product catalogue professional ground screws - Voltastream

product catalogue professional ground screws - Voltastream

product catalogue professional ground screws - Voltastream

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

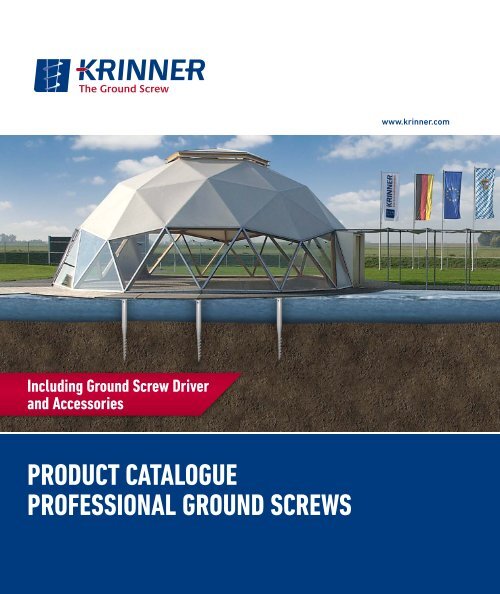

www.krinner.comIncluding Ground Screw Driverincluding and Accessories <strong>ground</strong> screw driverand accessoriesPRODUCT CATALOGUEProduct <strong>catalogue</strong>PROFESSIONAL GROUND SCREWSProfessional <strong>ground</strong> <strong>screws</strong>

editorialMore than 100 patents and innovationsfor our customers.Dear Partner,We are pleased to present you our latest <strong>product</strong> <strong>catalogue</strong>.The KRINNER team is proud to see that the <strong>ground</strong>-breaking invention of <strong>ground</strong><strong>screws</strong> has established itself as a real alternative to conventional concrete foundations.It has also come a long way since its invention: In this <strong>product</strong> <strong>catalogue</strong>, we presentyet another advancement of the <strong>ground</strong> screw. The fundamental shape, specificthread and driving methods have been optimized by new and innovative ideas. This hasresulted in a further increase in strength values as well as an improvement in handlingand driving. At the same time, we have expanded our <strong>product</strong> range for you and groupedour <strong>ground</strong> <strong>screws</strong> into new <strong>product</strong> classes. This will make it much easier for youto find the right solution among the many different applications.We have also expanded our service department for you. We have increased our workforceat our headquarters and now offer a range of services with fixed and variablecomponents to support you more on your projects.With our <strong>product</strong>s and the many applications for them, we are certain that you, as ourpartner, will continue to grow successfully with us.CordiallyHans-Jürgen SauterGeneral Manager, Krinner Schraubfundamente GmbH

CONTENTSServiceAdvantages – added valueServices and solutionsBack<strong>ground</strong> knowledgePre-dimensioning tableSustainabilityQuality managementApplicationsTimber-Frame ConstructionAdvertising and Traffic SystemsUrban, Garden and Landscape ConstructionHall and Container ConstructionFencing SystemsSolar Systems

CONTENTSGround Screw Product SeriesE SeriesF SeriesG SeriesK SeriesM SeriesU SeriesX SeriesDriversKR E 10 Ground Screw DriverKR E 20 Ground Screw DriverKR H Manual Screwing ToolS1 Manual Screwing ToolKR D 55 Ground Screw DriverKR B 40 Ground Screw DriverKR B 60 Ground Screw DriverKR B 250 Ground Screw DriverCable DetectorAccessories

MODERN FOUNDATION CONSTRUCTIONefficient · safe · sustainableRespect for the natural environmentis a further argument for<strong>professional</strong> <strong>ground</strong> <strong>screws</strong>: Thesoil remains unsealed, so foundationscan be removed cleanlywithout hassle.Building modern foundations with KRINNER Ground Screws (KSF) does notonly fit right into nature and our environment, but also presents entirelynew, rational, time- and cost-saving building processes for the constructionworker.This quick and uncomplicated foundation method allows high quality solutionsat low cost. It ecologically and economically outperforms previousbuilding methods.Using practical and handy drivers and equipment, KRINNER <strong>ground</strong> <strong>screws</strong>are quick to install, precisely adjustable and suitable for all types of soil,even on hillsides.The <strong>ground</strong> <strong>screws</strong> made of hot-dip galvanized steel or resilient plasticguarantee utmost stability, safety and durability.Advantages at a glance:• Time and cost benefits• Suitable for all types of firm <strong>ground</strong>• Statically tested and proven• No earthworks or concrete pouring• Short installation time• Immediately loadable• Quick changes of position• Terrain remains undamaged• Can also be installed into sealed surfaces• Easily to dismantle and reusable• Long life and high stability• Environmentally friendly, ecological, sustainable

SERVICES AND SOLUTIONSindividual · competent · comprehensiveCompetence from the initial ideato implementation.COMPETENCE FROM THE INITIAL IDEA TO IMPLEMENTATIONKRINNER develops customized <strong>product</strong> solutions using <strong>ground</strong> <strong>screws</strong> asfoundations for various application fields. As your competent partner, weoffer you a comprehensive package from the initial idea to implementation.Every solution is developed individually and tailored specifically to the customer‘swishes using the highest quality components.EXPERTISE – FOR EVERYONEKRINNER offers innovative solutions and comprehensive knowledge transfer.We address users directly and make our knowledge available in trainingcourses, seminars and workshops.OUR SERVICES – VALUE DISCIPLINES FOR DYNAMIC DEVELOPMENTIn response to the rising demand for our innovative <strong>product</strong>s and individualservices, we offer a series of comprehensive packages. With our unique sellingpoints and key differentiators in this sector, we provide our customersand partners a significant edge in the global competition.

SERVICES AND SOLUTIONSindividual · competent · comprehensiveCUSTOMER SERVICE – AvailABILITY WHEN IT IS NEEDEDWith expertise, experience and customer-focused thinking and action, ourcustomer service team offers you a comprehensive package of services andsolutions:• National and international customer service• Pre-sales and after-sales service• Quick handling of customer inquiries• Communication interface between partners, sales force and engineering• Comprehensive partner support and advice for all solutions• Coordination of on-time deliveries• Complaints managementENGINEERING – BY PROFESSIONALS FOR PROFESSIONALSExpert engineers and technicians put their competence and expertise intothe success of your screw foundation projects and accompany and supportyou right from the start. Every project has its own requirements, different<strong>ground</strong> conditions and individual applications. Our engineering service thereforeoffers individualized, customer-specific solutions.• Technical advice• Structural analysis and individual measurements of the KSF• Performance of load tests• Project management from planning to control to supervision duringKRINNER <strong>ground</strong> screw installation projectsRESEARCH AND DEVELOPMENT – LEADING THROUGH INNOVATIONFuture technology is the catalyst in our corporate development and innovationour strength. With our engagement we encourage future-oriented andsustainable new developments.• Market-oriented developments that satisfy the interestsof our partners and customers• Implementation of new, improved and future-oriented solutionsto increase the value added• Effective customer-focused development process that culminatesin competitive <strong>product</strong>s• Sustainable development for economic utilization

SERVICES AND SOLUTIONSindividual · competent · comprehensiveCatalogue of Engineering ServicesBasic Service Items UnitTechnical Advice1. Technical training(basic package, advanced seminars)1.1 Statics training1.2 Training on driver and excavator operation1.3 Product training courses2. Technical advice at events, trade fairs andcustomer appointments3. Preliminary evaluation and material conceptionfor preparing offersStructural Analyses1. Structural analysis of the KSF2. Structural analysis and development of theadaptation to KSFLoad TestsPlanning, performance and analysis of loadtests on site including photographic documentationProject Management1. Planning of projects1.1 Preliminary evaluation and planning servicesincluding preperation of implementationand detailed plans for the KSF1.2 Agreement of bills of quantities forspecification of terms1.3 Coordination and scheduling of theKSF installation process2. Project control for KSF installation2.1 Project-specific organization, definition ofinterfaces and responsibilities2.2 Preparation, planning and performance ofprojects for KSF installation. Project-relatednegotiations with third parties for conflictmanagement in the interests of the contractee2.3 Scheduling and resource planning3. Site management and supervision for KSFinstallationService and Maintenance ContractsService and maintenance of the KSF in the formof monitoring measuresDaily rates plustravel expensesAccommodation*Hourly rates plustravel expensesAccommodationDaily rates plus travelexpensesAccommodationTechnical equipmentHourly rates plustravel expensesAccommodationTechnical equipmentHourly rates plustravel expensesAccommodation*Unless agreed upon in other packages

SERVICES AND SOLUTIONSindividual · competent · comprehensiveIndividual Items in the Catalogue of ServicesItem Description UnitTechnical EquipmentKR D 100 Ground Screw Driverincl. 1 machine operatorKR D 55 Ground Screw Driverincl. 1 machine operatorKR B 60 Ground Screw Driverincl. excavator and 1 machine operatorKR B 40 Ground Screw Driverincl. excavator and 1 machine operatorWheel loader/telescopic handlerincl. 1 machine operatorCompressor for KR D 55 Ground Screw Driverincl. pre-drilling equipment – DTH hammerincl. 1 machine operatorCompressor for KR D 100 Ground Screw Driverincl. pre-drilling equipment – DTH hammerincl. 1 machine operatorKR D 55 Ground Screw Driverincl. pre-drilling equipment – hydraulic hammerincl. 1 machine operatorCarriage with vehicleCarriage without vehicleTechnical PersonnelProject ManagerEngineerSite ForemanTechnicianChief ErectorTechnical AssistantsAssemblers/Machine OperatorsCommercial StaffAssembly AssistantsTravel Expenses*Travel to/from, vehicle up to 3.5 tTravel to/from, vehicle from 3.5 t to 7.5 tTravel to/from, vehicle over 7.5 tTravel to/from by rail, air or shipFixed rate for accommodation and mealsHourly ratesHourly ratesHourly ratesHourly ratesHourly ratesFor KSF < 140 mmHourly ratesFor KSF > 140 mmHourly ratesHourly ratesHourly ratesHourly ratesHourly ratesHourly ratesHourly ratesHourly ratesHourly ratesHourly ratesHourly ratesHourly ratesHourly ratesPer kmPer kmPer kmBy receipts*Toll road/motorway charges calculated separately

