S W F / B - T 12 01 C S W F / E - T 1 2 01 C - Amatec

S W F / B - T 12 01 C S W F / E - T 1 2 01 C - Amatec

S W F / B - T 12 01 C S W F / E - T 1 2 01 C - Amatec

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

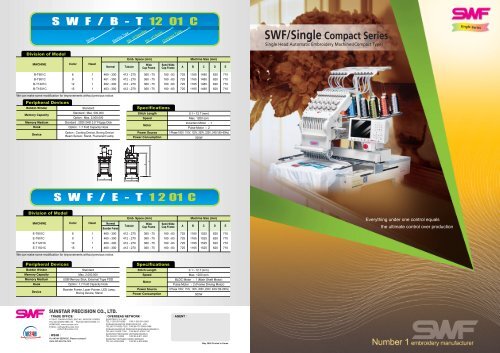

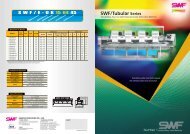

S W F / B - T <strong>12</strong> <strong>01</strong> CSeriesMachine TypeNo. of NeedlesNo. of HeadsCompact TypeDivision of ModelMACHINE Color HeadNormalEmb. Space (mm)TubularWideCap FrameSemi-WideCap FrameMachine Size (mm)A B C D EB-T6<strong>01</strong>C 6 1 460 300 4<strong>12</strong> 270 360 75 180 83 725 1165 1480 620 710B-T9<strong>01</strong>C 9 1 461 300 4<strong>12</strong> 270 360 75 180 83 725 1165 1480 620 710B-T<strong>12</strong><strong>01</strong>C <strong>12</strong> 1 462 300 4<strong>12</strong> 270 360 75 180 83 725 1165 1480 620 710B-T15<strong>01</strong>C 15 1 463 300 4<strong>12</strong> 270 360 75 180 83 725 1165 1480 620 710We can make some modification for improvements without previous notice.Peripheral DevicesBobbin WinderMemory CapacityMemory MediumHookDeviceStandardStandard : Max. 500,000Option : Max. 2,000,000Standard : 2DD/2HD 3.5” Floppy DiskOption : 1.7 Fold Capacity HookOption : Cording Device, Boring DeviceBeam Sensor, Stand, Fluorecent LampSpecificationsStitch Length0.1 ~ <strong>12</strong>.7 (mm)SpeedMax. <strong>12</strong>00 rpmInduction Motor 1MotorPulse Motor 2Power Source 1-Phase 100V, 110V, <strong>12</strong>0V, 200V, 220V, 240V (50~60Hz)Power Consumption500WDivision of ModelS W F / E - T 1 2 <strong>01</strong> CMACHINE Color HeadNormalBoarder FrameEmb. Space (mm)TubularWideCap FrameSemi-WideCap FrameMachine Size (mm)A B C D EE-T6<strong>01</strong>C 6 1 460 300 4<strong>12</strong> 270 360 75 180 83 725 1165 1525 620 710E-T9<strong>01</strong>C 9 1 460 300 4<strong>12</strong> 270 360 75 180 83 725 1165 1525 620 710E-T<strong>12</strong><strong>01</strong>C <strong>12</strong> 1 460 300 4<strong>12</strong> 270 360 75 180 83 725 1165 1525 620 710E-T15<strong>01</strong>C 15 1 460 300 4<strong>12</strong> 270 360 75 180 83 725 1165 1525 620 710We can make some modification for improvements without previous notice.Peripheral DevicesBobbin WinderMemory CapacityMemory MediumHookDeviceStandardMax. 2,000,000USB Memory Stick, External Type FDDOption : 1.7 Fold Capacity HookBoarder Frame, Laser Pointer, LED Lamp,Boring Device, StandSpecificationsStitch Length0.1 ~ <strong>12</strong>.7 (mm)SpeedMax. <strong>12</strong>00 rpmBLDC Motor 1 (Main Shaft Motor)MotorPulse Motor 2 (Frame Driving Motor)Power Source 1-Phase 100V, 110V, <strong>12</strong>0V, 200V, 220V, 240V (50~60Hz)Power Consumption500WSUNSTAR PRECISION CO., LTD.| TRADE OFFICE |#178-67, GAJWA-DONG, SEO-KU, INCHON, KOREATEL:(82-32)580-5980~93 FAX:(82-32)579-8350~51HOMPAGE: www.sunstar.co.krE-MAIL: swftrade@sunstar.comswftech@sunstar.com| W24H |For W24H SERVICE, Please contact!!www.swf-service.com| OVERSEAS NETWORK | | AGENT |SUNSTAR U.S.A. INCTEL:1-305-591-9596 FAX:1-305-591-0661FOSHAN SUNSTAR PRECISION CO., LTD.TEL:86-757-8520-7222 FAX:86-757-8563-0468FOSHAN SUNSTAR PRECISION SHANGHAI BRANCHTEL:86-21-6353-7146 FAX:86-21-6353-7147SUNSTAR PRECISION VIETNAM BRANCHTEL:84-8-811-6990 FAX:84-8-811-6991SUNSTAR VIETNAM (HANOI) BRANCHTEL:84-4-835-8360 FAX:84-4-835-8360May 2006 Printed in Korea

