LIFETIME Final Presentation - Laboratory of Marine Engineering

LIFETIME Final Presentation - Laboratory of Marine Engineering

LIFETIME Final Presentation - Laboratory of Marine Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

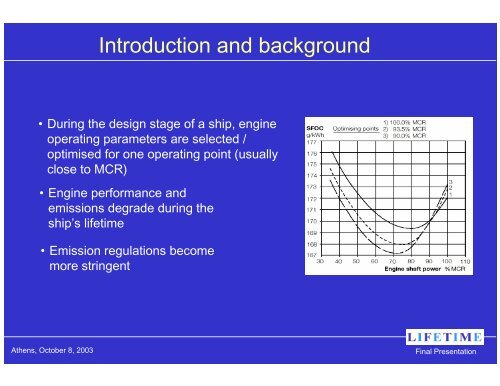

Introduction and background<br />

• During the design stage <strong>of</strong> a ship, engine<br />

operating parameters are selected /<br />

optimised for one operating point (usually<br />

close to MCR)<br />

• Engine performance and<br />

emissions degrade during the<br />

ship’s lifetime<br />

• Emission regulations become<br />

more stringent<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Introduction and background<br />

Y<br />

X<br />

CONTROL<br />

UNIT<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

LOW IN FUEL AND EMISSIONS TWO-STROKE<br />

INTELLIGENT MARINE ENGINE<br />

GROWTH Project G3RD-CT-2000-00245 - STARTING DATE: 1.4.2000 - DURATION: 39 months<br />

• DANAOS Shipping Co. (EL)<br />

• National Technical University <strong>of</strong> Athens / LME (EL)<br />

• MAN B&W Diesel A/S (DK)<br />

• ABB Service A/S (DK)<br />

• Germanischer Lloyd AG (D)<br />

• Hapag-Lloyd Container Linie AG (D)<br />

• CIMAC - National Members Association Greece (EL)<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Objectives and Methodology<br />

<strong>LIFETIME</strong> OBJECTIVES:<br />

To establish correlations between performance,<br />

emissions, and engine operating parameters, applicable to<br />

a wide variety <strong>of</strong> direct drive marine engines.<br />

To develop control systems including the correlations<br />

above, able to optimise engine performance, based on<br />

standard measurable operating and external parameters, with<br />

emissions level as an optimisation constraint.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Objectives and Methodology<br />

<strong>LIFETIME</strong> METHODOLOGY:<br />

(I) To perform a series <strong>of</strong> full scale shipboard tests and<br />

testbed experiments <strong>of</strong> powerplant performance and<br />

emissions for large two stroke marine engines, to compound<br />

the partner’s cumulated experience and information<br />

repository<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Objectives and Methodology<br />

<strong>LIFETIME</strong> METHODOLOGY:<br />

(II) To conduct a series <strong>of</strong> detailed simulations <strong>of</strong> ship powerplant<br />

operation using comprehensive advanced mathematical<br />

models, calibrated using the results <strong>of</strong> (I), so as to arrive at<br />

OBJ.1:<br />

Correlations linking performance, emissions and the<br />

engine parameters.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Objectives and Methodology<br />

<strong>LIFETIME</strong> METHODOLOGY:<br />

(III) To use simulation models, in combination with engine control<br />

systems design procedures and electronic system test bed<br />

trials, so as to arrive at OBJ.2 :<br />

Engine add-on systems including the optimisation<br />

correlations <strong>of</strong> OBJ.1.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Objectives and Methodology<br />

<strong>LIFETIME</strong> METHODOLOGY:<br />

(IV) To install prototype systems respectively on:<br />

- A conventional direct-drive slow-speed engine <strong>of</strong> a<br />

Danaos containership<br />

- A state-<strong>of</strong>-the-art ultra-large-bore engine <strong>of</strong> a newly built<br />

Hapag-Lloyd containership<br />

- The “Intelligent" engine <strong>of</strong> the MAN B&W research testbed<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Objectives and Methodology<br />

<strong>LIFETIME</strong> PROTOTYPE CONTROL SYSTEM<br />

2-stroke <strong>Marine</strong> Diesel Engine<br />

- Cylinder pressures<br />

and temperatures<br />

- Receivers pressures<br />

and temperatures<br />

- Crankshaft speed,<br />

torque and position<br />

- T/C speed<br />

- Fuel index<br />

- Lub oil pressure<br />

and temperature<br />

Control System<br />

- Ambient conditions<br />

- Fuel quality<br />

Set <strong>of</strong> Correlations between<br />

performance, emissions and<br />

engine operating parameters<br />

- Injection timing<br />

- Exhaust valve closing<br />

- Injection pulse<br />

- Lub oil dosage<br />

- T/C system control<br />

- Air cooler contol<br />

- Starting air system control<br />

- Cylinders and turbochargers<br />

cut out at part loads<br />

Control schemes algorithm<br />

Emissions<br />

Estimation<br />

- Optimization criterion<br />

- Ordered speed<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Work Overview<br />

On-board<br />

Experiments<br />

Simulations<br />

Correlations<br />

<strong>LIFETIME</strong> PROTOTYPE<br />

SYSTEMS<br />

Observer<br />

Testbed<br />

Experiments<br />

Control<br />

Schedules<br />

Engine<br />

Control<br />

Unit<br />

Full Scale<br />

Tests<br />

Analysis <strong>of</strong><br />

results<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Vessels for shipboard measurement campaigns<br />

Hapag-Lloyd’s containership “Antwerpen Express”<br />

Hapag-Lloyd’s containership “Shanghai Express”<br />

Odfjell’s chemical carrier “Bow Cecil”<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Research Centre and Intelligent Engine Testbed<br />

Exterior view <strong>of</strong> the MAN B&W facility<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Research Centre and Intelligent Engine Testbed<br />

View <strong>of</strong> the engine testbed with the 4T50MX Research Engine<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

The two possible configurations <strong>of</strong> the Intelligent Engine<br />

Installation <strong>of</strong> the IE<br />

Fuel Injection and Exhaust Valve<br />

control systems<br />

in parallel to<br />

the conventional camshaft<br />

on the 6L60MC engine<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Turbocharger test centre<br />

Exterior view <strong>of</strong> the ABB facility<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Turbocharger test centre<br />

ABB Turbocharger on the test rig<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Intelligent Engine<br />

Performance<br />

& Emissions<br />

Investigations<br />

MAN B&W Testbed<br />

“Bow Cecil” engine room<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Turbocharger measurement points setup<br />

Turbine blades<br />

(condition as supplied for tests)<br />

Turbocharger<br />

Performance<br />

Investigations<br />

at ABB Testbed<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Turbine nozzle ring contamination<br />

Nozzle ring No1<br />

(condition as supplied for tests)<br />

Nozzle ring No2<br />

(condition as supplied for tests)<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Compressor impeller preparation<br />

