BRIDGE GULLIES - RECONSTRUCTION ATTACHMENTS ...

BRIDGE GULLIES - RECONSTRUCTION ATTACHMENTS ...

BRIDGE GULLIES - RECONSTRUCTION ATTACHMENTS ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

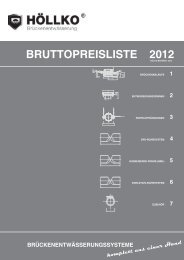

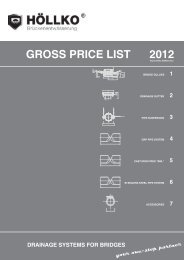

TABLE OF CONTENTSGeneral informationChapter 01Bridge gullies forpedestrian bridges, steel- and railwaybridges, and curb gulliesChapter 05PagePage- Bridge gully drawing according to RIZ WAS1- Installation instructions for Höllko bridge gully2000, 2300, and 2500 series- Specification drawing RIZ WAS1Bridge gullyHöllko 2000 series according to WAS1,300 x 400mm- Bridge gully Höllko 2000/1- Bridge gully Höllko 2000/2- Bridge gully Höllko 2000/2E- Bridge gully Höllko 2000/3- Bridge gully Höllko 2000/4- Bridge gully Höllko 2000/5- Bridge gully Höllko 2000/5E- Bridge gully Höllko 2000/6- Bridge gully Höllko 2000/7- Top part Höllko 1010- Intermediate flange for Höllko design 2000- Flange ring for installation rotated by 45°- Circular flange ringBridge gullyHöllko 2300 series according to WAS1,300 x 500mm0405 - 0708Chapter 0210111213141516171819202121Chapter 03- Bridge gully Höllko 320- Bridge gully Höllko 330- Bridge gully Höllko 340- Levelling frame Höllko 30- Bridge gully Höllko 347- Bridge gully Höllko 348- Bridge gully Höllko 349- Bridge gully Höllko 350- Bridge gully Höllko 400- Bridge gully Höllko 410- Bridge gully Höllko 450- Bridge gully Höllko 1000- Bridge gully Höllko 1001- Bridge gully Höllko 1002Reconstruction attachments, top parts- Top part Höllko 1020- Top part Höllko 1030- Top part Höllko 1040- Top part Höllko 1050- Reconstruction attachment Höllko 1065- Reconstruction attachment Höllko 1070- Reconstruction attachment Höllko 1080- Reconstruction attachment Höllko 1082- Reconstruction attachment Höllko 1083- Reconstruction attachment Höllko 10854849505152535455565758596061Chapter 0664656667686970717273- Bridge gully Höllko 2300/1- Bridge gully Höllko 2300/2- Bridge gully Höllko 2300/2E- Bridge gully Höllko 2300/3- Bridge gully Höllko 2300/4- Bridge gully Höllko 2300/5- Bridge gully Höllko 2300/5E- Bridge gully Höllko 2300/6- Bridge gully Höllko 2300/7- Intermediate flange for Höllko design 2300- Flange ring for installation rotated by 45°- Circular flange ring242526272829303132333434Dripping spouts,cleansing connection pipes andmanhole covers- Dripping spout Höllko 1210- Dripping spout Höllko 1220- Dripping spouts, section types- Dripping ring- Cleansing connection pipeHöllko 1300, 1310 and 1320- Manhole cover Höllko 1500Chapter 07767677777879Bridge gullyHöllko 2500 series according to WAS1,500 x 500mm- Bridge gully Höllko 2500/1- Bridge gully Höllko 2500/2- Bridge gully Höllko 2500/2E- Bridge gully Höllko 2500/3- Bridge gully Höllko 2500/4- Bridge gully Höllko 2500/5- Bridge gully Höllko 2500/5E- Bridge gully Höllko 2500/6- Bridge gully Höllko 2500/7- Intermediate flange for Höllko design 2500- Special flange ring for combinationwith Höllko 2000 and 2300 gulliesChapter 043637383940414243444546Accessories for bridge gulliesand dripping spouts- Installation support for gully drains- Fibre cement socket- Base plates for top parts- Handle key- Sludge traps- Dripping ringsChapter 088282828383832Subject to technical changes - © with Höllko®

INSTALLATION INSTRUCTIONS<strong>BRIDGE</strong> GULLYSERIES2000230025003

Bridge gully according to (specification drawing)RIZ WAS1Rotary Height-adjustable Sliding Angle-adjustableBA4.I1.CDLegend for the components:3.EF2.5.1. Top part with frame, grid, and adjustingscrews2. Sludge trap3. Flange ring with clamping plates andscrew connection4. Intermediate flange (optional)5. Base part6. Installation supportLegend for the adjustment options:II6.A. RotaryB. Opening angle ≥ 100°C. Relocatability ± 20mmD. Height adjustment andangle adjustment of the top part byadjusting screwsE. RotaryF. Curb markLegend for positioning:I. Driving directionII. Curb4Subject to technical changes - © with Höllko®

INSTALLATION INSTRUCTIONSHöllko 2000, 2300, and 2500 series according to RIZ WAS 11.) Base partPosition the base part 30-40mm below the upper concrete edge; observe the mark on the base part (curb). If thebase part must be installed rotated by 90° or 180°, the distance from the outer edge of the base part to the mark(curb) must remain the same. An easier adjustment with additional installation support is possible (see accessorieson page 82). The exact position of the clamping bolts of the flange ring must be paid attention to (see sketch). Pourconcrete in the base part and produce a circumferential even concrete surface, 40mm wide, around the base part.>_4030-40>_70Roadway areacurbRoadway areacurb2.) SealCORRECTWRONGApply a sealing layer (according to specification drawing ) across the entire surface of the flange of thebase part (protect the screw threads).3.) Flange ringUnscrew the thread protection (screws M12x15mm) from theblind holes of the base part.Attach the flange ring comletely to the surface below,using the attached threaded pins M12x70mm, clamping plates,and nuts in order to clamp theseal. However, do not tighten the screws yet,since the top part must still be positioned correctly.TREADED PIN M12X70HEXAGONAL NUT M12CLAMPING PLATE 70/40/4FLANGE RINGSEALBASE PARTINSTALLATION SUPPORTSubject to technical changes - © with Höllko® 5

INSTALLATION INSTRUCTIONSHöllko 2000, 2300, and 2500 series according to RIZ WAS 14.) Top partAfter having produced the curb, align the top part (at a distance of 20-40mm) laterally by relocating the flange ring.Tighten the flange ring fixture.The driving direction must be observed (grid must close in driving direction).Position the top part at the designed height (10mm below upper edge of the road surface) and inclination by usingthe adjusting bolts in the top part.In order to transfer the traffic load, the top part must be lined with a suitable load-bearing material between theupper edge of the flange ring and the lower edge of the frame.Produce the soak layer and the base course.FRICTION LOCKADJUSTING BOLT M16DRIVING DIRECTIONHINGECLAMPING PLATEDRIVING DIRECTION6Subject to technical changes - © with Höllko®

