Instruction manual "optoNCDT 2300" - Micro-Epsilon

Instruction manual "optoNCDT 2300" - Micro-Epsilon

Instruction manual "optoNCDT 2300" - Micro-Epsilon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

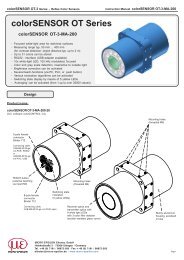

<strong>Instruction</strong> Manual<strong>optoNCDT</strong> 2300ILD 2300-2ILD 2300-50ILD2300-2LLILD2300-2BLILD 2310-10ILD 2300-5ILD 2300-100ILD2300-10LLILD2300-5BLILD 2310-20ILD 2300-10ILD 2300-200ILD2300-20LLILD2310-50BLILD 2310-50ILD 2300-20ILD2300-50LLILD 2300-40

MICRO-EPSILONMESSTECHNIKGmbH & Co. KGKönigbacher Strasse 1594496 Ortenburg / GermanyTel. +49 (0) 8542 / 168-0Fax +49 (0) 8542 / 168-90e-mail info@micro-epsilon.dewww.micro-epsilon.comCertified acc. to DIN EN ISO 9001: 2008EtherCAT® is registered trademark and patented technology,licensed by Beckhoff Automation GmbH, Germany.

Contents1. Safety....................................................................................................................................... 111.1 Symbols Used................................................................................................................................................ 111.2 Warnings......................................................................................................................................................... 111.3 CE Compliance............................................................................................................................................... 121.4 Proper Use...................................................................................................................................................... 131.5 Proper Environment........................................................................................................................................ 132. Laser Class.............................................................................................................................. 143. Functional Principle, Technical Data...................................................................................... 173.1 Short Description............................................................................................................................................ 173.2 Real Time Control (A-RTSC)........................................................................................................................... 173.3 Exposure Control............................................................................................................................................ 173.4 Technical Data................................................................................................................................................ 183.5 Indicator Elements at Sensor......................................................................................................................... 234. Delivery.................................................................................................................................... 244.1 Unpacking....................................................................................................................................................... 244.2 Storage........................................................................................................................................................... 245. Installation............................................................................................................................... 255.1 Diffuse Reflection............................................................................................................................................ 255.2 Direct Reflection.............................................................................................................................................. 295.3 Electrical Connections.................................................................................................................................... 315.3.1 Connection Possibilities................................................................................................................ 315.3.2 Supply Voltage.............................................................................................................................. 335.3.3 Laser on......................................................................................................................................... 335.3.4 Input and Outputs......................................................................................................................... 345.3.5 Ethernet......................................................................................................................................... 355.3.6 EtherCAT....................................................................................................................................... 365.3.7 Connector and Sensor Cable....................................................................................................... 37<strong>optoNCDT</strong> 2300

7.6.2 Trigger Counter............................................................................................................................. 687.6.2.1 General......................................................................................................................... 687.6.2.2 Trigger ID (T)................................................................................................................ 687.6.2.3 Trigger Event Counter.................................................................................................. 687.6.2.4 Trigger Measurement Value Counter........................................................................... 697.6.2.5 Example........................................................................................................................ 697.6.2.6 Function........................................................................................................................ 707.6.2.7 Presets for Trigger Mode and Trigger Edge................................................................ 717.6.3 Synchronization............................................................................................................................. 727.7 Loading, Saving, Extras ................................................................................................................................. 747.7.1 Loading/Saving Settings............................................................................................................... 747.7.2 Extras............................................................................................................................................. 758. Digital Interfaces..................................................................................................................... 768.1 Preliminary Remarks....................................................................................................................................... 768.2 Ethernet........................................................................................................................................................... 768.2.1 Default Settings............................................................................................................................. 768.2.2 Data Format Output Values, Measurement Value Frame Ethernet............................................... 778.2.3 Measurement Data Transmission to a Measurement Value Server, Measurement Value Block.. 818.2.4 Ethernet Video Signal Transmission............................................................................................. 838.3 RS422............................................................................................................................................................. 838.4 EtherCAT......................................................................................................................................................... 858.5 Change Ethernet to EtherCAT........................................................................................................................ 859. Value Output............................................................................................................................ 869.1 RS422............................................................................................................................................................. 869.1.1 Possible Output Values and Output Sequence............................................................................ 889.1.2 Error Codes................................................................................................................................... 899.2 Ethernet........................................................................................................................................................... 909.3 EtherCAT......................................................................................................................................................... 909.4 Analog Output................................................................................................................................................. 919.5 Error Handling................................................................................................................................................ 91<strong>optoNCDT</strong> 2300

10. <strong>Instruction</strong>s for Operating...................................................................................................... 9210.1 Reflection Factor of the Target Surface.......................................................................................................... 9210.2 Error Influences ............................................................................................................................................. 9310.2.1 Light from other Sources .............................................................................................................. 9310.2.2 Color Differences .......................................................................................................................... 9310.2.3 Surface Roughness ...................................................................................................................... 9310.2.4 Temperature Influences ................................................................................................................ 9310.2.5 Mechanical Vibration .................................................................................................................... 9310.2.6 Movement Blurs ............................................................................................................................ 9310.2.7 Angle Influences ........................................................................................................................... 9410.3 Optimizing the Measuring Accuracy ............................................................................................................. 9510.4 Cleaning.......................................................................................................................................................... 9610.5 Protective Housing ........................................................................................................................................ 9710.5.1 Versions......................................................................................................................................... 9710.5.2 Guidelines ..................................................................................................................................... 9710.5.3 Delivery ......................................................................................................................................... 9711. RS422 Connection with USB Converter............................................................................... 10012. Software Support with MEDAQLib....................................................................................... 10013. Warranty................................................................................................................................. 10114. Decommissioning, Disposal................................................................................................. 10115. Service, Repair...................................................................................................................... 102AppendixA 1 Optional Accessories.................................................................................................................................... 103A 2 Factory Setting.............................................................................................................................................. 106A 2.1 Parameters.................................................................................................................................................... 106A 2.2 Set Default Settings...................................................................................................................................... 107A 3 PC2300-0.5/Y................................................................................................................................................ 108A 4 PC2300-x/OE................................................................................................................................................ 109A 5 IF2004/USB................................................................................................................................................... 110<strong>optoNCDT</strong> 2300

<strong>optoNCDT</strong> 2300A 6 ASCII Communication with Sensor.............................................................................................................. 111A 6.1 General......................................................................................................................................................... 111A 6.2 Commands Overview................................................................................................................................... 113A 6.3 General Commands..................................................................................................................................... 117A 6.3.1 General ....................................................................................................................................... 117A 6.3.1.1 Help............................................................................................................................ 117A 6.3.1.2 Sensor Information .................................................................................................... 117A 6.3.1.3 Synchronization ........................................................................................................ 118A 6.3.1.4 Booting the Sensor ................................................................................................... 118A 6.3.1.5 Reset Counter............................................................................................................ 119A 6.3.1.6 Switching the Command Reply, ASCII Interface ...................................................... 119A 6.3.1.7 PRINT......................................................................................................................... 120A 6.3.2 User Level.................................................................................................................................... 121A 6.3.2.1 Change of the User Level........................................................................................... 121A 6.3.2.2 Change to User in the User Level.............................................................................. 121A 6.3.2.3 User Level Request.................................................................................................... 121A 6.3.2.4 Set Standard User...................................................................................................... 121A 6.3.2.5 Change Password...................................................................................................... 121A 6.3.3 Triggering..................................................................................................................................... 122A 6.3.3.1 Trigger Selection ....................................................................................................... 122A 6.3.3.2 Effect of the Trigger Input........................................................................................... 122A 6.3.3.3 Trigger Level .............................................................................................................. 122A 6.3.3.4 Number of Measurement Values Displayed.............................................................. 123A 6.3.3.5 Software Trigger Pulse............................................................................................... 123A 6.3.3.6 Trigger Output all Values............................................................................................ 123A 6.3.4 Interfaces..................................................................................................................................... 124A 6.3.4.1 Ethernet...................................................................................................................... 124A 6.3.4.2 Setting Measurement Server..................................................................................... 124A 6.3.4.3 Setting RS422 ........................................................................................................... 124A 6.3.4.4 Change between Ethernet / EtherCAT....................................................................... 125A 6.3.4.5 Units Web-Interface.................................................................................................... 125A 6.3.5 Load / Save Settings................................................................................................................... 125A 6.3.5.1 Save Parameter ......................................................................................................... 125A 6.3.5.2 Load Parameter ......................................................................................................... 125A 6.3.5.3 Default Settings ......................................................................................................... 125