Compressor wheel<br />

coated with glass fibres<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Compressor<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Partners onboard “Shanghai Express” for measurements<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

“Shanghai Express” Propulsion Plant: 9K90MC engine<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Measurement <strong>of</strong> brake power, MS “Shanghai Express”<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Comparison <strong>of</strong> independent power measurement<br />

for main engine MS “Shanghai Express”<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

MS “Shanghai Express” sampling points for gaseous emissions (1), particulate matter (2),<br />

opacity (3) and filter smoke number (4)<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

“Shanghai Express”<br />

Exhaust gas<br />

measurements<br />

Sampling probe for gaseous emission<br />

Sampling probe for particulate emission<br />

Sampling points and analysers for<br />

measurement <strong>of</strong> opacity<br />

and filter smoke number<br />

Sampling point for gaseous<br />

and particulate emission<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

“Shanghai-Express” - ABB DAQ (SeMCa) connected to the 3rd turbocharger<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

“Antwerpen Express” Propulsion Plant: 7K98MC engine<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

“Antwerpen Express”<br />

Air management<br />

system<br />

measurements<br />

Turbine outlet measurements<br />

Temperature and pressure<br />

Compressor outlet measurements<br />

Temperature and pressure<br />

Turbocharger speed sensor<br />

Air-filter with thermocouples<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Measuring data acquisition system ZXTFLEX/ABB<br />

onboard “Antwerpen Express”<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Analysers for exhaust gas measurement, MS “Antwerpen Express”<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Analysis <strong>of</strong> ageing effect<br />

The ageing process<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Analysis <strong>of</strong> ageing effect - Methodology<br />

Collection <strong>of</strong> performance data and component running hours for 4 ships<br />

(DANAOS, HL, GCA members) out <strong>of</strong> 12 candidate<br />

Data pre-processing and selection <strong>of</strong> key operational parameters to be<br />

investigated<br />

Statistical analysis <strong>of</strong> ageing ratios - regression models<br />

Results assessment - conclusions<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Analysis <strong>of</strong> ageing effect - Data Summary<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Analysis <strong>of</strong> ageing effect - Typical results<br />

Ship: Maersk Livorno<br />

(DANAOS)<br />

30%<br />

ε∆Pcyl_cmp<br />

25%<br />

20%<br />

The ageing ratio is defined as a deviation ratio <strong>of</strong> the operating parameter<br />

15%<br />

value, in a specific engine load condition, to the corresponding value <strong>of</strong> the<br />

10%<br />

5% sea trial performance curves.<br />

0%<br />

35000 40000 45000 50000 55000 60000 65000 70000 75000 80000 85000<br />

M/E Hours Period1 Period2 Period3 EST EST21 Linear (Period1) Linear (Period2) Linear (Period3)<br />

Compression pressure ageing ratio ε and corresponding ageing models<br />

30%<br />

25%<br />

20%<br />

15%<br />

10%<br />

5%<br />

ε∆Texh_bTC<br />

20000<br />

18000<br />

16000<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

4000<br />

2000<br />

TC Hours<br />

0%<br />

0<br />

35000 40000 45000 50000 55000 60000 65000 70000 75000 80000<br />

M/E Hours<br />

TC Hours Period1 Period2 Peiod3 Predict Linear (Period1) Linear (Period2) Linear (Peiod3)<br />

Exhaust gas temperature before T/C ageing ratio ε and corresponding ageing models<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Analysis <strong>of</strong> ageing effect - Conclusions<br />

♦ Performance degradation significant after 15000 hours<br />

♦ Newly built ships no ageing phenomena for 2 years (min)<br />

♦ Established ageing effects (after 15000 – 20000 hrs)<br />

- Exhaust Temperature before T/C<br />

- Cylinder compression pressure<br />

- Turbocharger speed<br />

- Scavenging air pressure.<br />

♦ 5% increase in SFOC AGEING<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Multi-zone Combustion Model<br />

EQUIVALENCE RATIO MAP, 10 deg ATDC<br />

TEMPERATURE MAP, 10 deg ATDC<br />

71<br />

61<br />

41<br />

21<br />

1<br />

2<br />

3<br />

1.5<br />

1.4<br />

1.3<br />

1.2<br />

1.1<br />

1.0<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

2500<br />

2400<br />

2300<br />

2200<br />

2100<br />

2000<br />

1900<br />

1800<br />

1700<br />

1600<br />

1500<br />

FUEL JET DEVELOPMENT vs TIME<br />

GREY : 0 deg ATDC<br />

PURPLE : 5 deg ATDC<br />

BLUE : 10 deg ATDC<br />

RED : 20 deg ATDC<br />

FUEL BURNT PERCENTAGE MAP, 10 deg ATDC<br />

NOx MAP, 10 deg ATDC<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

3000<br />

2750<br />

2500<br />

2250<br />

2000<br />

1750<br />

1500<br />

1250<br />

1000<br />

750<br />

500<br />

250<br />

0<br />

Fuel spray development<br />

with time<br />

Maps in fuel spray at one time instant:<br />

Equivalence ratio<br />

Temperature<br />

% fuel mass burnt<br />

NOx<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Multi-zone Combustion Model<br />

NOx MAP, 0 deg ATDC<br />

3000<br />

2750<br />

2500<br />

2250<br />

2000<br />

1750<br />

1500<br />

1250<br />

1000<br />

750<br />

500<br />

250<br />

100<br />

50<br />

10<br />

0<br />

NOx MAP (ppm), 5 deg ATDC<br />

3000<br />

2750<br />

2500<br />

2250<br />

2000<br />

1750<br />

1500<br />

1250<br />

1000<br />

750<br />

500<br />

200<br />

100<br />

50<br />

0<br />

NOx MAP, 10 deg ATDC<br />

NOx MAP, 20 deg ATDC<br />

3000<br />

2750<br />

2500<br />

2250<br />

2000<br />

1750<br />

1500<br />

1250<br />

1000<br />

750<br />

500<br />

250<br />

0<br />

5000<br />

4000<br />

3000<br />

2750<br />

2500<br />

2250<br />

2000<br />

1750<br />

1500<br />

1250<br />

1000<br />

750<br />

500<br />

250<br />

0<br />

NOx maps in fuel spray at 4 time instants<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Engine Performance Modelling<br />

“Shanghai Express”<br />

Measured engine<br />

performance<br />

data (7 hours)<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Engine Performance Modelling<br />

Comparison between measured data and simulation results<br />

after determining the engine governor constants<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

T/C Fouling Modelling<br />

Endurance test<br />

with high ash fuel<br />

on a large 4-S engine<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Simulations - 7K98MC engine<br />

PARAMETRIC RUNS<br />

Measured and predicted engine<br />

performance and emissions parameters<br />

for various values <strong>of</strong> VIT change<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Simulations - 7K98MC engine<br />