INSTALLATION INSTRUCTIONSHöllko 2000, 2300, and 2500 series according to RIZ WAS 15.) Protective layer and road surfaceCreate the protective layer and the road surface.6.) JointsSeal the joints.107.) MaintenanceThe sludge traps must be inspected and cleaned regularly. The sedimentation located in the frame and the basepart must be removed. Each time before closing the grid, its bearing points and the hinge area must be cleanedthoroughly in order to avoid damages.8.) TrafficabilityIn general, our gullies and reconstruction attachments comply with EN124. By default, our gullies and reconstructionattachments are equipped with hinges and friction locks, to ensure easy maintentance. If vehicles pass thesein a permanent manner, a screwed type (grid with frame and 4-fold screw connection with screw locking device) isrequired.9.) Further installation instructionsIn addition to these installation instructions, you will find further installation instructions on the internet atwww.hoellko.com, for example installation of E-gullies and reconstruction attachments, etc.Subject to technical changes - © with Höllko® 7

(Specification drawing) RIZ WAS 1EXAMPLE DRAWINGS IN ACCORDANCEWITH GERMAN LAW8Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2000/1Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 400mm,designs HÖLLKO 2000/150 (ND 150) and 2000/100 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 400mm, test load class D 400Slot width 36mm – intake capacity 565cm 2 (standard) and/orSlot width 16mm – intake capacity 350cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with lateral outlet ND 150 (ND 100), 3° inclinationSludge trap made of steel sheet, hot-galvanised, volume 6L71710For notes on the installationprocedure, see installationinstructions page 4-8.TOP VIEW SW36 (top part, including grid, flange, base part)FRICTION LOCKSECTIONDRIVING DIRECTION430Ø580HINGE30-40FLANGE RING95-160320180160100Ø160Ø110180TOP VIEW SW16 (top part only, including grid)Ø380FRICTION LOCK365DRIVING DIRECTION430HINGE320Gully made of cast ironRated width Item no. SW 36 Item no. SW 16ND100 BA2000-100-SW36 BA2000-100-SW16ND150 BA2000-150-SW36 BA2000-150-SW16Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36 Item no. SW 16ND100 BA2000-100-SW36-VA BA2000-100-SW16-VAND150 BA2000-150-SW36-VA BA2000-150-SW16-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 20- Circular flange / vario flange Accessories on page 21- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 8310Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2000/2Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 400mm,designs HÖLLKO 2000/250 (ND 150) and 2000/200 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 400mm, test load class D 400Slot width 36mm – intake capacity 565cm 2 (standard) and/orSlot width 16mm – intake capacity 350cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with vertical outlet ND 150 (ND 100)Sludge trap made of steel sheet, hot-galvanised, volume 6L71710For notes on the installationprocedure, see installationinstructions page 4-8.TOP VIEW SW36 (top part, including grid, flange, base part)FRICTION LOCKSECTIONDRIVING DIRECTION430Ø580HINGE30-40FLANGE RING95-160320140330TOP VIEW SW16 (top part only, including grid)Different nozzle lengthsupon requestØ160Ø110Ø380FRICTION LOCKDRIVING DIRECTION430HINGE320Gully made of cast ironRated width Item no. SW 36 Item no. SW 16ND100 BA2000-200-SW36 BA2000-200-SW16ND150 BA2000/250-SW36 BA2000-250-SW16Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36 Item no. SW 16ND100 BA2000-200-SW36-VA BA2000-200-SW16-VAND150 BA2000-250-SW36-VA BA2000-250-SW16-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 20- Circular flange / vario flange Accessories on page 21- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83Subject to technical changes - © with Höllko® 11

<strong>BRIDGE</strong> GULLY 2000/2EProduct description/tender specificationCast-iron bridge gully for incremental launching methods,including flange and flange ring with soaking slots according tospecification drawing WAS 1, according to DIN EN 124/1229,grid size 300 x 400mm,gully with suspended pipe made of stainless steel,material 1.4571,designs HÖLLKO 2000/250E (ND 150) and 2000/200E (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 400mm, test load class D 400Slot width 36mm – intake capacity 565cm 2 (standard) and/orSlot width 16mm – intake capacity 350cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Suspended pipe made of stainless steel,material 1.4571 ND 150 (ND 100), GRP jacket pipe ND 200Sludge trap made of steel sheet, hot-galvanised, volume 6LFRICTION LOCK71710For notes on the installationprocedure, see installationinstructions page 4-8.TOP VIEW SW36 (top part, including grid, flange, base part)DRIVING DIRECTION430Ø580SECTIONHINGE30-40FLANGE RING95-160320TOP VIEW SW16 (top part only, including grid)210AS REQUIREDCE-CONNECTORJACKET PIPE GRPØ160Ø110Ø380AS REQUIREDDRIPPING RING(OPTIONAL)FRICTION LOCKHINGEDRIVING DIRECTION430320Gully made of cast ironRated width Item no. SW 36 Item no. SW 16ND100 BA2000-200E-SW36 BA2000-200E-SW16ND150 BA2000-250E-SW36 BA2000-250E-SW16Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36 Item no. SW 16ND100 BA2000-200E-SW36-VA BA2000-200E-SW16-VAND150 BA2000-250E-SW36-VA BA2000-250E-SW16-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 20- Circular flange / vario flange Accessories on page 21- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83- Dripping ring Accessories on page 8312Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2000/3Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 400mm,designs HÖLLKO 2000/350 (ND 150) and 2000/300 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 400mm, test load class D 400Slot width 36mm – intake capacity 565cm 2 (standard) and/orSlot width 16mm – intake capacity 350cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with asymmetrical outlet 45°, ND 150 (ND 100)Sludge trap made of steel sheet, hot-galvanised, volume 6L71710For notes on the installationprocedure, see installationinstructions page 4-8.TOP VIEW SW36 (top part, including grid, flange, base part)FRICTION LOCKSECTIONHINGEDRIVING DIRECTION430Ø58030-40FLANGE RING95-160320146366185TOP VIEW SW16 (top part only, including grid)Different nozzle lengthsupon requestØ380511Ø160Ø110FRICTION LOCKHINGEDRIVING DIRECTION430320Gully made of cast ironRated width Item no. SW 36 Item no. SW 16ND100 BA2000-300-SW36 BA2000-300-SW16ND150 BA2000-350-SW36 BA2000-350-SW16Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36 Item no. SW 16ND100 BA2000-300-SW36-VA BA2000-300-SW16-VAND150 BA2000-350-SW36-VA BA2000-350-SW16-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 20- Circular flange / vario flange Accessories on page 21- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83Subject to technical changes - © with Höllko®13

