- by a Demand Draft favouring “<strong>The</strong> <strong>Indian</strong><strong>Institute</strong> <strong>of</strong> <strong>Welding</strong>” payable at Kolkata. Bound copies <strong>of</strong> question papers <strong>of</strong> two previously held examinations at a price <strong>of</strong>Rs.225/- by Demand Draft are also available from the Head Office.EXEMPTION AVAILABLE IN THE REVISED SYSTEM OF COURSEQUALIFICATIONSUBJECTS EXEMPTED10+2: with Maths, Physics, Chemistry NILDiploma in Engineering AME – 1, AME – 2, AME – 3,AME – 5*, AME – 7*, AME – 8*, AME – 11*Bachelor <strong>of</strong> Science (B.Sc) AME – 1, AME – 2, AME – 3Degree in Engineering or equivalent AME – 1 to AME – 6,*Also AME – 7, 8, 9, 10, 11, 12, 16, 17NOTE: * Provided the subject has been successfully completed during the Qualifying Examination (Column 1).Exemption has to be claimed. In all claims, mark sheets must be produced to get exemption at the time <strong>of</strong> registration andexemption would be given only, if all documents, to the satisfaction <strong>of</strong> the examination committee are received.Pr<strong>of</strong>. Joshi M. DasController <strong>of</strong> ExaminationSUBJECTS (REVISED SYLLABUS)PART A PART B PART CAME-1 : Elementary Mathematics AME-7 : Strength <strong>of</strong> Materials AME-16 : Engineering EconomicsAME-2 : Physics AME-8 : Electrical Engineering & AME-17 : Computation Methods &ElectronicsComputer ProgrammingAME-3 : Chemistry AME-9 : Material Science AME-18 : Weldment Design & WeldProcedureAME-4 : General English AME-10 : Production Engineering AME-19 : Testing & Quality AssuranceAME-5 : Applied Mechanics AME-11 : Engineering Drawing AME-20 : <strong>Welding</strong> Metallurgy-IIAME-6 : Industrial Sociology AME-12 : Engineering Mathematics AME-21 : <strong>Welding</strong> ApplicationsAME-13 : <strong>Welding</strong> Metallurgy-IAME-14 : Heat & Mass TransferAME-15 : <strong>Welding</strong> & Allied Processes-IN. B. : Last Date for Enrolment : May 12, 2012.WELDING - For Nation Biulding29AME-22 : <strong>Welding</strong> & Allied Processes-IIAME-23 : <strong>Welding</strong> Equipment &ConsumablesAME-24 : Advanced <strong>Welding</strong> Technology

INDIAN WELDING JOURNAL Volume 45 No.1 January 2012ANB – India NewsTransition Route for IWCP (IWE/IWT/IWS/IWP) Reopens:IAB authorized period for qualification <strong>of</strong> International <strong>Welding</strong> Coordination Personnel (IWCP) through the'Transition Route' had initially ended on 31st December 2010. However, during the IAB meeting at Chennai in July2011 the same was extended up to 31st January 2012. We are informed that the IAB, during the meeting at Paris inJanuary 2012 has given further extension for International <strong>Welding</strong> Coordination Personnel till 31st July 2012.However, it must be noted by all concerned that the qualification criteria remains frozen as on 31stDecember 2010. That means all qualifications and experience prescribed must have been obtained by 31stDecember 2010.During the period from November 2011 - January 2012, there were a total <strong>of</strong> 5 refresher courses held at Kolkata (2nos.), Baroda, Chennai and Delhi. A total <strong>of</strong> 60 candidates have appeared in the course.International <strong>Welding</strong> Inspection Personnel (Basic / Standard / Comprehensive)courses by the Transition Route:<strong>The</strong> above course aims at integrating knowledge in <strong>Welding</strong> Technology and <strong>Welding</strong> Inspection and Organisations /Candidates engaged in <strong>Welding</strong> Inspection activity will find it extremely useful for their skill development andacceptance by various authorities. So, interested organizations / candidates may find it useful to visit our websitewww.iiwindia.com or write to us at anb@iiwindia.comStandard and Alternative Route for obtaining IWE / IWT qualifications:Standard Route: IWE / IWT candidates can presently avail this route at our Approved Training Body (ATB) M/s.Corner Stone Academy as per the access conditions. Qualified candidates without any experience subject to fulfilment<strong>of</strong> all conditions may enroll. At present the second batch <strong>of</strong> candidates for IWE / IWT diploma are in the process <strong>of</strong>completion <strong>of</strong> their