bulletin - Siempelkamp

bulletin - Siempelkamp

bulletin - Siempelkamp

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

High spindle speeds (up to 3,500 rpm)<br />

Rectangular thermo-symmetrical carrying sleeve with hydrostatic guides<br />

at all four sides<br />

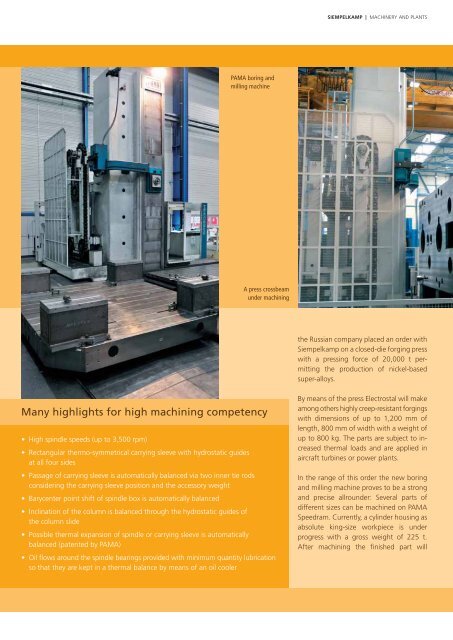

PAMA boring and<br />

milling machine<br />

Passage of carrying sleeve is automatically balanced via two inner tie rods<br />

considering the carrying sleeve position and the accessory weight<br />

Barycenter point shift of spindle box is automatically balanced<br />

Inclination of the column is balanced through the hydrostatic guides of<br />

the column slide<br />

Possible thermal expansion of spindle or carrying sleeve is automatically<br />

balanced (patented by PAMA)<br />

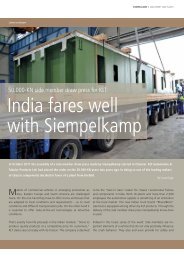

A press crossbeam<br />

under machining<br />

Many highlights for high machining competency<br />

Oil fl ows around the spindle bearings provided with minimum quantity lubrication<br />

so that they are kept in a thermal balance by means of an oil cooler<br />

SIEMPELKAMP | MACHINERY AND PLANTS<br />

the Russian company placed an order with<br />

<strong>Siempelkamp</strong> on a closed-die forging press<br />

with a pressing force of 20,000 t permitting<br />

the production of nickel-based<br />

super-alloys.<br />

By means of the press Electrostal will make<br />

among others highly creep-resistant forgings<br />

with dimensions of up to 1,200 mm of<br />

length, 800 mm of width with a weight of<br />

up to 800 kg. The parts are subject to increased<br />

thermal loads and are applied in<br />

aircraft turbines or power plants.<br />

In the range of this order the new boring<br />

and milling machine proves to be a strong<br />

and precise allrounder: Several parts of<br />

different sizes can be machined on PAMA<br />

Speedram. Currently, a cylinder housing as<br />

absolute king-size workpiece is under<br />

progress with a gross weight of 225 t.<br />

After machining the fi nished part will