<strong>BRIDGE</strong> GULLY 2000/4Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 400mm,designs HÖLLKO 2000/450 (ND 150) and 2000/400 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 400mm, test load class D 400Slot width 36mm – intake capacity 565cm 2 (standard) and/orSlot width 16mm – intake capacity 350cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base with asymmetrical, vertical outlet ND 150 (ND 100)Sludge trap made of steel sheet, hot-galvanised, volume 6L71710For notes on the installationprocedure, see installationinstructions page 4-8.TOP VIEW SW36 (top part, including grid, flange, base part)FRICTION LOCKSECTIONHINGEDRIVING DIRECTION430Ø580FLANGE RING95-16030-40320TOP VIEW SW16 (top part only, including grid)145330FRICTION LOCKØ160Ø110110HINGEDRIVING DIRECTION430Ø380Different nozzle lengthsupon request320Gully made of cast ironRated width Item no. SW 36 Item no. SW 16ND100 BA2000-400-SW36 BA2000-400-SW16ND150 BA2000-450-SW36 BA2000-450-SW16Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36 Item no. SW 16ND100 BA2000-400-SW36-VA BA2000-400-SW16-VAND150 BA2000-450-SW36-VA BA2000-450-SW16-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 20- Circular flange / vario flange Accessories on page 21- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 8314Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2000/5Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 400mm,designs HÖLLKO 2000/550 (ND 150) and 2000/500 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 400mm, test load class D 400Slot width 36mm – intake capacity 565cm 2 (standard) and/orSlot width 16mm – intake capacity 350cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base with vertical outlet ND 150 (ND 100)Without sludge trap(Sludge trap made of steel sheet, hot-galvanised, volume 3Lavailable upon request)71710For notes on the installationprocedure, see installationinstructions page 4-8.TOP VIEW SW36 (top part, including grid, flange, base part)FRICTION LOCKSECTIONHINGEDRIVING DIRECTION430Ø580FLANGE RING95-14530-4032026575TOP VIEW SW16 (top part only, including grid)Ø160FRICTION LOCKDifferent nozzle lengthsupon requestØ110Ø380HINGEDRIVING DIRECTION430320Gully made of cast ironRated width Item no. SW 36 Item no. SW 16ND100 BA2000-500-SW36 BA2000-500-SW16ND150 BA2000-550-SW36 BA2000-550-SW16Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36 Item no. SW 16ND100 BA2000-500-SW36-VA BA2000-500-SW16-VAND150 BA2000-550-SW36-VA BA2000-550-SW16-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 20- Circular flange / vario flange Accessories on page 21- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83Subject to technical changes - © with Höllko®15

<strong>BRIDGE</strong> GULLY 2000/5EProduct description/tender specificationCast-iron bridge gully for incremental launching methods,including flange and flange ring with soaking slots according tospecification drawing WAS 1, according to DIN EN 124/1229,grid size 300 x 400mm,gully with suspended pipe made of stainless steel, material 1.4571,designs HÖLLKO 2000/550E (ND 150) and 2000/500E (ND 100)71710Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 400mm, test load class D 400Slot width 36mm – intake capacity 565cm 2 (standard) and/orSlot width 16mm – intake capacity 350cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Suspended pipe made of stainless steel,material 1.4571 ND 150 (ND 100), GRP jacket pipe ND 200Without sludge trap(Sludge trap made of steel sheet, hot-galvanised,volume 3L, available upon request)SECTIONFRICTION LOCKHINGEDRIVING DIRECTIONFor notes on the installationprocedure, see installationinstructions page 4-8.TOP VIEW SW36 (top part, including grid, flange, base part)430Ø58030-40FLANGE RING95-145320145AS REQUIREDCE-CONNECTORJACKET PIPE GRPØ160Ø110Ø380AS REQUIREDDRIPPING RING(OPTIONAL)FRICTION LOCKHINGETOP VIEW SW16 (top part only, including grid)DRIVING DIRECTION430320Gully made of cast ironRated width Item no. SW 36 Item no. SW 16ND100 BA2000-500E-SW36 BA2000-500E-SW16ND150 BA2000-550E-SW36 BA2000-550E-SW16Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36 Item no. SW 16ND100 BA2000-500E-SW36-VA BA2000-500E-SW16-VAND150 BA2000-550E-SW36-VA BA2000-550E-SW16-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 20- Circular flange / vario flange Accessories on page 21- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83- Dripping ring Accessories on page 8316Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2000/6Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 400mm,designs HÖLLKO 2000/650 (ND 150) and 2000/600 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 400mm, test load class D 400Slot width 36mm – intake capacity 565cm 2 (standard) and/orSlot width 16mm – intake capacity 350cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with asymmetrical outlet 45°, ND 150 (ND 100)Without sludge trap(Sludge trap made of steel sheet, hot-galvanised, volume 3L,available upon request)71710For notes on the installationprocedure, see installationinstructions page 4-8.TOP VIEW SW36 (top part, including grid, flange, base part)FRICTION LOCKSECTIONHINGEDRIVING DIRECTION430Ø580301 30-40FLANGE RING8195-145185320TOP VIEW SW16 (top part only, including grid)Different nozzle lengthsupon requestØ380511Ø160Ø110FRICTION LOCKHINGEDRIVING DIRECTION430320Gully made of cast ironRated width Item no. SW 36 Item no. SW 16ND100 BA2000-600-SW36 BA2000-600-SW16ND150 BA2000-650-SW36 BA2000-650-SW16Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36 Item no. SW 16ND100 BA2000-600-SW36-VA BA2000-600-SW16-VAND150 BA2000-650-SW36-VA BA2000-650-SW16-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 20- Circular flange / vario flange Accessories on page 21- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83Subject to technical changes - © with Höllko®17

<strong>BRIDGE</strong> GULLY 2000/7Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 400mm,designs HÖLLKO 2000/750 (ND 150) and 2000/700 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 400mm, test load class D 400Slot width 36mm – intake capacity 565cm 2 (standard) and/orSlot width 16mm – intake capacity 350cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with asymmetrical, vertical outlet ND 150 (ND 100)Without sludge trap(Sludge trap made of steel sheet, hot-galvanised, volume 3Lavailable upon request)71710For notes on the installationprocedure, see installationinstructions page 4-8.TOP VIEW SW36 (top part, including grid, flange, base part)FRICTION LOCKSECTIONHINGEDRIVING DIRECTION430Ø58080 30-40FLANGE RING95-145320265TOP VIEW SW16 (top part only, including grid)Ø160FRICTION LOCKDifferent nozzle lengthsupon request110Ø380Ø110HINGEDRIVING DIRECTION430320Gully made of cast ironRated width Item no. SW 36 Item no. SW 16ND100 BA2000-700-SW36 BA2000-700-SW16ND150 BA2000-750-SW36 BA2000-750-SW16Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36 Item no. SW 16ND100 BA2000-700-SW36-VA BA2000-700-SW16-VAND150 BA2000-750-SW36-VA BA2000-750-SW16-VAOptions-Additional height adjustment options due to intermediate flange Accessories on page 20- Circular flange / vario flange Accessories on page 21- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 8318Subject to technical changes - © with Höllko®

TOP PART 1010Product description/tender specificationCast-iron top part with integratedflange ring (special design height 65mm)suitable for bridge gullies of the 2000 seriesclass D 400 according to DIN EN 124/1229, grid size 300 x 400mm,design HÖLLKO 101071710Top part sliding and rotarySlot width 36mm – intake capacity 565cm² (standard)Slot width 16mm – intake capacity 350cm²Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)suitable sludge traps available upon requestInstallation notes:When using the top bridge gullypart, the standard flange ring is not required.Special solution for base gully parts ofthe 2000 series that were concreted in too highSECTIONTOP VIEW SW36 (top part, including grid)FRICTION LOCK30565114HINGEDRIVING DIRECTION430Ø580320450TOP VIEW (INSTALLED CONDITION (left))TOP VIEW (INSTALLED CONDITION (right))DRIVING DIRECTIONDRIVING DIRECTIONHINGEFRICTION LOCKFRICTION LOCKHINGETop part made of cast ironDesign Item no. Item no.left BAOT1010-SW36-L BAOT1010-SW16-Lright BAOT1010-SW36-R BAOT1010-SW16-RSubject to technical changes - © with Höllko® 19