stipulated course curriculum in preparation for appearing in the final examinations. .Alternate Route: This route is extremely suitable for candidates who fulfill the access conditions for the StandardRoute and also have the minimum 4 years prescribed experience in the welding industry to avoid attending lessons inan ATB and appear for the final examinations. A few candidates have already applied to qualify under this route andare waiting to appear in the final examinations.Welder Certification Activity:Encouraging progress is made in the above activity. TELCON along with their vendors has entrusted ANB - India withconducting certification tests for all their own and vendors welders in multiple units spread all over India. ANB - Indiahas also undertaken welder's certification, preparation <strong>of</strong> WPS, WPQR for many organizations that follow ISO, EN andASME Sec. IX standards. <strong>The</strong> recent formation <strong>of</strong> ANBCC for certification <strong>of</strong> companies under ISO 3834 has opened upnew area for certification <strong>of</strong> welders and the emerging market is being fully exploited.All interested organizations / candidates are requested to visit our website under Internationalsection www.iiwindia.com or write to anb@iiwindia.com to get the details <strong>of</strong> the qualificationrequired, fees and the course calendar.30

GUIDELINES FOR AUTHORSGUIDELINES FOR AUTHORS FOR SUBMISSION OF PAPERSTO THE INDIAN WELDING JOURNALINTRODUCTION<strong>The</strong> <strong>Indian</strong> <strong>Welding</strong> <strong>Journal</strong> (IWJ) is the <strong>of</strong>ficial journal <strong>of</strong>the <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Welding</strong> (IIW-India), and it ispublished four times a year. Papers are invited in theareas <strong>of</strong> welding and allied processes for publication inthe IWJ as per the following categories;a) Original papersb) Conference papers (For journal special issues, etc.)c) Critical assessments / Reviewsd) Case studies / Application areasTITLE PAGE<strong>The</strong> title page should include:<strong>The</strong> name(s) <strong>of</strong> the author(s)A concise and informative title<strong>The</strong> affiliation(s) and address(es) <strong>of</strong> the authors<strong>The</strong> e-mail address, telephone and fax numbers <strong>of</strong>the corresponding authorABSTRACTAn abstract should be <strong>of</strong> 150 to 250 words and it shouldnot contain any undefined abbreviations or unspecifiedreferencesKEYWORDSFour (4) to six (6) keywords can be used for indexingpurposesTEXTText FormattingManuscripts should be submitted either in PDF version orin Word files.Margins and Spacing<strong>The</strong> top, bottom, left, and right margins should be keptone inch each, with justified format. Spacing shouldadhere to the following format:<strong>The</strong> body text <strong>of</strong> the paper should be single-spacedand fully justified in 11-point Arial font. Leave one linespace between paragraphs, but do not indent the firstline <strong>of</strong> a new paragraph. Page numbers should becentered at the bottom, and the first page should benumbered.Insert a line space after the final paragraph in asection.First level heading should be consequently numberedlike 1., 2., etc., left justified, all caps and bold. Insertone line space before and after a first level heading.Second level heading should be numberedconsequently like 1.1., 1.2., 2.1., 2.2., etc., leftjustified, with running letter and bold, with one linespace above it.<strong>The</strong> heading <strong>of</strong> Abstract, Appendix and Referencesare to be all caps, 11-point, bold, and centered, withtwo line spaces above, and one below.Figures and TablesFigures and tables should appear close to their firstcitation inside the text. Each table or figure should becentered. Each table and each figure should havecentered titles that should be self explanatory. Tabletitles should go above the table and figure captionsbelow the figure. Leave one line space between the titleand the table or figure. Figures and tables are to benumbered consequently. Refer these inside the text asTable 1 or Figure 1, etc. In addition, each figure shouldbe given as separate file(s), naming the file as Fig 1, Fig2, etc. Figures (including photographs, line drawing,etc.) must be clear and reproducible.33

