5600 SeriesThe Seal Family That Changes To Fit Your ... - John Crane

5600 SeriesThe Seal Family That Changes To Fit Your ... - John Crane

5600 SeriesThe Seal Family That Changes To Fit Your ... - John Crane

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

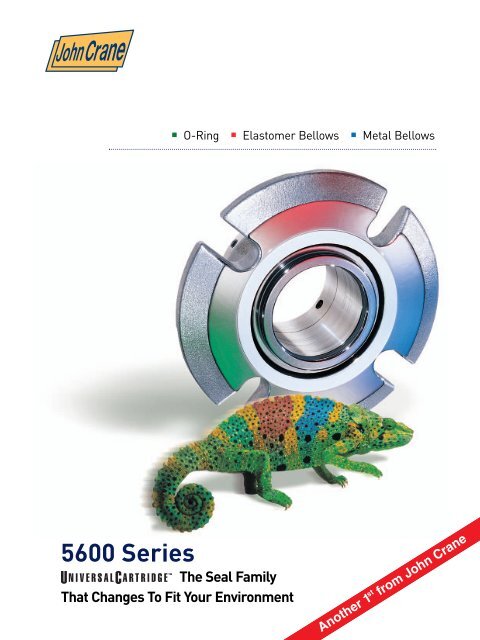

■ O-Ring ■ Elastomer Bellows ■ Metal Bellows<br />

<strong>5600</strong> Series The <strong>Seal</strong> <strong>Family</strong><br />

<strong>That</strong> <strong>Changes</strong> <strong>To</strong> <strong>Fit</strong> <strong>Your</strong> Environment<br />

st<br />

Another 1 from <strong>John</strong> <strong>Crane</strong>

<strong>5600</strong> Series<br />

Many Applications...One <strong>Seal</strong> <strong>Family</strong><br />

The First Truly Universal Cartridge Has Built-In Modularity,<br />

which allows customization for specific applications. Designed for the Chemical, Petrochemical,<br />

Pharmaceutical, Pulp & Paper, Power Generation, Food & Beverage, Ethanol, and Wastewater industries,<br />

the Universal Cartridge can accommodate a full range of fluids, including:<br />

• water • hydrocarbons • caustics • acids<br />

O-ring<br />

<strong>Seal</strong> Head<br />

Elastomer Bellows<br />

<strong>Seal</strong> Head<br />

Operating Parameters*<br />

Metal Bellows<br />

<strong>Seal</strong> Head<br />

Type 5610/5610Q Single and Type 5620/5620P Dual O-ring <strong>Seal</strong>s<br />

Type 5615/5615Q Single and Type 5625/5625P Dual Metal Bellows <strong>Seal</strong>s<br />

Temperatures: -29°C to 205°C / -20°F to 400°F<br />

Pressures: Up to 21 bar g / 300 psig<br />

Speeds: Up to 25 m/s / 5000 fpm<br />

Type 5611/5611Q Single Elastomer Bellows <strong>Seal</strong><br />

Temperatures: -29°C to 205°C / -20°F to 400°F<br />

Pressures: Up to 27 bar g / 400 psig<br />

Speeds: Up to 25 m/s / 5000 fpm<br />

Changing the seal head transforms an o-ring seal<br />

into a metal bellows seal, or into an elastomer<br />

bellows seal with a sleeve change.<br />

* Contact <strong>John</strong> <strong>Crane</strong> Engineering for applications over ratings.

Modular Concept<br />

The three basic seal configurations can be offered in a<br />

variety of arrangements to suit specific applications.<br />

• All configurations share a common gland plate,<br />

mating ring, collar, and spacers.<br />

• All single seals can be supplied with a quench gland.<br />

• Pumping rings are available to assist barrier fluid<br />

circulation on dual applications.<br />

The o-ring and metal bellows<br />

designs are available in<br />

dual arrangements.<br />

Engineered <strong>To</strong> Be The Performance Leader<br />

<strong>Seal</strong> Configuration Single Arrangement Dual Arrangement<br />

(Double or Tandem)<br />

O-ring<br />

Rotating Seat<br />

Rotating Head<br />

Elastomer Bellows<br />

Rotating Head<br />

Metal Bellows<br />

Rotating Seat<br />

Rotating Head<br />

■ ■<br />

■ ■<br />

The modularity of these seals does not limit their capabilities. In fact, the seal family introduced a number of<br />

high-end design features that make the Universal Cartridge the most powerful seal of its kind.<br />