<strong>BRIDGE</strong> GULLY FLANGEProduct description/tender specificationCast-iron flange ring suitable forbase parts of the design HÖLLKO 2000installed rotated by 45°,grid size 300 x 400mm,TOP VIEWInstallation notes:The flange ring replacesthe standard flange.TOP VIEW(INSTALLED CONDITION WITH BASE PARTROTATED BY 45°)SECTIONØ580495FLANGEBASE PARTFlange ring made of cast iron290495205Design height (mm) Item no.15 FL2000VCurbProduct description/tender specificationCast-iron flange ring (circular design)for completely pressing the sealing layersuitable for design HÖLLKO 2000,grid size 300 x 400mmTOP VIEWInstallation notes:The flange ring replaces thestandard flange.SECTION580580Circular flange ring made of cast ironDesign height (mm) Item no.15 FL2000RSubject to technical changes - © with Höllko®21

SPACE FOR NOTES22Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2300 SERIES ACCORDING TOWAS1GRID SIZE 300 X 500Subject to technical changes - © with Höllko® 23

<strong>BRIDGE</strong> GULLY 2300/1Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 500mm,designs HÖLLKO 2300/150 (ND 150) and 2300/100 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 500mm, test load class D 400Slot width 36mm – intake capacity 700cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with vertical outlet ND 150 (ND 100), 3° inclinationSludge trap made of steel sheet, hot-galvanised, volume 6L71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)FLANGE RING18016095-160100Ø16030-40Ø110180FRICTION LOCKDRIVING DIRECTION520Ø580Ø380365HINGE320Gully made of cast ironRated width Item no. SW 36ND100BA2300-100-SW36ND150BA2300-150-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2300-100-SW36-VAND150BA2300-150-SW36-VAOptions-Additional height adjustment options due to intermediate flange Accessories on page 33- Circular flange / vario flange Accessories on page 34- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 8324Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2300/2Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 500mm,designs HÖLLKO 2300/250 (ND 150) and 2300/200 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 500mm, test load class D 400Slot width 36mm – intake capacity 700cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with vertical outlet ND 150 (ND 100)Sludge trap made of steel sheet, hot-galvanised, volume 6L71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)30-40FLANGE RING95-160140330FRICTION LOCKDRIVING DIRECTION520Ø580HINGEØ160Ø110Ø380320Different nozzle lengtsupon requestGully made of cast ironRated width Item no. SW 36ND100BA2300-200-SW36ND150BA2300-250-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2300-200-SW36-VAND150BA2300-250-SW36-VAOptions-Additional height adjustment options due to intermediate flange Accessories on page 33- Circular flange / vario flange Accessories on page 34- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83Subject to technical changes - © with Höllko® 25

<strong>BRIDGE</strong> GULLY 2300/2EProduct description/tender specificationCast-iron bridge gully for incremental launching methods,including flange and flange ring with soaking slots according tospecification drawing WAS 1, according to DIN EN 124/1229,grid size 300 x 500mm,drain with suspended pipe made of stainless steel, material1.4571,designs HÖLLKO 2300/250E (ND 150) and 2300/200E (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 500mm, test load class D 400Slot width 36mm – intake capacity 700cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Suspended pipe made of stainless steel, material 1.4571 ND 150(ND 100) GRP jacket pipe ND 200Sludge trap made of steel sheet, hot-galvanised, volume 6L71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)30-40FLANGE RING95-160FRICTION LOCK210AS REQUIREDCE-CONNECTORJACKET PIPE GRPØ160Ø110Ø380AS REQUIREDDRIPPING RING(OPTIONAL)HINGEDRIVING DIRECTION320520Ø580Gully made of cast ironRated width Item no. SW 36ND100 BA2300-200E-SW36ND150 BA2300-250E-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2300-200E-SW36-VAND150BA2300-250E-SW36-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 33- Circular flange / vario flange Accessories on page 34- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83- Dripping ring Accessories on page 8326Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2300/3Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 500 mm,designs HÖLLKO 2300/350 (ND 150) and 2300/300 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 500mm, test load class D 400Slot width 36mm – intake capacity 700cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with asymmetrical outlet 45°, ND 150 (ND 100)Sludge trap made of steel sheet, hot-galvanised, volume 6L71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)30-40366FLANGE RING14695-160185FRICTION LOCKDRIVING DIRECTION520Ø580HINGEØ380511Ø160Ø110320Different nozzle lengthsupon requestGully made of cast ironRated width Item no. SW 36ND100BA2300-300-SW36ND150BA2300-350-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2300-300-SW36-VAND150BA2300-350-SW36-VAOptions-Additional height adjustment options due to intermediate flange Accessories on page 33- Circular flange / vario flange Accessories on page 34- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83Subject to technical changes - © with Höllko® 27

<strong>BRIDGE</strong> GULLY 2300/4Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 500 mm,designs HÖLLKO 2300/450 (ND 150) and 2300/400 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 500mm, test load class D 400Slot width 36mm – intake capacity 700cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with asymmetrical, vertical outlet ND 150(ND 100) Sludge trap made of steel sheet, hot-galvanised, volume 6L71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)FLANGE RING95-16030-40FRICTION LOCK330145DRIVING DIRECTION520Ø580Ø160HINGE110Ø380Ø110320Different nozzle lengthsupon requestGully made of cast ironRated width Item no. SW 36ND100BA2300-400-SW36ND150BA2300-450-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2300-400-SW36-VAND150BA2300-450-SW36-VAOptions-Additional height adjustment options due to intermediate flange Accessories on page 33- Circular flange / vario flange Accessories on page 34- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 8328Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2300/5Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 500 mm,designs HÖLLKO 2300/550 (ND 150) and 2300/500 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 500mm, test load class D 400Slot width 36mm – intake capacity 700cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with vertical outlet ND 150 (ND 100)Without sludge trap(Sludge trap made of steel sheet, hot-galvanised, volume 3Lavailable upon request)71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)FLANGE RING95-14526530-4075FRICTION LOCKDRIVING DIRECTION520Ø580Ø160HINGEØ110Ø380320Different nozzle lengthsupon requestGully made of cast ironRated width Item no. SW 36ND100BA2300-500-SW36ND150BA2300-550-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2300-500-SW36-VAND150BA2300-550-SW36-VAOptions-Additional height adjustment options due to intermediate flange Accessories on page 33- Circular flange / vario flange Accessories on page 34- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83Subject to technical changes - © with Höllko® 29