INDIAN WELDING JOURNAL Volume 45 No.1 January 2012REFERENCESCitation<strong>The</strong> list <strong>of</strong> references should only include works that arecited in the text and that have been published oraccepted for publication. Reference citations in the textshould be identified by numbers in square brackets.Some examples :1. <strong>The</strong> effect has been widely studied [5-9,12]2. <strong>The</strong> same results has been observed by Reddy et al.[17].ExampleBadheka, V. J. and Albert, S. K. (2009); Improving theweld penetration by application <strong>of</strong> oxide coating in GTAW<strong>of</strong> P91 steel, Proc. Nat. Weld. Sem., Kolkata, India, p.18.Sabiruddin K., Das S. and Bhattacharya A. (2009);Application <strong>of</strong> the analytic hierarchy process foroptimization <strong>of</strong> process parameters in GMAW, IWJ,42(1), pp.38-46.APPENDICES AND ACKNOWLEDGMENTAppendices, if needed absolutely, should be placed afterreferences section. Uses <strong>of</strong> appendices are notencouraged, in general. Acknowledgment, appendices,etc., if any, may follow the References section.ensure the widest possible protection and dissemination<strong>of</strong> information under copyright laws.PEER REVIEW PROCESSManuscripts <strong>of</strong> contributed articles submitted undereach category will be peer reviewed. Author(s) will becommunicated with the review results without revealingthe names <strong>of</strong> reviewers, and if needed, author(s) will berequired to incorporate necessary changes in his/theirmanuscript for final acceptance. Typically, there are fourreview recommendations:a) Publish as it is (accept),b) Minor revisions (conditionalacceptance), c) Major revisions (revise and resubmit), d)Reject.For further information /clarification pleasecontact<strong>The</strong> Chief Editor<strong>Indian</strong> <strong>Welding</strong> <strong>Journal</strong><strong>The</strong> <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Welding</strong>3A, Dr. U. N. Brahmachari Street,Kolkata- 700 017.Email: iwj.iiw@gmail.comWebsite: www.iiwindia.comCOPYRIGHTAuthors will be asked to transfer copyright <strong>of</strong> the articleto the <strong>Indian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Welding</strong>(IIW-India). This will34

ESAB INDIA AWARDDiffusible Hydrogen Measurement in Steel Weldsusing an Electrochemical Hydrogen Sensor1 1 2 2 *Girish Kumar Padhy , V. Ramasubbu , N. Murugesan , C. Remash and S.K. Albert1 2Material Technology Division, Material Chemistry Division, Indira Gandhi Centre for Atomic Research,Kalpakkam-603102, Tamilnadu, India.ABSTRACTDiffusible hydrogen (H ) measurement in steel welding consumables having cellulose, rutile and basic coatingDhas been carried out using a Proton Exchange Membrane Based Hydrogen Sensor (PEMHS). <strong>The</strong> sensor is anelectrochemical fuel cell based device which uses Nafion@117 as proton exchange membrane electrolyte. Thiscan detect hydrogen in an Ar+H mixture with detectable limit <strong>of</strong> 1 ppm. Further, H measurements have also2 Dbeen carried out on basic coated electrodes <strong>of</strong> modified 9Cr-1Mo steel, with very low levels <strong>of</strong> H content.DResults obtained have been compared with those obtained from H measurement using mercury manometerDas per standard ISO 3690. One to one correlation has been obtained between these two different methods <strong>of</strong>measurements. This sensor has shown good sensitivity, accuracy and precision hence is reliable for H Dmeasurement. In addition to the above measurement, this method was used to study hydrogen evolution fromthe weldments as a function <strong>of</strong> time. <strong>The</strong> paper presents and discusses the principles <strong>of</strong> H measurement usingDthis sensor, its applications for H measurements in weldment, the results obtained, its application to study theDhydrogen evolution from weldment as a function <strong>of</strong> time and the possibility <strong>of</strong> using this sensor formeasurement <strong>of</strong> hydrogen evolved from the weld specimens at high temperatures.Keywords: Diffusible Hydrogen, Nafion Hydrogen Sensor, Hot Extraction, Hydrogen Diffusivity1.0 INTRODUCTIONHydrogen in the