NOx model Validation<br />

Predicted NOx using MOTHER and comparison with engine shop trials data<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Simulations - 7K98MC engine<br />

Creation <strong>of</strong> parameter maps (to be used for control)<br />

NOx (gr/kWh)<br />

23<br />

22<br />

21<br />

20<br />

19<br />

18<br />

17<br />

16<br />

15<br />

14<br />

13<br />

12<br />

11<br />

10<br />

Engine Load @ 75% <strong>of</strong> MCR<br />

VIT Change (deg)<br />

184<br />

183<br />

182<br />

181<br />

180<br />

179<br />

178<br />

177<br />

176<br />

175<br />

174<br />

173<br />

BSFC (gr/kWh)<br />

9<br />

-5 -4 -3 -2 -1 0 1 2 3 4 5<br />

Fuel Index Change (%)<br />

172<br />

-5 -4 -3 -2 -1 0 1 2 3 4 5<br />

Fuel Index Change (%)<br />

Typical NOx and BSFC maps for 75% load<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Simulations <strong>of</strong> Ageing and Wear<br />

Empirical models <strong>of</strong> component wear<br />

Piston ring wear<br />

Cylinder liner wear<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Possible Types <strong>of</strong> Correlation<br />

• Ship-specific look-up table<br />

* Simple but less accurate<br />

* Results based on a few experimental measurements<br />

* Valid only in range close to the measured values<br />

• Process model<br />

* Physical model including in-cylinder processes for NOx formation<br />

* Able to account for out-<strong>of</strong>-range inputs<br />

* Ageing effect can be incorporated<br />

* Higher execution time<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

<strong>LIFETIME</strong> Control System<br />

INTELLIGENT Engine<br />

Control System<br />

Set <strong>of</strong> Correlations between<br />

performance, emissions and<br />

engine operating parameters<br />

Control schemes algorithm<br />

Ship-specific correlation to be included in “Control” system<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

<strong>LIFETIME</strong> Control System<br />

Mathematical functional correlation (MAN B&W):<br />

where K 1 , K 2 , α engine-specific constants<br />

Oxygen concentration & Maximum temperature from:<br />

* A/F ratio (stoichiometric)<br />

* Scavenging pressure<br />

* Scavenging temperature<br />

* other measured operational parameters<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

<strong>LIFETIME</strong> observer system (NOx-Box)<br />

2-S <strong>Marine</strong> Diesel Engine<br />

- Receivers pressures<br />

and temperatures<br />

- Crankshaft speed,<br />

and torque<br />

- T/C speed<br />

- Fuel index<br />

- VIT<br />

Observer System<br />

Process model<br />

was included<br />

in “observer”<br />

(NTUA)<br />

MOTHER<br />

Mathematical Model<br />

NOx<br />

Estimation<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

<strong>LIFETIME</strong> observer system (NOx-Box)<br />

• Process model (MoTher code) embedded in PC platform (NOx-BOX)<br />

• Several engine operating parameters required for input and validation purposes<br />

• PC connected to onboard Data Acquisition (DAQ) System<br />

NOx MAP, 10 deg ATDC<br />

3000<br />

2750<br />

2500<br />

2250<br />

2000<br />

1750<br />

1500<br />

1250<br />

1000<br />

750<br />

500<br />

250<br />

0<br />

SCAVENGING<br />

RECEIVER<br />

P,T<br />

INLET<br />

VALVES<br />

CYLINDERS<br />

RPM<br />

LOAD<br />

FUEL<br />

RACK<br />

EXHAUST<br />

VALVES<br />

VIT<br />

T e<br />

EXHAUST<br />

RECEIVER<br />

P,T<br />

TURBINE<br />

RPM<br />

PLENUM AFTER<br />

TURBINE<br />

P<br />

Embedded<br />

MoTher<br />

DAQ<br />

Monitoring<br />

system<br />

NOx-Box<br />

Communication<br />

Serial link<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

<strong>LIFETIME</strong> observer system (NOx-Box)<br />

Calibration <strong>of</strong> estimated NOx value<br />

• Initial calibration using on-board measurements and simulation runs<br />

• Validation error (Predicted-Measured)<br />

• Error exceeds limit re-calibration <strong>of</strong> MoTher code constants<br />

IMPLEMENTATION<br />

• NOx-BOX onboard “Antwerpen Express” (HL) using automatic data input<br />

• NOx-BOX onboard “APL Scotland” (DANAOS) using manually inserted parameter<br />

values<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

<strong>LIFETIME</strong> observer system (NOx-Box)<br />

DANAOS Containership“APL Scotland”<br />

Hapag-Lloyd’s containership<br />

“Antwerpen Express”<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Determination <strong>of</strong> the operating parameters to be controlled<br />

Determination based on:<br />

• Simulation results <strong>of</strong> the powerplant performance performed in WP5<br />

(Powerplant simulation)<br />

• Engine-specific correlation between operating prameters and emissions<br />

obtained in WP6<br />

• Available control options for the conventional and intelligent engines.<br />

Basic selected controlled parameters<br />

• Injection timing<br />

• Choice <strong>of</strong> injection pr<strong>of</strong>ile<br />

• Exhaust valve open timing<br />

• Exhaust valve close timing<br />

• Hydraulic supply pressure (injection pressure)<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Validation <strong>of</strong> control schemes<br />

Development <strong>of</strong> engine running modes<br />

• Low Emission mode<br />

• Economy Mode<br />

4.0<br />

170<br />

160<br />

150<br />

Fuel Injection & Exhaust Valve Timing<br />

Cylinder Pressure<br />

Fuel Oil Consumption<br />

Low Emission mode<br />

Low Emission mode<br />

Economy mode<br />

Economy mode<br />

Exhaust valve close<br />

Pmax<br />

Pcomp<br />

Low Emission mode<br />

Economy mode<br />

2.0<br />

140<br />

[g /kW h ]<br />

0.0<br />

-2.0<br />

Timing<br />

[bar abs.]<br />

130<br />

120<br />

110<br />

100<br />

Exhaust valve open<br />

-4.0<br />

90<br />

-6.0<br />

80<br />

Injection Timing<br />

70<br />

50 60 70 80 90 100 110<br />

50 60 70 80 90 100 110<br />

50 60 70 Engine 80 Load [%] 90 100 110<br />

Engine Load [%]<br />

Engine Load [%]<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Testbed implementation <strong>of</strong> the control schemes<br />

Validation <strong>of</strong> the control schemes in the MAN B&W testbed<br />

in Copenhagen in order to:<br />

• To expand the knowledge <strong>of</strong> the engine combustion cycle with regard<br />

to exhaust emissions and efficiency<br />

• To determine the influence <strong>of</strong> variation in-cylinder compression<br />

pressure and maximum combustion pressure on the engine operational<br />

behaviour<br />

• To make an initial evaluation <strong>of</strong> the control schemes proposed for the<br />

intelligent engine and to expand the knowledge with regard to<br />

adjustments on the conventional (mechanically actuated) engine<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Testbed implementation <strong>of</strong> the control schemes<br />

