aerospace, space, high technology and special ... - Kartal Rulman

aerospace, space, high technology and special ... - Kartal Rulman

aerospace, space, high technology and special ... - Kartal Rulman

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Oil lubrication with :<br />

N.dm 5 2 Millions (1)<br />

0 5 200 (1)<br />

Pmax 5 2000 MPa (1)<br />

Oil lubrication with :<br />

N.dm >2 Millions (1)<br />

e >200°C (1)<br />

Pmax >2000MPa (1)<br />

. ._. - ...-<br />

CONDITIONS<br />

Oil lubrication with corrosive environment<br />

Highly corrosive<br />

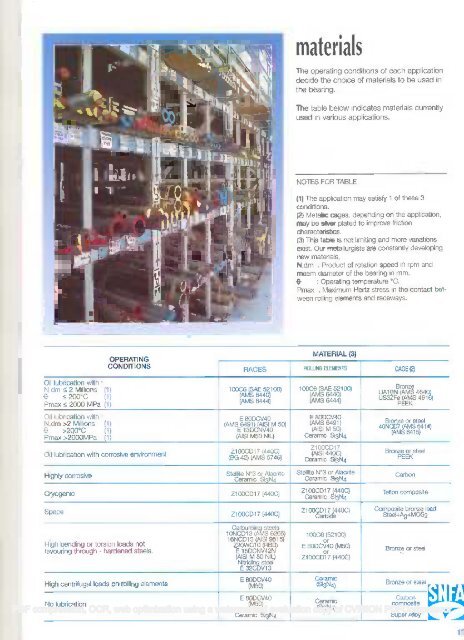

materials<br />

The operating conditions Of each application<br />

decide the choice of materials to be used in<br />

the bearing.<br />

The table below indicates materials currently<br />

used in various applications.<br />

NOTES FOR TABLE<br />

(1) The application may satisfy 1 of these 3<br />

conditions.<br />

(2) Metallic cages, depending on the application,<br />

may be silver plated to improve friction<br />

characteristics.<br />

(3) This table is not limiting <strong>and</strong> more variations<br />

exist. Our metallurgists are oonstantly developing<br />

new materials.<br />

N.dm Product of rotation speed in rpm <strong>and</strong><br />

meam diameter of the bearing in mm.<br />

A- : Operating temperature °C.<br />

Pmax Maximum Hertz stress in the contact between<br />

rolling elements <strong>and</strong> raceways.<br />

MATERIAL (3)<br />

RACES ROWNGELEI/ENTS CAGE 0<br />

1c`TAIIA6E44100)<br />

(WS 6444)<br />

6491) ((AISI<br />

(AISI M50 NIL)<br />

Z100CD17 (440C)<br />

(BG 42} (AMS 5749)<br />

Stellite N.3 Or Aacnte<br />

Ceramic Sip,'<br />

Cryogenic Z100CD17 (440C)<br />

Space 2100CD17 (440C)<br />

High bending or torsion loads not<br />

favouring through - hardened steels.<br />

High centrifugal loads on rolling elements<br />

Carburing steels<br />

10NC013 (AMS 6265)<br />

16NCD13 (AISI 9515)<br />

Z20WC10 (RBD)<br />

E 150CN42N<br />

rAISI M 50 NIL)<br />

'V 2RAT1V<br />

E 800Cv40<br />

(M50}<br />

1-,,,,,6,r6E,x0o)<br />

(AMS 6444}<br />

E 80DCV40<br />

(AMS 6491}<br />

(AISI M 50)<br />

Ceramic Si3N4<br />

Z100CD17<br />

{AISI 440C)<br />

Ceramic Si3N4<br />

Stab% No3 or Alacrite<br />

Ceramic Si3N4<br />

Z100CD17 (440C)<br />

Ceramic SQN4<br />

Z1008EXX40C)<br />

10006 (52100)<br />

Of<br />

E 800CV40 (M50}<br />

Of<br />

Z100CD I 7 (440C)<br />

Ceramic<br />

(SI3N4)<br />

Bronze<br />

UAl ON (AMS 4640}<br />

US3ZFe MS 4616)<br />

PEEK<br />

Bronze Or steel<br />

4ONgaggi4)<br />

Bronze rEgr steel<br />

Carbon<br />

Teflon compOSite<br />

Cc."STer3::IN'aird<br />

Bronze or steel<br />

Bronze or steel<br />

E 80DCV40<br />

Carbon<br />

No lubrication<br />

(m50)<br />

Ceramic<br />

I<br />

composite<br />

PDF compression, OCR, web optimization using a watermarked evaluation copy t of CVISION PDFCompressor<br />

Ceramic Si3N4<br />

Super Alby 6.77<br />

1.4