Waterjet propulsion solutions - Laboratory of Marine Engineering

Waterjet propulsion solutions - Laboratory of Marine Engineering

Waterjet propulsion solutions - Laboratory of Marine Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

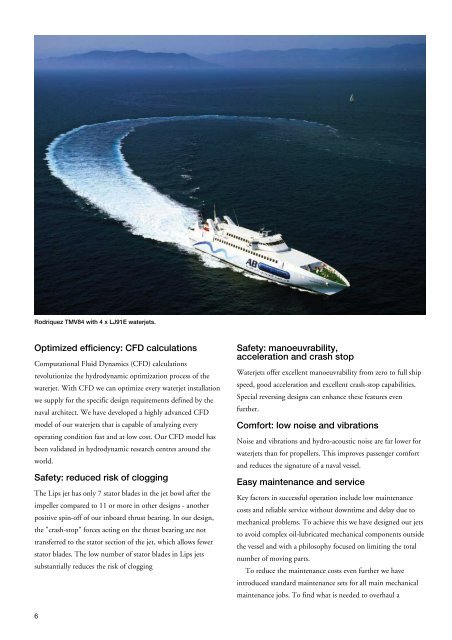

Rodriquez TMV84 with 4 x LJ91E waterjets.Optimized efficiency: CFD calculationsComputational Fluid Dynamics (CFD) calculationsrevolutionize the hydrodynamic optimization process <strong>of</strong> thewaterjet. With CFD we can optimize every waterjet installationwe supply for the specific design requirements defined by thenaval architect. We have developed a highly advanced CFDmodel <strong>of</strong> our waterjets that is capable <strong>of</strong> analyzing everyoperating condition fast and at low cost. Our CFD model hasbeen validated in hydrodynamic research centres around theworld.Safety: reduced risk <strong>of</strong> cloggingThe Lips jet has only 7 stator blades in the jet bowl after theimpeller compared to 11 or more in other designs - anotherpositive spin-<strong>of</strong>f <strong>of</strong> our inboard thrust bearing. In our design,the "crash-stop" forces acting on the thrust bearing are nottransferred to the stator section <strong>of</strong> the jet, which allows fewerstator blades. The low number <strong>of</strong> stator blades in Lips jetssubstantially reduces the risk <strong>of</strong> cloggingSafety: manoeuvrability,acceleration and crash stop<strong>Waterjet</strong>s <strong>of</strong>fer excellent manoeuvrability from zero to full shipspeed, good acceleration and excellent crash-stop capabilities.Special reversing designs can enhance these features evenfurther.Comfort: low noise and vibrationsNoise and vibrations and hydro-acoustic noise are far lower forwaterjets than for propellers. This improves passenger comfortand reduces the signature <strong>of</strong> a naval vessel.Easy maintenance and serviceKey factors in successful operation include low maintenancecosts and reliable service without downtime and delay due tomechanical problems. To achieve this we have designed our jetsto avoid complex oil-lubricated mechanical components outsidethe vessel and with a philosophy focused on limiting the totalnumber <strong>of</strong> moving parts.To reduce the maintenance costs even further we haveintroduced standard maintenance sets for all main mechanicalmaintenance jobs. To find what is needed to overhaul a6