Validation <strong>of</strong> the control schemes in the MAN B&W testbed<br />

in Copenhagen in order to:<br />

• To expand the knowledge <strong>of</strong> the engine combustion cycle with regard<br />

to exhaust emissions and efficiency<br />

• To determine the influence <strong>of</strong> variation in-cylinder compression<br />

pressure and maximum combustion pressure on the engine operational<br />

behaviour<br />

• To make an initial evaluation <strong>of</strong> the control schemes proposed for the<br />

intelligent engine and to expand the knowledge with regard to<br />

adjustments on the conventional (mechanically actuated) engine<br />

• A test series <strong>of</strong> 42 tests (about 1000 running hours) was carried out with a<br />

parameter variation <strong>of</strong> compression pressure and maximum firing pressure<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Analysis<br />

Observations:<br />

• For a fixed Pmax, decreasing Pcomp (or increasing Pmax minus Pcomp<br />

pressure) results in decreasing NOx. The effect is small at high loads, but<br />

stronger at lower loads<br />

• The HC emission at high loads (75% and 100%) is not affected by either Pmax<br />

or Pcomp variations<br />

• CO emissions decrease with increasing Pcomp, i.e. decreasing with higher<br />

air/fuel ratio caused by larger air amount trapped in the cylinder at the higher<br />

compression pressure<br />

• The effect <strong>of</strong> Pmax and Pcomp on PM (Particulate matter) emission follows the<br />

same trend as that <strong>of</strong> HC emission<br />

• Use <strong>of</strong> the compression pressure influence on NOx emissions, in the<br />

MAN B&W NOx function.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Prototype Control Systems<br />

Design and implementation <strong>of</strong> the prototype control systems<br />

• MAN B&W Prototype for the Intelligent Engine<br />

• On-line NOx-BOX observer system for the ultra-large bore engine<br />

• Off-line NOx-BOX observer system for the conventional engine<br />

Managerial decision<br />

• “Antwerpen Express” <strong>of</strong> HL was replaced by “Tokyo Express” <strong>of</strong> HL for the<br />

measurement campaign.<br />

Initial calibration <strong>of</strong> the prototype control systems<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Ultra-Large Bore Engine<br />

On-line NOx-BOX Observer System - General<br />

• A portable computer connected to the ship’s engine monitoring system able to<br />

calculate continuously the level <strong>of</strong> NOx emission<br />

• Includes the MOTHER simulation code to calculate the engine NOx level<br />

using the values <strong>of</strong> several measured engine operating parameters<br />

• Input data for the NOx-BOX calculations are provided on-line by the<br />

monitoring system <strong>of</strong> the ship<br />

SCAVENGING<br />

RECEIVER<br />

P,T<br />

INLET<br />

VALVES<br />

CYLINDERS<br />

RPM<br />

FUEL<br />

RACK<br />

EXHAUST<br />

VALVES<br />

VIT<br />

EXHAUST<br />

RECEIVER<br />

P,T<br />

TURBINE<br />

RPM<br />

PLENUM AFTER<br />

TURBINE<br />

P<br />

LOAD<br />

T e<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Brake Power<br />

per cylinder (kW)<br />

Ultra-Large Bore Engine<br />

On-line NOx-BOX Observer System - Development<br />

160<br />

• Development <strong>of</strong> the User Interface<br />

Pmax (bar)<br />

BSFOC (gr/kWh)<br />

Rel. A/F Ratio (-)<br />

6000<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

BMEP (bar)<br />

140<br />

120<br />

100<br />

Predicted<br />

80<br />

Reference data<br />

60<br />

185<br />

180<br />

175<br />

170<br />

165<br />

160<br />

2.8<br />

2.6<br />

2.4<br />

2.2<br />

2<br />

1.8<br />

1.6<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

20 30 40 50 60 70 80 90 100 110<br />

Load (%)<br />

• Development <strong>of</strong> the communication protocol between the NOx-BOX and the<br />

25<br />

ship’s monitoring system – Testing with STN ATLAS emulator<br />

• Initial calibration using the engine shop trials<br />

NOx (gr/kWh)<br />

30<br />

20<br />

15<br />

10<br />

5<br />

30 40 50 60 70 80 90 100 110<br />

Load (%)<br />

MOTHER results<br />

Engine Shop Trials<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Engine Running Mode s<strong>of</strong>tware has been developed and integrated<br />

in the ME Engine Control System (ECS). It includes:<br />

• The generic engine running mode<br />

• The engine running mode controller<br />

Intelligent Engine<br />

• The injection and exhaust valve close timing maps<br />

Fuel Injection & Exhaust Valve Timing<br />

• The user interface on Main Operating Panel <strong>of</strong> the ECS<br />

Low Emission mode<br />

Economy mode<br />

Exhaust valve close<br />

Timing<br />

Exhaust valve open<br />

Injection Timing<br />

Athens, October 8, 2003<br />

50 60 70 80 90 100 110<br />

Engine Load [%]<br />

<strong>Final</strong> <strong>Presentation</strong>

Conventional Engine<br />

Off-line NOx-BOX Observer System - General<br />

• A computer able to calculate the level <strong>of</strong> NOx emission manual data input <strong>of</strong><br />

measured engine operating parameters<br />

VESSEL: ENGINE: MAN B&W 12K90 MC<br />

• Includes the MOTHER simulation<br />

Engine Operation<br />

code<br />

Data<br />

to calculate the engine NOx level<br />

(Fill the values <strong>of</strong> the shipboard measurement<br />

instruments;<br />

using measured engine operating parameters<br />

Date: Date: Date:<br />

use the units indicated in brackets) Time Time Time Time Time Time Time Time Time<br />

Scav. Air Pressure (receiver) [bar]<br />

• Input data for the NOx-BOX calculations are provided <strong>of</strong>f-line by the ship’s<br />

Scav. air temp. after cooler [deg C]<br />

operator<br />

Exhaust Receiver Pressure [bar]<br />

Turbine Inlet Temperature [deg C]<br />

Barometric Pressure (engine room) [mbar]<br />

Shaft Torque [kNm]<br />

Engine Speed [rpm]<br />

Engine Power (MID) [BHP]<br />

Engine Power (SEMS) [BHP]<br />

Fuel Pump Index (average) [-]<br />

Pmax adjustment index (V.I.T.) [-]<br />

Turbocharger RPM [rpm]<br />

Athens, October 8, 2003<br />

Pmax [bar] (if available)<br />

<strong>Final</strong> <strong>Presentation</strong>

Conventional Engine<br />

Off-line NOx BOX Observer System - Development<br />

• Development <strong>of</strong> the User Interface<br />

• Initial calibration using the engine shop trials<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Prototype Control Systems<br />