SWF/B-T6<strong>01</strong>C/9<strong>01</strong>C/<strong>12</strong><strong>01</strong>C/15<strong>01</strong>CTUBULAR COMPACT Machine"Fast, efficient and compact.The SWF range of compact single head machinesbring embroidery into the smallest spaces.As well as being the ideal industrial single headembroidery machine, low noise makes them perfectfor home, shop or exhibition use as well."SWF/E-T6<strong>01</strong>C/9<strong>01</strong>C/<strong>12</strong><strong>01</strong>C/15<strong>01</strong>CBorder WorkInstall the easy-to-remove border table to do anything possiblewith a flat embroidery machine.Tubular WorkYou can embroider large T-shirts, sweaters, as well as small pieces.GreasingThe drop-type greasing is easy for users and maintains clean work environment.Cap WorkPractical range of embroidery - from the center of the cap to the both sides.Durable Ceramic EyeletAdoption of durable ceramic eyelets in all thread coursesprevents wear-out of the courses.High-Speed Embroidery<strong>12</strong>00rpm of high-speed embroideryNew Control BoxSWF/B-T6<strong>01</strong>C- Convenient A/S due to the rack-type structure- Free voltage- Smaller control box- Complicated cabling -freethanks to the backplane boardEverything under one control equalsthe Option ultimate Parts Control over productionOperationExpanded Memory SizeThe machine can store a maximum of 100 design. The basic memory sizeis 2 million stitch.Mirror Image Conversion and Design DirectionYou can turn the from 0 to 359 in the increments of 1 and also reversethe design in the X direction(mirror image).Enlarging and Reduction DesignYou can reduce or enlarge the embroidery design in size from 50% to200% by 1% along the X and Y axis.Automatic Selection of Needle BarYou can select the order of the needle bars up to the 99th.General Repetition WorkThe same design can be repeated up to 99 times along the X and Y axis.Special Repetition WorkSeveral designs can be repeated up to 63 times at different angles anddirections.Automatic OffsetThe frame automatically returns to the offset point when the embroidery isfinished to make it easier for you to switch the frames. You can selectAUTOMATIC OFFSET at PARAMETER SELECT MODE to move theframe automatically to the desired point, making it easier to do appliquesand to switch the frames.Manual OffsetYou can manually move the frame to the pre-selected point to do appliquesor change the frames during embroidery work. The frame can be movedback to its original place by simply pressing the right buttons.Return to StartThe frame can be moved back to the start point of the design during theembroidery work.Non-StitchingThe frame and the needle bar can move back and forth by the units of 1,100, 1000, and 10000 stitches and by color without stitching.Frame ReversalWhen the thread breaks or runs out of track, you can move the needle barback to the starting point of the design in the units of one to ten stitches.Automatic Return to Stop Point in Unexpected BlackoutWhen the power fails unexpectedly, the frame moves back to the exactpoint where the stitching stopped. This helps reduce the number of defects.EditingYou can delete, change, or insert stitch data and function codes (jump,finish, trimming).Individual Head OperationYou can work on the specific head with a broken thread.Laser PointOption PartsBorder FrameLED LampNew Operation Box 6.4-inch LCD: Concise and clear screen lay-out (high definition) Key-type User Interface Portable FDD Serial port USB port USB port LAN port for network connection Key board connecting cable(PS/2 port) Wide Cap Frame Semi -Wide Cap Frame Boring Device