Timber Bulletin May/Jun - Minnesota Forest Industries

Timber Bulletin May/Jun - Minnesota Forest Industries

Timber Bulletin May/Jun - Minnesota Forest Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

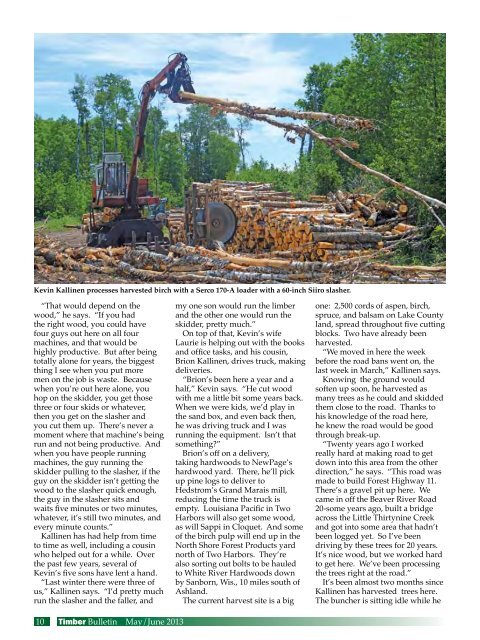

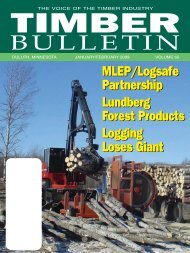

Kevin Kallinen processes harvested birch with a Serco 170-A loader with a 60-inch Siiro slasher.“That would depend on thewood,” he says. “If you hadthe right wood, you could havefour guys out here on all fourmachines, and that would behighly productive. But after beingtotally alone for years, the biggestthing I see when you put moremen on the job is waste. Becausewhen you’re out here alone, youhop on the skidder, you get thosethree or four skids or whatever,then you get on the slasher andyou cut them up. There’s never amoment where that machine’s beingrun and not being productive. Andwhen you have people runningmachines, the guy running theskidder pulling to the slasher, if theguy on the skidder isn’t getting thewood to the slasher quick enough,the guy in the slasher sits andwaits five minutes or two minutes,whatever, it’s still two minutes, andevery minute counts.”Kallinen has had help from timeto time as well, including a cousinwho helped out for a while. Overthe past few years, several ofKevin’s five sons have lent a hand.“Last winter there were three ofus,” Kallinen says. “I’d pretty muchrun the slasher and the faller, andmy one son would run the limberand the other one would run theskidder, pretty much.”On top of that, Kevin’s wifeLaurie is helping out with the booksand office tasks, and his cousin,Brion Kallinen, drives truck, makingdeliveries.“Brion’s been here a year and ahalf,” Kevin says. “He cut woodwith me a little bit some years back.When we were kids, we’d play inthe sand box, and even back then,he was driving truck and I wasrunning the equipment. Isn’t thatsomething?”Brion’s off on a delivery,taking hardwoods to NewPage’shardwood yard. There, he’ll pickup pine logs to deliver toHedstrom’s Grand Marais mill,reducing the time the truck isempty. Louisiana Pacific in TwoHarbors will also get some wood,as will Sappi in Cloquet. And someof the birch pulp will end up in theNorth Shore <strong>Forest</strong> Products yardnorth of Two Harbors. They’realso sorting out bolts to be hauledto White River Hardwoods downby Sanborn, Wis., 10 miles south ofAshland.The current harvest site is a bigone: 2,500 cords of aspen, birch,spruce, and balsam on Lake Countyland, spread throughout five cuttingblocks. Two have already beenharvested.“We moved in here the weekbefore the road bans went on, thelast week in March,” Kallinen says.Knowing the ground wouldsoften up soon, he harvested asmany trees as he could and skiddedthem close to the road. Thanks tohis knowledge of the road here,he knew the road would be goodthrough break-up.“Twenty years ago I workedreally hard at making road to getdown into this area from the otherdirection,” he says. “This road wasmade to build <strong>Forest</strong> Highway 11.There’s a gravel pit up here. Wecame in off the Beaver River Road20-some years ago, built a bridgeacross the Little Thirtynine Creekand got into some area that hadn’tbeen logged yet. So I’ve beendriving by these trees for 20 years.It’s nice wood, but we worked hardto get here. We’ve been processingthe trees right at the road.”It’s been almost two months sinceKallinen has harvested trees here.The buncher is sitting idle while he10<strong>Timber</strong> <strong>Bulletin</strong> <strong>May</strong>/<strong>Jun</strong>e 2013