Initial installation <strong>of</strong> the prototype control systems<br />

• MAN B&W Prototype for the Intelligent Engine (MAN B&W Testbed,<br />

Copenhagen)<br />

• On-line NOx-BOX observer system for the ultra-large bore engine (Tokyo<br />

Express)<br />

• Off-line NOx-BOX observer system for the conventional engine (APL<br />

Scotland)<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Ultra-Large Bore Engine<br />

On-line NOx-BOX Observer System<br />

• Installed onboard “Tokyo Express” <strong>of</strong> HL at the port <strong>of</strong> Bremerhaven<br />

• After the initial functionality tests, full system tests were performed during normal<br />

ship operation, while sailing towards Le Havre (France) with an intermediate stop at<br />

Rotterdam<br />

• After the completion <strong>of</strong> the trip, the prototype NOx-BOX was removed and taken<br />

back to NTUA for analysis <strong>of</strong> results and re-calibration<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Intelligent Engine<br />

Engine Running Mode s<strong>of</strong>tware installation<br />

• New Engine Control System (ECS) hardware & cabling<br />

• New mechanical/hydraulic components for controlling exhaust valve, injection<br />

valve and start air valves<br />

• The injection and exhaust valve close timing maps<br />

• Test setup for providing stimuli from all control stations (Bridge, ECR and<br />

Local)<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Conventional Engine<br />

Off-line NOx-BOX Observer System - Installation<br />

• A CD with the installation program <strong>of</strong> the OFF-LINE NOx-BOX prototype was<br />

sent to “APL Scotland” containership <strong>of</strong> DANAOS for installation<br />

• The program was installed on a ship's computer and worked with manually<br />

entered data<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Prototype Control Systems<br />

Recalibration <strong>of</strong> the prototype control systems<br />

• Recalibration <strong>of</strong> the on-line NOx-BOX system sea-trials onboard “Tokyo<br />

Express”<br />

• Latest corrections and final calibration / fine-tuning <strong>of</strong> the intelligent engine<br />

control system (ECS) in the MAN B&W testbed in Copenhagen.<br />

• No recalibration needed for the Off-line version <strong>of</strong> NOx-BOX onboard APL<br />

Scotland.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Ultra-Large 140 Bore 5000 Engine<br />

120<br />

On-line NOx-BOX Observer System<br />

Pmax (bar)<br />

100<br />

• The analysis <strong>of</strong> “Tokyo Express” sea trials, led to the necessity <strong>of</strong> NOx-BOX<br />

80<br />

measured<br />

2000<br />

predicted<br />

prototype recalibration.<br />

60<br />

kW/CYL<br />

4000<br />

3000<br />

1000<br />

20 40 60 80 100<br />

Load %<br />

20 40 60 80 100<br />

Load %<br />

40000<br />

• The severe fluctuations 24 <strong>of</strong> predicted NOx emissions and brake power at part<br />

loads were attributed 20to:<br />

30000<br />

NOx [gr/kWh]<br />

16<br />

• the deviation <strong>of</strong> “Tokyo Express” propeller curve from “Antwerpen<br />

12<br />

Express” propeller curve, used in initial calibration.<br />

10000<br />

8<br />

• the narrow initial calibration range <strong>of</strong> prototype<br />

20 40 60 80 100<br />

Load %<br />

50 60 70 80 90 100<br />

Engine rpm<br />

• Recalibration was performed with use <strong>of</strong> the results <strong>of</strong> the “Tokyo Express”<br />

sea trials.<br />

Pb [kW]<br />

20000<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Conventional Engine<br />

Off-line NOx_BOX Observer System<br />

• The initial calibration <strong>of</strong> the OFF-LINE NOx-BOX prototype was successful<br />

and good agreement between the recorded and calculated engine<br />

performance parameters has been obtained during the onboard tests<br />

28<br />

K90 Simulation Results<br />

160<br />

26<br />

140<br />

• No re-calibration <strong>of</strong> the OFF-LINE<br />

Measured<br />

NOx-BOX prototype was necessary<br />

Predicted<br />

24<br />

120<br />

22<br />

100<br />

20<br />

80<br />

18<br />

60<br />

N Ox (g r/KWh)<br />

55 60 65 70 75 80 85 90 95<br />

rpm<br />

Pow e r (KW/cyl)<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

0<br />

M a xim u m Pre ssu re (b a r)<br />

55 60 65 70 75 80 85 90 95<br />

rpm<br />

55 60 65 70 75 80 85 90 95<br />

rpm<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Ultra-Large Bore Engine<br />

On-line NOx-BOX Observer System<br />

• The ON-LINE NOx-BOX prototype was re-installed onboard “Tokyo Express” at<br />

the port <strong>of</strong> Bremerhaven, for the sea trial campaign to the port <strong>of</strong> Le Havre,<br />

France<br />

• The prototype used the same protocols and connection equipment as in the<br />

previous trials (Sep 2002), since no communication problem was observed<br />

• Initial functionality tests and full system tests were performed. During the trip the<br />

data acquired were logged in order to be analysed in WP11.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Engine Running Mode s<strong>of</strong>tware<br />

Intelligent Engine<br />

• The installation <strong>of</strong> test wall for in-<strong>of</strong>fice ‘hardware in the loop’ test <strong>of</strong> the<br />

complete ECS was completed on the Intelligent engine T50ME-X<br />

• A series <strong>of</strong> functionality tests, preparing the system for the full-scale trials<br />

was also performed.<br />

• The following parameters have been calibrated in order to achieve the<br />

desired performance and emission values for the two running modes<br />

(optimisation <strong>of</strong> SFOC or NOx emissions):<br />

• Compression ratio as function <strong>of</strong> engine load<br />

• Maximum cylinder pressure as function <strong>of</strong> engine load<br />

• Exhaust valve open angle as function <strong>of</strong> engine load<br />

• Hydraulic supply pressure as function <strong>of</strong> engine load<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Work Overview<br />

On-board<br />

Experiments<br />

Simulations<br />

Correlations<br />

<strong>LIFETIME</strong> PROTOTYPE<br />

SYSTEMS<br />

Observer<br />

Testbed<br />

Experiments<br />

Control<br />

Schedules<br />

Engine<br />

Control<br />

Unit<br />

Full Scale<br />

Tests<br />

Analysis <strong>of</strong><br />

results<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Ultra-Large Bore Engine<br />