<strong>optoNCDT</strong> 2300A 6.4 Measurement................................................................................................................................................ 126A 6.4.1 General........................................................................................................................................ 126A 6.4.1.1 Measurement Mode .................................................................................................. 126A 6.4.1.2 Selection of Peak for Displacement Measurement.................................................... 126A 6.4.1.3 Video Signal Request................................................................................................. 126A 6.4.1.4 Measuring Rate.......................................................................................................... 126A 6.4.1.5 Laser Power................................................................................................................ 127A 6.4.2 Video Signal................................................................................................................................ 127A 6.4.2.1 Reduction of Region of Interest (ROI)........................................................................ 127A 6.4.2.2 Video Averaging......................................................................................................... 127A 6.4.3 Material Data Base...................................................................................................................... 128A 6.4.3.1 Reading of Material Data Base.................................................................................. 128A 6.4.3.2 Choose Material......................................................................................................... 128A 6.4.3.3 Display Material ......................................................................................................... 128A 6.4.3.4 Edit Material Table...................................................................................................... 129A 6.4.3.5 Delete Material Table.................................................................................................. 129A 6.4.4 Measurement Value Processing................................................................................................. 129A 6.4.4.1 Averaging of Measurement Value.............................................................................. 129A 6.4.4.2 Spike Correction........................................................................................................ 129A 6.4.4.3 Values used for Statistics........................................................................................... 130A 6.4.4.4 Reset the Statistics..................................................................................................... 130A 6.4.4.5 Setting Masters / Zero................................................................................................ 130A 6.5 Data Output.................................................................................................................................................. 131A 6.5.1 General........................................................................................................................................ 131A 6.5.1.1 Selection Digital Output............................................................................................. 131A 6.5.1.2 Output Data Rate........................................................................................................ 131A 6.5.1.3 Error Processing........................................................................................................ 131A 6.5.1.4 Specified Measured Value Output............................................................................. 131A 6.5.2 Select Measurement Values to be Output.................................................................................. 132A 6.5.2.1 Request Data Selection.............................................................................................. 132A 6.5.2.2 Data Selection Displacement Measurement ............................................................ 132A 6.5.2.3 Data Selection Thickness Measurement................................................................... 132A 6.5.2.4 Data Selection Statistic Values................................................................................... 133A 6.5.2.5 Data Selection Optional Values ................................................................................ 133A 6.5.2.6 Set Video Output........................................................................................................ 133A 6.6 Example Command Sequence During Measurement Selection................................................................. 134A 6.7 Error Messages............................................................................................................................................. 135

A 7 EtherCAT....................................................................................................................................................... 139A 7.1 Generall......................................................................................................................................................... 139A 7.2 Preamble....................................................................................................................................................... 139A 7.2.1 Structure of EtherCAT®-Frames................................................................................................. 139A 7.2.2 EtherCAT® Services.................................................................................................................... 140A 7.2.3 Addressing and FMMUs.............................................................................................................. 141A 7.2.4 Sync Manager............................................................................................................................. 141A 7.2.5 EtherCAT State Machine............................................................................................................. 142A 7.2.6 CANopen over EtherCAT............................................................................................................ 142A 7.2.7 Process Data PDO Mapping....................................................................................................... 143A 7.2.8 Service Data SDO Service........................................................................................................... 144A 7.3 CoE – Object Directory................................................................................................................................. 145A 7.3.1 Characteristics............................................................................................................................. 145A 7.3.2 Communication Specific Standard Objects (CiA DS-301)......................................................... 145A 7.3.2.1 Object 1000h: Device type......................................................................................... 146A 7.3.2.2 Object 1001h: Error register...................................................................................... 146A 7.3.2.3 Object 1003h: Predefined error field.......................................................................... 146A 7.3.2.4 Object 1008h: Manufacturer device name................................................................ 146A 7.3.2.5 Object 1009h: Hardware version............................................................................... 146A 7.3.2.6 Object 100Ah: Software version................................................................................ 147A 7.3.2.7 Object 1018h: Device identification........................................................................... 147A 7.3.2.8 Object 1A00h: TxPDO Mapping................................................................................. 147A 7.3.2.9 Object 1A01 up to 1A63: TxPDO mapping................................................................ 148A 7.3.2.10 Object 1C00h: Synchronous manager type.............................................................. 148A 7.3.2.11 Object 1C13h: TxPDO assign.................................................................................... 148A 7.3.2.12 Object 1C33h: Synchronous parameter.................................................................... 149A 7.3.3 Manufacturer Specific Objects.................................................................................................... 150A 7.3.3.1 Object 2001h: User level............................................................................................ 151A 7.3.3.2 Object 2005h: Sensor informations (further)............................................................. 151A 7.3.3.3 Object 2010h: Loading/saving settings..................................................................... 152A 7.3.3.4 Object 2050h: Advanced settings.............................................................................. 152A 7.3.3.5 Object 2101h: Reset................................................................................................... 152A 7.3.3.6 Object 2105h: Factory settings.................................................................................. 153A 7.3.3.7 Object 2131h: Light source........................................................................................ 153A 7.3.3.8 Object 2154h: Measuring program............................................................................ 153A 7.3.3.9 Object 2161h: Peak selection at distance measuring............................................... 153A 7.3.3.10 Object 2181h: Averaging, error processing, statistics and spike correction............ 154A 7.3.3.11 Object 21B0h: Digital interfaces, selection of transmitted data (measurements)..... 156A 7.3.3.12 Object 21C0h: Ethernet............................................................................................. 157<strong>optoNCDT</strong> 2300

<strong>optoNCDT</strong> 2300A 7.3.3.13 Object 21E0h: Zeroing/Mastering.............................................................................. 158A 7.3.3.14 Object 2250h: Measuring rate................................................................................... 158A 7.3.3.15 Object 2410h: Triggermodi........................................................................................ 159A 7.3.3.16 Object 2711h: Reduction of region of interest........................................................... 160A 7.3.3.17 Object 2800h: Material info........................................................................................ 160A 7.3.3.18 Object 2801h: Material select.................................................................................... 161A 7.3.3.19 Object 2802h: Material table edit............................................................................... 161A 7.3.3.20 Object 603Fh: Sensor - error..................................................................................... 162A 7.3.3.21 Object 6065h: Measurement values.......................................................................... 162A 7.4 Error Codes for SDO Services...................................................................................................................... 162A 7.5 Measurement Data Formats......................................................................................................................... 164A 7.6 ILD2300 with Oversampling in EtherCAT..................................................................................................... 164A 7.7 ILD2300 Distributed Clock............................................................................................................................ 172A 7.7.1 Synchronization........................................................................................................................... 172A 7.7.1.1 Synchronization off.................................................................................................... 173A 7.7.1.2 Slave........................................................................................................................... 173A 7.7.1.3 Slave Alternating........................................................................................................ 173A 7.7.1.4 Apply Selected Settings ............................................................................................ 173A 7.7.1.5 Setting Regardless of TwinCat................................................................................... 173A 7.8 Measuring Rates and Measurement Values with EtherCAT........................................................................ 174A 7.9 Meaning of EtherCAT-STATUS-LED............................................................................................................. 174A 7.10 EtherCAT Configuration with the Beckhoff TwinCAT©-Manager................................................................. 175A 7.11 Finish EtherCAT............................................................................................................................................ 181A 7.12 Troubleshooting............................................................................................................................................ 182A 8 Control Menu................................................................................................................................................ 186

Safety1. SafetyThe handling of the sensor assumes knowledge of the instruction <strong>manual</strong>.1.1 Symbols UsedThe following symbols are used in this instruction <strong>manual</strong>:iMeasure1.2 WarningsIndicates a hazardous situation which, if not avoided, may result in minor or moderateinjury.Indicates a situation which, if not avoided, may lead to property damage.Indicates a user action.Indicates a user tip.Indicates hardware or a button/menu in the software.Avoid unnecessary laser radiation to be exposed to the human body.Switch off the sensor for cleaning and maintenance.Switch off the sensor for system maintenance and repair if the sensor is integrated into a system.Caution - use of controls or adjustments or performance of procedures other than those specified may causeharm.Connect the power supply and the display-/output device in accordance with the safety regulations for electricalequipment.> > Danger of injury> > Damage to or destruction of the sensorAvoid shock and vibration to the sensor.> > Damage to or destruction of the sensorThe power supply may not exceed the specified limits.<strong>optoNCDT</strong> 2300Page 11

