Whittlesea Sewage Treatment Plant - Yarra Valley Water

Whittlesea Sewage Treatment Plant - Yarra Valley Water

Whittlesea Sewage Treatment Plant - Yarra Valley Water

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

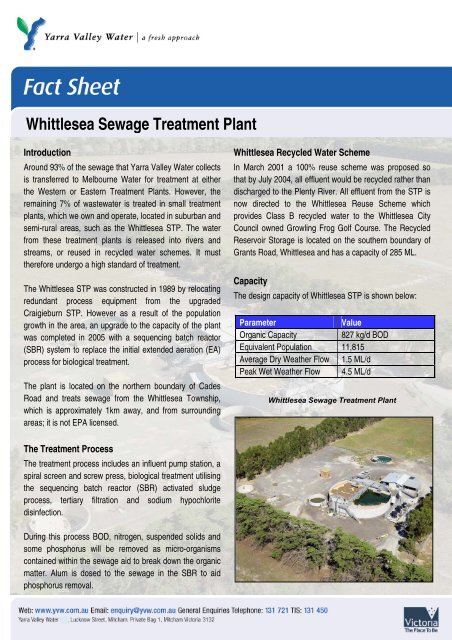

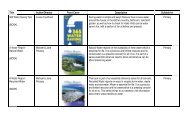

<strong>Whittlesea</strong> <strong>Sewage</strong> <strong>Treatment</strong> <strong>Plant</strong>IntroductionAround 93% of the sewage that <strong>Yarra</strong> <strong>Valley</strong> <strong>Water</strong> collectsis transferred to Melbourne <strong>Water</strong> for treatment at eitherthe Western or Eastern <strong>Treatment</strong> <strong>Plant</strong>s. However, theremaining 7% of wastewater is treated in small treatmentplants, which we own and operate, located in suburban andsemi-rural areas, such as the <strong>Whittlesea</strong> STP. The waterfrom these treatment plants is released into rivers andstreams, or reused in recycled water schemes. It musttherefore undergo a high standard of treatment.The <strong>Whittlesea</strong> STP was constructed in 1989 by relocatingredundant process equipment from the upgradedCraigieburn STP. However as a result of the populationgrowth in the area, an upgrade to the capacity of the plantwas completed in 2005 with a sequencing batch reactor(SBR) system to replace the initial extended aeration (EA)process for biological treatment.The plant is located on the northern boundary of CadesRoad and treats sewage from the <strong>Whittlesea</strong> Township,which is approximately 1km away, and from surroundingareas; it is not EPA licensed.<strong>Whittlesea</strong> Recycled <strong>Water</strong> SchemeIn March 2001 a 100% reuse scheme was proposed sothat by July 2004, all effluent would be recycled rather thandischarged to the Plenty River. All effluent from the STP isnow directed to the <strong>Whittlesea</strong> Reuse Scheme whichprovides Class B recycled water to the <strong>Whittlesea</strong> CityCouncil owned Growling Frog Golf Course. The RecycledReservoir Storage is located on the southern boundary ofGrants Road, <strong>Whittlesea</strong> and has a capacity of 285 ML.CapacityThe design capacity of <strong>Whittlesea</strong> STP is shown below:ParameterValueOrganic Capacity827 kg/d BODEquivalent Population 11,815Average Dry Weather Flow 1.5 ML/dPeak Wet Weather Flow 4.5 ML/d<strong>Whittlesea</strong> <strong>Sewage</strong> <strong>Treatment</strong> <strong>Plant</strong>The <strong>Treatment</strong> ProcessThe treatment process includes an influent pump station, aspiral screen and screw press, biological treatment utilisingthe sequencing batch reactor (SBR) activated sludgeprocess, tertiary filtration and sodium hypochloritedisinfection.During this process BOD, nitrogen, suspended solids andsome phosphorus will be removed as micro-organismscontained within the sewage aid to break down the organicmatter. Alum is dosed to the sewage in the SBR to aidphosphorus removal.

<strong>Whittlesea</strong> STP <strong>Treatment</strong> ProcessFig 1 (right): Briefly describes the main treatment processes that occur at the plantFig 2 (below): A schematic diagram of the plant’s treatment processCaustic SodaAlumInflowInletPumpStationScreeningSBR UnitWASScreenings toLandfillSludgeTankGravityDeck<strong>Sewage</strong> is pumped into the treatment plantPreliminary <strong>Treatment</strong>The sewage is dosed with caustic soda to maintain aneutral pHThe flow of sewage passes through screens so thatrubbish and other large objects can be removedSecondary <strong>Treatment</strong>The screened effluent then flows into one side of thesequencing batch reactor (SBR) where the sewage isaerated as the basin fills.Simultaneously, the other half of the tank which hasalready been aerated undergoes settling anddecantingOnce the aeration period has finished, the airflow isdirected to the other half which will now be filled withsewage and aerated, while the other side undergoessettling and decantingRemoval of soluble organic matter; phosphorus;nitrogen and suspended solids occursAlum is dosed to the SBR to promote phosphorusremovalWaste sludge from the SBR is thickened and eductedoff-siteReuse SchemeSodiumHypochloriteEqualisationBasinSand FiltersEduct off-siteTertiary <strong>Treatment</strong>The effluent then flows into an equalisation basin andis pumped through sand filters to remove suspendedsolids and phosphorus which escape from thebiological treatment phase.The effluent is also dosed with sodium hypochlorite forpreliminary disinfection at the equalisation basin; andfinal disinfection on the discharge of the sand filters, inorder to destroy any disease causing pathogens thatare still presentNow the effluent is of an acceptable standard to bereused