On-line NOx-BOX Observer System<br />

• Full scale measurements <strong>of</strong> the engine performance and emissions were<br />

performed onboard “Tokyo Express”<br />

• Measurements were conducted with the ship main engine operating on 23 -<br />

100% <strong>of</strong> its rated power.<br />

• Operational parameters <strong>of</strong> the engine were measured by three independent<br />

sources (GL, MAN B&W and HL).<br />

• The On-line NOx-BOX kept log <strong>of</strong> the data and NOx estimates, gathered<br />

during the full-scale trials.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

GL Measurements<br />

Ultra-Large Bore Engine<br />

• Exhaust gas and fuel samples have been analysed in the laboratory <strong>of</strong> GL<br />

prior to onboard measurements to find out the particulate matter composition<br />

and the influence <strong>of</strong> fuel quality on emissions.<br />

• Emissions measurements at required operating points specified by IMO for<br />

Test Cycle E3 have been conducted.<br />

Test Cycle E3<br />

power<br />

100 %<br />

75 %<br />

50 %<br />

25 %<br />

speed<br />

100 %<br />

91 %<br />

80 %<br />

63 %<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

GL Measurements<br />

Ultra-Large Bore Engine<br />

• The specific emissions were calculated with Method 2 (Carbon Balance)<br />

according to IMO NOX Technical Code.<br />

• The engine operational parameters were recorded by the partners.<br />

Parameter<br />

Unit<br />

Operating point / Power<br />

power % <strong>of</strong> max. actual power<br />

-<br />

100%<br />

91%<br />

83%<br />

58%<br />

55%<br />

30%<br />

23%<br />

power % <strong>of</strong> rated power<br />

-<br />

84%<br />

76%<br />

69%<br />

49%<br />

46%<br />

25%<br />

19%<br />

speed % <strong>of</strong> rated speed<br />

-<br />

98%<br />

96%<br />

91%<br />

81%<br />

80%<br />

63%<br />

55%<br />

measured power<br />

kW<br />

33575<br />

30427<br />

27725<br />

19529<br />

18416<br />

10054<br />

7794<br />

measured NO x<br />

in exhaust gas<br />

g/kWh<br />

16.0<br />

17.7<br />

17.9<br />

16.9<br />

18.0<br />

18.5<br />

19.4<br />

measured NO x<br />

in exhaust gas<br />

kg/h<br />

537<br />

538<br />

497<br />

330<br />

331<br />

186<br />

151<br />

weighting factor<br />

-<br />

0.2<br />

-<br />

0.5<br />

-<br />

0.15<br />

0.15<br />

-<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

MAN B&W Measurements<br />

Ultra-Large Bore Engine<br />

40000<br />

• MAN B&W conducted measurements <strong>of</strong> ship operational data (power and<br />

rotational speed<br />

35000<br />

measurements) onboard “Tokyo Express”<br />

• Results<br />

Power, kW<br />

30000<br />

25000<br />

20000<br />

• The engine speed measurements for all three independent measurements<br />

differed<br />

15000<br />

not more than 1% in relation to the speed measured by GL.<br />

10000<br />

• The power measurement by MAN B&W was in a range <strong>of</strong> +7% to +12% in<br />

relation to 5000the GL power measurement<br />

• The on board 0 measurement system <strong>of</strong> the ship showed a maximum<br />

0 10 20 30 40 50 60 70 80 90 100<br />

difference <strong>of</strong> 10% (up to 15% for low Speed, engine rpm load).<br />

Germanischer Lloyd (GL) HAPAG-Lloyd, ship's system HAPAG-Lloyd / MAN B&W Diesel A/S, indicator system<br />

Test Cycle E3: “Test cycle for Propeller-law-operated main and propeller-law-operated auxiliary engine application “<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Ultra-Large Bore Engine<br />

On-line NOx-BOX Operation<br />

• The On-line NOx-BOX kept log <strong>of</strong> the data and NOx estimates, gathered<br />

during the full-scale trials performed in the sea-passage Bremerhaven-Le<br />

Havre.<br />

• Engine operational data were collected along with the estimates generated by<br />

the NOx-BOX inference algorithm.<br />

• Comparison <strong>of</strong> measured NOx by GL and calculated NOx by ON-LINE NOx-<br />

BOX has been conducted.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Ultra-Large Bore Engine<br />

On-line NOx-BOX measurements – Selection <strong>of</strong> Results<br />

35000<br />

40000<br />

25<br />

Power<br />

Power<br />

vs.<br />

vs.<br />

Time<br />

RPM<br />

Laptop PC<br />

overheating period<br />

Power, kW<br />

Power, kW<br />

30000<br />

35000<br />

25000 30000<br />

20000 25000<br />

15000 20000<br />

10000 15000<br />

5000<br />

10000<br />

5000<br />

0<br />

Athens, October 8, 2003<br />

0<br />

NOx emissions, gr/kWh<br />

20:01:12<br />

20:29:15<br />

20<br />

15<br />

10<br />

5<br />

0<br />

Weighted emissions (IMO, Test Cycle 3) Measured, GL<br />

GL: 17.5 gr/kWh<br />

Measured - Dec 27, 2002<br />

Predicted<br />

(Dec 27, 2002) NTUA: No prediction 17.67 gr/kWh<br />

Predicted, NTUA<br />

due to “out (Dec 28, 2002) Measured - Dec 28, 2002<br />

<strong>of</strong> range data” error<br />

Calibration curve<br />

Measured<br />

21:06:44<br />

21:36:42<br />

22:10:07<br />

22:41:05<br />

23:10:51<br />

23:43:32<br />

8:37:19<br />

8:54:31<br />

9:13:10<br />

9:32:38<br />

9:52:04<br />

50 55 60 65 70 75 80 85 90 95<br />

Time (hh,mm,ss)<br />

RPM<br />

10:10:47<br />

10:32:50<br />

Measured - GL<br />

0 5000 10000 15000 20000 25000 30000 35000 40000<br />

Power, kW<br />

10:52:48<br />

11:10:07<br />

11:30:18<br />

11:49:46<br />

12:07:42<br />

13:06:57<br />

13:38:33<br />

13:59:18<br />

14:16:53<br />

14:34:22<br />

14:53:17<br />

<strong>Final</strong> <strong>Presentation</strong>

Ultra-Large Bore Engine<br />

On-line NOx-BOX Observer System<br />

NOx<br />

Estimation<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Intelligent Engine - Results<br />

Intelligent Engine<br />

• The full-scale tests included variation <strong>of</strong> the controllable parameters for the<br />

two running modes under consideration (emission mode, performance mode)<br />

• A series <strong>of</strong> functionality tests, preparing the system for the full-scale trials was<br />

also performed.<br />

• The full-scale tests demonstrated the flexibility <strong>of</strong> the system, and the<br />

possibilities with regard to emission and fuel consumption adjustment.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Conventional Engine<br />

Off-line NOx-BOX Observer System<br />

• For 30 days the crew recorded input data as well as some validation data in<br />

pre-specified datasheets.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Conventional Engine<br />