BACKGROUND KNOWLEDGEindividual · competent · comprehensiveDesignation system for KRINNER Ground ScrewsNominal lengthShaft diameterFor exampleKSF E 140x1300-E76-100Further specifications: E – Diameter settingR – Rectangular flange plateNominal lengthM – Moment (torque)P – Planar flangeShaft diameterM – Number and dimensions ofside threadsSeries E – Eccenter systemF – FlangeG – Threaded fasteningK – Conical plasticM – Mounting on threadU – U-shaped post shoeX – Special applicationsKRINNER Ground ScrewsDesignation system for KRINNER Ground Screw DriverFor exampleKR E 20 Driver Z1F3 – Flange connectionB1 – JawsZ1 – Spline shaftK34 – Insertion depthMachine size – power categoryD – DumperB – Excavator mountingE – Electrical manual toolH – Manually toolKRINNER driver or driving tool KR E 20 Driver Z1

BACKGROUND KNOWLEDGE ON INSTALLATIONThe following criteria apply to KRINNER Ground Screws made of hot-dip galvanizedsteel for stable erection of structural elements and for bearing loads by redirection intothe <strong>ground</strong>. These criteria serve as a guideline for <strong>professional</strong> and qualified execution.ASSESSMENT AND PREPARATIONBefore installing screw foundations, an assessment and calculation must be made onthe basis of the existing loads and respective <strong>ground</strong> conditions. A reference value andpre-dimensioning table is provided for preselecting the <strong>ground</strong> <strong>screws</strong>. The final foundationdesign must be based on onsite load tests performed in compliance with DIN EN1537 and DIN EN 4125.THE FOLLOWING CONSIDERATIONS ARE ESSENTIAL FOR THE CORRECT CHOICE OF GROUND SCREW:• Calculation of the maximum service load by taking the ultimate load or characteristicultimate loads as a basis by dividing the respective ultimate load by a safety factor.Ultimate loads are those loads that either cause rupture or extraction of the <strong>ground</strong><strong>screws</strong>. Their average value is obtained by means of individual tests on the buildingmaterial. Permissible loads are service loads that already include an appropriatelyrated safety factor. However, these only apply if the manufacturer‘s specifications arecomplied with.• Rating of the internal load-bearing capacity based on a relevant structural analysismodel in compliance with DIN EN 1997-1 Eurocode 7 and DIN 1055-2:2010-11.• Rating of the external load-bearing capacity of the KRINNER <strong>ground</strong> screw accordingto DIN 18800 and based on load tests carried out in compliance with DIN EN 1 537,DIN 4125 and DIN 1054:2010-12.• Service life or usable lifetime of the structures and buildings to be erected on screwfoundations.• For assessment of the soil conditions and the local installation terms, appropriateinvestigation and testing of the soil must be carried out according to DIN EN ISO14688-2:2011-06 and a geotechnical report must be produced.INSTALLATIONKRINNER Ground Screws are basically installed into firm <strong>ground</strong> using driving equipmentdesigned to the appropriate performance level. The <strong>ground</strong> screw is driven intothe <strong>ground</strong> without vibration by a rotary drive with simultaneous downward pressure.Insertion of the screw leads to sideways displacement and compaction of the soil.• For pinpoint accuracy and perfectly vertical insertion, it is recommended to pre-drillusing a hammer drill or rotary hammer with a drill bit approx. 40 mm in diameterand equal in length to the depth of insertion.• A little water can also be poured into the predrilled borehole before inserting thescrew for optimal lubrication.• If the <strong>ground</strong> does not allow installation by displacement, then there is the optionof partially or fully removing material in the size of the core diameter of the <strong>ground</strong>screw using suitable drilling means.

Driving a <strong>ground</strong> screw into the <strong>ground</strong> generates a turning force or insertion torque.The torque applied during insertion serves to drive the <strong>ground</strong> screw along its axis. Themanufacturing parameters can be automatically determined during quality control.During insertion, the special indications in the operating instructions for the driver ordriving tool must strictly be observed. The foundation-specific requirements must betaken into consideration and the installation performed according to the current state ofthe art.REQUIREMENTS AND SAFETY AT THE CONSTRUCTION SITEAll points marked out for installation of <strong>ground</strong> <strong>screws</strong> must be tested for possibleobstacles such as under<strong>ground</strong> cables, pipelines and building constructions. This musthappen with a safety radius. Built drawings and cable/pipeline plans must be presentedand inspected. For an optimal preparation for building, it is recommended to inspectthe available cabling pipeline plans and to use conventional cable detection deviceson the site. The insertion points and the necessary surrounding space for the drivingmachinery used for installation must be kept freely accessible. Any changes made tothe <strong>ground</strong> after the geological survey has been performed, for instance earthworks,backfill, shifting etc., may require a new survey. Naturally, occurring changes in theearth such as land subsidence, landslide, floods, earthquakes etc. will void all warranty.Liability for damage due to inadequate or faulty structural analysis is excluded. In thecase of swampy <strong>ground</strong>s, high <strong>ground</strong>water levels, softening of the terrain by heavyrainfall or flood, <strong>ground</strong> <strong>screws</strong> may not be installed.TYPES OF FAILUREOverloading improper assembly or <strong>ground</strong> of insufficient load-bearing capacity maycause <strong>ground</strong> <strong>screws</strong> to be pulled out or lead to steel rupture or material failure in thefoundation or to <strong>ground</strong> subsidence.CORROSION PROTECTIONKRINNER Ground Screws and accessories such as fasteners and connectors areprotected against corrosion by hot-dip galvanization according to DIN EN ISO 1461.Depending on the <strong>ground</strong> characteristics, a soil analysis must be performed accordingto DIN 50929 to assess any aggressiveness against galvanized steels. Corrosive attackis a critical factor in the service life of the <strong>ground</strong> <strong>screws</strong> and determines the necessityof corrosion protection measures. If the head plates of the <strong>ground</strong> <strong>screws</strong> ever need tobe drilled on the construction site, then they must be subsequently treated with a zincdust-basedcoating. Wherever required by the application, approved coatings are to berecommended for the surrounding area for the connections to the foundation.Other technical details and information to be taken into consideration are provided inthe technical data sheets on the KRINNER <strong>ground</strong> <strong>screws</strong> atwww.schraubfundamente.de.

SUSTAINABILITYEnvironment & Safety: KRINNER‘s obligationWhen developing new <strong>product</strong>s, KRINNER always focuses on sustainable andnature-friendly solutions.With our <strong>professional</strong> Ground Screws, we do not only achieve cost and time savingsfor our customers, by simple and ecologically sound installation – we also allowclean removal without any sealing of soil. Furthermore, KRINNER Ground Screwsdo not require cost intensive construction site roads that impact vegetation – butmoreover offers vehicles for <strong>ground</strong> conserving transport.Partners, planners, architects, dealers, tradesmen, specialists, and private andpublic building owners all benefit from our innovations and the synergies of ourenvironmental and sustainability policy.ENVIRONMENTAL POLICY & GUIDELINESKRINNER commits itself to make resources available for necessary measures and tosupport the requirements of environmental management. We do this by:• Promoting the use of high quality, regional and environmentally sound <strong>product</strong>s• Selecting and using environmentally safe equipment and materials• Saving energy and water• Reducing waste quantities through selected procurement and reasonable wasteseparation• Adherence to environmental regulations• Continuous improvement of our environmental performance• Covering our own electricity consumption with renewable energy sources

QUALITY MANAGEMENTInnovations for the present and the futureThe satisfaction of our customers and economic efficiency of our actions are the primaryconcerns behind our quality policy. This includes improving all procedures andprocesses in our operations in order to deliver <strong>product</strong>s and services of consistentlyhigh quality and to minimize nonconformity costs.All employees are integrated into the continuous improvement process and contributewith motivation and dedication. Every individual plays his or her part in reachingthe quality objectives in his or her department.• Satisfied customers thanks to cost-efficient <strong>product</strong>s of thedesired quality on the desired deadline• Qualified and motivated employees with personalresponsibility and team spirit• Products and services of consistently high qualityQUALITY MANAGEMENT SUPPORTS THE ACHIEVEMENT OF THESE OBJECTIVESConsistent implementation and continuous improvement of the QM system by allemployees increases the sense of responsibility and motivation and improves theidentification with the company and its <strong>product</strong>s. Clear definition of processes,responsibilities and interfaces ensures greater transparency and efficiency in organization,function and procedure. Friction losses within the company are reducedand the possibility of error is diminished. Specific training and <strong>professional</strong> developmentof employees as well as the use of efficient working methods and techniquesincrease qualifications and motivation.

APPLICATIONSversatile · individual · flexibleOptimal stability and installationwithin minutes impress users fromall industries.KRINNER Ground Screws offer the ideal solution for creating foundations foran extensive range of applications.Objects mounted on <strong>ground</strong> <strong>screws</strong> range from advertising structures andtraffic installations, to hall and container building construction, to applicationsin timber-frame construction and fencing, to urban development andlandscaping.This includes event stands, sports facilities and grandstands, <strong>product</strong>ion,storage and exhibition halls, school buildings, container and detached buildings,disaster control centers, garden sheds, urban furniture, transportfacilities and noise protection systems, large-format advertising, flagpoles,pedestrian bridges, fencing and gate systems, and much more.The high load capacity of the <strong>ground</strong> <strong>screws</strong> and their efficient installationallow architects and building owners to produce a modern, long-lasting foundationwith clear economic advantages.Customers using KRINNER Ground Screws all around the world are impressedwith their handling, stability and versatility.The application examples given in this <strong>product</strong> <strong>catalogue</strong> provide first cuesfor selecting the right kind of <strong>ground</strong> screw.

