The New-Generation Hydraulic Excavator - Nasta AS

The New-Generation Hydraulic Excavator - Nasta AS

The New-Generation Hydraulic Excavator - Nasta AS

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

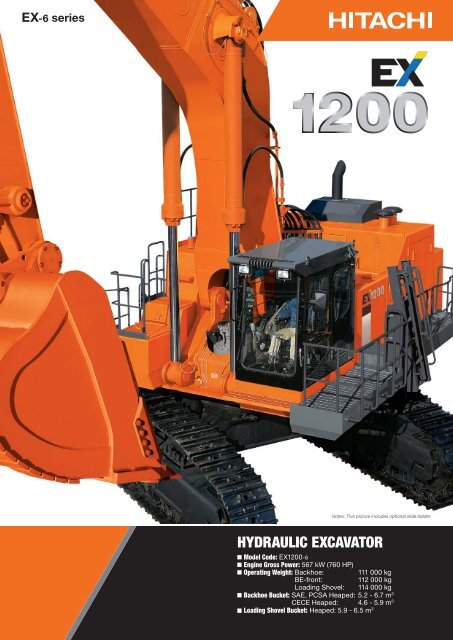

EX-6 seriesNotes: This picture includes optional slide ladder.HYDRAULIC EXCAVATORModel Code: EX1200-6Engine Gross Power: 567 kW (760 HP)Operating Weight: Backhoe: 111 000 kgBE-front:112 000 kgLoading Shovel: 114 000 kgBackhoe Bucket: SAE, PCSA Heaped: 5.2 - 6.7 m 3CECE Heaped: 4.6 - 5.9 m 3Loading Shovel Bucket: Heaped: 5.9 - 6.5 m 3

<strong>The</strong> <strong>New</strong>-<strong>Generation</strong> <strong>Hydraulic</strong> <strong>Excavator</strong>:<strong>The</strong> Hitachi Giant EX1200<strong>The</strong> Hitachi EX1200, a new-generation giant hydraulic excavator,is designed for extraordinary production and toughness onlarge-scale mines, quarries and civil-engineering projects. <strong>The</strong>EX1200 comes with lots of leading-edge technologies, includingthe high-power engine, sophisticated hydraulic system,strengthened undercarriage, an array of safety devices, andeco- and environment-friendly design.2

Notes: This picture includes optional slide ladder and custom-designed reinforcing plates for side track frame.3

Impressive ProductivityMore production thanks to Hitachi’s cutting-edgingtechnologiesProduction: Approximately 9% Increase (H/P modes)(vs. conventional model with BE front)Advanced <strong>Hydraulic</strong> TechnologiesBoom Recirculation SystemBoom- and Swing-Priority ModesBoom Mode SelectorPressurized oil is efficiently recirculatedin the boom circuit, assisted by theboom self-weight when the boomlowers. This design delivers morepressurized oil to the arm from thepump to increase arm lowering speedin combined operation of the boom andarm.<strong>The</strong> boom- or swing-priority mode canbe selected for higher production.Boom-Priority Mode<strong>The</strong> two boom modes, comfort andpowerful modes, can be selectedaccording to job needs, extendingthe service life of the machine. Whenthe boom mode selector is On, thecomfort mode is selected for efficientexcavation, while the selector is Off,the powerful mode for productiveexcavation.When swing angle is small in a cycle of digging,swinging and dumping, boom raise speed increases toreduce a cycle time.Swing-Priority ModeCombined Operation of Boom and ArmComfort modeONIncluding optional switchesPowerful modeOFFIn combined operation of swing +boom lower + arm roll-out, or in leveling(boom lower + arm roll-out), arm rolloutspeed can be increased greatly. Avariable throttle, provided in the armcircuit, adjusts the oil flow in combinedoperation with arm roll-out.When swing angle is large in a cycle of digging,swinging and dumping, swing speed increases toreduce a cycle time.Three work modes can be selected bysetting the switch tothe three positionsbelow.<strong>The</strong>re is little lifting or pulling of the bodyso there is less vibration and shock.Much lifting and pulling of the body sothere is more vibration and shock.Arm Roll-outSwingBoom LowerPosition 1: Boom-priority modePosition 2: Normal modePosition 3: Swing-priority modeBucket Roll-outMP4

