Failure Analysis of Electrical and Electronic Products and Components

Failure Analysis of Electrical and Electronic Products and Components

Failure Analysis of Electrical and Electronic Products and Components

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

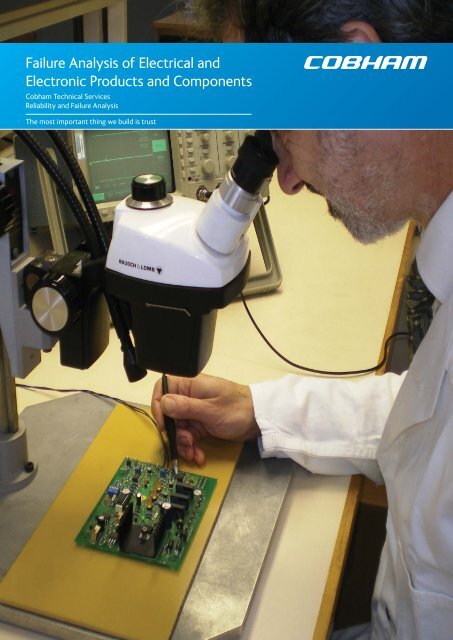

<strong>Failure</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Electrical</strong> <strong>and</strong><br />

<strong>Electronic</strong> <strong>Products</strong> <strong>and</strong> <strong>Components</strong><br />

Cobham Technical Services<br />

Reliability <strong>and</strong> <strong>Failure</strong> <strong>Analysis</strong><br />

The most important thing we build is trust

<strong>Failure</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Electrical</strong> <strong>and</strong><br />

<strong>Electronic</strong> <strong>Products</strong> <strong>and</strong> <strong>Components</strong><br />

Cobham Technical Services<br />

Reliability <strong>and</strong> <strong>Failure</strong> <strong>Analysis</strong><br />

Maintaining reliability<br />

Reliability in electronic systems is important,<br />

whether you are a designer, manufacturer,<br />

distributor or user <strong>of</strong> equipment. Cobham<br />

Technical Services has many decades <strong>of</strong><br />

experience in identifying the causes <strong>of</strong><br />

reliability problems from product down to<br />

component level. Cobham Technical Services<br />

provides impartial, expert <strong>and</strong> fast diagnosis<br />

<strong>of</strong> problems from design through to use <strong>and</strong><br />

failure in the field, working with you to find<br />

a solution.<br />

Where reliability problems arise<br />

There are many situations where having further<br />

information can solve reliability problems <strong>and</strong><br />

significantly save time <strong>and</strong> money. Here are<br />

some typical cases which Cobham Technical<br />

Services regularly investigates:<br />

Thermal <strong>and</strong>/or mechanical stress<br />

Can cause many types <strong>of</strong> failure including<br />

internal fractures. The SEM image shows<br />

Ball Grid Array (BGA) connections which have<br />

fractured from thermal fatigue.<br />

Fire<br />

Even when fire has burned away the region<br />

that caused it, identifying the probable cause<br />

is <strong>of</strong>ten still possible; sometimes from analysing<br />

a similar non-failed product. It is not always at the<br />

most obvious cause. The image shows a burned<br />

out cable connection.<br />

� Production stoppages threatening costly<br />

delays <strong>and</strong> losses<br />

� Field returns, where it is essential to<br />

know whether the fault is due to design,<br />

assembly or use<br />

� Conflicting insurance or legal claims<br />

� Assessing new production techniques<br />

� Checking whether components are<br />

counterfeit or below acceptable quality<br />

� Analysing a supply chain to locate the<br />

source <strong>of</strong> a fault<br />

� Assessing the quality <strong>of</strong> manufacture<br />

� Determining whether a series <strong>of</strong> faults<br />

is due to a batch <strong>of</strong> components or<br />

a change in a process<br />

� Assessing if there should be a product recall.<br />

<strong>Failure</strong> analysis services<br />

Cobham Technical Services advises across<br />

the electronics manufacturing industry from<br />

aerospace, automotive <strong>and</strong> rail through to<br />

domestic, IT infrastructure <strong>and</strong> medical.<br />

<strong>Analysis</strong> <strong>of</strong> thous<strong>and</strong>s <strong>of</strong> cases over more<br />

than 30 years at Cobham Technical Services<br />

has generated an invaluable accumulation<br />

<strong>of</strong> experience. This capability will help you<br />

underst<strong>and</strong> the root cause <strong>of</strong> any reliability<br />

problem <strong>and</strong> help avoid costly repetitions.<br />

Cobham Technical Services <strong>of</strong>fers a range<br />

<strong>of</strong> services:<br />

� <strong>Failure</strong> analysis: a practical approach to<br />

failure from whole equipment down to all<br />

active <strong>and</strong> passive electronic components,<br />

providing you with an analysis <strong>of</strong> faults,<br />

How products fail<br />

Continuing improvements in the reliability <strong>of</strong> electronics have led to the expectation that they will never fail. The result is a greater pressure<br />