APPLICATIONSversatile · individual · flexibleTIMBER-FRAME CONSTRUCTIONIdeal for sustainable, efficient and long-term building ideas madewith or entirely of wood.ADVERTISING AND TRAFFIC SystemsThe attractive and cost-efficient alternative thanks to quick anduncomplicated installation.URBAN, garden and landscape constructionAn ecologically and economically optimal and modern solution.HALL AND CONTAINER CONSTRUCTIONQuick, flexible and economical: This is modern construction.FENCING systemsThe optimal solution for almost every terrain:fast, stable and <strong>professional</strong>.SOLAR systemSLong-term environmental soundness and cost savings:The perfect foundation for every <strong>ground</strong> mounted system.

TIMBER-FRAMEcONSTRUCTIONwww.krinner.comTIMBER-FRAME CONSTRUCTIONecological · no concrete · durable

TIMBER-FRAME CONSTRUCTIONecological · no concrete · durableBuilding with wood is a sustainable and future-oriented solution, hence it is only logical to chooseKRINNER Ground Screws for the foundation. The terrain remains untouched and since no soilsealing is required the overall logistical effort is minimal.A big advantage, since the designs and the building process can be planned much more effectivelyand without loss of time.EXAMPLE SOLUTIONS AND APPLICATIONS:Multi-level timberconstructionsCarportsTree housesJetties on waterWooden houses Bridges Grape gardens FencingPergolas/pavilions Decks Pathways StairsRECOMMENDED GROUND SCREWS:Depending on your project requirements, the E Series, F Series and U Series of <strong>ground</strong> <strong>screws</strong> aswell as most of the G Series are especially suitable for timber-frame construction.

www.krinner.comADVERTISINGAND TRAFFIC SystemsADVERTISING AND TRAFFIC Systemsefficient · no concrete · stable

ADVERTISING AND TRAFFIC SIGNPOSTINGefficient · no concrete · stableSaving time and costs, gaining customers and new space – being quick and easy to install, KRINNERGround Screws create attractive and effective alternatives with enormous savings potential.At the same time, creating an entirely new innovative placement for opportunities –foundations can namely be built onto asphalted, paved or greened areas without interfering with the site.EXAMPLE SOLUTIONS AND APPLICATIONS:Advertising pylons Sign plates Advertising on buildings Perimeter advertisingFlagpoles Traffic signposts Delineator posts Expressway signpostingGuideposts Info boards Large-format advertising Advertising boardsRECOMMENDED GROUND SCREWS:Depending on your project requirements, the E Series, F Series, M Series and X Series of <strong>ground</strong><strong>screws</strong> as well as most of the G Series are especially suitable for advertising and traffic signposting.

www.krinner.comURBAN, gardenAND LANDSCAPE constructionURBAN, gardenand landscape constructioneconomical · no concrete · flexible

URBAN, garden and LANDSCAPeconstructioneconomical · no concrete · flexibleOptimize the cityscape quickly, safely and ecologically and simultaneously save costs – KRINNER GroundScrews allow selective construction without major construction sites. The installation of the foundationis completed within few minutes – resulting in an optimal economical as well as ecological solution.No earth removal and no concrete. That not only saves enormous amounts of time, but also savesresidents the burden of major construction sites.EXAMPLE SOLUTIONS AND APPLICATIONS:Shelters & benches Barriers Turnstiles Public sculpturesNoise barriers Art objects Play<strong>ground</strong> equipment Bike shedsPrivacy and soundscreensAwnings & shade systems Trashcans Pylon artOTHER POSSIBLE APPLICATIONS:Video and surveillance systems, shelter and event facilities, streetlamps, ball screens,parking meters and cabinets.RECOMMENDED GROUND SCREWS:Depending on your project requirements, the E Series, F Series, K Series and M Series of <strong>ground</strong><strong>screws</strong> as well as most of the G Series are especially suitable for urban development andlandscaping.

www.krinner.comHALL AND CONTAINERCONSTRUCTIONHALL AND CONTAINERCONSTRUCTIONsafe · no concrete · uncomplicated

HALL AND CONTAINER BUILDINGCONSTRUCTIONsafe · no concrete · uncomplicatedFoundation depths of up to 3.5 meters and the high quality of KRINNER Ground Screws allow evenexpansive constructions to be completed on a tight schedule. Whether for halls or stages, containerbuildings or pre-fabricated garages: All <strong>ground</strong> <strong>screws</strong> are structurally tested and certified for compressive,tensile and horizontal loads according to the most stringent guidelines..Safety and long service life are guaranteed – even under extreme loads.EXAMPLE SOLUTIONS AND APPLICATIONS:Production halls &warehousesOffice container buildingsContainer systemson piersContainer systems fortemporary buildingsVehicle depotsEvent stands &grandstandsContainer buildingswith wood facadesFuturistic modulesGlass houses &greenhousesCube modulesLoading rampsPre-fabricated garagesModular constructions Closed modules Transformer stations Multi-level containerconstructionsRECOMMENDED GROUND SCREWS:Depending on your project requirements, the E Series, M Series and F Series of <strong>ground</strong> <strong>screws</strong> aswell as most of the G Series are especially suitable for hall and container building construction.

www.krinner.comFENCING systemsrational · no concrete · <strong>professional</strong>FENCING systems

FENCINGrational · no concrete · <strong>professional</strong>Garden, industrial or high-security fences; for safety, decoration or security purposes: The KRINNERGround Screws developed specifically for fencing systems present unlimited possibilities for efficientimplementation of any project.Patented eccenter and granulate systems allow precise installation with pinpoint accuracy, regardlessof whether the terrain is flat or hilly.EXAMPLE SOLUTIONS AND APPLICATIONS:Industrial fences Construction site fences Chicken wire fences Ball screensFences on hillsides Wildlife fences Wooden fences Gate systemsRECOMMENDED GROUND SCREWS:Depending on your project requirements, the E Series, F Series, K Series and U Series of <strong>ground</strong><strong>screws</strong> as well as most of the G Series are especially suitable for fencing.

www.krinner.comSOLAR systemSmodular · no concrete · ecologicalSOLAR systemS

SOLAR systemSmodular · no concrete · ecologicalRising energy prices and growing scarcity of fossil resources are driving factors for the developmentand utilization of renewable energy sources. Especially, when it comes to solar energy KRINNERbundles extensive knowledge in foundation construction, energy technology and solar technology tooffer alternatives in the field of renewable energies – alternatives for people and the environment!From system planning, to installation, to the maintenance of customized <strong>ground</strong> mounted solarsolutions for entrepreneurs and investors, we realize the best solutions for obtaining clean energy.EXAMPLE SOLUTIONS AND APPLICATIONS:Gänsdorf, Germany Gänsdorf, Germany Großenpinning, GermanySenftenberg, GermanyLeiwen, GermanyLeibertingen, GermanySchwarzhof, GermanyCarlino, ItalyMelbourne, AustraliaSault Ste. Marie, CanadaSouthern SpainVeprek, Czech Rep.RECOMMENDED SYSTEM:The KRINNER Flex III system is perfectly suited for use in free-standing photovoltaic and CSPsystems. Concrete-free and flexible screw foundations do not seal the soil and can also be ideallyaligned to the sun.

E Serieswww.krinner.comE SERIESThe KRINNER Ground Screw with eccentricadjustment for exact alignment

E SERIESThe KRINNER Ground Screw with eccentricadjustment for exact alignmentThe E Series of <strong>ground</strong> <strong>screws</strong> can be optionally equipped with excenter to suit the applicationconditions. The excenter allows fine adjustment and ensures perfect vertical alignmentof the erected object. The system is especially well suited to resonance- and vibration-dampedinstallation of poles and masts.RECOMMENDED DRIVERS:For correct insertion of E Series <strong>ground</strong> <strong>screws</strong>, use the Ground Screw DriverKR E 10 or KR E 20, KR D 55 driver, or KR B 40, KR B 60 or KR B 250Lot-o-Mat.TIPS FOR INSTALLATION:Before inserting the excenter, fill a small amount of granulate into thescrew foundation. Tap the fixing ring down with a hammer before fixingwith <strong>screws</strong>.• Facilitates tightening of the excenter• Dampens resonance and vibrations

Overview of E SeriesKSF E 140x2100-E76-100 KSF E 140x1600-E76-100 KSF E 140x1300-E76-100 KSF E 89x1000-E60 KSF E 89x800-E60 KSF E 89x550-E60Length (mm)2100 1600 1300 1000 800 550Tube diameter (mm)139.70 139.70 139.70 88.90 88.90 88.90Weight (kg)23.50 18.50 15.00 5.50 4.30 3.50Item number25500 26160 25502 24100 24080 24055KSF E 140x2100-E76-100KSF E 140x1600-E76-100KSF E 140x1300-E76-100KSF E 89x1000-E60KSF E 89x800-E60KSF E 89x550-E60