weldments <strong>of</strong> carbonand alloyed steels when accompaniedwith a crack susceptible microstructureand tensile residual stress in theweldment causes Hydrogen AssistedCracking (HAC) in the weld metal and inthe heat affected zone (HAZ). As thesecracks are not acceptable in weldments,formation <strong>of</strong> these cracks should beprevented. For predicting the susceptibility<strong>of</strong> weldment to HAC, amount <strong>of</strong>diffusible hydrogen (H ) content in steelDweldment is used extensively (Yuriokaand Suzuki, 1990). Though manysources such as shielding gas,oil/grease, hydrocarbons on the surfaceto be welded and moisture in thesurrounding atmosphere may contributeto hydrogen in welds, the chiefsource is the chemically bonded water inthe flux coated on the welding electrode(IIW Doc.II-805-85, 1985) which dissociateinto hydrogen and oxygen atoms inthe arc during welding. Very hightemperature (~1600°C) <strong>of</strong> the moltenmetal causes dissolution <strong>of</strong> largeamount <strong>of</strong> hydrogen atoms present inthe arc atmosphere in the weld poolwhereas oxygen atoms form oxideswhich become parts <strong>of</strong> the slag formedduring welding. In general, solubility <strong>of</strong>hydrogen in ferritic steel is less than 2ppm by weight at STP. However, therapid cooling rate (80-150K/second) <strong>of</strong>the deposited metal during weldingdoes not allow hydrogen to equilibratewith the deposited metal and results insupersaturation <strong>of</strong> hydrogen in the* Corresponding author E-mail : shaju@igcar.gov.in35

INDIAN WELDING JOURNAL Volume 45 No. 1 January 2012deposited metal, which starts diffusinginto the HAZ or out <strong>of</strong> the weld duringsolidification and subsequent cooling.During this diffusion, most <strong>of</strong> thehydrogen is retained at various defectscalled traps which are classified (Hirth,1980) as reversible traps (e.g. grainboundaries, lath boundaries, dislocationsetc.) and irreversible traps(e.g. vacancy, particle matrix, inclusionsetc.) in the weld and in the HAZ. At roomtemperature, irreversible traps havehigher binding energies and release <strong>of</strong>hydrogen from these traps is difficult.However, reversible traps, owing to theirlower binding energies [(Iino, 1987),(Iino, 1998)] release hydrogen insubsequent times which is able todiffuse further. Hence, only a part <strong>of</strong> thetotal trapped hydrogen tends to diffuseat or near room temperature (25-45°C)which is referred as diffusible hydrogen(H ). Cracking is caused by interaction <strong>of</strong>DH with defects, which are locations <strong>of</strong>Dstress concentration in the welds.Hence, H content in the weld metalDshall be controlled and estimation <strong>of</strong>hydrogen by a suitable technique is thefirst step in the efforts to avoid cracking.An understanding <strong>of</strong> the H content isDalso useful to predict the minimumpreheat temperature to be employedduring welding <strong>of</strong> steels to avoidcracking [(Suzuki and Terasaki, 1986),(Ito and Bessyo, 1968)]. As one <strong>of</strong> themajor sources <strong>of</strong> hydrogen is thewelding consumables, they areclassified based on the H content in theDweld metal produced by them.Measurement <strong>of</strong> H content from a weldDis carried out by measuring hydrogenevolved from the weld at a fixedtemperature for a given duration.Standards such as ISO, AWS, DIN, BISand IS have recommended proceduresfor H measurements which includeDmercury (ANSI/AWS A4.3-86, DIN 8572,ISO 3690, IS-11802-1986, JIS Z3118-1986) and gas chromatography (ANSI/AWS A4.3-86, ISO 3690, JIS Z3118-1986, Ohtsubo et al., 1985, Quintanaand Dennecker, 1986) methods. A goodagreement between the results hasbeen reported with measurementscarried out using mercury and gaschromatography methods (De Abreu etal., 1995). However, these methods arenot free from drawbacks. Limitations inusing the mercury method are thehealth and safety issues associated inthe handling <strong>of</strong> mercury, the longdurations <strong>of</strong> hydrogen collection (72hours or longer after welding (Ravi andHonavar, 1987)), non-applicability <strong>of</strong>this method at higher temperature forhydrogen collection which would reducethe time <strong>of</strong> hydrogen