Notes: <strong>The</strong> bucket pictured is custom designed.Improved PerformanceIncreased Boom Lifting ForceIncreased Digging ForceExcavation Closer to Machine<strong>The</strong> boom lifting force is increased toeasily lift large rocks on quarries andmines.Boom lifting force:Approximately 8% increase(vs. conventional model with BE front; armpositioned vertically and bucket resting on ground)Improved MobilityMobility is improved to achieve sharpersteering with more traction force.Traction force:Approximately 14% increase(vs. conventional model)Digging force is increased for powerfulexcavation on quarries and mines,using the BE or standard front.Improved Swing PerformanceSwing performance, even on a gradient,is improved for efficient trenching forpiping laying, and for wall excavationusing the bucket side.Swing torque:Approximately 8% increase(vs. conventional model)<strong>The</strong> front linkage is redesigned toallow the front to excavate closer tothe machine for well combination withdump trucks.(vs. conventional model)BE front: 620 mmStandard front: 790 mm5

High Durability Means Long-LastingProduct ValueStrengthened undercarriage for higher durabilityeven in heavy-duty applicationsStrengthened UndercarriageEnlarged Track LinksStrengthened Idler PedestalDurable Idler BracketsTrack links are enlarged to increasestrength for higher durability andreliability especially on rugged ground.At the idler pedestal that sustainsthe front idler, its contact length islengthened by approximately 90% toincrease strength and service life.Thickened durable plates of idlerbrackets increase reliability of theidlers.Enlarged Upper/Lower Rollers,Sprockets and IdlersContact areaTracks are strengthened for highermobility by increasing roller width anddiameter, sprocket tooth width, andidler width.6

Sophisticated DesignsCenter Track Frame<strong>New</strong> Delivery Filters<strong>The</strong> center track frame of integralcast steel structure can avoid stressconcentration, and increase reliability.Delivery filters, newly added to thedelivery side of hydraulic pumps,effectively protect hydraulic lines fromaccidents.Integral cast steelRock Buckets5.2 m 3 / 5.8 m 3Durable Swing Bearing<strong>The</strong> number of balls, in the swingbearing that sustain the upperstructure,is increased to boost the load-carryingcapacity by approximately 6% (vs.conventional model). This improvementallows for smoother swing even inheavy-duty operation.Rock buckets are specificallystrengthened to resist wear and impact.5.8 m 3 Rock BucketSeparate Oil Cooler<strong>The</strong> oil cooler is separated from theradiator to effectively cool downhydraulic oil. This helps extend theservice life of hydraulics.Notes: This picture includes custom-designed components,including reinforcing plates for side track frame.Rugged Travel Devices<strong>The</strong> travel devices are compactdesignedto reduce damage for highermobility, reducing downtime.(1) Dual wear plates(2) Reinforced bucket corners(3) Large bucket teeth for rock excavation(4) Dual side shrouds(5) Cutting edge shroudsReliable Grease-Filled Floating PinsTwo grease-filled floating pins, at theboom top and at A linkage, increasethe sealing ability, extend pin life, andreduce repair costs. Wear plates areprovided on both sides of a boss at thearm top.7

Enhanced Operator Comfort<strong>The</strong> spacious cab is ergonomically designed with excellentvisibility to enhance operator comfort with less operator fatigue<strong>New</strong> Spacious, Operator-Oriented Cab<strong>The</strong> new spacious cab, resting onelastic fluid-filled mounts, enhancesoperator comfort, and gives excellentvisibility. Vibration and sound areinsulated for comfort ride and pleasantoperation with less fatigue.RubberSilicone oilSpringExcellent VisibilityShort-Stroke LeversPressurized Cab<strong>The</strong> glass windows are enlarged forexcellent visibility, especially rightforwardvisibility during travel andexcavation.Fingertip-control short-stroke leversallows for long, continuous operation,with the help of armrests.Control lever effort:Approximately 30% decrease(vs. conventional model)<strong>The</strong> cab is pressurized to keep out dustand debris.Comfort-Designed Operator SeatOverhead LED LightAmple Foot SpaceFoot space is extended forward, andpedals are reshaped for pleasant footcontrol.<strong>The</strong> operator seat is ergonomicallydesigned for long-hour pleasantoperation. <strong>The</strong> seatback is widenedto hold the operator securely, andthe headrest is reshaped for operatorcomfort.An overhead LED light, with longerservice life than lightbulb, is newlyutilized for lighting in the cab. Thisallows the operator to log on a nightshift.8

Notes: This picture includes optional air-suspension seat and switches.Miscellaneous AccessoriesControl PanelFull-Auto Air Conditionerand FM/AM RadioDrink Holder Hot & Cool Box Large Storage Space Sun visor (Optional)Multi-Function,Multi-Language MonitorA large multi-function, multi-languageLCD monitor is well positioned for easyreading.Rearview Camera<strong>The</strong> large color LCD monitor, teamedup with a rearview camera atop thecounterweight, gives unobstructedrearward view. This enhances safetywhen the machine swings and movesrearward.Scheduled MaintenanceReplacement intervals of engine oil,hydraulic oil, filters can be preset on themonitor. <strong>The</strong> monitor alerts the operatorof the scheduled replacement whennecessary.Rearview Camera9