Technical Data Sheet E SeriesBasic InfoKSF E 140x2100-E76-100KSF E 140x1600-E76-100Nominal length (mm)2100 1600 1300Tube diameter (mm)139.70 139.70 139.70Weight (kg)23.50 18.50 15.00Item number25500 26160 25502KSF E 140x1300-E76-100Construction• Flange: GP240GH• Continuous welded helix• Coating: Hot-dip galvanizedaccording to DIN EN ISO 1461ApplicationsAccessoriesExcenter Set-E76Item No. 26810Excenter Set-E80Item No. 26814Excenter Set-E90Item No. 26813KSF E 140x1300-E76-100Excenter Set-E100Item No. 26809Reducer-E76-E60Item No. 26821Reducer-E76-E70Item No. 26822Cover Plate2 mm-E76-100Item No. 26819Cover Plate8 mm-E76-100Item No. 26829AttachmentScrew-E76-100Item No. 21837Countersunk-E76-100Item No. 26830Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DatafKSF E 140x2100-E76-100KSF E 140x1600-E76-100KSF E 140x1300-E76-100abcLength (mm) (±25 mm)2110 1640 1310Outer diameter (mm)139.70 139.70 139.70Inner diameter (mm)132.50 132.50 132.50ghdDiameter setting* (mm)100 | 90 | 80 | 76** 100 | 90 | 80 | 76** 100 | 90 | 80 | 76**deDepth setting (mm) (±25 mm)975 | 1010 | 1040 | 1040 730 | 775 | 810 | 810 565 | 630 | 650 | 650fThreadi3 x M12 3 x M12 3 x M12gPitch circle diameter (mm)192 192 192ecbhFlange outer diameter (mm)220 220 220iFlange thickness (mm)14 14 14a* The diameter setting (d) determines the depth setting (e)** Tip for installation: To adjust the depth setting, it is recommended to fill inballast or insert an accessory plateOnline ServiceKSF E 140x2100-E76-100KSF E 140x1600-E76-100KSF E 140x1300-E76-100WebkeyE2550011D E2616011D E2550211DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet E SeriesBasic InfoKSF E 89x1000-E60 KSF E 89x800-E60 KSF E 89x550-E60Nominal length (mm)1000 800 550Tube diameter (mm)88.90 88.90 88.90Weight (kg)5.50 4.30 3.50Item number24100 24080 24055Construction• Coating: Hot-dip galvanized according to DIN EN ISO 1461• Continuous welded helix• Patented conical body forged from a single piece of tubingApplicationsKSF E 89x800-E60AccessoriesCover Plate 2 mm-E60Item No. 24808Clamp Ring-E60Item No. 24802Excenter-E60Item No. 24801Fair Level-E60Item No. 24803Excenter Set-E60Item No. 24817Fixing Screw-E60Item No. 21808Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DatagabcdeKSF E 89x1000-E60 KSF E 89x800-E60 KSF E 89x550-E60Length (mm) (±25 mm)1000 800 550Outer diameter (mm)88.90 88.90 88.90Inner diameter (mm)81.70 81.70 81.70Diameter setting* (mm)60 60 60Depth setting (mm) (±25 mm)270 270 270cdifhjfAlignment range3° (incl. Excenter) 3° (incl. Excenter) 3° (incl. Excenter)gThreade3 x M8 3 x M8 3 x M8bhPitch circle diameter (mm)118 118 118iFlange outer diameter (mm)136 136 136jFlange thickness (mm)3 3 3a*Diameter setting (a) result in depth setting (e) and alignment range (f)Online ServiceKSF E 89x1000-E60 KSF E 89x800-E60 KSF E 89x550-E60WebkeyE2410011D E2408011D E2405511DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

www.krinner.comF SERIESF SERIESThe KRINNER Ground Screw with flange platesfor modular use

F SERIESThe KRINNER Ground Screw with flangeplates for modular useThe F Series of <strong>ground</strong> <strong>screws</strong> are equipped with round or rectangular flanges. This allowsthe supported object to be fastened to ensure the greatest stability and safety of heavy oreven extreme static loads.RECOMMENDED DRIVERS:For correct insertion of F Series <strong>ground</strong> <strong>screws</strong>, use the Ground Screw DriverKR E 10 or KR E 20, KR D 55, or KR B 40, KR B 60*or KR B 250* Lot-o-Mat.*Only partially suitable for flat flange.INSTRUCTIONS FOR INSTALLING A GROUND SCREW WITH RECTANGULAR FLANGE (-R):1 2Drive the <strong>ground</strong> screw vertically into the earth. Connect the post anchor to the wood beam.Place the post anchor (with post) onto the flangeplate and align it.3 4Screw the post anchor onto the flange plate.Done.

Overview of F SeriesKSF F 140x2100-M KSF F 140x1600-M KSF F 140x1600-P KSF F 140x1300-P KSF F 76x1600-R KSF F 76x1300-R KSF F 76x1000-R KSF F 76x800-RLength (mm)2100 1600 1600 1300 1600 1300 1000 800Tube diameter (mm)139.7 139.70 139.70 139.70 76.10 76.10 76.10 76.10Weight (kg)24.00 20.00 17.00 13.50 12.00 7.50 6.00 4.50Item number25490 25489 25484 25483 25478 25477 25476 25475KSF F 140x2100-MKSF F 140x1600-MKSF F 140x1600-PKSF F 140x1300-PKSF F 76x1600-RKSF F 76x1300-RKSF F 76x1000-RKSF F 76x800-R

Technical Data Sheet F SeriesBasic InfoKSF F 140x1600-PNominal length (mm)1600 1300Tube diameter (mm)139.70 139.70Weight (kg)17.00 13.50Item number25484 25483KSF F 140x1300-PConstruction• Flange: Sheet metal S355• Continuous welded helix• Coating: Hot-dip galvanized according to DIN EN ISO 1461ApplicationsAccessoriesCover Plate 2 mm-PItem No. 26818KSF F 140x1300-PSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataKSF F 140x1600-PKSF F 140x1300-PfeabcdeLength (mm) (±25 mm)1592 1262Shaft outer diameter (mm)139.70 139.70Inner diameter (mm)132.50 132.50Pitch circle diameter (mm)167 167Pitch circle holes (mm)cdghf6 x ∙ 13 6 x ∙ 13Oblong holebgh6 x ∙ 13 - < 20° 6 x ∙ 13 - < 20°Flange outer diameter (mm)199 199Flange thickness (mm)8 8aOnline ServiceKSF F 140x1600-PWebkeyF2548411DKSF F 140x1300-PF2548311DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet F SeriesBasic InfoKSF F 140x2100-MNominal length (mm)2100 1600Tube diameter (mm)139.70 139.70Weight (kg)24.00 20.00Item number25490 25489KSF F 140x1600-MConstruction• Flange: Sheet metal S355• Continuous welded helix• Coating: Hot-dip galvanized according to DIN EN ISO 1461ApplicationsKSF F 140x1600-MSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataeKSF F 140x2100-MKSF F 140x1600-MabcdeLength (mm) (±25 mm)2065 1665Shaft outer diameter (mm)139.70 139.70Inner diameter (mm)132.50 132.50Pitch circle diameter (mm)180 180Pitch circle holes (mm)cdfgfg12 x ∙ 17 12 x ∙ 17Flange outer diameter (mm)220 220Flange thickness (mm)15 15baOnline ServiceKSF F 140x2100-MWebkeyF2549011DKSF F 140x1600-MF2548911DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet F SeriesBasic InfoKSF F 76x1600-R KSF F 76x1300-R KSF F 76x1000-R KSF F 76x800-RNominal length (mm)1600 1300 1000 800Tube diameter (mm)76.10 76.10 76.10 76.10Weight (kg)12.00 7.50 6.00 4.50Item number25478 25477 25476 25475Construction• Flange: Sheet metal S355• Continuous welded helix• Coating: Hot-dip galvanized according to DIN EN ISO 1461ApplicationsAccessoriesKSF F 76x1300-RPost Bearer Plane-RItem No. 28006Post Bearer M24-RItem No. 28007Post Bearer M44-RItem No. 28008Post Bearer Sword-RItem No. 28009Post BearerSide Flaps-RItem No. 28010Post BearerVario PS150-RItem No. 28019Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

eiTechnical DatakabKSF F 76x1600-R KSF F 76x1300-R KSF F 76x1000-R KSF F 76x800-RLength (mm) (±25 mm)1575 1275 1045 815Shaft outer diameter (mm)76.10 76.10 76.10 76.10djfhcInner diameter (mm)68.90 70.90 70.90 70.90gdHole diameter (mm)6 x ∙ 11 6 x ∙ 11 6 x ∙ 11 6 x ∙ 11ePitch circle diameter (mm)116 116 116 116bcfgFlange length (mm)189 189 189 189Flange thickness (mm)5 5 5 5ahFlange width (mm)140 140 140 140iOblong hole grid size (mm)100 100 100 100jOblong hole length (mm)49 49 49 49kOblong hole diameter (mm)11 11 11 11Post AnchorOnline ServiceKSF F 76x1600-R KSF F 76x1300-R KSF F 76x1000-R KSF F 76x800-RWebkeyF2547811D F2547711D F2547611D F2547511DFlat RM24-RM44-RBlade RSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comSide Tabs RVario PS 150-R

www.krinner.comG SERIESG SERIESThe KRINNER Ground Screwwith thread fixing

G SERIESThe KRINNER Ground Screwwith thread fixingThe G Series of <strong>ground</strong> <strong>screws</strong> are equipped with one, three or four threaded screw connections.They are ideally suited to quick, vertical and permanent assembly of objects such asmasts and fence posts.Optionally, fence posts can also be secured quickly and permanently using thespecial granulate.RECOMMENDED DRIVERS:For correct insertion of G Series <strong>ground</strong> <strong>screws</strong>, use the Ground Screw DriverKR E 10 or KR E 20, KR D 55 driver, or KR B 40, KR B 60 or KR B 250Lot-o-Mat.These <strong>ground</strong> <strong>screws</strong> can also be driven into loose soil using manual drivingtools or lever bars.