<strong>BRIDGE</strong> GULLY 2300/5EProduct description/tender specificationCast-iron bridge gully for incremental launching methods,including flange and flange ring with soaking slots according tospecification drawing WAS 1, according to DIN EN 124/1229,grid size 300 x 500mm, drain with suspended pipe made ofstainless steel, material 1.4571,designs HÖLLKO 2300/550E (ND 150) and 2300/500E (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 500mm, test load class D 400Slot width 36mm – intake capacity 700cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Suspended pipe made of stainless steel, material 1.4571 ND 150 (ND 100)GRP jacket pipe ND 200.Without sludge trap.(Sludge trap made of steel sheet, hot-galvanised, volume 3L,available upon request)71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)30-40FLANGE RING95-145FRICTION LOCK145AS REQUIREDCE-CONNECTORJACKET PIPE GRPØ160AS REQUIREDDRIPPING RING(OPTIONAL)HINGEDRIVING DIRECTION520Ø580Ø110Ø380320Gully made of cast ironRated width Item no. SW 36ND100 BA2300-500E-SW36ND150 BA2300-550E-SW36Gully made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100 BA2300-500E-SW36-VAND150 BA2300-550E-SW36-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 33- Circular flange / vario flange Accessories on page 34- Base plates for load transfer when the height adjustment is screwed on Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83- Dripping ring Accessories on page 8330Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2300/6Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 500mm,designs HÖLLKO 2300/650 (DN 150) and 2300/600 (DN 100)71710Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 500mm, test load class D 400Slot width 36mm – intake capacity 700cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with asymmetrical outlet 45°, DN 150 (DN 100)Without sludge trap.(Sludge trap made of steel sheet, hot-galvanised, volume 3L,available upon request)For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)301 30-40FLANGE RING8195-145185FRICTION LOCKDRIVING DIRECTION520Ø580Ø380511Ø160Ø110HINGE320Different nozzle lengthsupon requestGully made of cast ironRated width Item no. SW 36ND100BA2300-600-SW36ND150BA2300-650-SW36Drain made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100 BA2300-600-SW36-VAND150 BA2300-650-SW36-VAOptions-Additional height adjustment options due to intermediate flange Accessories on page 33- Circular flange / vario flange Accessories on page 34- Base plates for load transfer when the height adjustment is screwed on Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83Subject to technical changes - © with Höllko® 31

<strong>BRIDGE</strong> GULLY 2300/7Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 300 x 500mm,designs HÖLLKO 2300/750 (ND 150) and 2300/700 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 300 x 500mm, test load class D 400Slot width 36mm – intake capacity 700cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with asymmetrical, vertical outlet ND 150 (ND 100)Without sludge trap(Sludge trap made of steel sheet, hot-galvanised, volume 3L,available upon request)71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)80 30-40FLANGE RING95-145265FRICTION LOCKDRIVING DIRECTION520Ø580Ø160HINGEØ110110Ø380320Different nozzle lengthsupon requestGully made of cast ironRated width Item no. SW 36ND100BA2300-700-SW36ND150BA2300-750-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2300-700-SW36-VAND150BA2300-750-SW36-VAOptions-Additional height adjustment options due to intermediate flange Accessories on page 33- Circular flange / vario flange Accessories on page 34- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 8332Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY - FLANGE - OPTIONSProduct description/tender specificationCast-iron intermediate flange for additionalheight adjustment suitable for design HÖLLKO 2300,grid size 300 x 500mmInstallation notes:The intermediate flange replaces thestandard flange.SECTION (FLANGE ONLY)SECTION (INSTALLED CONDITION)A455TOP PARTINTERMEDIATEFLANGE RINGABTOP VIEW (FLANGE ONLY)BASE PARTØ580Intermediate flange made of cast iron290455165Design heights (A) (mm) Adjustment range (B) (mm) Item no.60 140 - 205 ZWFL2300-06080 160 - 225 ZWFL2300-080120 200 - 265 ZWFL2300-120160 240 - 305 ZWFL2300-160200 280 - 345 ZWFL2300-200Subject to technical changes - © with Höllko® 33

<strong>BRIDGE</strong> GULLY FLANGEProduct description/tender specificationCast-iron flange ring suitable forbase parts of the design HÖLLKO 2300installed rotated by 45°,grid size 300 x 500mmTOP VIEWInstallation notes:The flange ring replaces thestandard flange.TOP VIEW(INSTALLED CONDITION WITH BASE PARTROTATED BY 45°SECTIONØ580495FLANGEBASE PART290495205Flange ring made of cast ironDesign height (mm) Item no.15 FL2300VCurbProduct description/tender specificationCast-iron flange ring (circular design)for completely pressing in the sealing layersuitable for design HÖLLKO 2300,grid size 300 x 500mmTOP VIEWInstallation notes:The flange ring replaces thestandard flange.SECTION580580Circular flange ring made of cast ironDesign height (mm) Item no.15 FL2300R34Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2500 SERIES ACCORDING TOWAS 1GRID SIZE 500 X 500Subject to technical changes - © with Höllko® 35

<strong>BRIDGE</strong> GULLY 2500/1Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 500 x 500mm,designs HÖLLKO 2500/150 (ND 150) and 2500/100 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 500 x 500mm, test load class D 400Slot width 36mm – intake capacity 1260cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with vertical outlet ND 150 (ND 100), 3° inclinationSludge trap made of steel sheet, hot-galvanised, volume 9.5L71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)FRICTION LOCKFLANGE RING17415095-16095Ø16030-40Ø110175DRIVING DIRECTIONHINGE500Ø720Ø500685500Gully made of cast ironRated width Item no. SW 36ND100BA2500-100-SW36ND150BA2500-150-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2500-100-SW36-VAND150BA2500-150-SW36-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 45- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 8336Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2500/2Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 500 x 500mm,designs HÖLLKO 2500/250 (ND 150) and 2500/200 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 500 x 500mm, test load class D 400Slot width 36mm – intake capacity 1260cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with vertical outlet ND 150 (ND 100)Sludge trap made of steel sheet, hot-galvanised, volume 9.5L71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)FLANGE RING95-160340140 30-40FRICTION LOCKDRIVING DIRECTION500Ø720Ø160HINGEØ110Ø500500Different nozzle lengthsupon requestGully made of cast ironRated width Item no. SW 36ND100BA2500-200-SW36ND150BA2500-250-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2500-200-SW36-VAND150BA2500-250-SW36-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 45- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83Subject to technical changes - © with Höllko® 37

<strong>BRIDGE</strong> GULLY 2500/2EProduct description/tender specificationCast-iron bridge gully for incremental launching methods,including flange and flange ring with soaking slots according tospecification drawing WAS 1, according to DIN EN 124/1229,grid size 500 x 500mm,gully with suspended pipe made of stainless steel,material 1.4571,designs HÖLLKO 2500/250E (ND 150) and 2500/200E (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 500 x 500mm, test load class D 400Slot width 36mm – intake capacity 1260cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Suspended pipe made of stainless steel, material 1.4571 ND 150 (ND 100)GRP jacket pipe ND 200Sludge trap made of steel sheet, hot-galvanised, volume 9.5L71710For notes on the installationprocedure,see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)FLANGE RINGCE-CONNECTORJACKET PIPE GRPAS REQUIRED95-160DRIPPING RING(OPTIONAL)220 30-40AS REQUIREDDRIVING DIRECTIONHINGE500Ø720Ø500500Gully made of cast ironRated width Item no. SW 36ND100 BA2500-200E-SW36ND150 BA2500-250E-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2500-200E-SW36-VAND150BA2500-250E-SW36-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 45- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83- Dripping ring Accessories on page 8338Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2500/3Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 500 x 500mm,designs HÖLLKO 2500/350 (ND 150) and 2500/300 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotaryGrid size 500 x 500mm, test load class D 400Slot width 36mm – intake capacity 1260cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with asymmetrical outlet 45°, ND 150 (ND 100)Sludge trap made of steel sheet, hot-galvanised, volume 9.5L71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)FLANGE RING369153Different nozzle lengthsupon requestØ50062395-160 95-160185Ø160Ø11030-40FRICTION LOCKDRIVING DIRECTIONHINGE500500Ø720Gully made of cast ironRated width Item no. SW 36ND100BA2500-300-SW36ND150BA2500-350-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2500-300-SW36-VAND150BA2500-350-SW36-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 45- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83Subject to technical changes - © with Höllko® 39