to correct problems, when they do occur, <strong>and</strong> to prevent repetition. There are numerous potential reasons why even the best systems or<br />

components can fail, for example:<br />

Poor soldering<br />

Examination <strong>of</strong> solder joints <strong>and</strong> wetting will<br />

indicate the quality <strong>of</strong> the soldering process,<br />

for example on lead-free joints. The image<br />

shows poor wetting <strong>of</strong> a component lead,<br />

with perhaps insufficient time at temperature.<br />

<strong>Electrical</strong> overstress<br />

Can cause melting, breakdown, oxidation<br />

<strong>and</strong> other effects. The image shows a power<br />

transistor with a voltage breakdown.<br />

Contamination <strong>and</strong> migration<br />

Contamination can be introduced during<br />

manufacture or use. Migration can occur under<br />

electrical stress <strong>and</strong> is exacerbated by heat <strong>and</strong><br />

moisture. The SEM image shows migration <strong>of</strong><br />

a metal across an insulating surface.<br />

Mechanical abrasion<br />

Defective surface finish can:<br />

Cause or result from abrasion <strong>and</strong> wear,<br />

Cause mechanical malfunction or electrical failure,<br />

Cause adhesion <strong>of</strong> coatings to fail.<br />

Surface analysis can quantify roughness, waviness,<br />

curl <strong>and</strong> other parameters.

conclusions on the mechanism <strong>of</strong> failure,<br />

identification <strong>of</strong> the stage at which it<br />

occurred, <strong>and</strong> recommendations on<br />

correction <strong>and</strong> prevention.<br />

� Analytical services: with expert<br />

interpretation.<br />

� Design review: assessment <strong>of</strong> the electronic<br />

design or build quality <strong>of</strong> a product,<br />

subassembly or component.<br />

� Technical review: state-<strong>of</strong>-the-art reviews<br />

<strong>of</strong> a particular technology. Previous<br />

examples include high temperature<br />

Data collection<br />

It is crucial that all the samples <strong>and</strong> historic<br />

data available is obtained. Details from<br />

manufacturing history, or use, or previous<br />

failures may give key information.<br />

Non Destructive Tests<br />

These include electrical measurements,<br />

internal inspection, <strong>and</strong> probes such as X-ray<br />

or Scanning Acoustic Microscopy. The micr<strong>of</strong>ocus<br />

X-ray image shows a pcb via with very thin copper<br />

at the centre.<br />

Package Opening<br />

Techniques include:<br />

Mechanical lid removal<br />

Chemical jet etching<br />

The image shows an integrated circuit with<br />

epoxy package material removed by jet etching<br />

to reveal the chip <strong>and</strong> wire bonds.<br />

Internal Examination<br />

This includes both Optical Microscopy<br />

<strong>and</strong> Scanning Electron Microscopy<br />

The image shows a ‘tomb-stoned’<br />

ceramic capacitor.<br />

electronics, non-volatile memories <strong>and</strong><br />

electronics for use in satellites.<br />

� Expert witness <strong>and</strong> investigation to<br />

support legal actions: technical evidence<br />

<strong>of</strong>ten clarifies who is at fault <strong>and</strong> in what<br />

way. Cobham Technical Services works for<br />

solicitors, companies <strong>and</strong> courts providing<br />

expert witness statements <strong>and</strong> reports to<br />

support claims. These can be for a single<br />

party or joint witness situations.<br />

� Financial loss engineering support:<br />

while the direct causes <strong>of</strong> failure <strong>and</strong><br />

unreliability are technical, <strong>of</strong>ten it is the<br />

underlying issues such as adequacy <strong>of</strong> the<br />

design <strong>and</strong> design process, allocation <strong>of</strong><br />

fault <strong>and</strong> consequential financial losses<br />

which are <strong>of</strong> central importance. Cobham<br />

Technical Services deploys its technical<br />

capability to provide evidence to support<br />

claims <strong>and</strong> quantify costs.<br />

A structured approach<br />

Cobham Technical Services employs a multidisciplinary team from diverse backgrounds <strong>and</strong> with many years <strong>of</strong> experience <strong>of</strong> diagnosing<br />

reliability <strong>and</strong> failure problems. <strong>Electronic</strong> components are analysed by using a consistent methodology <strong>and</strong> a careful sequence to ensure<br />

that all the evidence is obtained <strong>and</strong> correctly used to assess the cause <strong>of</strong> failure:<br />