Overview of G SeriesKSF G 114x1300-4xM16 KSF G 114x1000-4xM16 KSF G 89x1300-4xM12 KSF G 89x1000-4xM12 KSF G 89x800-4xM12Length (mm)1300 1000 1300 1000 800Tube diameter (mm)114.30 114.30 88.90 88.90 88.90Weight (kg)11.00 8.50 7.80 6.60 5.80Item number25461 25460 25459 25458 25457KSF G 76x2100-3xM16 KSF G 76x1600-3xM16 KSF G 76x1300-3xM16 KSF G 76x800-4xM12 KSF G 66x650-3xM8 KSF G 66x650-1xM8 KSF G 66x550-1xM8Length (mm)2100 1600 1300 800 650 650 550Tube diameter (mm)76.10 76.10 76.10 76.10 66 66 66Weight (kg)14.00 10.50 8.50 3.80 1.85 1.60 1.60Item number25456 25455 25454 24083 25452 20065 20055KSF G 114x1300-4xM16KSF G 114x1000-4xM16KSF G 89x1300-4xM12KSF G 89x1000-4xM12KSF G 89x800-4xM12KSF G 76x2100-3xM16KSF G 76x1600-3x M16KSF G 76x1300-3xM16KSF G 76x800-4xM12KSF G 66x650-3xM8KSF G 66x650-1xM8KSF G 66x550-1xM8

Technical Data Sheet G SeriesBasic InfoKSF G 114x1300-4xM16Nominal length (mm)1300 1000Tube diameter (mm)114.30 114.30Weight (kg)11.00 8.50Item number25461 25460KSF G 114x1000-4xM16Construction• Nut: DIN EN ISO 4032 - 8• Continuous welded helix• Coating: Hot-dip galvanized according to DIN EN ISO 1461ApplicationsAccessoriesKSF G 114x1300-4xM16SpecialGranulate 1500 gItem No. 21824SpecialGranulate 500 gItem No. 21823Screwing Bar long2.40 kgItem No. 24805Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataKSF G 114x1300-4xM16KSF G 114x1000-4xM16abcdefLength (mm) (±25 mm)1300 990Shaft outer diameter (mm)114.30 114.30Inner diameter (mm)107.10 107.10Diameter setting (mm)100 | 90 | 80 | 76 100 | 90 | 80 | 76Depth setting (mm) (±25 mm)490 | 540 | 570 | 590 350 | 400 | 440 | 460Thread4 x M16 4 x M16fbdceaOnline ServiceKSF G 114x1300-4xM16WebkeyG2546111DKSF G 114x1000-4xM16G2546011DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet G SeriesBasic InfoKSF G 89x1300-4xM12 KSF G 89x1000-4xM12 KSF G 89x800-4xM12Nominal length (mm)1300 1000 800Tube diameter (mm)88.90 88.90 88.90Weight (kg)7.80 6.60 5.80Item number25459 25458 25457Construction• Nut: DIN EN ISO 4032 - 8• Continuous welded helix• Coating: Hot-dip galvanized according to DIN EN ISO 1461ApplicationsAccessoriesKSF G 89x1300-4xM12SpecialGranulate 1500 gItem No. 21824SpecialGranulate 500 gItem No. 21823Screwing Bar long2.40 kgItem No. 24805Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataKSF G 89x1300-4xM12 KSF G 89x1000-4xM12 KSF G 89x800-4xM12abcdefLength (mm) (±25 mm)1280 1080 830Shaft outer diameter (mm)88.90 88.90 88.90Inner diameter (mm)83.70 83.70 83.70Diameter setting (mm)76 | 40x60 | 60 | 48 76 | 40x60 | 60 | 48 76 | 40x60 | 60 | 48Depth setting (mm) (±25 mm)970 | 1020 | 1055 | 1090 780 | 830 | 855 | 900 520 | 570 | 600 | 640Thread4 x M12 4 x M12 4 x M12fbdecaOnline ServiceKSF G 89x1300-4xM12 KSF G 89x1000-4xM12 KSF G 89x800-4xM12WebkeyG2545911D G2545811D G2545711DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet G SeriesBasic InfoKSF G 76x2100-3xM16 KSF G 76x1600-3xM16 KSF G 76x1300-3xM16Nominal length (mm)2100 1600 1300Tube diameter (mm)76.10 76.10 76.10Weight (kg)14.00 10.50 8.50Item number25456 25455 25454Construction• Nut: DIN EN ISO 4032 - 8• Continuous welded helix• Coating: Hot-dip galvanized according to DIN EN ISO 1461ApplicationsKSF G 76x1300-3xM16Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataKSF G 76x2100-3xM16 KSF G 76x1600-3xM16 KSF G 76x1300-3xM16aLength (mm) (±25 mm)2080 1580 1280bShaft outer diameter (mm)76.10 76.10 76.10bcInner diameter (mm)68.90 68.90 68.90ddDiameter setting (mm)60 60 60efDepth setting (mm) (±25 mm)1815 1315 1020Thread3 x M16 3 x M16 3 x M16fceaOnline ServiceKSF G 76x2100-3xM16 KSF G 76x1600-3xM16 KSF G 76x1300-3xM16WebkeyG2545611D G2545511D G2545411DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet G SeriesBasic InfoKSF G 76x800-4xM12Nominal length (mm)800Tube diameter (mm)76.10Weight (kg)3.80Item number24083Construction• Nut: DIN EN ISO 4032 - 8• Continuous welded helix• Coating: Hot-dip galvanized according to DIN EN ISO 1461ApplicationsKSF G 76x800-4xM12AccessoriesSpecialGranulate 1500 gItem No. 21824SpecialGranulate 500 gItem No. 21823Screwing Bar long2.40 kgItem No. 24805Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataKSF G 76x800-4xM12abcLength (mm) (±25 mm)810Shaft outer diameter (mm)76.10Inner diameter (mm)70.90bddDiameter setting (mm)70 | 60 | 48 | 40 | 34efDepth setting (mm) (±25 mm)460 | 590 | 650 | 690 | 730Thread4 x M12fceaOnline ServiceKSF G 76x800-4xM12WebkeyG2408311DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet G SeriesBasic InfoKSF G 66x650-3xM8Nominal length (mm)650Tube diameter (mm)66Weight (kg)1.85Item number25452Construction• Nut: DIN EN ISO 4032 - 8• Continuous welded helix• Coating: Hot-dip galvanized according toDIN EN ISO 1461• Patented conical body forgedfrom a single pieceKSF G 66x650-3xM8ApplicationsAccessoriesSpecialGranulate 500 gItem No. 21823Screwing Bar short0.60 kgItem No. 20070Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataKSF G 66x650-3xM8abcLength (mm) (±25 mm)650Shaft outer diameter (mm)66Inner diameter (mm)62bddDiameter setting (mm)62 | 55.5 | 50 | 43 | 38.5 | 34eDepth setting (mm) (±25 mm)210 | 228 | 245 | 276 | 317 | 395ffThread3 x M8ceaOnline ServiceKSF G 66x650-3xM8WebkeyG2545211DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet G SeriesBasic InfoKSF G 66x650-1xM8Nominal length (mm)650 550Tube diameter (mm)66 66Weight (kg)1.80 1.60Item number20065 20055KSF G 66x550-1xM8Construction• Continuous welded helix• Coating: Hot-dip galvanized according to DIN EN ISO 1461• Patented conical body forged from a single pieceKSF G 66x650-1xM8ApplicationsAccessoriesSpecialGranulate 500 gItem No. 21823Reduction Sleeve Set-G660.10 kgItem No. 21806Pivot Linkage Cover-G660.30 kgItem No. 21804Twisting Element-G 660.10 kgItem No. 21839Screwing Bar short0.60 kgItem No. 20070Foundation Cap-G 660.20 kgItem No. 21805Cover Plate-G 660.10 kgItem No. 21856Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataKSF G 66x650-1xM8KSF G 66x550-1xM8abLength (mm) (±20 mm)650 550Shaft outer diameter (mm)66 66bdcInner diameter (mm)62 62dDiameter setting (mm)62 | 55.5 | 50 |43 | 38.5 | 3462 | 55.5 | 50 |43 | 38.5 | 34eDepth setting (mm) (±20 mm)210 | 228 | 245 |276 | 317 | 395110 | 128 | 145 |176 | 217 | 295fcfThread1 x M8 1 x M8eaOnline ServiceKSF G 66x650-1xM8WebkeyG2006511DKSF G 66x550-1xM8G2005511DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

www.krinner.comK SERIESK SERIESThe resistant KRINNER Ground Screwmade of plastic

K SERIESThe resistant KRINNER Ground Screwmade of plasticThe affordable K Series of <strong>ground</strong> <strong>screws</strong> are made of extremely durable plastic and guaranteea long service life. With their conical shape and by using special granulate as a ballast,these foundations achieve remarkable stability values. This series is especially suited toputting up fence posts and signposts.RECOMMENDED DRIVERS:For correct insertion of K Series <strong>ground</strong> <strong>screws</strong>, use the Ground Screw DriverKR E 10 or KR E 20, KR D 55, or KR B 40, KR B 60 or KR B 250Lot-o-Mat. These <strong>ground</strong> <strong>screws</strong> can also be driven into loose soil usingmanual driving tools.INSTRUCTIONS FOR INSTALLING K SERIES GROUND SCREWS:Drive the <strong>ground</strong> screw vertically intothe earth using a manual driver or driving tool.1 2Insert the post into the screw foundationand align it vertically.Fill special granulate into the screw foundationaround the vertical post.3 4Tap the post, e.g. with the handle of a hammer,to compact the granulate. Done.Recommendation for installation: If tensile loads are to be applied, e.g. on a cornerpost, then a cement emulsion must be poured in after installation.