collection. Also,this method provides no scope forstudies such as the evolution <strong>of</strong>hydrogen from the weld as a function <strong>of</strong>time from a single specimen, theevolution <strong>of</strong> hydrogen at higher temperaturesetc. For welding consumablemanufacturers the test duration <strong>of</strong> 72hours is quite long; but time cannot beshortened with this method as themeasurement cannot be carried out athigh temperatures. Gas chromatographymethod permits heating <strong>of</strong>samples up to a maximum <strong>of</strong> 400°Creducing the test duration to 20-30minutes. However, the equipment iscostly. Another method, involved incollection <strong>of</strong> H over glycerin (JIS Z3113-D1975) is in limited use [(Quintana,1984), (Siewert, 1986)] because itlacked accuracy and furnished lower HDcontents than those obtained using gaschromatography and mercury methods(Kotecki and La Fave, 1985). <strong>The</strong> lowerH contents obtained using theDcollection <strong>of</strong> hydrogen over glycerin isattributed to the fact that hydrogen ispartially soluble in glycerin. Many othertechniques such as determination <strong>of</strong> HDcontent using mass spectrometer[(Noble, 1985), (Pressouyre et al.,1988)], low frequency impedance basednon contact diffusible hydrogen sensor(Lasseigne, 2008), and computer aideddetermination <strong>of</strong> diffusible hydrogen(Karkhin and Levchenko, 2007) are alsoreported.H measurement can also be carried outDusing chemical sensors available fordetection and measurement <strong>of</strong>hydrogen in gas mixtures. <strong>The</strong>sesensors include pellistor sensors[(Krawczyk, 2003), (http://www.e2v.com)], semiconductor sensors (Linet al., 2003), thermal conductivity baseddevices, electrochemical sensors etc.Pellistor sensors require atmospherescontaining oxygen/air in explosive rangehence are not suitable for H measure-Dment. Semiconductor sensors are basedon conductivity changes caused by thechemisorbed oxygen due to hydrogenexposure. Hence oxygen is requiredalong with hydrogen. <strong>The</strong>rmal conductivitybased devices are bulky and notsuitable for field applications. Electrochemicalsensors for hydrogenmeasurement include both potentiometric[(Miura, 1983), (Miura andYamazoe 1988)] and amperometric[(Miura, 1984), (Miura, 1989)].Potentiometric sensors are suitable atlow concentrations but are nonlinear inresponse. Amperometric sensors arelinear in response and use <strong>of</strong> an amperometricsensor, H /Pt//PVA//Pt/O2,2(comprising <strong>of</strong> a proton-conductingpolymer, Polyvinyl Alcohol (PVA) as itselectrolyte) for H measurement hasDbeen reported [(Albert et al., 1997),(Albert, Ph.D <strong>The</strong>sis, 1996)]. <strong>The</strong> resultsobtained from the sensor agreed well36

Girish Kumar Padhy - Diffusible Hydrogen Measurement in Steel Welds using an Electrochemical Hydrogen Sensorwith that <strong>of</strong> the standard GasChromatography method. However, itwas seen that the PVA membranesuffers from poor long term stability. Amodest comparison <strong>of</strong> all the availablesolid and liquid electrolytes showed thatNafion is the best available polymermembrane because <strong>of</strong> its high longevity(>60,000 hours), high chemical stabilityand high ionic conductivity to opt forPEM fuel cell applications [(Smitha et al.,2005), (Neburchilov et al., 2005),(Viswanathan and Helen, 2007)]. Nafionbased electrochemical cells, H /Pt// 2Nafion//Pt/O2, has been used formeasurement <strong>of</strong> hydrogen in Argon[(Sakthivel and Weppner, 2006),(Velayuthamet al., 2004), (Ramesh etal., 2008)]. <strong>The</strong> present study is involvedin the application <strong>of</strong> this Nafion basedelectrochemical sensor for HD measurementin welding consumables.Table 1: Chemical compositions in <strong>of</strong> mild steeland modified 9Cr-1Mo in Wt%Elements Mild steel Modified 9Cr-1MoC 0.205 0.114Cr - 8.838Mo - 0.860Mn 0.551 0.403Si 0.061 0.309P 0.039 0.014Sr 0.047Nb - 0.080V - 0.027Cu 0.321Fe Balance Balance2.0 EXPERIMENTAL2.1 Materials used in the study2.1.1 Test specimenFor H measurement, the specimen wasDprepared as per standard ISO 3690. Atriplicate set <strong>of</strong> specimen assemblycomprising <strong>of</strong> a specimen <strong>of</strong> dimension30 mm x 15 mm x 10 mm, a run-on and arun-<strong>of</strong>f piece each <strong>of</strong> dimension 44 mm x15 mm x 10 mm were prepared frommild steel and modified 9Cr-1Mo steel.