Heavy Duty Well Service & Rotary Pump - Woma

Heavy Duty Well Service & Rotary Pump - Woma

Heavy Duty Well Service & Rotary Pump - Woma

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

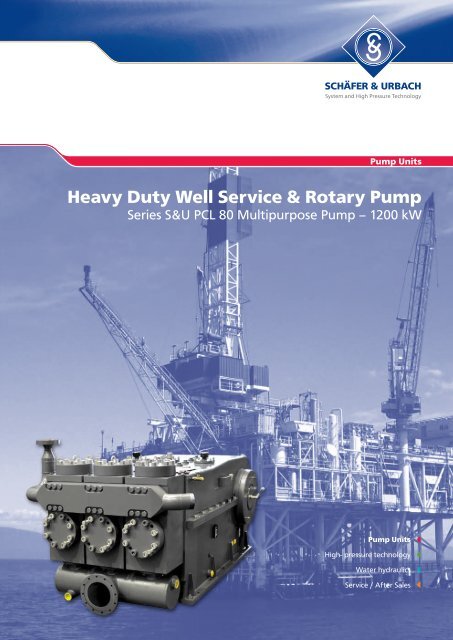

<strong>Pump</strong> Units<strong>Heavy</strong> <strong>Duty</strong> <strong>Well</strong> <strong>Service</strong> & <strong>Rotary</strong> <strong>Pump</strong>Series S&U PCL 80 Multipurpose <strong>Pump</strong> – 1200 kW

Tradition as basis – high-pressure as motivationAs specialists for sophisticated solutions SCHÄFER & URBACH have become renowned in the following areas.<strong>Pump</strong> UnitsHigh-pressure pumps HDPProcess pumps PPKMud pumps BTSlurry-<strong>Pump</strong>s SPLSteam- and Duplex pumpsSpecial pumpsHigh-pressure technologyTank- and industrial cleaning systemsHP Cleaning systemsHP Cleaning accessoriesWater hydraulicsDescaling systemsDrive systems for presses<strong>Service</strong> / After SalesEngineeringWelding technologyCommissioningFor more than 80 years SCHÄFER & URBACH have developed and supplied equipment and components for systems and highpressureplants to customers throughout the world. All of the supplied equipment is manufactured at the SCHÄFER & URBACHworkshop. The company assumes responsibility, as it supplies complete high-pressure and systems solutions made up ofcomponents which all fit together seamlessly – forming a perfect match and being ... all from one source.Industrial pumps – The right solution for any requirementReliability, robustness and high quality – these are the features on which SCHÄFER & URBACH has built the international successof its range of industrial pumps. The maintenance-friendly design, flexibility in combination and high manufacturing qualityof the plunger and piston pumps make these industrial pumping units optimal conveying means for a broad bandwidth ofapplications.All industrial pumps are tested for tightness, proper functioning and performance in a practice-oriented procedure. All data aredigitally logged and evaluated.

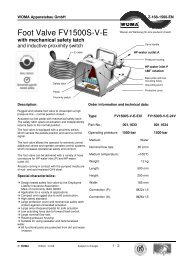

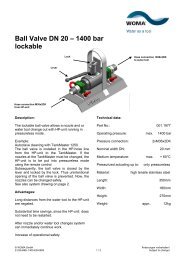

PCL 80 Multipurpose <strong>Pump</strong>Extremely compact heavy duty multipurpose oilfield pump for continuous operation.Unique featuresThe PCL 80 multipurpose pump from SCHÄFER & URBACH is a newly designed triplex oilfield pump.It is rated for a maximum operating pressure of 1300 bar (19,000 psi) and completely „Made in Germany“.The pump can have AC/DC electric drive with either water- or air-cooling, hydraulic drive or diesel-engine drive.Fields of applicationThe PCL 80 multipurpose pump is designed as a plunger pump up to 1300 bar for miscellaneous areas of applicationin deep drilling technology or as a piston pump for applications like drilling or supply pump with a flow rate up to3500 l/min (5250 l/min with special liners).Drive unitThe triplex pump combines the high requirements for power and operating life for the components of the power endThe maximum piston force is 80 t (17,400 lbs)The valve bodies, adjusted to the spec of the customer, allow pressures up to 1300 bar (19,000 psi)Horizontal center-split housing in extremely rigid welded constructionSingle-piece crankshaft made out of high-strength forged steelPlay-free spherical crosshead bearing in bronze and with exchangeable cylinder liners toSCHÄFER & URBACH designDouble-circuit forced lubrication for external supply and cooling, enabling use of the Complete speed rangeAll type of drives are possibleFluid sectionWater-lubricated pistons and valves according to international expendable and API standardsTriple split pump body made of P 280 GH or stainless steelMechanical and hydraulic quick clamps for liner and valve capHigh volumetric efficiency and excellent running smoothnessExtremely low maintenanceSpecifications and standardsIn addition to the generally applicable standards such as DIN EN 809 and DIN EN ISO 16330, PCL 80 multipurpose pumpcan be supplied according to API 674 or EN ISO 13710. ATEX certificate on request. All pump units are CE-certified.