Overview of K SeriesKSF K 60x800 KSF K 42x650 KSF K 34x550Length (mm)800 650 550Weight (kg)1.00 0.60 0.35Item number22080 22065 22000KSF K 60x800KSF K 42x650KSF K 34x550

Technical Data Sheet K SeriesBasic InfoKSF K 60x800 KSF K 42x650 KSF K 34x550Nominal length (mm)800 650 550Weight (kg)1.00 0.60 0.35Item number22080 22065 22000Construction• Material: PP-EPDM• Conical plastic shell with screwthread• UV-stabilized• Surface matt blackApplicationsKSF K 60x800AccessoriesSpecialGranulate 1500 gItem No. 21824SpecialGranulate 500 gItem No. 21823Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DatabKSF K 60x800 KSF K 42x650 KSF K 34x550aLength (mm)800 650 550bcOuter diameter (mm)163 136 98Diameter setting (mm)e75 | 60 x 40 = ∙ 72 | 70 |60 | 48 | 42 | 3448 | 42 | 34 42 | 34dDepth setting (mm)425 | 470 | 480 | 575640 | 660 | 690455 | 500 | 530 325 | 400ceAlignment range3° 2.7° 2.5°daOnline ServiceKSF K 60x800 KSF K 42x650 KSF K 34x550WebkeyK2208011D K2206511D K2200011DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

www.krinner.comM SERIESM SERIESThe KRINNER Ground Screwfor direct mounting on the thread

M SERIESThe KRINNER Ground Screwfor direct mounting on the threadThe M Series of <strong>ground</strong> <strong>screws</strong> have a central M thread that allows the supported object to bebolted directly onto the screw foundation. They are suitable for pre-assembled garages andcontainer buildings, for example.RECOMMENDED DRIVERS:For correct insertion of M Series <strong>ground</strong> <strong>screws</strong>, use the Ground Screw DriverKR E 10 or KR E 20, KR D 55, or KR B 40, KR B 60 or KR B 250Lot-o-Mat.

Overview of M SeriesKSF M 140x2100-M24 KSF M 114x2100-M24 KSF M 114x1600-M24 KSF M 114x1300-M24 KSF M 89x2100-M24 KSF M 89x1600-M24 KSF M 89x1300-M24Nominal length (mm)2100 2100 1600 1300 2100 1600 1300Tube diameter (mm)139.70 114.30 114.30 114.30 88.90 88.90 88.90Weight (kg)26.00 21.00 16.00 13.00 18.00 14.00 11.50Item number25400 25352 25351 25350 25302 25301 25300KSF M 76x2100-M16 KSF M 76x1600-M16 KSF M 76x1300-M16 KSF M 76x1300-M12 KSF M 76x1000-M12 KSF M 76x800-M12Nominal length (mm)2100 1600 1300 1300 1000 800Tube diameter (mm)76.10 76.10 76.10 76.10 76.10 76,10Weight (kg)16.00 12.50 10.00 7.00 5.30 4,20Item number25204 25203 25202 25201 25205 25200KSF M 140x2100-M24KSF M 114x2100-M24KSF M 114x1600-M24KSF M 114x1300-M24KSF M 89x2100-M24KSF M 89x1600-M24KSF M 89x1300-M24KSF M 76x2100-M16KSF M 76x1600-M16KSF M 76x1300-M16KSF M 76x1300-M12KSF M 76x1000-M12KSF M 76x800-M12

Technical Data Sheet M SeriesBasic InfoKSF M 140x2100-M24KSF M 114x2100-M24KSF M 114x1600-M24Nominal length (mm)2100 2100 1600 1300Tube diameter (mm)139.70 114.30 114.30 114.30Weight (kg)26 21 16 13Item number25400 25352 25351 25350KSF M 114x1300-M24Construction• Flange: Sheet metal S355• Nut: DIN EN ISO 4032-8• Continuous welded helix• Coating: Hot-dip galvanized accordingto DIN EN ISO 1461ApplicationsKSF M 140x2100-M24Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataKSF M 140x2100-M24KSF M 114x2100-M24KSF M 114x1600-M24KSF M 114x1300-M24gaLength (mm) (±25 mm)2070 2075 1575 1325hebShaft outer diameter (mm)139.70 114.30 114.30 114.30dfcdInner diameter (mm)132.50 107.10 107.10 107.10ThreadM24 M24 M24 M24ibePitch circle diameter (mm)180 150 150 150cfPitch circle holes (mm)ghi6 x ∙ 14 6 x ∙ 14 6 x ∙ 14 6 x ∙ 14Flange wrench size (mm)200 160 160 160Flange outer diameter (mm)225 182 182 182Flange thickness (mm)10 10 10 10aOnline ServiceKSF M 140x2100-M24KSF M 114x2100-M24KSF M 114x1600-M24KSF M 114x1300-M24WebkeyM2540011D M2535211D M2535111D M2535011DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet M SeriesBasic InfoKSF M 89x2100-M24 KSF M 89x1600-M24 KSF M 89x1300-M24Nominal length (mm)2100 1600 1300Tube diameter (mm)88.90 88.90 88.90Weight (kg)18.00 14.00 11.50Item number25302 25301 25300Construction• Flange: Sheet metal S355• Nut: DIN EN ISO 4032-8• Continuous welded helix• Coating: Hot-dip galvanized accordingto DIN EN ISO 1461ApplicationsKSF M 89x1600-M24Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataKSF M 89x2100-M24 KSF M 89x1600-M24 KSF M 89x1300-M24gabcdLength (mm) (±25 mm)2080 1580 1280Shaft outer diameter (mm)88.90 88.90 88.90Inner diameter (mm)81.70 81.70 81.70ThreadM24 M24 M24idhfeePitch circle diameter (mm)150 150 150cfPitch circle holes (mm)6 x ∙ 14 6 x ∙ 14 6 x ∙ 14bgFlange wrench size (mm)160 160 160hFlange outer diameter (mm)182 182 182iFlange thickness (mm)10 10 10aOnline ServiceKSF M 89x2100-M24 KSF M 89x1600-M24 KSF M 89x1300-M24WebkeyM2530211D M2530111D M2530011DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet M SeriesBasic InfoKSF M 76x2100-M16 KSF M 76x1600-M16 KSF M 76x1300-M16Nominal length (mm)2100 1600 1300Tube diameter (mm)76.10 76.10 76.10Weight (kg)16.00 12.50 10.00Item number25204 25203 25202Construction• Flange: Sheet metal S355• Nut: DIN EN ISO 4032-8• Continuous welded helix• Coating: Hot-dip galvanized accordingto DIN EN ISO 1461ApplicationsKSF M 76x1300-M16Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataKSF M 76x2100-M16 KSF M 76x1600-M16 KSF M 76x1300-M16gabcdLength (mm) (±25 mm)2078 1578 1278Shaft outer diameter (mm)76.10 76.10 76.10Inner diameter (mm)68.90 68.90 68.90ThreadM16 M16 M16idhfeePitch circle diameter (mm)150 150 150cfPitch circle holes (mm)6 x ∙ 14 6 x ∙ 14 6 x ∙ 14bgFlange wrench size (mm)160 160 160hFlange outer diameter (mm)182 182 182iFlange thickness (mm)8 8 8aOnline ServiceKSF M 76x2100-M16 KSF M 76x1600-M16 KSF M 76x1300-M16WebkeyM2520411D M2520311D M2520211DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet M SeriesBasic InfoKSF M 76x1300-M12 KSF M 76x1000-M12 KSF M 76x800-M12Nominal length (mm)1300 1000 800Tube diameter (mm)76.10 76.10 76.10Weight (kg)7.00 5.30 4.20Item number25201 25205 25200Construction• Flange: Sheet metal S355• Nut: DIN EN ISO 4032-8• Continuous welded helix• Coating: Hot-dip galvanized accordingto DIN EN ISO 1461ApplicationsKSF M 76x1000-M12Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataKSF M 76x1300-M12 KSF M 76x1000-M12 KSF M 76x800-M12gabcdLength (mm) (±25 mm)1275 1045 815Shaft outer diameter (mm)76.10 76.10 76.10Inner diameter (mm)70.90 70.90 70.90Thread (mm)M12 M12 M12idhfeePitch circle diameter (mm)116 116 116cfPitch circle holes (mm)6 x ∙ 11 6 x ∙ 11 6 x ∙ 11bgFlange wrench size (mm)120 120 120hFlange outer diameter (mm)136 136 136iFlange thickness (mm)5 5 5aOnline ServiceKSF M 76x1300-M12 KSF M 76x1000-M12 KSF M 76x800-M12WebkeyM2520111D M2520511D M2520011DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

www.krinner.comU SERIESU SERIESThe KRINNER Ground Screwfor easy beam assembly

U SERIESThe KRINNER Ground Screwfor easy beam assemblyThe U Series of <strong>ground</strong> <strong>screws</strong> are specially designed for all common dimensions of woodbeams. They are optimally suited to quick and easy fastening of lying beams or standingposts as well as for constructing carports and wooden decks.RECOMMENDED DRIVERS:For correct insertion of U Series <strong>ground</strong> <strong>screws</strong>, use the Ground Screw DriverKR E 10 or KR E 20. These Ground Screws can also be driven into loose soilusing screwing bar short or manual Ground Screw Drivers.INSTRUCTIONS FOR INSTALLING U SERIES GROUND SCREWS:1Place the wood post centered in the post shoewith about a 1 to 2 cm gap at the base.2For optimum stabilization, we recommend fixingthe center with a through-bolt. Drill the hole forthis from both sides.3Fasten the post to one of the U tabs with the firstscrew. Then align the post vertically and fastenwith the second screw.4Now press the fastened post down verticallyand screw it tight to the tab on the other sideof the U.

