You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

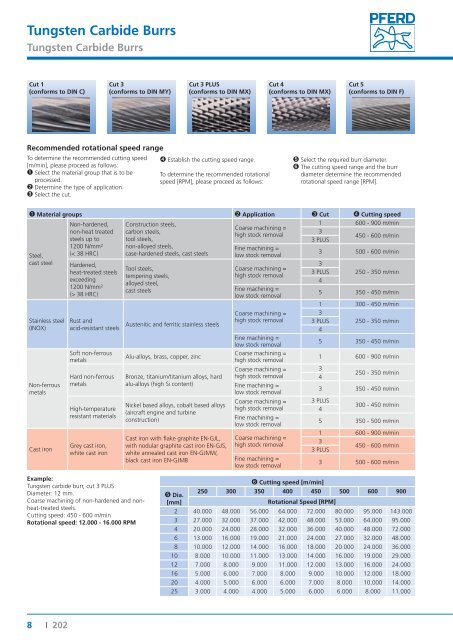

Tungsten Carbide <strong>Burrs</strong>Tungsten Carbide <strong>Burrs</strong>Cut 1(conforms to DIN C)Cut 3(conforms to DIN MY)Cut 3 PLUS(conforms to DIN MX)Cut 4(conforms to DIN MX)Cut 5(conforms to DIN F)Recommended rotational speed range➍ Establish the cutting speed range.To determine the recommended cutting speed[m/min], please proceed as follows:➊ Select the material group that is to beprocessed.➋ Determine the type of application.➌ Select the cut.To determine the recommended rotationalspeed [RPM], please proceed as follows:➎ Select the required burr diameter.➏ The cutting speed range and the burrdiameter determine the recommendedrotational speed range [RPM].➊ Material groups ➋ Application ➌ Cut ➍ Cutting speedNon-hardened, Construction steels,1 600 - 900 m/minCoarse machining =non-heat treated carbon steels,3high stock removal450 - 600 m/minsteels up to tool steels,3 PLUS1200 N/mm² non-alloyed steels,Fine machining =(< 38 HRC) case-hardened steels, cast steels3 500 - 600 m/minlow stock removalSteel,cast steelStainless steel(INOX)Non-ferrousmetalsCast ironHardened,heat-treated steelsexceeding1200 N/mm²(> 38 HRC)Rust andacid-resistant steelsSoft non-ferrousmetalsHard non-ferrousmetalsHigh-temperatureresistant materialsGrey cast iron,white cast ironTool steels,tempering steels,alloyed steel,cast steelsAustenitic and ferritic stainless steelsAlu-alloys, brass, copper, zincBronze, titanium/titanium alloys, hardalu-alloys (high Si content)Nickel based alloys, cobalt based alloys(aircraft engine and turbineconstruction)Cast iron with flake graphite EN-GJL,with nodular graphite cast iron EN-GJS,white annealed cast iron EN-GJMW,black cast iron EN-GJMBCoarse machining =high stock removalFine machining =low stock removalCoarse machining =high stock removalFine machining =low stock removalCoarse machining =high stock removalCoarse machining =high stock removalFine machining =low stock removalCoarse machining =high stock removalFine machining =low stock removalCoarse machining =high stock removalFine machining =low stock removal33 PLUS4250 - 350 m/min5 350 - 450 m/min1 300 - 450 m/min33 PLUS 250 - 350 m/min45 350 - 450 m/min1 600 - 900 m/min34250 - 350 m/min3 350 - 450 m/min3 PLUS4300 - 450 m/min5 350 - 500 m/min1 600 - 900 m/min3450 - 600 m/min3 PLUS3 500 - 600 m/minExample:Tungsten carbide burr, cut 3 PLUSDiameter: 12 mm.Coarse machining of non-hardened and nonheat-treatedsteels.Cutting speed: 450 - 600 m/minRotational speed: 12.000 - 16.000 RPM➎ Dia.[mm]➏ Cutting speed [m/min]250 300 350 400 450 500 600 900Rotational Speed [RPM]2 40.000 48.000 56.000 64.000 72.000 80.000 95.000 143.0003 27.000 32.000 37.000 42.000 48.000 53.000 64.000 95.0004 20.000 24.000 28.000 32.000 36.000 40.000 48.000 72.0006 13.000 16.000 19.000 21.000 24.000 27.000 32.000 48.0008 10.000 12.000 14.000 16.000 18.000 20.000 24.000 36.00010 8.000 10.000 11.000 13.000 14.000 16.000 19.000 29.00012 7.000 8.000 9.000 11.000 12.000 13.000 16.000 24.00016 5.000 6.000 7.000 8.000 9.000 10.000 12.000 18.00020 4.000 5.000 6.000 6.000 7.000 8.000 10.000 14.00025 3.000 4.000 4.000 5.000 6.000 6.000 8.000 11.0008 I <strong>202</strong>