Off-line NOx-BOX Observer System<br />

• The output <strong>of</strong> each NOx estimation cycle has been appropriately postprocessed<br />

to estimate the ship’s NOx emissions with regard to the main<br />

operational parameters logged onboard ship.<br />

-8<br />

-7<br />

-6<br />

28<br />

26<br />

24<br />

22<br />

20<br />

18<br />

16<br />

14<br />

12<br />

NOx emissions, gr/kWh<br />

-5<br />

-4<br />

-3<br />

-2<br />

-1<br />

0<br />

1<br />

2<br />

10<br />

Brake Power, kW<br />

28000 30000 32000 34000 36000 38000 40000 42000<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong><br />

Power Prediction Error, %<br />

29453 kW<br />

29661 kW<br />

29690 kW<br />

30149 kW<br />

30206 kW<br />

30273 kW<br />

30533 kW<br />

30543 kW<br />

30658 kW<br />

37657 kW<br />

37862 kW<br />

38025 kW<br />

38293 kW<br />

38802 kW<br />

39037 kW<br />

39041 kW<br />

39501 kW<br />

39696 kW<br />

41052 kW<br />

41297 kW<br />

41704 kW<br />

Engine Pow er, kW

Analysis <strong>of</strong> Results<br />

• Effect <strong>of</strong> control schemes on performance and emissions<br />

• NOx-BOX operation evaluation<br />

• Model-based vs. correlational methods <strong>of</strong> NOx estimation<br />

• Compressor map line position under different conditions<br />

• Future engine control systems<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Effect <strong>of</strong> control schemes on performance and emissions<br />

Findings <strong>of</strong> the Intelligent Engine measurements<br />

• For the RPM variation it was shown that the same tendency is observed for all<br />

loads, with a clear trend that higher RPM results in a lower NOx level.<br />

• For the Pmax variation and the Pcomp/Pscav variation the relation is close to<br />

linear, but with the gradient depending <strong>of</strong> the engine load.<br />

• Blow back variation did not have a significant influence on NOx emission, but<br />

remains an important factor with regard to scavenge efficiency and cleanness<br />

<strong>of</strong> the scavenge space.<br />

• The hydraulic pressure influenced both the fuel injection pressure and the<br />

opening <strong>of</strong> the exhaust valve.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

NOx-BOX operation evaluation<br />

Analysis <strong>of</strong> the operation and evaluation <strong>of</strong> the performance <strong>of</strong> NOx-<br />

BOX<br />

• NOx-BOX s<strong>of</strong>tware sensor is capable <strong>of</strong> accurately predicting the engine<br />

operational parameters, provided efficient calibration is done prior to onboard<br />

installation.<br />

• Power calculation accuracy is a valid criterion toward accurate NOx emissions<br />

prediction.<br />

• NOx emissions prediction is accurate in cases where suitable data <strong>of</strong> the<br />

engine performance, as well as measured NOx emissions have been used for<br />

the initial calibration <strong>of</strong> the NOx-BOX s<strong>of</strong>tware sensor<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

NOx-BOX operation evaluation<br />

Further development <strong>of</strong> NOx-BOX<br />

• Calibration with different parameters<br />

• Proper periodic recalibration<br />

• In fixed intervals<br />

• After scheduled on non-scheduled major engine modifications<br />

• With automatic recalibration methods (using an embedded optimisation<br />

code and adaptation schemes)<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Model-based vs. correlational methods <strong>of</strong> NOx estimation<br />

NOx emissions estimation<br />

The NOx emissions measured during the performance and emission tests on the 4T50MX test<br />

engine in Copenhagen by MAN B&W have been predicted using two methods, by MAN B&W and<br />

NTUA.<br />

• MAN B&W correlation function (engine-specific)<br />

An engine-specific formula (correlation) which associates measured operational<br />

parameters in the form <strong>of</strong> a NOx prediction function<br />

• NTUA thermodynamic s<strong>of</strong>tware (model-based)<br />

The MOTHER simulation code and the multizone combustion model which calculate the<br />

NOx emissions in several loading and operational conditions.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Model-based vs. correlational methods <strong>of</strong> NOx estimation<br />

MAN B&W NOx function vs. NTUA model-based NOx estimation (4T50MX<br />

engine)<br />

NOx emission (gr/kWh)<br />

NOx emission (gr/kWh)<br />

2516<br />

14<br />

20<br />

12<br />

NOx Emission (gr/kWh)<br />

15<br />

10<br />

8<br />

10<br />

6<br />

4<br />

5<br />

2<br />

0 0<br />

30<br />

(*)<br />

25<br />

20<br />

15<br />

MAN B&W<br />

MAN B&W (Measured) NTUA<br />

10<br />

NTUA (Calculated)<br />

MAN B&W (Measured)<br />

5<br />

MAN B&W (Calculated)<br />

NTUA (Calculated)<br />

MAN B&W (Calculated)<br />

0<br />

40% 60% 80% 100% 120%<br />

T02030 T02040<br />

(Pmax=161.5bar,<br />

(Pmax=105bar,<br />

Pcomp=136.7)<br />

Pcomp=85)<br />

T02031 T02041<br />

(Pmax=149.4bar,<br />

(Pmax=95bar,<br />

Pcomp=135.7)<br />

Pcomp=85)<br />

Engine Load (%)<br />

T02032 T02042<br />

(Pmax=136.2.5bar,<br />

(Pmax=85bar,<br />

Pcomp=135.9)<br />

Pcomp=85)<br />

T02043 T02033<br />

(Pmax=161.9bar,<br />

(Pmax=105bar,<br />

Pcomp=127.1)<br />

Pcomp=75)<br />

T02046 T02036<br />

(Pmax=159.8bar,<br />

(Pmax=105bar,<br />

Pcomp=115.4)<br />

Pcomp=65)<br />

Baseline<br />

Load 50% 75%<br />

(Load 100%)<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

60<br />

Model-based vs. correlational methods <strong>of</strong> NOx estimation<br />

60<br />

MAN B&W<br />

NTUA<br />

MAN B&W<br />

NTUA<br />

Calculatio n E rro r (% )<br />

40<br />

20<br />

40<br />

Load 75% Load 50%<br />

Calculation E rror (% )<br />

20<br />

(*)<br />

0<br />

T02030<br />

(Pmax=161.5bar,<br />

Pcomp=136.7)<br />

T02031<br />

(Pmax=149.4bar,<br />

Pcomp=135.7)<br />

T02032<br />

(Pmax=136.2.5bar,<br />

Pcomp=135.9)<br />

T02033<br />

(Pmax=161.9bar,<br />

Pcomp=127.1)<br />

T02036<br />

(Pmax=159.8bar,<br />

Pcomp=115.4)<br />

0<br />

T02040<br />

(Pmax=105bar,<br />

Pcomp=85)<br />

T02041<br />

(Pmax=95bar,<br />

Pcomp=85)<br />

T02042<br />

(Pmax=85bar,<br />

Pcomp=85)<br />

T02043<br />

(Pmax=105bar,<br />

Pcomp=75)<br />

T02046<br />

(Pmax=105bar,<br />

Pcomp=65)<br />

• Maximum error below 20%<br />

Calculation error <strong>of</strong> the two<br />

methods<br />

• Minimal error in tests with high maximum pressure<br />

• The MAN B&W function provides better calculations in the 75% load. The NTUA model-based method<br />

provides better calculations in the 50% load.<br />

• Brake power calculation accuracy estimated using the MOTHER code is a valid criterion toward accurate<br />