Overview of U SeriesKSF U 66x865-111 KSF U 66x730-111 KSF U 66x865-91 KSF U 66x730-91 KSF U 66x730-71 KSF U 66x550-71Length (mm)865 730 865 730 730 550Tube diameter (mm)66 66 66 66 66 66Weight (kg)2.90 2.80 2.90 2.70 2.60 2.20Item number21066 21062 21065 21061 21063 21060KSF U 66x865-111KSF U 66x730-111KSF U 66x865-91KSF U 66x730-91KSF U 66x730-71KSF U 66x550-71

Technical Data Sheet U SeriesBasic InfoKSF U 66x865-111 KSF U 66x730-111Nominal length (mm)865 730Tube diameter (mm)66 66Weight (kg)2.90 2.80Item number21066 21062Construction• Coating: Hot-dip galvanized according to DIN EN ISO 1461• Continuous welded helix• Patented conical body forged from a single piece of tubingKSF U 66x730-111ApplicationsAccessoriesScrewing Bar short0.60 kgItem No. 20070Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataabcdefghiKSF U 66x865-111 KSF U 66x730-111Length (mm)865 730Shaft outer diameter (mm)66 66Square hole spacing (mm)42 42Middle square hole spacing (mm)90 90Square hole spacing (mm)50 50Square hole diameter* (mm)11 11Gauge (mm)111 111U profile width (mm)70 70U profile depth (mm)130 130iagbh* To fit M10 carriage boltsOnline ServiceKSF U 66x865-111 KSF U 66x730-111dcfeWebkeyU2106611DU2106211DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet U SeriesBasic InfoKSF U 66x865-91 KSF U 66x730-91Nominal length (mm)865 730Tube diameter (mm)66 66Weight (kg)2.90 2.70Item number21065 21061Construction• Coating: Hot-dip galvanized according to DIN EN ISO 1461• Continuous welded helix• Patented conical body forged from a single piece of tubingKSF U 66x730-91ApplicationsAccessoriesScrewing Bar short0.60 kgItem No. 20070Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataabcdefghiKSF U 66x865-91 KSF U 66x730-91Length (mm)865 730Shaft outer diameter (mm)66 66Square hole spacing (mm)42 42Middle square hole spacing (mm)90 90Square hole spacing (mm)50 50Square hole diameter* (mm)11 11Gauge (mm)91 91U profile width (mm)70 70U profile depth (mm)130 130iagbh* To fit M10 carriage boltsOnline ServiceKSF U 66x865-91 KSF U 66x730-91dcfeWebkeyU2106511DU2106111DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet U SeriesBasic InfoKSF U 66x730-71 KSF U 66x550-71Nominal length (mm)730 550Tube diameter (mm)66 66Weight (kg)2.60 2.20Item number21063 21060Construction• Coating: Hot-dip galvanized according to DIN EN ISO 1461• Continuous welded helix• Patented conical body forged from a single piece of tubingKSF U 66x730-71ApplicationsAccessoriesScrewing Bar short0.60 kgItem No. 20070Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataabcdefghiKSF U 66x730-71 KSF U 66x550-71Length (mm)730 550Shaft outer diameter (mm)66 66Square hole spacing (mm)42 42Middle square hole spacing (mm)90 90Square hole spacing (mm)50 50Square hole diameter* (mm)11 11Gauge (mm)71 71U profile width (mm)70 70U profile depth (mm)130 130iagbh* To fit M10 carriage boltsOnline ServiceKSF U 66x730-71 KSF U 66x550-71WebkeyU2106311DU2106011DdcfeSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

www.krinner.comX SERIESX SERIESThe KRINNER Ground Screwfor special applications

X SERIESThe KRINNER Ground Screwfor special applicationsThe X series of <strong>ground</strong> <strong>screws</strong> have been developed for special applications – a kind oftailored foundation. The foundations are custom manufactured to fit requirements exactly.RECOMMENDED DRIVERS:For correct insertion of X Series Ground Screws, use the Ground Screw DriverKR E 10 or KR E 20 or the KR D 55 driver.These Ground Screws can also be driven into loose soil using manualscrewing bar short or Ground Screw Driver.

Overview of X SeriesKSF X 130x350-LPLength (mm)350Tube diameter (mm)178Weight (kg)0.60Item number22040KSF X 130x350-LP

Technical Data Sheet X SeriesBasic InfoKSF X 130x350-LPNominal length (mm)350Tube diameter (mm)178Weight (kg)0.60Item number22040Construction• Material: PP-EPDM• Conical plastic shell open at bothends with screw thread• UV-stabilized• Surface matt blackApplicationsKSF X 130x350-LPAccessoriesCover Sleeve-LPItem No. 22801Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical DataKSF X 130x350-LPabLength (mm)350Outer diameter (mm)178c/dbcInner diameter (mm)125dDiameter setting (mm)125eDepth setting (mm)150eaOnline ServiceKSF X 130x350-LPWebkeyX2204011DSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

www.krinner.comDRIVERSEffective solutions to optimizedriving in every situation.DRIVERS

DRIVERSEffective solutions to optimize driving inevery situation.KRINNER Ground Screws are driven into the <strong>ground</strong> using machinery and equipmentspecially developed by KRINNER promising a quick, easy and accurate performance.KRINNER offers optimal driving solutions for everything from simple grass meadowsto stiff soil conditions (Class V) and difficult rock conditions (Class VII). The range includespre-drilling gear for difficult rock conditions.

Technical Data Sheet KR E 10 Ground Screw DriverBasic InfoKR E 10 Ground Screw Driver-Z1*Electrical connection230 VLoad torque1st gear up to max. 3,000 NmPower1,800 WDirection of rotationRight/leftWeight20 kgItem number22925WebkeyMA2292511DTo drive small to medium-sized <strong>ground</strong> <strong>screws</strong> into the soil up to Class IIImanually. As for pinpoint accuracy and easy installation, we recommend predrillingwith a hammer drill or rotary hammer. The drill bit should be at least40 mm in diameter and approximately 800 mm long. A little water can also bepoured into the borehole after drilling for optimal lubrication.*Sales is subject to approvalSubject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

AccessoriesKR E 10 Linkage10.00 kg,Length: 1.70–2.80 mItem No. 22926KR E 10/20 Bar4.30 kgItem No. 21899Z1 Attachment-E1406.80 kgItem No. 21838Z1 Attachment-P894.20 kgItem No. 21829Z1 Attachment-F12345674.20 kgItem No. 21841Z1 Attachment-I1148.90 kgItem No. 21894Z1 Attachment-I1148.90 kgItem No. 21889Z1 Attachment-A76-33.40 kgItem No. 21892Z1 Attachment-A76-43.40 kgItem No. 21845Z1 Attachment-T663.70 kgItem No. 21833Z1 Attachment-V665.30 kgItem No. 22910Z1 Attachment-K6010.50 kgItem No. 22907Z1 Displacement-K608.60 kgItem No. 22908Z1 Attachment-K427.50 kgItem No. 22909Z1 Attachment-K343.80 kgItem No. 22904Z1 Attachment-U662.40 kgItem No. 21832Z1 Attachment-X13014.80 kgItem No. 22901Z1 Extension-L03-Z13.80 kgItem No. 21850Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet KR E 20 Ground Screw DriverBasic InfoKR E 20 Ground Screw Driver-Z1Electrical connection230 VLoad torque2nd gear up to max. 3,600 NmPower1,800 WDirection of rotationRight/leftWeight17.50 kgItem number21880WebkeyMA2188011DTo drive small to medium-sized <strong>ground</strong> <strong>screws</strong> into the soil up to Class IIImanually. As for pinpoint accuracy and easy installation, we recommend predrillingwith a hammer drill or rotary hammer. The drill bit should be at least40 mm in diameter and approximately 800 mm long. A little water can also bepoured into the borehole after drilling for optimal lubrication.Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

AccessoriesKR E 20 Linkage17.50 kg, Length:Min.: 1.70 m, Max.: 2.80 mItem No. 21883KR E 10/20 Bar4.30 kgItem No. 21899Z1 Attachment-E1406.80 kgItem No. 21838Z1 Attachment-P894.20 kgItem No. 21829Z1 Attachment-F12345674.20 kgItem No. 21841Z1 Attachment-I1148.90 kgItem No. 21894Z1 Attachment-A89-44.90 kgItem No. 21889Z1 Attachment-A76-33.40 kgItem No. 21892Z1 Attachment-A76-43.40 kgItem No. 21845Z1 Attachment-T663.70 kgItem No. 21833Z1 Attachment-V665.30 kgItem No. 22910Z1 Attachment-K6010.50 kgItem No. 22907Z1 Displacement-K608.60 kgItem No. 22908Z1 Attachment-K427.50 kgItem No. 22909Z1 Attachment-K343.80 kgItem No. 22904Z1 Attachment-U662.40 kgItem No. 21832Z1 Attachment-X13014.80 kgItem No. 22901Z1 Extension-L03-Z13.80 kgItem No. 21850Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet KR H Manual Screwing ToolBasic InfoKR H Manual Screwing Tool-Z1Weight12.00 kgItem number21842WebkeyMA2184211DTo drive small to medium-sized <strong>ground</strong> <strong>screws</strong> into the soil up to Class IIImanually. As for pinpoint accuracy and easy installation, we recommend predrillingwith a hammer drill or rotary hammer. The drill bit should be at least40 mm in diameter and approximately 800 mm long. A little water can alsobe poured into the predrilled borehole before inserting the screw for optimallubrication.Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