<strong>BRIDGE</strong> GULLY 2500/4Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 500 x 500mm,designs HÖLLKO 2500/450 (ND 150) and 2500/400 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotary.Grid size 500 x 500mm, test load class D 400Slot width 36mm – intake capacity 1260cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with asymmetrical, vertical outlet ND 150 (ND 100)Sludge trap made of steel sheet, hot-galvanised, volume 9.5L71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)FLANGE RING14095-160340145 30-40FRICTION LOCKDRIVING DIRECTION500Ø720Ø160HINGEØ110Different nozzle lengthsupon request156Ø500500Gully made of cast ironRated width Item no. SW 36ND100BA2500-400-SW36ND150BA2500-450-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no.SW 36ND100BA2500-400-SW36-VAND150BA2500-450-SW36-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 45- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 8340Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2500/5Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 500 x 500mm,designs HÖLLKO 2500/550 (ND 150) and 2500/500 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotary.Grid size 500 x 500mm, test load class D 400Slot width 36mm – intake capacity 1260cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with vertical outlet ND 150 (ND 100)Without sludge trap(Sludge trap made of steel sheet, hot-galvanised, volume 6.4L,available upon request)71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)FLANGE RING95-14527075 30-40FRICTION LOCKDRIVING DIRECTION500Ø720Ø160HINGEØ110Ø500500Different nozzle lengthsupon requestGully made of cast ironRated width Item no. SW 36ND100BA2500-500-SW36ND150BA2500-550-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2500-500-SW36-VAND150BA2500-550-SW36-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 45- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83Subject to technical changes - © with Höllko® 41

<strong>BRIDGE</strong> GULLY 2500/5EProduct description/tender specificationCast-iron bridge gully for incremental launching methods,including flange and flange ring with soaking slots according tospecification drawing WAS 1, according to DIN EN 124/1229,grid size 500 x 500mm,drain with suspended pipe made of stainless steel, material 1.4571,designs HÖLLKO 2500/550E (ND 150) and 2500/500E (ND 100)71710Top part height- and angle-adjustable (4.5°), sliding, and rotary.For notes on the installationGrid size 500 x 500mm, test load class D 400procedure, see installationSlot width 36mm – intake capacity 1260cm 2instructions page 4-8.Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Suspended pipe made of stainless steel, material 1.4571 ND 150 (ND 100)GRP jacket pipe ND 200Without sludge trap(Sludge trap made of steel sheet, hot-galvanised, volume 6.4L, available upon request)SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)30-40FLANGE RING95-145FRICTION LOCK148AS REQUIREDCE-CONNECTORJACKET PIPE GRPØ160AS REQUIREDDRIPPING RING(OPTIONAL)DRIVING DIRECTIONHINGE500Ø720Ø110Ø500500Gully made of cast ironRated width Item no. SW 36ND100 BA2500-500E-SW36ND150 BA2500-550E-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2500-500E-SW36-VAND150BA2500-550E-SW36-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 45- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83- Dripping ring Accessories on page 8342Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 2500/6Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 500 x 500mm,designs HÖLLKO 2500/650 (ND 150) and 2500/600 (ND 100)71710Top part height- and angle-adjustable (4.5°), sliding, and rotary.Grid size 500 x 500mm, test load class D 400Slot width 36mm – intake capacity 1260cm 2For notes on the installationTop part (frame and grid) with dampening insert,procedure, see installationwith hinge and friction lock (square, 14mm made of stainless steel)instructions page 4-8.Base part with asymmetrical outlet 45°, ND 150 (ND 100)Without sludge trap(Sludge trap made of steel sheet, hot-galvanised, volume 6.4L, available upon request)SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)FLANGE RING2458195-14518560 30-40FRICTION LOCKDRIVING DIRECTION500Ø720Ø500Ø160Ø110HINGE625500Different nozzle lengthsupon requestGully made of cast ironRated width Item no. SW 36ND100BA2500-600-SW36ND150BA2500-650-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2500-600-SW36-VAND150BA2500-650-SW36-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 45- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 83Subject to technical changes - © with Höllko® 43

<strong>BRIDGE</strong> GULLY 2500/7Product description/tender specificationCast-iron bridge gully with flange and flange ring, includingsoaking slots according to specification drawing WAS 1,according to DIN EN 124/1229, grid size 500 x 500mm,designs HÖLLKO 2500/750 (ND 150) and 2500/700 (ND 100)Top part height- and angle-adjustable (4.5°), sliding, and rotary.Grid size 500 x 500mm, test load class D 400Slot width 36mm – intake capacity 1260cm 2Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)Base part with asymmetrical, vertical outlet ND 150 (ND 100)Without sludge trap(Sludge trap made of steel sheet, hot-galvanised, volume 6.4L,available upon request)71710For notes on the installationprocedure, see installationinstructions page 4-8.SECTIONTOP VIEW SW36 (top part, including grid, flange, base part)FLANGE RING95-145707530-40FRICTION LOCK270DRIVING DIRECTION500Ø720Ø160Ø110HINGE156Ø500500Different nozzle lengthsupon requestGully made of cast ironRated width Item no. SW 36ND100BA2500-700-SW36ND150BA2500-750-SW36Base part made of stainless steel (top partmade of cast iron)Rated width Item no. SW 36ND100BA2500-700-SW36-VAND150BA2500-750-SW36-VAOptions- Additional height adjustment options due to intermediate flange Accessories on page 45- Base plates for load transfer for top part adjusted to the correct height Accessories on page 82- Installation support Accessories on page 82- Handle key Accessories on page 8344Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY - OPTIONS - FLANGEProduct description/tender specificationCast-iron intermediate flange for additionalheight adjustment suitable for design HÖLLKO 2500,grid size 500 x 500mmInstallation notes:The intermediate flange replaces thestandard flange.SECTION (FLANGE ONLY)SECTION (INSTALLED CONDITION)A620TOP PARTINTERMEDIATEFLANGE RINGABTOP VIEW (FLANGE ONLY)BASE PARTØ700350270Intermediate flange made of cast ironDesign heights (A) (mm) Adjustment range (B) (mm) Item no.62060 140 - 205 ZWFL2500-06080 160 - 225 ZWFL2500-080120 200 - 265 ZWFL2500-120160 240 - 305 ZWFL2500-160200 280 - 345 ZWFL2500-200Subject to technical changes - © with Höllko® 45

