Micro-Alloyed Heat-Resistant Alloy Reduces Costs ... - Rolled Alloys

Micro-Alloyed Heat-Resistant Alloy Reduces Costs ... - Rolled Alloys

Micro-Alloyed Heat-Resistant Alloy Reduces Costs ... - Rolled Alloys

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

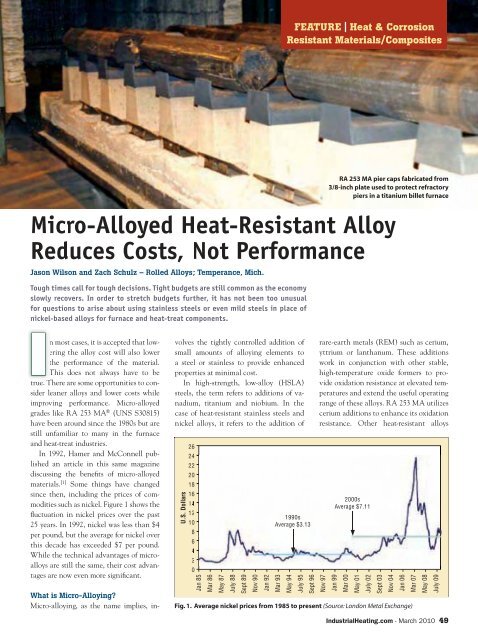

IFEATUREI <strong>Heat</strong> & Corrosion<strong>Resistant</strong> Materials/Compositestheir high nickel and lower chromium contents will not. Solutionannealing at 2050°F (when practical) can dissolve the sigmaphase and restore room-temperature ductility in RA 253 MA.Case History # 1 : Coal-Fired Power PlantsRA 253 MA has been used in the heat-treat and furnace industries,but its most significant use has been in coal-fired powerplants to replace 309 and 310 stainless. Here, it has proven itsability to withstand distortion better than other stainless steels. Ithas been commonly used for pulverized-coal injection nozzles intypical supercritical boilers as well as for cyclones in fluidized-bedboiler systems.Case History #2: Isothermal Annealing of ForgingsA Midwestern commercial heat-treat shop has been using corrugatedboxes manufactured from 11-gauge (0.120-inch) RA 253 MAsheet (Fig. 4). Two different-sized boxes are used. The operation isan "isothermal anneal" of various carbon-steel forgings. The typicalannealing temperature for most of the forgings is 1750°F witha maximum temperature of 1800°F. This is followed by fan cool to1185°F and then a still-air cool. Loads are up to 900 pounds.Distortion is a problem because the boxes are a rather close fit inthe furnace. As the sides bow out, they scrape away at the furnaceinsulation, which must be replaced. RA330 holds its shape fairlywell until it cracks, which is an acceptable failure mode. <strong>Alloy</strong> 309distorts very badly, which is not too surprising considering it hasabout half the creep strength of RA330. RA 253 MA has been thematerial of choice for the past four years based on its lower initialcost than RA330 and its equal or better resistance to distortion.Another captive heat-treat shop is also using corrugated RA253 MA boxes of much larger dimension (Fig. 5). Also made from11-gauge sheet, these boxes are 72 inches square. The bottoms ofthe boxes also utilize RA 253 MA round bar, 518 inch in diameter.This isothermal anneal is performed at 1600°F followed bycontrolled cooling to 1250°F.Case History #3: Steel Wire AnnealingRA 253 MA pipe is being used at one wire manufacturer for theheat treatment of steel wire between 1650 and 1800°F. Twenty-foot-long annealing tubes made from 1-inch, schedule-40 pipe areused in the furnace. A nitrogen atmosphere fills the tubes. RA 253MA has been the material of choice for over 10 years after testingside by side with nickel alloys such as RA330, alloy 601, Haynes230@ and alloy 600. The life of RA 253 MA is similar to alloy 601at about 40% of its cost.Fig.4. RA 253 MA corrugated boxes shown cooling down upon exitingan isothermal annealing operation at 1 750°F.Fig. 5. Close up of corrugated box and fabricated bottom grid, bothmade from RA 253 MA for an isothermal annealing process at 1600°F.NEW FromThe Duffy Cornpan]EnvironmentallyFriendly 1Mter-BasedThe Duffy Company283 E. Hellen Rd Palatine, I1 601CONDURSAL 777liFor all forms of GasCarburlzlng 81 CarbonltrldlngWater Based-EnvironmentallyFriendlyIProvides protection up to 2.5mm case depthsSuitable for temperatures upI to 1750°FApplication by Painting,Spraying and Immersion 1No special thinners requiredWashes off after heat THEtreatmentCONDURSAL N623aFor Gas Nltrldlng &qJ~itrocarburizind~~dased-EnvironmentallySuitable for Nitriding -. cyclesup to 90 hoursTemp. range: 930°F - 1150°FApplication by Painting,Spraying and ImmersionNo Special thinners requiredNo interference or 'radiation"to non-coated work piecesIFFY COMPANY',Call or visit our web site for by steel brush or,more information and pricing. shotblasting32 March 2010 - Indwtrial<strong>Heat</strong>ing.com