NOx emissions prediction<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Turbocharger components for surge free operation (ABB)<br />

Objectives<br />

• Development <strong>of</strong> a mathematical model define the engine operating line on the<br />

compressor map under normalised boundary conditions<br />

• Analysis <strong>of</strong> the turbocharger behavior under various turbocharger and engine<br />

operational conditions<br />

• Determination <strong>of</strong> turbocharger components for surge free turbocharger<br />

operation<br />

Method<br />

• Analysis <strong>of</strong> data from measurements performed in August 2001 on board the<br />

HL ship “Antwerpen Express” and on December 2002 on board the Hapag<br />

Lloyd ship “Tokyo Express”.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

“Antwerpen Express” running with clean and fouled turbochargers<br />

Ship: Hapag Lloyd "Antwerpen Express"<br />

Test Trials: 15.08.2001 and 23.08.2001<br />

Engine: MAN B&W 7K98MC with 3xTPL85-B11<br />

Engine operating lines with clean and fouled TCs<br />

Pe=32,52 MW<br />

n=94 rpm<br />

Pe=32,86 MW<br />

n=94 rpm<br />

Pe=25,31 MW<br />

n=86 rpm<br />

Pe=30,56 MW<br />

n=90 rpm<br />

Pe=20,09 MW<br />

n=80 rpm<br />

Pe=25,79 MW<br />

n=86 rpm<br />

Pe=16,44 MW<br />

n=75 rpm<br />

Pe=19,34 MW<br />

n=75 rpm<br />

TCs clean<br />

TCs fouled<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Turbocharger components for surge free operation<br />

• Engine parameter variations that have been investigated using<br />

turbochargers with clean and fouled turbines:<br />

• Engine speed variation (Engine speed: 89 to 95 rpm with constant bmep)<br />

• Exhaust valve open variation (Eo=-10 to +10 °CA) f or 100% - and 75%-load<br />

• Exhaust valve close variation (Ec=-20 to +20 °CA) for 100% - and 75%-<br />

load.<br />

• Measures in order to achieve optimum turbocharger operation:<br />

• Preventive measures like turbine dry cleaning with rice or nut shells or<br />

turbine and compressor washing with water<br />

• Turbocharger and engine manufacturer have to co-operate with the power<br />

plant enduser in order to find appropriate turbocharger cleaning intervals.<br />

• For a safe engine and turbocharger operation engine and turbocharging<br />

system designers have to co-operate in order to produce turbocharger<br />

components for surge free turbocharger operation.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Future engine control systems<br />

• Design aspects towards better efficiency – less emissions marine<br />

diesel engines<br />

• Control <strong>of</strong> operational parameters and optimization <strong>of</strong> engine performance<br />

with respect to fuel oil consumption and emissions leads to more<br />

sophisticated and reliable 2-stroke marine diesel engines<br />

• Use <strong>of</strong> advanced control schemes leads to improved performance <strong>of</strong> marine<br />

engines.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Future engine control systems<br />

• Advanced control features <strong>of</strong> the intelligent engine<br />

Exhaust valve movement<br />

80<br />

70<br />

mm<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

90 110 130 150 170 190 210 230 250 270 290<br />

Dg. C. A.<br />

Early closing<br />

Late closing<br />

Early opening<br />

Late opening<br />

Reference<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Future engine control systems<br />

• Innovations introduced with the Intelligent Engine<br />

• Hydraulic Power Supply unit<br />

• Hydraulic Cylinder Unit, including:<br />

electronically controlled fuel pump<br />

electronically controlled exhaust valve actuator<br />

• Electronically controlled starting air valves<br />

• Integrated electronic control <strong>of</strong> auxiliary blowers<br />

• Integrated electronic governor functions<br />

• Crankshaft position sensing and tacho system<br />

• Electronically controlled Alpha Lubricators for cylinder lubrication<br />

• PMI system - <strong>of</strong>f-line cylinder pressure measurement system<br />

• Local Operating Panel<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Future engine control systems<br />

• Advanced control features <strong>of</strong> the intelligent engine<br />

• Optimal control and flexibility <strong>of</strong> fuel injection in terms <strong>of</strong> pressure,<br />

timing, rate, shaping, main, pre & post injection pressure.<br />

• Optimal adaptation to different fuel.<br />

• Optimal adaptation to different operation modes.<br />

• Optimal combustion at all operation speeds and loads<br />

• Optimal engine acceleration<br />

• Reduced fuel consumption<br />

• Operational safety and flexibility<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Future engine control systems<br />

• The intelligent engine implementation<br />

Y<br />

X<br />

ECS<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

PART 4<br />

CONCLUSIONS<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

Work Progress<br />

CONCLUSIONS<br />

• Conduction <strong>of</strong> initial onboard and testbed measurements and correlation with<br />

simulation models.<br />

• Investigation <strong>of</strong> the engine ageing and turbocharger fouling effects.<br />

• Determination <strong>of</strong> the operating parameters values for optimum powerplant<br />

operation in terms <strong>of</strong> performance and emissions.<br />

• Development <strong>of</strong> advanced control schemes.<br />

• Design and development <strong>of</strong> electronic control and observer prototype<br />

systems.<br />

• Onboard installation and full-scale tests.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

CONCLUSIONS<br />

Outcome and possible implications <strong>of</strong> the <strong>LIFETIME</strong> project<br />

• The installation <strong>of</strong> advanced marine engines is promoting the EU policy<br />

concerned with improvement <strong>of</strong> working conditions<br />

• Adjustment <strong>of</strong> engine emissions according to regional or local legislation<br />

and requirements is promoting cost-effective marine operations<br />

• The development <strong>of</strong> emissions observer systems may lead to cost-effective<br />

real-time evaluation <strong>of</strong> ship emission legislation conformance<br />

• Environmental benefits can be directly associated with the reduction in<br />

exhaust emissions <strong>of</strong> marine powerplants, through the use <strong>of</strong> advanced<br />

control systems and technologies.<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>

The End<br />

Athens, October 8, 2003<br />

<strong>Final</strong> <strong>Presentation</strong>