Environment-Friendly Design with EnhancedSafetySafety-First Design, and Environmental Awareness with theClean EngineSafety-First DesignRugged Cabwith Integrated Headguard<strong>The</strong> rugged cab is integrated with theOPG* Level II (ISO) guard to protect theoperator from falling objects. <strong>The</strong> cabfront guard is an option.*Operator Protective GuardPilot Control Shut-Off Lever<strong>The</strong> shut-off lever for pilot control helpsto prevent unintentional movements.Step Light for Night Work<strong>The</strong> step light turns On for one minuteafter key-off. This feature is convenientin night-shift work.Angle-Adjustable HeadlightsHeadlights at the cab can be angleadjustedfor proper lighting at job site.Wide Sidewalks and Large HandrailsWide sidewalks and large handrailsare provided at key locations foreasy access to the cab, and for safeservicing and inspection. Handrailsconform to EN*.*European NormEnvironment Conscious Design<strong>New</strong> Clean EngineVariable-Speed Fan<strong>The</strong> clean engine, complying with theemission regulations EPA (U.S.) Tier 2,is mounted to reduce emissionscontaining NOx and PM (ParticulateMatter).<strong>The</strong> large 1 120 mm-diameter variable-speed electrohydraulicfan is provided for oil cooler cooling. Fan speedis optimally controlled according to job conditions,including atmospheric temperature, for effective coolingand noise suppression.10

An Array of Safety DevicesEvacuation Hammer Engine Stop Switch Cab Right-Side WindowGuardRecoiled Seat BeltLight on CounterweightAluminum Radiator, Oil Cooler and AirConditioner Condenser<strong>The</strong> aluminum radiator, oil cooler and airconditioner condenser are corrosionresistantand recyclable.Marking of RecyclablesAll recyclable resin parts are marked forthe convenience of recycling.Reducing the Burdento the EnvironmentLead-free components, including wireharness covering, oil cooler and controlunit, are utilized. No asbestos is used.11

Simplified MaintenanceFocusing on simple servicing, inspection and cleaningSimplified Cleaning Around EngineParallel Arrangement of Radiator and Oil CoolerSimplified Cleaning around Oil Cooler<strong>The</strong> radiator and oil cooler are arranged side by side to increase cooling efficiency.This also reduces cleaning time andeffort remarkably.Easy removalof dust and dirtfrom blowerEngine<strong>The</strong> air conditioner condenser isopenable for easy access and cleaningof the oil cooler located behind.RadiatorOil coolerInter-coolerSimplified MaintenanceAuto Dust Ejector (Air Cleaner)Extended Filter Replacement IntervalsAuto Lubrication System<strong>The</strong> auto dust ejector automaticallyejects airborne dust and particlesto keep filter elements clean andextend theirreplacementintervals.Replacement intervals of hydraulic oilfilters are extended from 500 hoursto 1000 hours, thus reducing runningcosts.<strong>The</strong> auto lubrication system is providedstandard at the front attachment tosimplify daily maintenance, except forthe bucket pinand swing circle.12

Functionally Layout of Devices and Utility SpaceDevices and walkways are functionally laid out for efficientservicing and inspection. <strong>The</strong> central walkway facilitates theservicing and maintenance of the engine.1 Engine2 Pump Drive Unit3 <strong>Hydraulic</strong> Pump x 34 <strong>Hydraulic</strong> Oil Tank5 Fuel Tank6 Engine Radiator7 Engine Air Cooler8 Oil Cooler9 Main Control Valve10 Swing Control Valve11 Swing Device x 212 Center Joint13 Filters14 Batteries15 Batteries and Lubricator Box16 Operator Cab17 Air Conditioning Unit18 Slide Ladder (Optional)Electric Grease GunOptional Slide LadderWide-Open Inspection DoorsAn electric grease gun (pail can type)is provided standard with a hose reelfor convenient lubrication of the swingcircle and bucket pin.<strong>The</strong> slide ladder is optionally availableon the left side of the machine foreasy access to the cab and workingplatform.Inspection doors open wide for easymaintenance.Easily Replaceable Air ConditionerFilterAn air conditioner filter is located to thecab door side behind the operator seatfor easy cleaning and replacing.MIC Mining<strong>The</strong> Hitachi MIC mining system comprises the DLU (Data Logging Unit) that logsdaily operating conditions and warnings, including operating data on the engineand hydraulics. <strong>The</strong> log can be downloaded by PC or PDA.SATELLITES MACHINE PC & PDA INTERNET(Option)Conveniently Located SwitchboardDATA LoggerDownloadvia CablePDA**PDA: Palm<strong>The</strong> switchboard is located in thecab at its rear for the convenience ofinspection.MMSDLUDownload ProgramTransmit Downloaded DataPCUploadvia Internet[Server]Upon RequestData Viewer ProgramCustomerDealersReportsWith switchboard lid opened13