I Get the SkillsFig.6. RA 253 MA bar-frame basket manufactured from M-inch-diameter round barCase History #4:Bar-Frame Baskets for <strong>Heat</strong> Reatmentof CastingsA commercial heat-treat shop in the southernU.S. is now using shallow baskets madefrom W-inch diameter EL4 253 MA roundbar. The basket is fabricated using pressurewelding. The heat treatment of castings inthis shop involves heating to 1800°F followedby a water quench. Prior to RA 253MA being used, the baskets were madeof EL4330 alloy. RA 253 MA and RA330both typically last roughly 350 cycles beforereplacement. During use, both EL4253 MA and RA330 require straightening.The average load on the baskets is 2,500pounds, and the heat-treatment cycle lastsbetween four and eight hours.Case History #5: Pier Caps forTitanium Billet <strong>Heat</strong> TreatmentPier caps fabricated from 318-inch-thickRA 253 MA plate replaced W-inch-thicktype 304 stainless pier caps at this U.S. titaniumcompany. Operating temperatureswere typically 1750°F with occasionalexcursions to 1900°F. The atmosphere inthis car-bottom furnace was gas-fired andoxidizing. Cycles varied in length from twoto eight hours. The type 304 stainless capslasted about three months until oxidationand distortion necessitated their replacement.Type 304 stainless is not suggestedfor use at temperatures above 1600°F. Thelead photo of the RA 253 MA pier capswas taken after eight months, and expectationswere for total life for the piers to bein excess of two years. At the time of thephotos, the RA 253 MA had already paidback its higher initial cost. IHReferences:1. J. Hamer and J. McConnell, Industrial<strong>Heat</strong>ing,April 1992253 MA is a trademark of Outokumpu Stainless.RA330 is a registered trademarkof <strong>Rolled</strong><strong>Alloy</strong>s, Haynes, 230 and 214 are registeredtrademarks of Haynes International.For more information: Contact Jason Wilson,technical marketing manager, <strong>Rolled</strong><strong>Alloy</strong>s, 125 West Sterns Rd., Temperance, MI;tel: 800-928-9482; fax: 734-847-3915; e-mail:jwilson@rolledalloys.com; web: www.rolledalloys.com.-..-I related information may beby searching for these (and other)ey wordsfterms via BNP Media SEARCHt www.industrialheating.com: micro-Iloy, HSLA steel, rare-earth metal, heatstainless,pressure welding,orrugated boxesi the marketplace.nll ASM instructors are industry expertsand have years of practical industry andteaching experience.Choose from top-rated classroom andlaboratory courses in our modernTraining Center.Increase your knowledgeand performanceKeep up with all the latesttechnical advancesImprove productivityCourse Title DateI<strong>Heat</strong> TreatiPractical Ht !ating 3/22-31<strong>Heat</strong> Treating for theNon-<strong>Heat</strong> Treater 4/26-4128Practical Induction<strong>Heat</strong> Treating 411 9-41Failure AnalysisPractical Failure Analysis 411 9-4\23Practical Fracture Mechanics 511 7-511 9Practical Fractography 511 9-5/21Practical Fracture Mechanicsand Practical Fractography -Take BOTH and SAVE! 511 7-5/21Materials EngineeringIntroduction to Polymers andIPolymerTesting 415-4RIntroduction to Metallurgy -Webinar 511 1-511 3Corrosion 51-<strong>Micro</strong> ural AFerrous <strong>Alloy</strong>sAdvanced MetallcTechniques (DomNuclearMaterials fcPower Plants 511 7-5/21Material & Code Compl~a~~seIssues for NucleaPower Dlgnk'24-5128Welding Inspection andQuality Control 513-5RBuild your Mure.Take a class.Visitwww.asminternational.orgleducation1.800.336.51 52, ext. 0PASW <strong>Heat</strong> Treatingu society"IYlmlwsdmlYnMIlh~l.Industrial<strong>Heat</strong>ing.com - March 2010 53

![RA333 Data Sheet [Heat Resistant Alloys] - Rolled Alloys](https://img.yumpu.com/50335849/1/190x245/ra333-data-sheet-heat-resistant-alloys-rolled-alloys.jpg?quality=85)