Safety> > Damage to or destruction of the sensorProtect the sensor cable against damage.> > Destruction of the sensor> > Failure of the measuring deviceAvoid continuous exposure to fluids on the sensor.> > Damage to or destruction of the sensorAvoid exposure to aggressive materials (washing agent, penetrating liquids or similar) on the sensor.> > Damage to or destruction of the sensor1.3 CE ComplianceThe following applies to the <strong>optoNCDT</strong> 2300: EMC regulation 2004/108/ECProducts which carry the CE mark satisfy the requirements of the EMC regulation 2004/108/EC ‘ElectromagneticCompatibility’ and the European standards (EN) listed therein. The EC declaration of conformity is keptavailable according to EC regulation, article 10 by the authorities responsible atMICRO-EPSILON MESSTECHNIKGmbH & Co. KGKönigbacher Straße 1594496 Ortenburg / Germany<strong>optoNCDT</strong> 2300The system satisfies the requirements of the standards--EN 61326-1: 2006-10 Electrical equipment for measurement, control and laboratory use - EMC requirements- Part 1: General requirements--DIN EN 55011: 2007-11 (Group 1, class B) Industrial, scientific and medical (ISM) radio-frequency equipment- Electromagnetic disturbance characteristics - Limits and methods of measurement--EN 61000-6-2: 2006-03 Electromagnetic compatibility (EMC), Part 6-2: Generic standards - Immunity forindustrial environmentsThe sensor fulfills the specification of the EMC requirements, if the instructions in the operating <strong>manual</strong> arefollowed.Page 12

Safety1.4 Proper Use--The <strong>optoNCDT</strong> 2300 system is designed for use in industrial and laboratory areas.--It is used• for measuring displacement, distance, position and elongation• for in-process quality control and dimensional testing--The sensor may only be operated within the limits specified in the technical data, see Chap. 3.4.--Use the sensor in such a way that in case of malfunctions or failure personnel or machinery are not endangered.--Take additional precautions for safety and damage prevention for safety-related applications.1.5 Proper Environment--Protection class: IP 65 (applies only when the sensor cable is plugged in)Lenses are excluded from protection class. Contamination of the lenses leads to impairment or failure of thefunction.--Operating temperature: 0 °C ... 50 °C (+32 up to +104 °F)--Storage temperature: -20 °C ... 70 °C (-4 up to +158 °F)--Humidity: 5 - 95 % (no condensation)--Ambient pressure: Atmospheric pressure--EMC according to:• EN 61326-1: 2006-10 Electrical equipment for measurement, control and laboratory use - EMC requirements- Part 1: General requirements• DIN EN 55011: 2007-11 (Group 1, class B) Industrial, scientific and medical (ISM) radio-frequency equipment- Electromagnetic disturbance characteristics - Limits and methods of measurement• EN 61000-6-2: 2006-03 Electromagnetic compatibility (EMC), Part 6-2: Generic standards - Immunity forindustrial environmentsThe protection class is limited to water, no penetrating liquids or similar!i<strong>optoNCDT</strong> 2300Page 13

Laser ClassNever deliberately lookinto the laser beam!Consciously closeyour eyes or turn awayimmediately if ever thelaser beam should hityour eyes.2. Laser ClassThe <strong>optoNCDT</strong> 2300 sensors operate with a semiconductor laser with a wavelength of 670 nm (visible/redILD 2300-x) resp. 405 nm (visible/blue ILD 2300-xBL). The sensors fall within Laser Class 2 (II). The laseris operated on a pulsed mode, the average power is ≤ 1 mW in each case, the peak power can be up to1.2 mW. The pulse frequency depends on the adjusted measuring rate /1.5 ... 49.02 kHz). The pulse durationof the peaks is regulated depending on the measuring rate and reflectivity of the target and can be 0.5 up to542 µs.iComply with all regulations on lasers!Although the laser output is low looking directly into the laser beam must be avoided. Due to the visible lightbeam eye protection is ensured by the natural blink reflex. The housing of the optical sensors may only beopened by the manufacturer, see Chap. 13. For repair and service purposes the sensors must always be sentto the manufacturer.The following warning labels are attached to the cover (front and/or rear side) of the sensor housing. Thelaser warning labels for Germany have already been applied (see above). Those for other non Germanspeakingcountries an IEC standard label is included in delivery and the versions applicable to the user’scountry must be applied before the equipment is used for the first time. Laser operation is indicated by LED,see Chap. 3.5.LASER RADIATIONDo not stare into beamClass 2 Laser ProductIEC 60825-1: 2008-05P0= 1 mW; PP= 1.2 mW; t=0.5...542 µsF=1.5...50 kHz; =670 nmIEC labelTHIS PRODUCT COMPLIESWITH FDA REGULATIONS21CFR 1040.10 AND 1040.11Only for USA<strong>optoNCDT</strong> 2300Page 14

Laser ClassLASER RADIATIONDo not stare into beamClass 2 Laser ProductIEC 60825-1: 2008-05P0= 1 mW; PP= 1.2 mW; t=0.5...542 µsF=1.5...50 kHz; =405 nmTHIS PRODUCT COMPLIESWITH FDA REGULATIONS21CFR 1040.10 AND 1040.11IEC label for ILD2300-x BLOnly for USADuring operation of the sensor the pertinent regulations acc. to IEC 60825-1 on „radiation safety of laserequipment“ must be fully observed at all times. The sensor complies with all applicable laws for the manufacturerof laser devices.Laser ffIn angeMid angeErrorEtherCATRUNERREthernetPower on<strong>optoNCDT</strong>ASER RADIATIONDo n t st re into be mCl ss 2 L ser Produ tIEC 60825-1: 2008-05P0= 1 mW; PP= 1 2 mW; t=0.5.. 542 µsF=1 5 . 50 kHz; =670 nmLaser spotFig. 1 True reproduction of the sensor with its actual location of the warning labels, ILD 2300<strong>optoNCDT</strong> 2300Page 15

Laser ClassLaser ffIn angeMid angeErrorEtherCATRUNERREthernetPower on<strong>optoNCDT</strong>ASER RADIATIONDo n t st re into be mCl ss 2 L ser Produ tIEC 60825-1: 2008-05P0= 1 mW; PP= 1 2 mW; t=0.5.. 542 µsF=1 5 . 50 kHz; =405 nmLaser spotFig. 2 True reproduction of the sensor with its actual location of the warning labels, ILD2300-x BLiIf both warning labels are covered over when the unit is installed the user must ensure that supplementarylabels are applied.<strong>optoNCDT</strong> 2300Page 16

Functional Principle, Technical Data3. Functional Principle, Technical Data3.1 Short DescriptionThe <strong>optoNCDT</strong> 2300 consists of an laser-optical sensor. The sensor usesthe principle of optical triangulation, that is, a visible, modulated point oflight is projected onto the target surface.The diffuse element of the reflection of the light spot is imaged by areceiver optical element positioned at a certain angle to the optical axisof the laser beam onto a high-sensitivity resolution element (CCD), in dependencyon displacement. From the output signal of the CCD elementa digital signal processor (DSP) in the sensor calculates the displacementbetween the light spot on the object being measured and the sensor.The displacement is linearized and then issued via digital interfaces.SMR = Start of measuring rangeMMR = MidrangeEMR = End of measuring range3.2 Real Time Control (A-RTSC)SMRMeasuringrangeSensorILD 2300Digital value RS422262077643 Start of measuring range32760 Midrange64876 End of measuring range262078Fig. 3 Definition of terms, outputsignalThe CMOS element determines the intensity of incident light during the exposure. This enables the sensor tocompensate for fluctuations in brightness on the object being measured. What is more, it does so in a rangefrom almost total absorption to almost total reflection. The new A-RTSC (Advanced Real-Time-Surface-Compensation)is a development of approved RTSC and allows a more accurate real-time surface compensationin the measurement process with a higher dynamic range.3.3 Exposure ControlDark or shining objects to be measured may require a longer exposure time. However, the sensor is not capableof providing exposure which is any longer than permitted by the measurement frequency. For a longerexposure time, therefore, the measurement frequency of the sensor has to be reduced either <strong>manual</strong>ly or bycommand, see Chap. 7.4.2.<strong>optoNCDT</strong> 2300Page 17

