Flowserve Gaseous Noise Control Brochure - Flowserve Corporation

Flowserve Gaseous Noise Control Brochure - Flowserve Corporation

Flowserve Gaseous Noise Control Brochure - Flowserve Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

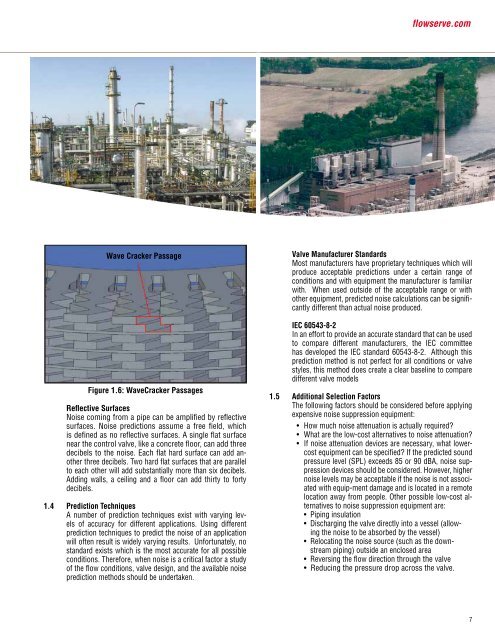

flowserve.comWave Cracker PassageFigure 1.6: WaveCracker PassagesReflective Surfaces<strong>Noise</strong> coming from a pipe can be amplified by reflectivesurfaces. <strong>Noise</strong> predictions assume a free field, whichis defined as no reflective surfaces. A single flat surfacenear the control valve, like a concrete floor, can add threedecibels to the noise. Each flat hard surface can add anotherthree decibels. Two hard flat surfaces that are parallelto each other will add substantially more than six decibels.Adding walls, a ceiling and a floor can add thirty to fortydecibels.1.4 Prediction TechniquesA number of prediction techniques exist with varying levelsof accuracy for different applications. Using differentprediction techniques to predict the noise of an applicationwill often result is widely varying results. Unfortunately, nostandard exists which is the most accurate for all possibleconditions. Therefore, when noise is a critical factor a studyof the flow conditions, valve design, and the available noiseprediction methods should be undertaken.Valve Manufacturer StandardsMost manufacturers have proprietary techniques which willproduce acceptable predictions under a certain range ofconditions and with equipment the manufacturer is familiarwith. When used outside of the acceptable range or withother equipment, predicted noise calculations can be significantlydifferent than actual noise produced.IEC 60543-8-2In an effort to provide an accurate standard that can be usedto compare different manufacturers, the IEC committeehas developed the IEC standard 60543-8-2. Although thisprediction method is not perfect for all conditions or valvestyles, this method does create a clear baseline to comparedifferent valve models1.5 Additional Selection FactorsThe following factors should be considered before applyingexpensive noise suppression equipment:• How much noise attenuation is actually required?• What are the low-cost alternatives to noise attenuation?• If noise attenuation devices are necessary, what lowercostequipment can be specified? If the predicted soundpressure level (SPL) exceeds 85 or 90 dBA, noise suppressiondevices should be considered. However, highernoise levels may be acceptable if the noise is not associatedwith equip-ment damage and is located in a remotelocation away from people. Other possible low-cost alternativesto noise suppression equipment are:• Piping insulation• Discharging the valve directly into a vessel (allowingthe noise to be absorbed by the vessel)• Relocating the noise source (such as the downstreampiping) outside an enclosed area• Reversing the flow direction through the valve• Reducing the pressure drop across the valve.7