Using <strong>John</strong> <strong>Crane</strong>’s proprietary computer analysis programs, CSTEDY SM and CTRANS SM , coupled with extensive<br />

product testing, we subjected and verified Universal Cartridge designs and materials to an array of varying<br />

pressures, temperatures, and fluids.<br />

5610 O-ring <strong>Seal</strong><br />

■<br />

■ ■<br />

■ ■<br />

The seal heads and mating rings are also<br />

completely reversible. With this capability, the seal<br />

can operate with either the seal head rotating to<br />

take advantage of self-cleaning rotational action,<br />

or the mating ring rotating, to achieve maximum<br />

seal face tracking and cooling.<br />

5611 Elastomer Bellows <strong>Seal</strong>

Enhanced Performance Benefits<br />

The One <strong>Seal</strong> <strong>Family</strong> For Global Applications<br />

Bellows Design<br />

• Superior bellows design provides low face load resulting in lower heat generation, low face<br />

wear, lower power consumption, and longer seal life.<br />

• Advanced metal bellows front adapter and insert designs provide superior face flatness<br />

control through full temperature/pressure transients.<br />

• Computer optimized seal face width and balance provide maximum tracking stability with<br />

minimum heat generation.<br />

• Mating ring design accommodates severe o-ring expansion experienced in high<br />

temperature or corrosive environments.<br />

• <strong>John</strong> <strong>Crane</strong>’s unique outboard seal flat drive sleeve adaptor provides superior torque<br />

transmission and drive reliability while eliminating sleeve distortion, stripped set screws,<br />

and axial misalignment during assembly.<br />

• Inherent reverse pressure balance capabilities assure process containment in the event of<br />

a pressure reversal.<br />

• The Universal Cartridge externally pressurized outboard seal arrangement improves<br />

cooling efficiency, allows venting of entrapped air, and avoids high tensile stress levels<br />

associated with internal pressurization.<br />

The capability of the Universal Cartridge to fit both ANSI and DIN pumps is a result<br />

of <strong>John</strong> <strong>Crane</strong>’s extensive analysis of common pump models and feasibility studies.<br />

With a slightly different rotation of the gland plate, the Universal Cartridge is like no<br />

other in that direct ANSI/DIN interchangeability is achievable. The Universal Cartridge<br />

is the first seal family with global application.<br />

5615 Metal Bellows <strong>Seal</strong>

<strong>5600</strong> Series<br />

The <strong>Seal</strong> <strong>That</strong> <strong>Changes</strong> to <strong>Fit</strong> <strong>Your</strong> Needs<br />

Modular <strong>Family</strong> Concept<br />

The modular family concept of <strong>John</strong> <strong>Crane</strong>’s Universal Cartridge<br />

will change your approach to sealing. Since the <strong>5600</strong> Series’<br />

components are interchangeable, you can apply one seal family<br />

throughout your plant. This gives you the flexibility to cover more<br />

applications with less inventory, which means your maintenance<br />

is simplified, downtime is reduced, plant operating efficiency is<br />

increased, and costs are lowered.<br />

Application-Tailored Arrangements<br />

The Universal Cartridge’s unique design delivers the superior operational capabilities of<br />

a <strong>John</strong> <strong>Crane</strong> seal, tailored precisely to fit your application. Whether your<br />

conditions require an o-ring, metal bellows or elastomer bellows seal, the<br />

Universal Cartridge is built from the ground up to meet your specifications.<br />

The seal is available in single or dual arrangements, with the option of<br />

rotating or stationary seal heads.<br />

Engineering Leadership<br />

With <strong>John</strong> <strong>Crane</strong>’s engineering leadership, the Universal Cartridge achieves another<br />

notable benefit. It represents the first global cartridge seal designed specifically to fit both<br />