Functional Principle, Technical Data3.4 Technical DataILD 2300-2ILD 2300-5ILD 2300-10ILD 2310-10Start of measuring rangeMeasuring range up to 30 kHz measuring rateMeasuring range 49.02 kHz measuring rateILD 2300-20ILD 2310-20ILD 2300-40ILD 2300-50ILD 2310-50ILD 2300-100ILD 2300-200100 mm 200 mm 300 mm 400 mm 500 mm 600 mmFig. 4 Measuring ranges for displacement measurement in direct and diffuse reflectionFootnotes to the technical data:Informations about measuring range, start of measuring range, midrange and end of measuring range depend on the measuring rate.1) 1. value: Measuring rate of 1.5 kHz up to 30 kHz. 2. value: Measuring rate 49.02 kHz.2) At a measuring rate of 20 kHz, without averaging.The specified data apply for a diffusely reflecting matt white ceramic target.SMR = Start of measuring range; MR = Midrange; EMR = End of measuring range<strong>optoNCDT</strong> 2300Page 18

Functional Principle, Technical DataType ILD 2300- 2 5 10 20 30 40 50 100 200Measuring range 1Start of measuring rangeMidrangeEnd of measuring range<strong>optoNCDT</strong> 2300mmmmmmmm2 / 2(.08 / .08)24 / 24(.94 / .94)25 / 25(.98 / .98)26 / 26(1.02 / 1.02)5 / 2(.20 / .08)24 / 24(.94 / .94)26.5 / 25(1.04 / .98)29 / 26(1.14 / 1.02)10 / 5(.39 / .20)30 / 35(1.18 / 1 38)35 / 37 5(1.38 / 1.48)40 / 40(1.57 / 1 57)20 / 10(.79 / .39)40 / 50(1.57 / 1 97)50 / 55(1.97 / 2.17)60 / 60(2.36 / 2.36)40 / 20(1.57 / 79)175 / 195(6.89 / 7.68)195 / 205(6.89 / 8.07)215 / 215(8.46 / 8.46)40 / 20(1.57 / .79)175 / 195(6.89 / 7.68)195 / 205(6.89 / 8.07)215 / 215(8.46 / 8.46)50 / 25(1.97 / .99)45 / 70(1.77 / 2.76)70 / 82.5(2.76 / 3.25)95 / 95(3.74 / 3.74)100 / 50(3 94 / 1.97)70 / 120(2 76 / 4.72)120 / 145(4.72 / 5.71)170 / 170(6 69 / 6.69)200 / 100(1.57 / 3.94)130 / 230(5.12 / 9.06)230 / 280(9.06 / 11.02)330 / 330(13.0 / 13.0)Linearity µm 0.6 1.5 2 4 12 12 10 30 60Resolution (at 20 kHz) 2 µm 0.03 0.08 0.15 0.3 0.6 0.6 0.8 1.5 3Measuring rate, programmable49.02 / 30 / 20 / 10 / 5 / 2.5 / 1.5 kHz (49.02 kHz with reduced measuring range)Light source (Laser diode) Wave length 670 nm, red, max. power 1 mW, laser class 2Permissible ambient light10,000 lx … 40,000 lxSMR, µm 55 x 85 70 x 80 75 x 85 140 x 200 230 230 255 x 350 350 1300Light spot diameterMR, µm 23 x 23 30 x 30 32 x 45 46 x 45 210 210 70 x 70 130 1300(±10 %)EMR, µm 35 x 85 70 x 80 110 x 160 140 x 200 230 230 255 x 350 350 1300Operating temperature0 ... +50 °C (+32 °F up to +122 °F)Storage temperature-20 ... +70 °C (-4 °F up to +158 °F)Protection classIP 65 (with plugged connection)Power supply UB24 VDC (11 ... 30 V); P < 3 WMeasurement value output,RS422, Ethernet, EtherCAT (selectable)Synchronization programmableSimultaneous or alternatingSensor cable (standard)0.25 m (with cable jack)Electromagnetic compatibility EN 61326-1: 2006-10; DIN EN 55011: 2007-11 (group 1, class B); EN 61 000-6-2: 2006-03Vibration (acc. to IEC 60068-2-6)2 g / 20 ... 500 HzShock (acc. to IEC 60068-2-29)15 g / 6 ms / 3 axesWeight (with 25 cm cable) 550 g 600 g 600 g 550 g 600 g1) 1. value: Measuring rate of 1.5 kHz up to 30 kHz. 2. value: Measuring rate 49.02 kHz, see Page 17.Page 19

Functional Principle, Technical DataType ILD 2300- 2LL 10LL 20LL 50LLMeasuring range 1Start of measuring rangeMidrangeEnd of measuring rangemmmmmmmm2 / 2(.08 / .08)24 / 24(.94 / .94)25 / 25(.98 / .98)26 / 26(1.02 / 1.02)10 / 5(.39 / .20)30 / 35(1.18 / 1.38)35 / 37,5(1.38 / 1.48)40 / 40(1.57 / 1.57)20 / 10(.79 / .39)40 / 50(1.57 / 1.97)50 / 55(1.97 / 2.17)60 / 60(2.36 / 2.36)50 / 25(1.97 / .99)45 / 70(1.77 / 2.76)70 / 82.5(2.76 / 3.25)95 / 95(3.74 / 3.74)Linearity µm 0.6 2 4 10Resolution (at 20 kHz) 2 µm 0.03 0.15 0.3 0.8Measuring rate, programmable49.02 / 30 / 20 / 10 / 5 / 2.5 / 1.5 kHz (49.02 kHz with reduced measuring range)Light source (Laser diode) Wave length 670 nm, red, max. power 1 mW, laser class 2Permissible ambient light10,000 lx … 40,000 lxLight spot diameter(±10 %)Operating temperatureStorage temperatureProtection classPower supply U BMeasurement value output, selectableSynchronization programmableSensor cable (standard)SMR, µm 85 x 240 120 x 405 185 x 485 350 x 320MR, µm 24 x 280 35 x 585 55 x 700 70 x 960EMR, µm 64 x 400 125 x 835 195 x 1200 300 x 19400 ... +50 °C (+32 °F up to +122 °F)-20 ... +70 °C (-4 °F up to +158 °F)IP 65 (with plugged connection)24 VDC (11 ... 30 V); P < 3 WRS422, Ethernet, EtherCATSimultaneous or alternating0.25 m (with cable jack)Electromagnetic compatibility (EMC) EN 61326-1: 2006-10; DIN EN 55011: 2007-11 (group 1, class B); EN 61 000-6-2: 2006-03Vibration (acc. to IEC 60068-2-6)2 g / 20 ... 500 HzShock (acc. to IEC 60068-2-29)15 g / 6 ms / 3 axesWeight (with 25 cm cable)550 g1) 1. value: Measuring rate of 1.5 kHz up to 30 kHz. 2. value: Measuring rate 49.02 kHz, see Page 17.<strong>optoNCDT</strong> 2300Page 20

Functional Principle, Technical DataType ILD 2310- 10 20 50Measuring range 1Start of measuring rangeMidrangeEnd of measuring rangemmmmmmmm10 / 5(.39 / .20)95 / 100(3.74 / 3.94)100 / 102.5(3.94 / 4.04)105 / 105(4.13 / 4.13)20 / 10(.79 / .39)90 / 100(3.54 / 3.94)100 / 105(3.94 / 4.13)110 / 110(4.33 / 4.33)50 / 25(1.97 / .98)550 / 575(21.7 / 22.6)575 / 587.5(22.6 / 23.1)600 / 600(23.6 / 23.6)Linearity µm 3 6 40Resolution µm 0,5 1 7.5Measuring rate, programmable49.02 / 30 / 20 / 10 / 5 / 2.5 / 1.5 kHz (49.02 kHz with reduced measuring range)Light source (Laser diode) Wave length 670 nm, red, max. power 1 mW, laser class 2Permissable ambient lightSpot diameterOperation temperatureStorage temperature10,000…40,000 lxSMR 400 x 500 200 400 ... 500MMR 400 x 500 60 400 ... 500EMR 400 x 500 200 400 ... 5000 ... +50°C-20 ... +70°CProtection class IP 65Power supplyInputs / OutputsInputsSensor cable24 VDC (11 … 30 V); P < 3 WEthernet, EtherCAT, RS422laser on/off; synchronization / trigger inputstandard: 0.25 m - integratedElectromagnetic compatibility (EMC) EN 61326-1: 2006-10; DIN EN 55011: 2007-11 (group 1. class B); EN 61 000-6-2: 2006-03Vibration (Shoc)2g / 20 ... 500Hz (15g / 6ms / 3 axes)Weight (with 25 cm cable)550 g1) 1. value: Measuring rate of 1.5 kHz up to 30 kHz. 2. value: Measuring rate 49.02 kHz, see Page 17.<strong>optoNCDT</strong> 2300Page 21