<strong>The</strong> chemical composition <strong>of</strong> steels usedis given in Table 1. <strong>The</strong> surfaces <strong>of</strong> thetriplicate set were finished at rightangles to ensure good contact betweenthe adjacent pieces. <strong>The</strong> sample wasweighed to the nearest 0.01g prior towelding. <strong>The</strong> specimen assembly wasclamped in a copper fixture. <strong>The</strong>dimensions <strong>of</strong> the fixture was such thatduring welding, the heat is conductedaway immediately from the testassembly to the fixture. Beads weredeposited with welding electrodes withdifferent hydrogen levels on thespecimen assembly by manual metal arcwelding (MMAW) process. A schematicdiagram <strong>of</strong> the specimen assembly isshown in Fig. 1.2 . 1 . 2 H y d r o g e n C o l l e c t i o nChamberA hydrogen collection chamber (Lundinet al., 1986) was used to collect H fromDthe weld specimen. <strong>The</strong> chamber ismade <strong>of</strong> stainless steel and has an inletand an outlet connected to needleAll dimensions are in mmFig. 1 : Schematic <strong>of</strong> the Specimen assemblyvalves. <strong>The</strong> chamber can be opened orclosed using a plug and the leaktightness <strong>of</strong> the plug is ensured with thehelp <strong>of</strong> an O-ring. <strong>The</strong> chamber wassubjected to helium leak testing and itwas found that the leak rate is less than-910 sccm. Fig. 2 shows the schematic <strong>of</strong>the chamber along with plug. <strong>The</strong>volume <strong>of</strong> the chamber is measured byfilling it with distilled water and drainingthe water completely into a measuringjar.2.1.3 Gas sampling valveAn 8-port gas sampling valve with a37

INDIAN WELDING JOURNAL Volume 45 No. 1 January 2012O-RingDia 40FlowControlValvesampling loop <strong>of</strong> known volume was used for sampling the gasfrom the hydrogen collection chamber for analysis. <strong>The</strong>sampling valve operates in two modes as shown in Fig. 3.Mode 1 is the sampling mode and Mode 2 is injection mode. Inmode 1, as shown in Fig. 3, the inlet <strong>of</strong> the sampling loop isconnected to the specimen chamber (sample gas) throughport 7 and port 8 and the outlet is open to atmosphere throughport 4 and port 3. In this mode only the carrier gas which entersthrough port 5, is passed onto the detector/sensor throughport 2 and port 1. In Mode 2, as shown in Fig. 4, the inlet <strong>of</strong> thesampling loop is connected to the carrier gas line through ports5 and port 4 and outlet to the detector/sensor through port 8and port 1. In this process, the sample gas collected in the loopwhile operating in Mode 1 is carried away to the sensor by thecarrier gas. While operating in this mode specimen chamber iskept closed so that gas inside the specimen chamber isconserved.For analysis <strong>of</strong> the gas, initially the valve was operated at mode1. <strong>The</strong> gas from the specimen chamber, which was filled at ahigher pressure than the ambient pressure, was used to flushthe sampling loop while the carrier gas was flowing into thesensor. At the end <strong>of</strong> flushing, the valve was switched over tomode 2 operation and the carrier gas flowed through thesampling loop to the sensor carrying the gas trapped in theloop along with it. <strong>The</strong> sensor gives a signal corresponding toconcentration <strong>of</strong> hydrogen in the gas mixture.2.1.4 Hydrogen SensorAll dimensions are in mmFig. 2 : Schematic diagram <strong>of</strong> HydrogenCollection ChamberFig. 3 : Valve in Mode 1 for sampling thediffusible hydrogen gas<strong>The</strong> hydrogen sensor used is an electro-chemical cell which hasNafion, a proton conducting polymer, as its electrolyte. <strong>The</strong>polymer is cast as a film, coated with platinum black on thesensing and counter electrode side. <strong>The</strong> sensing side <strong>of</strong> thecoated polymer is exposed to the hydrogen argon gas mixturewhile the counter side is exposed to air. Thus the sensorconsists <strong>of</strong> hydrogen exposed inner platinum film and airexposed outer platinum film with the conducting polymerNafion, sandwiched between them acts as a fuel cell. Amechanical barrier limits the supply <strong>of</strong> hydrogen at the sensingelectrode. A schematic representation <strong>of</strong> the sensor withconducting leads is shown in Fig. 5. Hydrogen present in theAr-H mixture gets chemisorbed at the sensing electrode and2+loses its electron to form H which permeates through thepolymer to reach the counter electrode where it encounters2-oxide ion (O , which is produced by taking up the electrons lostby hydrogen and oxygen from the ambient) to form H O.