AccessoriesZ1 Attachment-E1406.80 kgItem No. 21838Z1 Attachment-P894.20 kgItem No. 21829Z1 Attachment-F12345674.20 kgItem No. 21841Z1 Attachment-I1148.90 kgItem No. 21894Z1 Attachment-A89-44.90 kgItem No. 21889Z1 Attachment-A76-33.40 kgItem No. 21892Z1 Attachment-A76-43.40 kgItem No. 21845Z1 Attachment-T663.70 kgItem No. 21833Z1 Attachment-V665.30 kgItem No. 22910Z1 Attachment-K6010.50 kgItem No. 22907Z1 Displacement-K608.60 kgItem No. 22908Z1 Attachment-K427.50 kgItem No. 22909Z1 Attachment-K343.80 kgItem No. 22904Z1 Attachment-U662.40 kgItem No. 21832Z1 Attachment-X13014.80 kgItem No. 22901Z1 Extension-L03-Z13.80 kgItem No. 21850Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet S1 Manual Screwing ToolBasic InfoS1 Manual Screwing Tool-K34Weight6.70 kgItem number22900WebkeyMA2290011DTo drive KSF K34 x 550 <strong>ground</strong> <strong>screws</strong> into soft to medium soil types manually.As for pinpoint accuracy and easy installation, we recommend pre-drilling witha hammer drill or rotary hammer. The drill bit should be at least 40 mm in diameterand approximately 800 mm long. A little water can also be poured intothe predrilled borehole before inserting the screw for optimal lubrication.Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical Data Sheet KR D 55 Ground Screw DriversBasic InfoKR D 55 Ground Screw Driver-L30-F3KR D 55 Ground Screw Driver-L40-F3Load torqueMax. 5,000 NmDimensions1.20 m wide x 3.00 mlong (incl. mast)Max. 5,000 Nm1.20 m wide x 4.00 mlong (incl. mast)Height of mast3.75 m (erected) 4.75 m (erected)Direction of rotationRight/leftRight/leftWeight1,300 kg 1,400 kgItem number27500 27510WebkeyMA2750011DMA2751011DThe KR D 55 Ground Screw Driver is designed for easy insertion into soil classVII (difficult rock) within minutes in combination with appropriate pre-drillingequipment. The powerful, self-turning KR D 55 Ground Screw Driver is suitedto medium to large-scale projects. It easily drives in <strong>ground</strong> <strong>screws</strong> up to 2 min length.Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

AccessoriesF3 Attachment-E14010.00 kgItem No. 21901F3 Attachment-P897.00 kgItem No. 21904F3 Attachment-F12345677.40 kgItem No. 21902F3 Extension-L04-W809.00 kgItem No. 27125W80 Attachment-F12345679.00 kgItem No. 21912F3 Attachment-A114-38.40 kgItem No. 21907F3 Attachment-A89-410.00 kgItem No. 21906F3 Attachment-A76-311.70 kgItem No. 21903F3 Attachment-A76-410.60 kgItem No. 21905F3 Connection Flange-F22.00 kgItem No. 21908F3 Attachment-W1606.50 kgItem No. 21911F3 Attachment-Q604.00 kgItem No. 27133F2-W140 Attachment-K6010.00 kgItem No. 22912F2-W140 Displacement-K608.00 kgItem No. 22911F2-W140 Gimlet 80 x 200021.00 kgItem No. 28032F2-W140 Gimlet 135 x 200037.00 kgItem No. 28033F2-W140 Rock Hammer72 mm60.00 kgItem No. 28059F2-W140 Rock Hammer90 mm90.00 kgItem No. 28058F2-W140 Rock Hammer140 mm120.00 kgItem No. 28065RV50 Hydraulic Hammer215.00 kgItem No. 27080Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet KR B 40-B1 Ground Screw DriverBasic InfoKR B 40-B1 Ground Screw DriverLoad torqueMax. 5,000 NmDirection of rotationRight/leftWeight240 kgItem number27501WebkeyMA2750111DThe KR B 40 Ground Screw Driver is designed for easy insertion into soil classVII (difficult rock) within minutes in combination with appropriate pre-drillingequipment. The machine is to be mounted on a carrier machine (excavator)of 1.5 t to 3.0 t deadweight, in compliance with the tipping load chart of theexcavator. The excavator-mounted machine is equipped with a Lehnhoff 01/03quick coupling. Please inquire about compatibility with other models.Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Accessory ChartGround Screw Accessory Quantity/pcsE SERIESKSF E 140x2100-E76-100 KR B B1 Clamping Jaw-W220 3KSF E 140x1600-E76-100 KR B B1 Clamping Jaw-W220 3KSF E 140x1300-E76-100 KR B B1 Clamping Jaw-W220 3KSF E 89x1000-E60 KR B F2-W140 Attachment-P89 3KSF E 89x800-E60 KR B F2-W140 Attachment-P89 3KSF E 89x550-E60 KR B F2-W140 Attachment-P89 3F SERIESKSF F 140x1600-P KR B B1 Clamping Jaw-W220 3KSF F 140x1300-P KR B B1 Clamping Jaw-W220 3KSF F 140x2100-M KR B B1 Clamping Jaw-W220 3KSF F 140x1600-M KR B B1 Clamping Jaw-W220 3KSF F 76x1600-R KR B B1 Clamping Jaw-W140 and B1 Clamping Jaw-W200 2 eachKSF F 76x1300-R KR B B1 Clamping Jaw-W140 and B1 Clamping Jaw-W200 2 eachKSF F 76x1000-R KR B B1 Clamping Jaw-W140 and B1 Clamping Jaw-W200 2 eachKSF F 76x800-R KR B B1 Clamping Jaw-W140 and B1 Clamping Jaw-W200 2 eachG SERIESKSF G 114x1300-4xM16 KR B B1 Clamping Jaw-G114 4KSF G 114x1000-4xM16 KR B B1 Clamping Jaw-G114 4KSF G 89x1300-4xM12 KR B B1 Clamping Jaw-G89 4KSF G 89x1000-4xM12 KR B B1 Clamping Jaw-G89 4KSF G 89x800-4xM12 KR B B1 Clamping Jaw-G89 4KSF G 76x2100-3xM16 KR B B1 Clamping Jaw-G76 3KSF G 76x1600-3xM16 KR B B1 Clamping Jaw-G76 3KSF G 76x1300-3xM16 KR B B1 Clamping Jaw-G76 3KSF G 76x800-4xM12 KR B B1 Clamping Jaw-G76 4KSF G 66x650-3xM8 KR B B1 Clamping Jaw-G66 3K SERIESKSF K 60x800 KR B F2-W140 Attachment-K60 3KSF K 60x800 KR B F2-W140 Displacer-K60 3M-SERIESKSF M 140x2100-M24 KR B B1 Clamping Jaw-W200 3KSF M 114x2100-M24 KR B B1 Clamping Jaw-W160 3KSF M 114x1600-M24 KR B B1 Clamping Jaw-W160 3KSF M 114x1300-M24 KR B B1 Clamping Jaw-W160 3KSF M 89x2100-M24 KR B B1 Clamping Jaw-W160 3KSF M 89x1600-M24 KR B B1 Clamping Jaw-W160 3KSF M 89x1300-M24 KR B B1 Clamping Jaw-W160 3KSF M 76x2100-M16 KR B B1 Clamping Jaw-W160 3KSF M 76x1600-M16 KR B B1 Clamping Jaw-W160 3KSF M 76x1300-M16 KR B B1 Clamping Jaw-W160 3KSF M 76x1300-M12 KR B B1 Clamping Jaw-W120 3KSF M 76x1000-M12 KR B B1 Clamping Jaw-W120 3KSF M 76x800-M12 KR B B1 Clamping Jaw-W120 3Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable

Technical Data SheetAccessories for KR B DriversB1 Clamping Jaw-W1201.50 kgItem No. 28060B1 Clamping Jaw-W1401.30 kgItem No. 28012B1 Clamping Jaw-W1601.25 kgItem No. 28036B1 Clamping Jaw-W1801.20 kgItem No. 28073B1 Clamping Jaw-W2001.20 kgItem No. 28013B1 Clamping Jaw-W2201.10 kgItem No. 28014B1 Clamping Jaw-W2451.10 kgItem No. 28026B1 Clamping Jaw-W3001.40 kgItem No. 28047B1 Clamping Jaw-G60 PLUS2.30 kgItem No. 27142B1 Clamping Jaw-G602.21 kgItem No. 28021B1 Clamping Jaw-S602.35 kgItem No. 27141B1 Clamping Jaw-G662.10 kgItem No. 28015B1 Clamping Jaw-G762.00 kgItem No. 28016B1 Clamping Jaw-G892.10 kgItem No. 28017B1 Clamping Jaw-G1141.85 kgItem No. 28018F2-W140 Attachment-K6010.30 kgItem No. 22912F2-W140 Displacement-K6010.30 kgItem No. 22911F2-W140 Attachment-P897.00 kgItem No. 22913Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data SheetAccessories for KR B Ground Screw Drivers (to be continued)W160 Adapter-F21.30 kgItem No. 27505W200 Adapter-F233.50 kgItem No. 27508W220 Adapter-F233.00 kgItem No. 27507F2-W140 Gimlet 80x200021.00 kgItem No. 28032F2-W140 Gimlet 135x200037.00 kgItem No. 28033F2-W140 Rock Hammer72 mm60.00 kgItem No. 28059F2-W140 Rock Hammer90 mm90.00 kgItem No. 28058F2-W140 Rock Hammer140 mm120.00 kgItem No. 28065Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.com

Technical Data Sheet KR B 60-B1 Ground Screw DriverBasic InfoKR B 60-B1 Ground Screw DriverLoad torqueMax. 10,000 NmDirection of rotationRight/leftWeight330 kgItem number27502WebkeyMA2750211DThe KR B 60 Ground Screw Driver is designed for easy insertion into soil class VII(difficult rock) within minutes in combination with appropriate pre-drilling equipment.The machine is to be mounted on a carrier machine (excavator) of 5.0 tto 12.0 t deadweight, in compliance with the tipping load chart of the excavator.The excavator-mounted machine is equipped with a Lehnhoff 08 quick coupling.Please inquire about compatibility with other models.Subject to technical change!Krinner Schraubfundamente GmbH | Passauer Straße 55 | D-94342 StraßkirchenPhone: +49 9424 9401-80 | E-Mail: service@krinner.com | www.krinner.comefficient · no concrete · durable