Functional Principle, Technical DataType ILD 2300- 2BL 5BL ILD 2310-50BLMeasuring range 1Start of measuring rangeMidrangeEnd of measuring rangemmmmmmmm2 / 2(.08 / .08)24 / 24(.94 / .94)25 / 25(.98 / .98)26 / 26(1.02 / 1.02)1) 1. value: Measuring rate of 1.5 kHz up to 30 kHz. 2. value: Measuring rate 49.02 kHz, see Page 17.Use of sensor series ILD 2300-xBL in the distance measurement with diffuse and direct reflection.<strong>optoNCDT</strong> 23005 / 2(.20 / .08)24 / 24(.94 / .94)26.5 / 25(1.04 / .98)29 / 26(1.14 / 1.02)50 / 25(1.97 / .99)550 / 575(21.65 / 22.64)575 / 587.5(22.64 / 23.13)600 / 600(23.62 / 23.62)Linearity µm 0.6 1.5 40Resolution (at 20 kHz) µm 0.03 0.08 7.5Measuring rate, programmable49.02 / 30 / 20 / 10 / 5 / 2.5 / 1.5 kHz (49.02 kHz with reduced measuring range)Light source (Laser diode) Wave length 405 nm, blue, max. power 1 mW, laser class 2Permissible ambient light10.000 lx at 2.5 kHz measuring rateLight spot diameter(±10 %)SMR, µm 70 x 80 200 x 200 400 ... 500MR, µm 20 x 20 20 x 20 400 ... 500EMR, µm 80 x 100 200 x 400 400 ... 500Operating temperature 0 ... +50 °CStorage temperature -20 ... +70 °CProtection classIP 65 (with plugged connection)Power supply UB24 VDC (11 ... 30 V); P < 3 WMeasurement value output, selectableRS422, Ethernet, EtherCATSynchronization programmableSimultaneous or alternatingSensor cable (standard)0.25 m (with cable jack)Elektromagnetic compatibility EN 61326-1: 2006-10; DIN EN 55011: 2007-11 (group 1, class B); EN 61 000-6-2: 2006-03Vibration / Shock 2 g / 20 ... 500 Hz (acc. to IEC 60068-2-6) / 15 g / 6 ms / 3 axes (acc. to IEC 60068-2-29)Weight (with 25 cm cable) 550 g 550 g 800 gPage 22

Functional Principle, Technical Data3.5 Indicator Elements at SensorLED Color Labeling on sensor MeaningEtherCATEthernetoffgreen, flashing 2.5 Hzgreen, single flash, 200 ms ON / 1000 ms OFFgreenred, flashing 2.5 Hzred, single flash, 200 ms ON / 1000 ms OFFred, double flash, 200 ms ON / 200 ms OFF / 200 ms ON /400 ms OFFred, flashing 10 HzoffyellowRUNERRPower onAfter switching on the sensor both LEDs “EtherCAT/Ethernet” and “Status” are activated.LED Color Labeling on sensor MeaningState 1 yellow Midrange Target is in midrangeoff Laser off Laser beam is switched offgreen In range Sensor in operationred Error Target out of range, to low reflection1) LED display for measuring rates < 49.02 kHz only.INIT statePRE-OP stateSAFE-OP stateOP stateInvalid configurationNot requested state changeTimeout watchdogError during initializationNo supply voltageSupply voltage is available<strong>optoNCDT</strong> 2300Page 23

Delivery4. Delivery4.1 Unpacking--1 Sensor ILD 2300 with 0.25 m connection cable and cable jack--2 Laser warning labels according to IEC norm--RJ45 short-circuit plug--1 CD with program and instruction <strong>manual</strong>Check for completeness and shipping damage immediately after unpacking.In case of damage or missing parts, please contact the manufacturer or supplier.Optional accessory, packed separately:--1 Supply and output cable PC2300-x/SUB-D, cable length x = 3 m, 6 m or 9 m, with cable plug and 15-pol. SUB-D-jack,--1 Connection cable PC2300-0,5/Y with 15-pol. SUB-D-plug, RS422/power supply cable (0.5 m long) andEthernet cable with cable jack RJ45 (0.5 m long).See Appendix for further cables, see Chap. A 14.2 StorageStorage temperature: -20 up to +70 °C (-4 °F up to +158 °F)Humidity:5 - 95 % (no condensation)<strong>optoNCDT</strong> 2300Page 24

fa e h ungch n d n h b k na e a e 20 2 2 08 02 0 2 µ0 l 0N NInstallation5. InstallationThe <strong>optoNCDT</strong> 2300 sensor is an optical system for measurements with micrometer accuracy.iMake sure it is handled carefully when installing and operating.aserIn angeMid anger orE he CAT E he netRUNP we onERR<strong>optoNCDT</strong>ase f EtherCAT Et er etn angeRUNMi rangeP wer onEr orERR<strong>optoNCDT</strong>N bP = W P = W == H l=Diffuse reflectionDirect reflectionFig. 5 Distinction sensor assembly in diffuse and direct reflection5.1 Diffuse ReflectionThe sensor is mounted by means of 3 screws type M4. The bearing surfaces surrounding the fastening holes(through-holes) are slightly raised. The laser beam must be directed perpendicularly onto the surface of thetarget. In case of misalignment it is possible that the measurement results will not always be accurate.To align the sensor, please comply with the „<strong>Instruction</strong>s for Operation“, see Chap. 10.3, especially.If the sensors are to be used in soiled environments or in higher ambient temperatures than normal, MICRO-EPSILON recommends the use of protective housings, see Chap. 10.5.The suggested free space in the tuning range, is kept clear at least until the end of the measuring range offoreign material and ambient light of other laser sensors.The <strong>optoNCDT</strong> 2300 can be operated in direct and diffuse reflection.<strong>optoNCDT</strong> 2300Page 25

Installation97 (3.82)89 (3.50)30 (1.18)MR SMR Y2 (.08) 24 (.94) 1.5 (.06)44.55 (.20) 24 (.94) 3.5 (.14)10 (.39) 30 (1.18) 6.5 (.26)20 (.79) 40 (1.57) 10.0 (.39)50 (1.97) 45 (1.77) 23.0 (.91)75 (2.95)SMR 467 (2.64)33.5 (1.32)1013.548LaserMounting holesø4.5 for M4 screws7 715 (0.59)100 (3.94) 70 (2.76) 33.5 (1.32)MR = Measuring rangeSMR = Start of measuring rangeMillimeter (Inches)approx. 315 (12.4)48.5 (1.91)ø16(.63 dia.)MRLimits for freespace<strong>optoNCDT</strong> 2300Y2Keep this area free fromother light sources and/ortheir reflectionsFig. 6 Dimensional drawing, free space for the measuring ranges 2/5/10/20/50/100 mmFig. 7 Dimensional drawing sensor cablePage 26

Installation150 (5.90)140 (5.51)130 (5.52)35 (1.38)MR 40 (1.57) 200 (7.87)SMR 175 (6.89) 130 (5.12)MMR 195 (7.68) 230 (9.06)80 (3.15)70 (2.76)SMR91.6 (3.61)76 (2.99)ø5 (1.20 dia.)15 (0.59)3 x Mountinghole ø4.5(0.18 dia.)12 (0.47)17.5 (0.69)Start of measuring rangeMREMR 215 (8.46) 330 (12.99)a 22.1 ° 25.1 °j 21.9 ° 16.7 °e 21.8 ° 13.1 °A 101 (3.98) 91.6 (3.61)B 86 (3.39) 76.0 (2.99)MR = Measuring rangeSMR = Start of measuring rangeMMR = MidrangeEMR = End of measuring rangeMillimeter (Inches)End of measuring rangeFig. 8 Dimensional drawing and free space forthe measuring range 40/200 mm<strong>optoNCDT</strong> 2300Page 27