<strong>The</strong>2reactions taking place at the anode and at the cathode <strong>of</strong> the38

Girish Kumar Padhy - Diffusible Hydrogen Measurement in Steel Welds using an Electrochemical Hydrogen SensorFig. 4 : Valve in Mode 2 for injection <strong>of</strong> sampled gas onto the sensorabove electro-chemical cell are asfollows:At the anode+ -(Sensing side): H22H + 2eAt the cathode (Couneter+ -side): 2H + ½O2+ 2e H2ODuring the conduction <strong>of</strong> hydrogen ionthrough the polymer membrane, a shortcircuit current is produced and a peakcorresponding to the short circuitcurrent was observed in the dataacquisition system which in turn is usedto measure the concentration <strong>of</strong>Diffusion barrierPt (SensingElectrode)NafionPt (ReferenceElectrode)hydrogen in the hydrogen collectionchamber.2.2 Diffusible HydrogenMeasurement2.2.1 Preparation <strong>of</strong> specimen forthe HD measurementFig. 5 : Schematic <strong>of</strong> Hydrogen SensorFive different classes <strong>of</strong> electrodeswhich are known to have different levels<strong>of</strong> HDcontent were used for HDmeasure-ment using the sensor. Prior to welding,the specimen was degassed by holdingoit at 650 C for 1 hour and the weldingelectrodes were baked as per therequirement given in Table 2. Weldspecimens were prepared by depositingbeads <strong>of</strong> the above mentionedelectrodes on mild steel specimen andbead <strong>of</strong> the low hydrogen electrode,P91M (with a composition modified fromthat <strong>of</strong> E9015-B9), on modified 9Cr-1Mospecimen. Table 2 give the electrodedetails and welding parametersemployed for preparation <strong>of</strong> specimensfor H measurement. <strong>The</strong> specimenDassembly for H measurement wasDremoved from the copper fixtureimmediately after welding, quenched inice cold water followed by liquidnitrogen. <strong>The</strong> test specimen wasseparated from the run-on and run-<strong>of</strong>fpieces within 4-6 seconds. Any fluxremaining on the weld specimen wasremoved within 20 seconds and wasstored in liquid nitrogen until its transferinto the hydrogen collection chamber forcollection <strong>of</strong> H .D2.2.2 Collection and measurement<strong>of</strong> diffusible hydrogen using thesensorFor the collection <strong>of</strong> H evolved from theDweld specimen, it was cleaned withacetone to remove the ice/moisture,gently warmed to remove excessacetone and was transferred into thecollection chamber within one minute.<strong>The</strong> chamber along with the specimenwas flushed and pressurized with argongas to a known pressure higher than theambient. After pressurizing, the weldspecimen was held in the chamber for72 hrs for collection <strong>of</strong> H as a mixture <strong>of</strong>Dhydrogen in argon (Ar-H gas mixture).2Volume <strong>of</strong> H in the Ar-H gas mixture isD 2measured by the sensor as describedbelow.Prior to the measurement <strong>of</strong> Volume <strong>of</strong>H in the chamber, sensor was calibratedDwith different known concentrations <strong>of</strong>hydrogen in the Ar-H gas mixture <strong>of</strong> by2injecting a fixed volume (this volume is39