Infrared Spectroscopy<br />

helps identify materials by their characteristic<br />

IR absorption. The image shows comparison<br />

<strong>of</strong> IR curves <strong>of</strong> a contaminant <strong>and</strong> the<br />

suspected source material.<br />

Ion Chromatography<br />

Separates <strong>and</strong> quantifies the individual<br />

ions within a test solution. It is used to<br />

characterise unknown ionic materials (e.g.<br />

contaminants from a surface). The image<br />

shows unknown contaminants against a<br />

characterisation curve, <strong>and</strong> allows assessment<br />

<strong>of</strong> risk from contamination.<br />

Thermal analysis<br />

Thermo gravimetric analysis (TGA) <strong>and</strong><br />

differential scanning calorimetry (DSC) can<br />

give valuable information about the thermal<br />

behaviour <strong>of</strong> materials <strong>and</strong> their thermal history<br />

either during processing or since. The image<br />

shows thermal decomposition <strong>of</strong> two supposedly<br />

identical materials.<br />

Postulation <strong>and</strong> testing <strong>of</strong> failure mechanisms<br />

A hypothesis for the mechanism is developed<br />

against the available evidence <strong>and</strong> previous<br />

experience. The theory may be tested by<br />

deliberate trial on new samples.

Examples <strong>of</strong> problems in different markets<br />

Aerospace<br />

A series <strong>of</strong> small smoke incidents in the cabin<br />

<strong>of</strong> an aircraft lead to a large scale review.<br />

Cobham Technical Services identified the<br />

immediate cause to be associated with the<br />

method <strong>of</strong> assembly <strong>of</strong> the electronics <strong>and</strong><br />

recommended changing the position <strong>of</strong> the<br />

critical components on the board.<br />

Transport<br />

Problems had occurred with monitoring the<br />

position <strong>of</strong> doors on an underground train.<br />

Cobham Technical Services found that a<br />

suspect component had inadequate<br />

internal soldering.<br />

www.cobham.com/technicalservices<br />

ERA Technology Limited trading as Cobham Technical Services<br />

Domestic<br />

Several heating systems failed with emissions<br />

<strong>of</strong> fumes. The root cause was located by<br />

analysis at Cobham Technical Services in<br />

some poor quality capacitors.<br />

Industrial<br />

An extensive set <strong>of</strong> accelerated life tests<br />

generated a number <strong>of</strong> failures in high power<br />

control systems. Some <strong>of</strong> these were analysed<br />

at Cobham Technical Services to be caused<br />

by an inadequate cleaning process.<br />

Cobham Technical Services<br />

Cobham Technical Services works at the<br />

leading-edge <strong>of</strong> innovation by undertaking<br />

advanced design <strong>and</strong> development,<br />

producing high-performance custom<br />

components <strong>and</strong> sub-systems, delivering<br />

specialist technical consultancy services <strong>and</strong> by<br />

providing state-<strong>of</strong>-the-art electromagnetic<br />

<strong>and</strong> power system modelling s<strong>of</strong>tware<br />

products.<br />

Expert technical teams have extensive<br />

embedded programme management<br />

experience, which ensures efficient project<br />

planning, resource time management <strong>and</strong><br />

on-time delivery.<br />

These capabilities provide customers with<br />

high added-value <strong>and</strong> enhanced competitive<br />

advantage through reduced technical <strong>and</strong><br />

commercial risk, faster time-to-market <strong>and</strong><br />

improved performance <strong>of</strong> products, systems<br />

<strong>and</strong> engineering infrastructure assets.<br />

Industry-leading technology is delivered<br />

to government departments <strong>and</strong> global<br />

companies across market sectors as diverse<br />

as communications, aerospace, defence,<br />

transport, electronics, medical <strong>and</strong> energy.<br />

Cobham Technical Services is based<br />

across four sites located in Leatherhead,<br />

UK (ERA Technology), Abingdon, UK<br />

(Lightning Testing <strong>and</strong> Consultancy),<br />

Kidlington, UK (Vector Fields S<strong>of</strong>tware)<br />

<strong>and</strong> Aurora, USA (Vector Fields S<strong>of</strong>tware).<br />

For further information please contact:<br />

Cobham Technical Services<br />

ERA Technology<br />

Cleeve Road,<br />

Leatherhead,<br />

FM1303<br />

Surrey KT22 7SA UK<br />

REF: RFA25<br />

Tel: +44 (0)1372 367444<br />

Fax: +44 (0)1372 367134<br />

Email: era.info@cobham.com<br />

Web: www.cobham.com/technicalservices

![NC1147 (pdf 1.47 mb) Nitrogen Concentrator [OBIGGS] - Cobham plc](https://img.yumpu.com/51124104/1/190x245/nc1147-pdf-147-mb-nitrogen-concentrator-obiggs-cobham-plc.jpg?quality=85)