SPECIFICATIONSENGINEModel ............................... Cummins QSK23-CType ................................. Water-cooled, 4-cycle, 6-cylinder in line,turbo-charged direct injection chambertypediesel engine.Rated powerSAE J1995, gross ........ 567 kW (760 HP) at 1 800 min -1 (rpm)Net ............................... 552 kW (740 HP) at 1 800 min -1 (rpm)Piston displacement ..... 23.15 LFuel tank capacity ........ 1 470 LHYDRAULIC SYSTEMMain pumps ..................... 3 variable-displacement, swash platetype axial piston pumpsMaximum oil fl ow ............. 3 x 520 L/minPressure setting ............... 31.9 MPa (325 kgf/cm 2 )UPPERSTRUCTURESwing speed .................... 5.2 min -1 (rpm)UNDERCARRIAGETravel speeds ...................High: 0 to 3.5 km/hLow: 0 to 2.4 km/hMaximum traction force ... 707 kN (72 100 kgf)Gradeability ...................... 70% (35 degree) max.WEIGHTS AND GROUND PRESSUREBackhoeEX1200-6: Equipped with 9.0 m boom, 3.6 m arm, and 5.2 m 3(SAE, PCSA heaped) bucketShoe type Shoe width Operating weight Ground pressureDoublegrousers700 mm 111 000 kg 142 kPa (1.45 kgf/cm 2 )900 mm 113 000 kg 112 kPa (1.14 kgf/cm 2 )EX1200-6 BE-front: Equipped with 7.55 m BE-boom, 3.4 m BE-arm,and 6.7 m 3 (SAE, PCSA heaped) bucketShoe type Shoe width Operating weight Ground pressureDoublegrousers700 mm 112 000 kg 143 kPa (1.46 kgf/cm 2 )900 mm 114 000 kg 113 kPa (1.15 kgf/cm 2 )Loading ShovelEquipped with 6.5 m 3 (heaped) bottom dump bucketShoe type Shoe width Operating weight Ground pressureDoublegrousers700 mm 114 000 kg 146 kPa (1.49 kgf/cm 2 )BACKHOE ATTACHMENTSBucketCapacityWidthMaterials density kg/m 3No.BE-front9.0 m boomSAE, PCSA CECE WithoutWithWeightTypeof teethheaped heaped shroud shroud7.55 m BE-boom3.6 m arm3.4 m BE-arm5.2 m 3 4.6 m 3 1 940 mm 2 120 mm 5 4 910 kg — 1 8005.2 m 3 4.6 m 3 1 900 mm 2 000 mm 5 5 930 kg — 1 8005.8 m 3 5.1 m 3 2 120 mm 2 220 mm 5 6 930 kg 1 800 —6.7 m 3 5.9 m 3 2 300 mm 2 400 mm 5 6 650 kg 1 800 —Rock bucket General purpose bucket — Not applicableLOADING SHOVEL ATTACHMENTSBucketCapacity (heaped) Width No. of teeth Weight Type Materials density5.9 m 3 2 510 mm 6 9 780 kg 1 800 kg/m 36.5 m 3 2 700 mm 6 9 200 kg 1 800 kg/m 3Bottom dump type rock bucketBottom dump type general purpose bucket14