INDIAN WELDING JOURNAL Volume 45 No. 1 January 2012Table 2: Baking and <strong>Welding</strong> parameters <strong>of</strong> different electrodesElectrodes Baking <strong>Welding</strong> Voltage (Volt)conditions current (Amp)E6010 Not Baked 110 25ºE6013 125 C/1h 110 27ºE7016 250 C/2h 110 28ºE7018-1 250 C/2h 110 27ºP91M 300 C/2h 90 28equal to the volume <strong>of</strong> the sampling loop<strong>of</strong> the valve shown in Figs. 3 and 4) <strong>of</strong>the gas mixture onto the sensor with thehelp <strong>of</strong> the 8-port valve. Concentrations<strong>of</strong> hydrogen in the gas mixture werevaried by standard mass flowcontrollers. Signal/response <strong>of</strong> thesensor corresponding to each concentration<strong>of</strong> hydrogen in the Ar-H gas2mixture was recorded as a peak height<strong>of</strong> the peak is proportional to theconcentration <strong>of</strong> hydrogen in the gasmixture. After calibration, the inlet <strong>of</strong>sampling loop <strong>of</strong> the 8-port valve wasconnected to the chamber, the samplingloop is flushed and filled with the gas inthe chamber. Subsequently, by choosingthe injection mode <strong>of</strong> the eight portvalve, the gas mixture in the samplingloop was injected into the sensor. Aresponse corresponding to theconcentration <strong>of</strong> hydrogen in thechamber is recorded in the dataacquisition system and compared withthe calibration to obtain theconcentration <strong>of</strong> H collected in theDchamber. As the specimen chamber is ata higher pressure than the ambient, itwas possible to repeat the measurementat least thrice using the gas mixtureavailable in the chamber. Aftermeasuring H concentration, the weldDspecimen was taken out <strong>of</strong> the chamber,cleaned, dried and weighed. From thevolume <strong>of</strong> the chamber, hydrogenconcentration in the gas mixture,pressure <strong>of</strong> the gas inside the chamber,weight <strong>of</strong> the deposited metal, volume<strong>of</strong> H content was estimated and wasDreported in ml/100g <strong>of</strong> the depositedmetal. For each set <strong>of</strong> specimens, fiveseparate measurements were carriedout and the average values werereported.2.2.3 Measurement <strong>of</strong> diffusiblehydrogen with respect to timeIn addition to the standard 72 hourmeasurement, H measurement fromDweld specimen was also carried out atdifferent time intervals using the sensor.For feasibility <strong>of</strong> the measurements,they were carried out at long timeintervals after 72h. Apart from thedifference in the time duration <strong>of</strong>collection <strong>of</strong> H , the procedures <strong>of</strong>Dspecimen preparation and H measure-Dment were the same as discussed insections 2.2.1 and 2.2.2. In this study,H was collected from a single weldDspecimen for time intervals <strong>of</strong> 0-24, 24-48, 48-72, 72-120, 120-192, 192-264 hand was measured using the sensor.After measuring the concentration <strong>of</strong>hydrogen evolved for a certain timeinterval, the chamber containing thesame specimen was flushed andpressurized again with argon to a knownpressure and the measurement wasrepeated for the next interval until n<strong>of</strong>urther sizable hydrogen concentrationin the Ar-H mixture was obtained for a2subsequent time interval after 264 h <strong>of</strong>H measurement.D2.2.4 Measurement <strong>of</strong> diffusiblehydrogen at high temperature.For collection <strong>of</strong> H at high temperature,Da new chamber was designed (Fig. 6)which has heating arrangements insideit. Weld specimen was prepared as perthe standard procedure alreadydescribed and for H measurement itDwas transferred into heater inside thechamber. <strong>The</strong> chamber along with theweld specimen is flushed andpressurized with argon; then thespecimen is heated to 400°C for 0.5hand hydrogen diffused out from thespecimen is collected inside thechamber. It is cooled down to roomtemperature and the concentration <strong>of</strong>hydrogen is measured with the sensor.2.2.5 Measurement <strong>of</strong> diffusiblehydrogen by the mercury methodSince the sensor method is a newtechnique, all the H measurementsDcarried out using this method werecompared with similar measurementsusing mercury method followingstandard ISO 3690 procedure. <strong>The</strong>quenched and cleaned specimen wastransferred into the Y- tube filled withmercury. <strong>The</strong> Y- tube was evacuated andthe specimen inside was allowed forhydrogen evolution for 72 hours.Hydrogen evolved was collected in theburette <strong>of</strong> the Y-tube. This volume issubsequently converted to the volumeat STP and knowing the mass <strong>of</strong> thespecimen, H content was normalized byDthe following relationship:H =D(273273+T((P - H760100L - L2 1(V 2 - V 1 ) ml / 100g <strong>of</strong> weld deposit ..(1)(((40