Installation40 (1.57)18.5150 (5.90)140 (5 51)130 (5.52)75 (2.95)91.6 (3.61)3x Mountingholes ø4.5 mm70 (2.76)80 (3.15)71 (2.80)5 (.20)14( 55)ø6 (.24 dia.)95(3.74)132.3(5.21)190 (7.48)29.5(1.16)61 (2.40)73 (2.87)83 (3 26)5(.20)24(.94)24(.94) 48(1.89)ø515535 (1.38)SMRMR17.5(.69)Fig. 9 Dimensional drawing ILD2310, measuringranges 10/20 mmMR 10 (.39) 20 (.79)SMR 95 (3.74) 90 (3.54)MMR 100 (3.93) 100 (3.94)EMR 105 (4.13) 110 (4.33)Millimeter (Inches)MR=50 (1.97) SMR= 550 (21.65)Optically active,field to kept freeFig. 10 Dimensional drawing and freespace for the sensor ILD 2310-50<strong>optoNCDT</strong> 2300Page 28

Installation5.2 Direct ReflectionThe sensor is mounted by means of 3screws type M4. The bearing surfacessurrounding the fastening holes (throughholes)are slightly raised.Mount the sensor so, that the reflected laserlight hits the receiver element.44.597 (3.8)89 (3.5)MR SMR + 0.5 MR alpha2 (0.08) 25 (0.98) 20.5 °5 (0.20) 26.5 (1.04) 20 °10 (0.39) 35 (1.38) 17.5 °20 (0.79) 50 (1.97) 13.8 °SMR = Start of measuring range75 (3.0)67 (2.6)33.5Mounting holes3x ø4.5 (dia. 0.18)for M4 screwsMR = Measuring rangeMillimeter (Inches)41013 548Limits for freeSpaceSMR + 0.5 MRMR (dir.R)Fig. 11 Dimensional drawing and free spacefor the measuring ranges 2/5/10/20 mm2alpha<strong>optoNCDT</strong> 2300Page 29

InstallationMounting steps:--Switch on the operating voltage--Make sure that the “State“ LED on the top side of the sensor.--Position a shining or mirroring target.Measuring object--Move the optional assembly aid between sensor and target.--The LED “State“ flashes yellow.--Mount the sensor by means of 3 screws type M4.--Remove the fit-up aid between sensor and measuring object.<strong>optoNCDT</strong> 2300Page 30

Installation5.3 Electrical Connections5.3.1 Connection PossibilitiesSource Cable/power supply InterfacePC2300-x/SUB-D and PC2300-0,5/YPC2300-x/C-Box/RJ45EtherCATPC2300-x/OE orPC2300-x/SUB-Dand PC2300-0,5/YC-BoxPS 2020PC2300-x/OERS422-USB ConverterPC2300-x/IF2008 (IF2008-Y) orPC2300-x/SUB-D and PC2300-0,5/YPC2300-x/IF2008IF2004/USBEthernetSPSand IF2008-Y-adaptercableEthernetUSBIF2008PCFig. 12 Connection examples on ILD 2300PC2300-x/CSPCSP 2008Sensor supply isdone by peripheral<strong>optoNCDT</strong> 2300Page 31

InstallationThe different periphery devices can be connected by the illustrated connection cables to the 14-pin sensorplug, see Fig. 14. The devices PCI interface card IF2008, 4-way converter IF2004/USB and universal controllerCSP2008 also supply the operating voltage (24 V DC) of the sensor via the appropriate connection cable.Peripheral Sensor channels InterfaceRS422-USB converteroneIF2004/USBfourIF2008, PCI interface card fourRS422CSP2008, universal controller twoExtension terminal CSP2008 twoEthernet (network, PC)anyEtherCAT (master)anyEthernet / EtherCATPLC, ILD2300 or the like --- SynchronizationSwitch, button, PLC or the like --- Switching input laser On/OffFig. 13 Max. sensor channels on the peripheral devices<strong>optoNCDT</strong> 2300Page 32

Installation5.3.2 Supply VoltageNominal value: 24 V DC (11 ... 30 V, max. 150 mA).Switch on the power supply unit, once wiring is completed.11 ...30 VDCConnect the inputs “1“ and “2“ at the sensor with a 24 V voltage supply.12ILD 2300SensorPinPC2300-x/YColorSupply1 white +U B2 brown GroundUse the supply voltage for measurement instrumentsonly and not for drive units or similar sources of pulseinterference at the same time. MICRO-EPSILONrecommends using an optional available power supplyunit PS2020 for the sensor.Fig. 14 Connection of supply voltage5.3.3 Laser onThe measuring laser on the sensor is activated via an optocoupler input. This is advantageous if the sensorhas to be switched off for maintenance or similar. Switching can be done with a transistor (for example opencollector in an optocoupler) or a relay contact.iIf pin Pin 3 is not connected with +U Band Pin 4 is not connected with ground, the laser is off. The wiringfor laser on/off with the supply voltage is already done in the PC2300-x/SUB-D and PC2300-0, 5/Ycables.Type 1 Type 2 PC2300-x/Y +UBwhite 1ILD 2300TTL o. U OUTappr. 5mAgreen 3HTLLaser off:U max.OUT < 0.8 VLaser on:30 V2.8 V < U OUT < 30 Vyellowbrown42GroundThere is no external resistorfor current limiting required.Connect Pin 1 with 3 and Pin2 with 4 for permanent „Laseron“.Reaction Time for Laser-On:Correct measuring data aresent by the sensor approximately1 ms after the laserwas switched on.Fig. 15 Electrical wiring for laser off<strong>optoNCDT</strong> 2300Page 33

Installation3241101112 14135 6Fig. 16 Sensor roundpin plug, view: Solderpinside male cableconnector, insulator9785.3.4 Input and OutputsSignalSensorCable PC2300-x/SUB-D 1CommentDesignation Pin15-pol. Sub-D+ U b1 Supply voltage (11 ... 30 VDC) 1Ground 2System ground for supply andground potential for RS422-level9+Laser on/off 3 Optocoupler input, potential-free2Laser off: U E≤ 0,8 V (Low)- Laser on/off 4 Laser on: 2,8 V ≤ U E≤ 30 V (High)10Sync-in/out 2 5Synchronous- respectively trigger signals, symmetrically,RS422-Pegel, terminating resistor3/Sync-in/out 2 6120 Ohm switchable, input or output selecteddepending on the synchronization mode11RxD-RS422 7 Serial input RS422, symmetrically,4/RxD-RS422 8 Internally terminated with 120 Ohm12TxD-RS422 95Serial output RS422, symmetrically/TxD-RS422 10 13Tx - Ethernet 116Ethernet output, potential-free/Tx - Ethernet 12 14Rx - Ethernet 137Ethernet input, potential-free/Rx - Ethernet 14 15Screen Housing No galvanic connection to ground Housing1) You will find more cables in appendix.2) In trigger operation, see Chap. 7.6.1, the input is used for triggering.Plug connector: ODU MINI-SNAP, 14-pol., series B, dimension 2,code F, IP 68.<strong>optoNCDT</strong> 2300Page 34

PInstallation5.3.5 EthernetTo connect the sensor via the Ethernet interface the internet protocols TCP and UDP are used. This requiresgenerally a PC with a web browser such as Mozilla Firefox and a free Ethernet interface or a network connection.Standard protocol is TCP/IP.Connect the sensor to a PC via a direct Ethernet connection (LAN) or Switch (Intranet). Thereforeuse a LAN cable with RJ-45-male connectors and the optionally available cables PC2300-x/SUB-D andPC2300-0.5/Y.PC2300-0.5/YPatch cableaser o fIn angeMid angeErrorEthe CAT E hernetRUNP wer onERR<strong>optoNCDT</strong>PC2300-x/SUB-DL serstr hluni ht in den trahl b i kenL ser Kl sse 2nach D N N 60825 1: 2008-05P = 1 mW; P = 1 2 mW; t=0 5. .542 µsF=1,5 . 50 kHz; =670 nmPS2020NL230 VACPEFig. 17 Measurement setup with Ethernet connection<strong>optoNCDT</strong> 2300Page 35