PCL 80 plunger pumpwith gland designAs plunger pump the application range is 130 MPa(1300 bar = 19,000 psi) and can be deployed perfectlyin the following fields of deep drilling technology:CementingFracs and stimulation<strong>Well</strong> servicingPiston-Ø Inch 3,5 4 4,5 5 5,5 6 6,5mm 88,9 101,6 114,3 127 139,7 152,4 165,1Operating press. max bar 1289 987 780 632 522 439 374Revolutions per min<strong>Pump</strong>ing rate in l/min265 min -1 1012 1321 1672 2065 2498 2973 3489235 min -1 897 1172 1483 1831 2215 2636 3094205 min -1 783 1022 1294 1597 1932 2300 2699175 min -1 668 873 1104 1363 1650 1963 2304145 min -1 554 723 915 1130 1367 1627 1909115 min -1 439 573 726 896 1084 1290 151485 min -1 324 424 536 662 801 954 111970 min -1 267 349 442 545 660 785 922Revolutions per minAllowed pressures in bar at a limit of 1200kW265 min -1 712 545 431 349 288 242 206235 min -1 803 614 486 393 325 273 233205 min -1 920 704 557 451 373 313 267175 min -1 1078 825 652 528 436 367 312145 min -1 1289 987 780 632 522 439 374115 min -1 1289 987 780 632 522 439 37485 min -1 1289 987 780 632 522 439 37470 min -1 1289 987 780 632 522 439 374<strong>Pump</strong>ing rates at 100% vol. efficiency. Other speeds and capacities on request.Dimensions and weightlength (mm) width (mm) height (mm) WeightPCL 80 plunger pump 2420 1515 1200 Approx. 8,700 kg (bare shaft)

Power UnitsSCHÄFER & URBACH combines several functionaldevices and components, such as:<strong>Pump</strong>sDrivesGearsControlling unitsPeripheral bodies to an economic and efficient pump unitAdvantages:Rugged designSmall dimensions and low weightComplementary componentsSaving of time during assemblyPerfect layout of connectors and mountingsPCL 80DrivesSCHÄFER & URBACH provides different typesof drives according to specification:Mechanical drive with electric motorsHydraulic drives with diesel-engines20 foot container,hydraulic drive<strong>Pump</strong> unit PCL 80 with electric motor 1200 kWPCL 80 pump unitwith diesel engine

Liner tensioning deviceAs liners in mud pumps are wear parts, they must be replacedfrom time to time. For faster and simpler replacement of theliners, SCHÄFER & URBACH has developed an innovative, fullyhydraulic tensioning device.Valve cap tensioning deviceValve caps must be re-tensioned from time to time.An innovative tensioning device developed bySCHÄFER & URBACH now speeds up and facilitates thisoperation.Advantages:Short tensioning and release times of just a few minutesSimple construction comprising only very few componentsFatigue-resisting tensioning, due to absence of springsResonatorsThe use of resonators as pulsation dampening devices achievesan excellent dampening effect over a wide range of pressuresand volumetric flow rates. The damping effect is achieved asa result of a part of the pressure waves being reflected insidethe resonator.SUMO - S&U MonitoringThe innovative automatic monitoring system for piston pumps(patent pending) is a highly sophisticated and very reliablemaintenance tool, which detects, displays and signals any errorstatus very early and accurately.Main features:Monitoring of gear section and fluid endResistance strain gauges and solid borne sound sensors forhigh-definition measurementHigh-performance panel-PC for data collection and analysisGraphic display of monitored statusData transfer to superordinate system control and backRemote access by system control or direct to panel-PCApplicable with new systems and can be refitted to existingpump units

Tradition as basis – high-pressure as motivationSCHÄFER & URBACH GmbHHeadquarters:Kaiserswerther Straße 7440878 Ratingen - GermanyPhone: (+49) 21 02 / 45 07 - 0Fax: (+49) 21 02 / 45 07 - 45Branch Office:Breitenseer Weg 2-697633 Hoechheim - GermanyPhone: (+49) 97 64 / 91 91 - 0Fax: (+49) 97 64 / 91 91 - 40E-Mail: info@schaefer-urbach.comInternet: www.schaefer-urbach.comDIN EN ISO 9001:2008EU Guidelines: 97/23/EG pressure equipmentEU Guidelines: 94/9/EG ATEX forcleaning lances and high-pressure equipmentEU Guidelines: ZH 1/406 forliquid jetsQualification accordingto DIN 18800 Part 7Certificate according toDIN EN 3834-2 for welded structuresCertificate according toAD Guidelines HP 0 (TRB 200), TRD and TRR 100Specialist firm according to §19 WHGSCHÄFER & URBACH · PCL80_0412 · Errors excepted. Technical changes possible.