ANSI B73.1M and DIN 24960 pumps, and is qualified to API-682 Category I.<br />

Standardizing with the Universal Cartridge family for the<br />

multiple applications in your plant will:<br />

• Simplify installation and maintenance<br />

• Standardize piping<br />

• Increase seal reliability<br />

• Reduce the possibility of misapplication<br />

• Cut inventory requirements<br />

• Streamline plant operations<br />

• Simplify upgrades<br />

This means ultimate efficiency with minimal<br />

costs—the most productive way to do business.<br />

The seal that changes<br />

to fit your environment<br />

will change the way you<br />

do business.

Available Locally<br />

The Universal Cartridge is available through your local <strong>John</strong> <strong>Crane</strong> sales/service engineer to meet<br />

your specific requirements. Interchangeability of parts allows us to keep a full inventory throughout<br />

our extensive worldwide network. Contact your nearest <strong>John</strong> <strong>Crane</strong> stocking center for timely<br />

delivery of the Universal Cartridge—the world’s first truly universal seal that changes to fit<br />

your environment.<br />

Expanding the Scope<br />

<strong>John</strong> <strong>Crane</strong> continues to expand the technology envelope of the Universal Cartridge seal family.<br />

New extensions within the <strong>5600</strong> family include dry running capability, liquid quench arrangements,<br />

and API-682 qualified Category I seal designs.<br />

Dry Running<br />

5610D single o-ring wet/dry running seal design is ideal for intermittent dry running of pumps that<br />

may be encountered on batch operations or tank loading or unloading applications. The type 5610D<br />

can be used on dry running top entry vessels operating at slow speed and low pressure.<br />

5620D is a dual o-ring seal arrangement incorporating a dry running secondary containment seal.<br />

The 5620D eliminates the need for liquid lubrication and associated support system, contains primary<br />

seal emissions and nominal leakage, as well as provides an additional level of safety against process<br />

or system upsets.<br />

Liquid Quench<br />

5610LQ / 5611LQ / 5615LQ—These new single seal versions incorporate an external lip seal as the<br />

liquid quench containment device. This design allows complete isolation of the seal faces from<br />

atmosphere. These seal versions are ideal for crystallizing services such as caustics.<br />

API-682 Category I Qualified<br />

5610Q-1/5620P-1/5620D-1/5615Q-1 / 5625P-1—Qualification tested API-682 compliant Category I<br />

designs for ANSI and ISO enlarged bore seal chambers.<br />

Europe<br />

Slough, UK<br />

Tel: 44-1753-224000<br />

Fax: 44-1753-224224<br />

Latin America<br />

São Paulo, Brazil<br />

Tel: 55-11-3371-2500<br />

Fax: 55-11-3371-2599<br />

Middle East, Africa, Asia<br />

Dubai, United Arab Emirates<br />

Tel: 971-4-3438940<br />

Fax: 971-4-3438970<br />

North America<br />

Morton Grove, Illinois USA<br />

1-800-SEALING<br />

Tel: 1-847-967-2400<br />

Fax: 1-847-967-3915<br />

For your nearest <strong>John</strong> <strong>Crane</strong> facility, please contact one of the locations above.<br />

If the products featured will be used in a potentially dangerous and/or hazardous process, your <strong>John</strong> <strong>Crane</strong> representative should be consulted prior to their selection and use.<br />

In the interest of continuous development, <strong>John</strong> <strong>Crane</strong> Companies reserve the right to alter designs and specifications without prior notice. It is dangerous to smoke while handling<br />

products made from PTFE. Old and new PTFE products must not be incinerated.<br />

©2004 <strong>John</strong> <strong>Crane</strong> Inc. Print 07/04 www.johncrane.com ISO 9001, ISO 14001, ISO/TS 16949 Certified B-<strong>5600</strong>

![B Series-Port [2675] - John Crane](https://img.yumpu.com/12598399/1/190x253/b-series-port-2675-john-crane.jpg?quality=85)