PPInstallation5.3.6 EtherCATThrough the Ethernet connection, the sensor can also be integrated into an EtherCAT environment.Connect the sensor to a 2-port EtherCAT junction. Use a LAN cable with RJ-45-male connectors and theoptionally available cables PC2300-x/SUB-D and PC2300-0.5/Y.PC2300-0.5/YPatch cableaser o fIn angeMid angeErrorEthe CAT E hernetRUNP wer onERRPC2300-x/SUB-DRunEtherCAT/CSP2008<strong>optoNCDT</strong>X1L serstr hlungi ht in den trahl b i kenL ser Kl sse 2nach D N N 60825 1: 2008-05P = 1 m ; P = 1 2 mW; t=0 5. .542 µsF=1,5 . 50 kHz; =670 nmRS422extension terminalPC2300-x/CSPPS2020NLX2BECKHOFF EK1122230 VACPE2-Port-EtherCATjunctionPC/Notebookaser o fIn angeMid angeErrorEthe CAT E hernetRUNP wer onERREtherCAT/CSP2008<strong>optoNCDT</strong>L serstr hlungi ht in den trahl b i kenL ser Kl sse 2nach D N N 60825 1: 2008-05P = 1 m ; P = 1 2 mW; t=0 5. .542 µsF=1,5 . 50 kHz; =670 nmFig. 18 Measurement setup with EtherCAT connection<strong>optoNCDT</strong> 2300Alternatively, a connection via the RS422 extension terminal and the cable PC2300-x/CSP is possible.Both are available as optional accessories.Page 36

Installation5.3.7 Connector and Sensor CableNever bend the sensor cable by more than the bending radius of 90 mm.The sensor comes with a permanently mounted connection cable of 0.25 m in length. A 3 m, 6 m or 9 m sensorcable has to be attached to the connection cable.MICRO-EPSILON recommends the use of the standard sensor cable in the appendix, see Chap. A 1, with achain-type cable capability.The connector and the cable component are marked with red markings which have to be aligned oppositeeach other before connection. In addition, they come with guidance grooves to prevent them from beingwrongly connected. To release the plug-in connection, hold the plug-in connector on the grooved grips (outersleeves) and pull apart in a straight line. Pulling on the cable and the lock nut will only lock the plug-in connector(ODU MINI-SNAP FP - lock) and will not release the connection.Avoid subjecting the cable to excessive pull force. If a cable of over 5 m in length is used and it hangsvertically without being secured, make sure that some form of strain-relief is provided close to the connector.Never twist the connectors in opposite directions to one another when connected.Connect the cable shield to the potential equalization (PE, protective earth conductor) on the evaluator(control cabinet, PC housing) and avoid ground loops.Never lay signal leads next to or together with power cables or pulse-loaded cables (e.g. for drive unitsand solenoid valves) in a bundle or in cable ducts. Always use separate ducts.Recommended strand cross-section for self-made connection cables: ≥ 0.14 mm² (AWG 25)Disconnect or connect the D-sub connection between RS422 and USB converter, when the sensor isdisconnected from power supply only.i<strong>optoNCDT</strong> 2300Page 37

Operation6. Operation6.1 Getting Ready for OperationInstall and assemble the <strong>optoNCDT</strong> 2300 in accordance with the instructions set out, see Chap. 5.Connect the sensor with the indicator or monitoring unit and the power supply.The laser diode in the sensor can only be activated if at the input „Laser on/off“ Pin 1 is connected to 3 andPin 2 to 4, see Chap. 5.3.3.Once the operating voltage has been switched on the sensor runs through an initialization sequence. Thisis indicated by the momentary activation of all the LEDs. Once initialization has been completed, the sensortransmits a „->“ via the serial interface. The initialization takes up to 10 seconds. Within this period, the sensorneither executes nor replies to commands.To be able to produce reproducible measurements the sensor typically requires a start-up time of 20 minutes.If the “state“ LED is not on, this means that--either there is no operating voltage or--the laser has been switched off.6.2 Operation via EthernetIn the sensor, dynamic Web pages are created that contain the current settings of the sensor and the periphery.The operation is only possible as long as an Ethernet connection to the sensor exists.6.2.1 PreconditionsYou need a web browser (for example Mozilla Firefox or Internet Explorer) on a PC with a network connection.To support a basic first commissioning of the sensor, the sensor is set to a direct connection.The parallel operation using a web browser and ASCII commands is possible; the last setting applies. Rememberto save the settings.<strong>optoNCDT</strong> 2300Page 38

OperationDirect connection to PC, sensor with static IP (Factory setting)NetworkPC with static IP PC with DHCP Sensor with dynamic IP, PC with DHCPConnect the sensor to a PC via a direct Ethernet connection (LAN). Usean optionally available cable PC2300-x and PC2300-0.5/Y.Now start the SensorFinder.exe program.You will find this program on the providedCD.Click the button Find sensors. Selectthe designated sensor from the list. Inorder to change the address settings,click the button Change IP-Address.••Address type: static IP address••IP address: 169.254.168.150 1••Subnet mask: 255.255.0.0Click the button Change, to transmit thechanges to the sensor.Click the button Start browser toconnect the sensor with your defaultbrowser.1) Requires that the LAN connection on thePC uses, for example, the following IP address:169.254.168.1.Wait until Windows has establisheda network connection(Connection with limited connectivity).Now start the SensorFinder.exeprogram. You willfind this program on theprovided CD.Click the button Findsensors. Select the designatedsensor from thelist.Click the button StartBrowser button to connectthe sensor with yourdefault browser.Connect the sensor to a switch (Intranet). Usean optional available cable PC2300-x undPC2300-0.5/Y.Enter the sensor in the DHCP / register the sensorin your IT department.The sensor gets assigned an IP address from yourDHCP server. You can check this IP address with theSensorFinder.exe program.Now start the SensorFinder.exe program.You will find this program on the provided CD.Click the button Find sensors. Select thedesignated sensor from the list.Click the button Start browser, to connectthe sensor with your default browser.Alternatively: If DHCP is enabled and the DHCPserver is linked with the DNS server, an access ispossible on „ILD2300_SN01234567“ („01234567“Serial number of your sensor)Start a web browser on your PC. Type„ILD2300_Serial number“ in the address bar ofyour web browser.6.2.2 Access via EthernetOnce the sensor is provided with an IP address, which is valid for your environment and it is known to you, you can connect the sensorwith a web browser, see Chap. 6.2.1.<strong>optoNCDT</strong> 2300Page 39

OperationInteractive websites for programming the sensor now appear in the web browser.The parallel operation using a Web browser and ASCII commands is possible; the last setting applies. Rememberto save the settings.Programming the sensor. In the top navigationbar other auxiliary functions (settings, videosignal, etc.) are available. All settings in thewebsite will be immediately executed in thesensor after pressing the button Apply.Fig. 19 First interactive website after selectionof the IP address.The look of the website may change depending on the features. Each page contains descriptions of theparameters and so tips for filling out the web site.Further sub-menus, such as measuring rateand triggering, are available via the left navigationof the website.iAfter programming all the settings areto be stored permanently in a set ofparameters. The next time you turn onthe sensor they are available again.<strong>optoNCDT</strong> 2300Page 40

Operation6.2.3 Measurement Presentation via Web BrowserFor graphical description of the measuring results “Java“ must be enabled and updated in the browser.Start the measurement value display (Measurement) in the horizontal navigation bar.iFig. 20 Web interfaceIf you leave the diagram display in a separate tab or window of the browser running, you do not have torestart the description each time.Click the button Start, for starting the display of the measurement results.The demo can only be started, if a possible saving of measured values is completed via Ethernet, becauseonly one of two features can be active via Ethernet.<strong>optoNCDT</strong> 2300Page 41

OperationFig. 21 Display of measurement results<strong>optoNCDT</strong> 2300Page 42

Operation6.2.4 Video Signal via Web BrowserWith the presentation of raw and filtered video signals the effects of the adjustable video filter (video averaging)are shown. The raw signal corresponds to the signal of the detector.The filtered signal is--independent of the video averaging settings in the settings menu,--preprocessed through the first signal processing stage.There is no linear relationship between the position of the peaks in the video signal and the output measurementvalue.<strong>optoNCDT</strong> 2300Fig. 22 Display of video signalsPage 43