<strong>BRIDGE</strong> GULLY - OPTIONS - FLANGEProduct description/tender specificationCast-iron flange ring suitable for top partsof the 2000 and 2300 series,grid size 300 x 400mm and grid size 300 x 500mm,in combination with base parts of the 2500 seriesInstallation notes:The flange ring in combination with thetop parts of the 2000 (300 x 400mm)and 2300 series (300 x 500mm) isused for base parts set too closely to the *curbof the 2500 series.The flange ring replaces the standard flange.The required top parts of the 2000 and/or 2300series must be ordered separately.SECTION (INSTALLED CONDITION)SECTION (FLANGE ONLY)FLANGE RING100-165*Curb140 30-40834050 20Ø160Ø110Ø500TOP VIEW (FLANGE ON BASE PART)TOP VIEW (FLANGE ONLY)ADJUSTMENT RANGE FLANGE ON BASE PARTR355DRIVING DIRECTION75 170245Ø710Ø720R355Ø310710*Curb395565170Special flange ring made of cast ironDesign heights (mm) Item no.20 FL2500S46Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> <strong>GULLIES</strong> FOR PEDESTRIAN <strong>BRIDGE</strong>S,STEEL AND RAILWAY <strong>BRIDGE</strong>S, AS WELL AS CURB <strong>GULLIES</strong>PEDESTRIAN <strong>BRIDGE</strong>SSTEEL <strong>BRIDGE</strong>SRAILWAY <strong>BRIDGE</strong>SAND CURB <strong>GULLIES</strong>Subject to technical changes - © with Höllko® 47

<strong>BRIDGE</strong> GULLY 320Product description/tender specificationCast-iron bridge gully for pedestrian bridgesand parking buildings,class B 125, according to DIN EN 124/1229,grid size 300 x 300mmdesign HÖLLKO 32071710Base part with lateral and/or vertical outlet ND 100with/without grid screw connectionSlot width 16mm – intake capacity 270cm²Sludge trap made of steel sheet, hot-galvanised, volume 2.5LSECTION (lateral outlet)TOP VIEW (lateral outlet)SCREW CONNECTION DIN 912 M10MATERIAL 1.430120050Ø2602351553°Ø110300300SECTION (vertical outlet)TOP VIEW (vertical outlet)SCREW CONNECTION DIN 912 M10MATERIAL 1.430130050180280Ø110Ø260300Gully for pedestrian bridges / parking buildingsRated width Item no. CommentND100 lateral BA320-100 grid without screw connectionND100 lateral BA320-100-VS grid with screw connectionND100 vertical BA320-200 grid without screw connectionND100 vertical BA320-200-VS grid with screw connectionOptions- Additional height adjustment options due to levelling frame Accessories on page 5148Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 330Product description/tender specificationCast-iron bridge gully for pedestrian bridgesand parking buildings,class B 125, according to DIN EN 124/1229,grid size 300 x 300mmwith connecting flange and soaking slotsdesign HÖLLKO 33071710Base part with lateral and/or vertical outlet ND 100with/without grid screw connectionSlot width 16mm – intake capacity 270cm²Sludge trap made of steel sheet, hot-galvanised, volume 2.5LSECTION (lateral outlet)TOP VIEW (lateral outlet)SCREW CONNECTION DIN 912 M10MATERIAL 1.4301SOAK SLOT150155Ø110SOAK SLOT300400235300400SCREW CONNECTION DIN 912 M10MATERIAL 1.4301SOAK SLOT300400503°Ø260SECTION (vertical outlet)TOP VIEW (vertical outlet)SOAK SLOT50180280Ø110Ø260300400Gully for pedestrian bridges / parking buildingsRated width Item no. CommentND100 lateral BA330-100 grid without screw connectionND100 lateral BA330-100-VS grid with screw connectionND100 vertical BA330-200 grid without screw connectionND100 vertical BA330-200-VS grid with screw connectionOptions- Additional height adjustment options due to levelling frame Accessories on page 51Subject to technical changes - © with Höllko® 49

<strong>BRIDGE</strong> GULLY 340Product description/tender specificationCast-iron bridge gully for pedestrian bridgesand parking buildings,class B 125 according to DIN EN 124/1229, grid size 300 x 300mm,with connecting flange, soaking slots,and flange with screw connectiondesign HÖLLKO 34071710Base part with lateral and/or vertical outlet ND 100with/without grid screw connectionSlot width 16mm – intake capacity 270cm²Sludge trap made of steel sheet, hot-galvanised, volume 2.5LSECTION (lateral outlet)TOP VIEW (lateral outlet)SCREW CONNECTION DIN 912 M10MATERIAL 1.4301SOAK SLOT150235Ø110SOAK SLOT300400300400SCREW CONNECTION DIN 912 M10MATERIAL 1.4301SOAK SLOT30040015550Ø2603°SECTION (vertical outlet)TOP VIEW (vertical outlet)SOAK SLOT50180280300400Gully for pedestrian bridges / parking buildingsRated width Item no. CommentND100 lateral BA340-100 grid without screw connectionND100 lateral BA340-100-VS grid with screw connectionND100 vertical BA340-200 grid without screw connectionND100 vertical BA340-200-VS grid with screw connectionOptions- Additional height adjustment options due to levelling frame Accessories on page 5150Subject to technical changes - © with Höllko®

LEVELLING FRAME 30Product description/tender specificationCast-iron levelling frame 300 x 300mm, H=50mmsuitable for bridge gullies of the 320, 330, and 340 seriesdesign HÖLLKO 30with/without thread for grid screw connectionInstallation notes:The levelling frame is height-combinable withfurther levelling frames at increments of 50mmSECTIONTOP VIEW50Ø206300300Gully for pedestrian bridges / parking levelsDesign heights Item no. Comment50mm AR30 grid without screw connection50mm AR30-VS grid with screw connectionSubject to technical changes - © with Höllko® 51