DIMENSIONSUnit: mm5 4305 380R 4 8504 7404 350*5 4401 0201 6601 8207003 9004 6005 0906 500*LOADING SHOVELWORKING RANGESBackhoeMeter14Loading ShovelMeter141212108642024681012CDEB B’EH1100A’A18 16 14 12 10 8 6 4 20Ground LineBoom length 7.55 m BE-boom 9.0 mArm length 3.4 m BE-arm 3.6 mA Max. digging reach 13 750 mm 15 350 mmA’ Max. digging reach (on ground) 13 360 mm 15 010 mmB Max. digging depth 8 050 mm 9 380 mmB’ Max. digging depth (8’ level) 7 920 mm 9 260 mmC Max. cutting height 12 410 mm 13 460 mmD Max. dumping height 8 050 mm 9 080 mmE Max. vertical wall 5 180 mm 6 450 mmBucket diggingforce kN (kgf)Arm crowdforcekN (kgf)ISOSAE: PCSAISOSAE: PCSA569(58 000)512(52 200)438(44 700)425(43 400)Meter482(49 200)440(44 900)430(43 900)422(43 000)10864202468HGEE'EH1100Ground LineFACBD14 12 10 8 6 4 2 0 MeterBucket capacity (heaped) 6.5 m 3A Min. digging distance4 510 mmB Min. level crowding distance6 580 mmC Level crowding distance4 370 mmD Max. digging reach11 500 mmE Max. cutting height12 410 mmE’ Max. dumping height 8 750 mmF Max. digging depth4 780 mmG Working radius at max. dumping height6 140 mmH Max. bucket opening width1 880 mmCrowding force577 kN (58 900 kgf)Breakout force594 kN (60 600 kgf)15

STANDARD EQUIPMENTStandard equipment may vary by country, so please consult your Hitachi dealer for details.ENGINE• H/P mode control• P mode control• E mode control• 75 A alternator• Dry-type air fi lter with clean dustcup• Cartridge-type engine oil fi lter• Cartridge-type fuel fi lter• Water fi lter• Radiator, air cooler and oil coolerwith dust protective net• Radiator reserve tank• Fan guard• Isolation-mounted engine• Auto-idle system• Overheat prevention deviceHYDRAULIC SYSTEM• Engine speed sensing system• E-P control system• OHS (Optimum <strong>Hydraulic</strong> System)• FPS (Fuel-saving Pump System)• Swing/boom priority mode system• Heavy lifting system• Boom mode selector system• Forced-lubrication and forcedcooling pump drive system• Control valve with main relief valve• Line fi lter (Delivery fi lter)• Suction fi lter• Full-fl ow fi lter• Pilot fi lter• Pump drain fi lterCAB• All-weather sound-suppressedsteel integrated cab withheadguard (OPG Level II (ISO)conforming), laminated glasswindshield, reinforced/tinted (greencolor) glass side and rear windows,intermittent wiper interlocked withfront windshield washer, adjustablereclining seat with adjustablearmrests, footrest, electrical horn,auto-tuning AM-FM radio withdigital clock, seat belt, cigarettelighter, ashtray, parcel pocket, glovecompartment, fl oor mat, auto-idleswitch, evacuation hammer, autoair conditioner with defroster, hotand cool box, engine control dial,pilot control shut-off lever, LEDroom lamp.MONITOR SYSTEM• Meters:Hour meter, engine coolanttemperature gauge and fuel gauge,auto-idle, indicator, lubricationmode indicator.• Warning indicators:Radiator water level, engine oillevel, hydraulic oil level, fuel level,auto lubrication, air-fi lter restriction,pump transmission oil pressure,alternator, over heat, engine oilpressure, engine stop, preheat andengine warning.DATA LOGGING SYSTEM• DLU (Data-logging unit)continuously records performanceof the engine and the hydraulicsystem. <strong>The</strong> record can be downloadedby PDA (Palm).LIGHTS• 2 working lights• 2 cab lights• 1 step light• 2 counterweight lightsUPPERSTRUCTURE• Undercover• 17 500 kg counterweight• Electric grease gun with hose reel• Centralized lubrication system forswing bearing• Control valves with main reliefvalves and port relief valves• Slow return orifi ces and make upvalves for cylinder circuitsUNDERCARRIAGE• Spring-set/hydraulic-released disctype parking brake• <strong>Hydraulic</strong> (grease) track adjusterwith shock absorbing recoils spring• Travel motor cover• Track and idler guardsMISCELLANEOUS• Standard tool kit• ISO conforming stairs and handrails• Wide side walk• Auto-lubrication system for frontattachment• 12 V power terminal board• Slip resistance tapes• Elevated cab (for Loading Shovel)OPTIONAL EQUIPMENTOptional equipment may vary by country, so please consult your Hitachi dealer for details.• Air-suspension seat• Travel motion alarm device• High cab kit (for Backhoe)• Full track guard• Slide ladder• Sun visor<strong>The</strong>se specifi cations are subject to change without notice.Illustrations and photos show the standard models, and may or may not include optionalequipment, accessories, and all standard equipment with some differences in color and features.Before use, read and understand the Operator’s Manual for proper operation.Hitachi Construction Machinery Co., Ltd.www.hcme.comKS-EN112EU