Operation6.3 Programming via ASCII CommandsAs an added feature you can program the sensor via an ASCII interface, physically RS422 and / or Ethernet.This requires, that the sensor must be connected either to a serial RS422 interface via a suitable interfaceconverter, see Chap. A 1, or a plug-in-card to a PC / PLC. In addition, the Ethernet interface can be used via asuitable program, for example Telnet.Pay attention in the programs used to the correct RS422 default setting or a valid Ethernet address.Once connected, you can transfer the commands from the appendix, see Chap. A 6, via the terminal or Telnetto the sensor.6.4 Timing, Measurement Value FluxThe sensor operates internally with real time cycles in a pipeline mode:1. Exposure: Charging the image detector in the receiver (measurement),2. Reading: Reading out of the imaging device and converting into digital data,3. Computing (2 cycles),4. Synchronous output.Each cycle takes about 20 μs at a measuring rate of 49.02 kHz. The measured value N is available after eachcycle with a constant lag of four cycles in respect to the real time event. The delay between the input reactionand the output signal is therefore about 60 µs up to 80 μs. The processing of the cycles occurs sequentiallyin time and parallel in space (pipelining). This guarantees a constant real time data stream.<strong>optoNCDT</strong> 2300Page 44

OperationMeasurement programDiffusedisplacement measurementDirectdisplacement measurementDirectthickness measurementLinearization diffusemeasurement arrangement,laser power 1 mWLinearization direct measurement arrangement,laser power switchableRefractive index correctionDisplacement measurementhighest peak, peak with the largest surface, 1. peakAverageselected displacementSetting masters / zeroingselected peakStatistics calculation fordisplacementThickness measurementthickness, 1. & 2. peakAveragethickness & 1. & 2. displacementSetting masters / zeroingthicknessStatistics calculation forthicknessDisplacement measurement ondiffuse reflecting targetsDisplacement measurementon direct reflecting targetsThickness measurement on directreflecting transparent targetsGrey shadedfields require aselection.Fig. 23 Adjustment possibilities of the <strong>optoNCDT</strong> 2300ValueDark-borderedfields require youto specify a value.<strong>optoNCDT</strong> 2300Page 45

Control Menu, Set Sensor Parameter7. Control Menu, Set Sensor Parameter7.1 Preliminary Remarks to the AdjustmentsYou can program the <strong>optoNCDT</strong> 2300 simultaneously in two different ways:--using a web browser via the sensor Web interface--ASCII command set and a terminal program via RS422 or Ethernet (Telnet). Received measurement valuesare displayed with binary character.iIf you do not save the programming permanently in the sensor, you lost the settings after turning off thesensor.7.2 Overview ParameterThe following parameters can be set or change in the <strong>optoNCDT</strong> 2300, see Fig. 20 menu Settings.LoginDefault settingsData outputMeasurement controlParameter, extras7.3 Login, Change User LevelEntering a password, change user levelMeasurement program, measurement frequency, averaging, behaviorin the case of error, setting zero/setting masters and material database for thickness measurementSelection and setting of digital interface, data to be emitted, underscanningTriggering, synchronization of sensorsLoading/saving parameter- and interface settingsMenu language, factory settingThe assignment of a password prevents unauthorized changing of settings on the sensor. When delivered,the password protection is not enabled. The sensor operates in the user level “expert“. The password protectionshould be enabled after configuration of the sensor. The default password for the expert level is “000“.The default password or a user-defined password is not changed by a software update. The expertpassword is independent of the setup and is therefore not together loaded or saved with the setup.i<strong>optoNCDT</strong> 2300Page 46

Control Menu, Set Sensor ParameterThe following functions are available for the user:UserExpertPassword required no yesLooking settings yes yesChanging settings, changing password no yesMeasurement value, looking video signal yes 1 yesScaling diagrams yes yesSetting factory setting no yesFig. 24 Rights in the user hierarchyLoginYou are currently logged in as User.PasswordType the default password “000“ or a userdefinedpassword in the Password fieldand confirm with login.Change with a click on the Logout buttonin the mode user.LoginFig. 25 Change in the expert user levelThe user management allows you to assign a custom password in the “expert“ mode.Password Value Case-sensitive rules are observed for all passwords. Numbers are allowed.Special characters are not allowed.User level whenswitching onUser /ExpertSpecifies the user level, with which the sensor starts after the re-starting.For this purpose, MICRO-EPSILON recommends the selection user.1) Only if there is no measurement output via a different interface. Otherwise you must be logged in expertmode.<strong>optoNCDT</strong> 2300Page 47

fch n d n h b k na e a e 20 2 2 08 02 0 2 µ0 0N NControl Menu, Set Sensor Parameter7.4 Default Settings7.4.1 Measurement ProgramSettings for the measurement programs in the <strong>optoNCDT</strong> 2300.MeasurementsetupPeak to be measureddiffuse reflection /direct reflection /displacement measurement /direct reflection thicknessmeasurementfirst peak /highest peak /widest peakDisplacement measurement by diffuse reflection; sensorevaluates the reflected stray light. Displacement or thicknessmeasurement by direct reflection; Sensor evaluatesthe light, which is reflected at the target surface. The sensoruses the first both peaks for thickness measurement.Defines, which signal is used for the evaluation in the linesignal. First Peak: Nearest peak to sensor. Highest peak:Standard, peak with the highest intensity.Widest Peak: Signal with the largest area, use by smalladjacent faults100 %nearSensorfaraserIn angeMid anger orE he CAT E he netRUNP we onERR<strong>optoNCDT</strong>Lase f Eth rCAT Et ernetn rangeRUNMi rangeP wer onEr orERR<strong>optoNCDT</strong>N bP = W P = W == H =50 %FirstpeakHighestpeakWidestpeakDiffuse reflection Direct reflection 129257 384 512ValueGrey shadedfields require aselection.Dark-borderedfields require youto specify a value.7.4.2 Measuring RateSetting for the measuring rate in the <strong>optoNCDT</strong> 2300 and so the data rate.Measuring rate 1.5 / 2.5 / 5 / 10 / 20/ 30 / 49.02 kHzDark and shining objects may require a slower measuring rate. Thecontrol do not expose longer than the measuring rate allows. Themeasurement range of the sensor is reduced at 49.02 kHz.<strong>optoNCDT</strong> 2300The measuring rate defines the number of measurements performed by the sensor per second.Page 48

Control Menu, Set Sensor ParameteriSynchronized sensors must always be set to the same measuring rate. Use a high measuring rate forlight colored and matt objects to be measured. Use a low measuring rate for dark or shiny objects to bemeasured (e.g. surfaces covered in black lacquer), for better measurement results.At a maximum measuring rate of 49.02 kHz the CMOS element is exposed 49.020 times per second.The lower the measuring rate, the longer the maximum exposure time. The real-time control of the sensorreduces the exposure time in dependency on the amount of light hitting the CMOS element and thereforecompensates for reflection changes at the same time, e.g. caused by imprints on the surface of the objectbeing measured.The output rate gives the actual number of measurement values at the sensor output per second. The maximumoutput rate can never exceed the measuring rate. The maximum frequency of the Ethernet interface isdependent on the number of output values.RS422 specificity: To detect a data loss on the receiver side, the sensor sends in this case a runtime error. Ifnot all data can be output via RS422, error codes are issued in the next record.Calculation of the output rate using the RS422 serial interface:Abbreviations used:Output rate = Measuring rate / n * ODRn = Partial factorint =Integral part of ( )b = Byte/measurement value (binary format b=3)MF = Measuring rate [Hz]n = int (b * 11 * MF / BR) + 1BR = Baud rate [Baud]ODR = Output data rateFig. 26 Relation of measuring rate to output rate on the RS422<strong>optoNCDT</strong> 2300Page 49

Control Menu, Set Sensor ParameterCalculation of the data rate / refresh rate:DR [kSa/s] = (MR / a * (Td/Tn)) / ODRAbbreviations used:DR = Data rateMR = Measuring rate [Hz]a = 1, simultaneous synchronizationa = 2, alternating synchronization (master resp. slave)Td = Trigger pulse durationTn = Trigger non-pulse periodODR = Output data rateFig. 27 Ethernet and RS422 data rate in accordance with the channel bandwidth<strong>optoNCDT</strong> 2300Page 50