<strong>BRIDGE</strong> GULLY 347Product description/tender specificationBridge gully for pedestrian steel bridgesclass B 125 according to DIN EN 124/1229, grid size 300 x 300mm,design HÖLLKO 34771710Gully body made of steel S235 JR, hot-galvanisedwith lateral and/or vertical outlet ND 100Grid made of cast ironwith/without grid screw connectionSlot width 16mm – intake capacity 270cm²Sludge trap made of steel sheet, hot-galvanised, volume 2.5LThe following options are available upon request:- Different design heights- Soak holes- Drain nozzles ND 125/ND 150- Drain bodies and sludge traps made of stainless steelSECTION (lateral outlet)TOP VIEW (lateral outlet)SCREW CONNECTION DIN 912 M10MATERIAL 1.4301200501553°206Ø110300300235Different nozzle lengthsupon request300SECTION (vertical outlet)TOP VIEW (vertical outlet)SCREW CONNECTION DIN 912 M10MATERIAL 1.430130028050180Different nozzle lengthsupon requestØ110300300Gully for pedestrian steel bridgesRated width Item no. CommentND100 lateral BA347-100 grid without screw connectionND100 lateral BA347-100-VS grid with screw connectionND100 vertical BA347-200 grid without screw connectionND100 vertical BA347-200-VS grid with screw connection52Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 348Product description/tender specificationBridge gully for steel bridgesclass D 400 according to DIN EN 124/1229, grid size 160 x 500mm,design HÖLLKO 34871710Gully body made of steel S235 JR, hot-galvanisedwith lateral and/or vertical outlet ND 150with/without soak holes ø 30mmGrid made of cast ironSlot width 38mm – intake capacity 265cm²with hinge and friction lock (square, 16mm made of stainless steel)Sludge trap made of steel sheet, hot-galvanised, volume 3.8LThe following designs are available upon request:Installation notes:Install the bridge gully in a way thatthe grid is closed in driving direction.Remove the cover caps from the soak holesof the roadway and the front side.- Different design heights- Drain nozzles ND 100/ND 125- Drain bodies and sludge traps made of stainless steelSECTION (lateral outlet longitudinal side)TOP VIEW (lateral outlet longitudinal side)DRIVING DIRECTION70500193220264272FRICTION LOCK1592506 SOAK HOLES160100HINGEDifferent nozzle lengthsupon request159SECTION (vertical outlet)TOP VIEW (vertical outlet)DRIVING DIRECTION70500220250340FRICTION LOCK1596 SOAK HOLES160HINGEDifferent nozzle lengthsupon requestBridge gully for steel bridgesRated width Item no. CommentND150 BA348-150-LS Lateral outlet (longitudinal side)ND150 BA348-250 Vertical outletSubject to technical changes - © with Höllko® 53

<strong>BRIDGE</strong> GULLY 349Product description/tender specificationBridge gully for steel bridgesclass D 400 according to DIN EN 124/1229, grid size 190 x 500mm,design HÖLLKO 34971710Gully body made of steel S235 JR, hot-galvanisedwith lateral and/or vertical outlet ND 150with/without soak holes ø 30mmGrid made of cast ironSlot width 38mm – intake capacity 370cm²with hinge and friction lock (square, 16mm made of stainless steel)Sludge trap made of steel sheet, hot-galvanised, volume 5LThe following designs are available upon request:- Different design heights- Drain nozzles ND 100/ND 125- Drain bodies and sludge traps made of stainless steelSECTION (lateral outlet longitudinal side)Installation notes:Install the bridge gully in a way thatthe grid is closed in driving direction.Remove the cover caps from the soak holesof the roadway and the front side.TOP VIEW (lateral outlet longitudinal side)DRIVING DIRECTION70500193220264272FRICTION LOCKDifferent nozzle lengthsupon request159250SECTION (lateral outlet front side)6 SOAK HOLES190100HINGE159TOP VIEW (lateral outlet front side)DRIVING DIRECTION26424421529570500FRICTION LOCK159Different nozzle lengthsupon request356SECTION (vertical outlet)1006 SOAK HOLES190DRIVING DIRECTIONHINGETOP VIEW (vertical outlet)70500220250FRICTION LOCK340Different nozzle lengthsupon request54159Gully for steel bridgesRated width Item no. Comment6 SOAK HOLES190ND150 BA349-150-LS Lateral outlet (longitudinal side)ND150 BA349-150-SS Lateral outlet (front side)ND150 BA349-250 Vertical outletHINGESubject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 350Product description/tender specificationBridge gully for steel bridgesclass D 400 according to DIN EN 124/1229, grid size 260 x 500mm,design HÖLLKO 35071710Gully body made of steel S235 JR, hot-galvanisedwith lateral and/or vertical outlet ND 150with/without soak holes ø 30mmGrid made of cast ironSlot width 36mm – intake capacity 520cm² (standard) and/orSlot width 16mm – intake capacity 305cm²with hinge and friction lock (square, 16mm made of stainless steel)Sludge trap made of steel sheet, hot-galvanised, volume 8LThe following designs are available upon request:- Different design heights- Drain nozzles ND 100/ND 125- Drain bodies and sludge traps made of stainless steelSECTION (lateral outlet longitudinal side)70Installation notes:Install the bridge gully in a way thatthe grid is closed in driving direction.Remove the cover caps from the soak holesof the roadway and the front side.TOP VIEW (lateral outlet longitudinal side)DRIVING DIRECTION500FRICTION LOCKWITH GRID SW 36193220264272WITH GRID SW 36Different nozzle lengthsupon request250SECTION (lateral outlet front side)6 SOAK HOLES260100159HINGETOP VIEW (lateral outlet front side)70DRIVING DIRECTIONWITH GRID SW 16243215264295500FRICTION LOCK159WITH GRID SW 36Different nozzle lengthsupon request3561006 SOAK HOLES260HINGESECTION (vertical outlet)TOP VIEW (vertical outlet)DRIVING DIRECTIONWITH GRID SW 3670220250500FRICTION LOCK340WITH GRID SW 36Different nozzle lengthsupon request159Gully for steel bridgesRated width Item no. Item no. CommentND150 BA350-150-LS-SW36 BA350-150-LS-SW16 Lateral outlet (longitudinal side)ND150 BA350-150-SS-SW36 BA350-150-SS-SW16 Lateral outlet (front side)ND150 BA350-250-SW36 BA350-250-SW16 Vertical outlet6 SOAK HOLES260HINGESubject to technical changes - © with Höllko® 55

<strong>BRIDGE</strong> GULLY 400Product description/tender specifi cationBridge gully for steel bridgesclass D 400 according to DIN EN 124/1229, grid size 200 x 600mm,design HÖLLKO 40071710Gully body made of steel S235 JR, hot-galvanisedwith lateral and/or vertical outlet ND 150with/without soak holes ø 30mmGrid made of cast ironSlot width 36mm – intake capacity 480cm²with hinge and friction lock (square, 16 mm made of stainless steel)Sludge trap made of steel sheet, hot-galvanised, volume 6.7LThe following designs are available upon request:- Different design heights- Drain nozzles ND 100/ND 125- Drain bodies and sludge traps made of stainless steelSECTION (lateral outlet longitudinal side)Installation notes:Install the bridge gully in a way thatthe grid is closed in driving direction.Remove the cover caps from the soak holesof the roadway and the front side.TOP VIEW (lateral outlet longitudinal side)DRIVING DIRECTION70600193220261272FRICTION LOCKDifferent nozzle lengthsupon request1592506 SOAK HOLES200100HINGE159SECTION (lateral outlet front side)TOP VIEW (lateral outlet front side)DRIVING DIRECTION26824422430370FRICTION LOCK600159Different nozzle lengthsupon request407SECTION (vertical outlet)1006 SOAK HOLES200TOP VIEW (vertical outlet)HINGEDRIVING DIRECTION22025070340FRICTION LOCK600Different nozzle lengthsupon requestGully for steel bridgesRated width Item no. CommentND150 BA400-150-LS Lateral outlet (longitudinal side)ND150 BA400-150-SS Lateral outlet (front side)ND150 BA400-250 Vertical outlet561593006 SOAK HOLES200HINGESubject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 410Product description/tender specificationBridge gully for steel bridgesclass D 400 according to DIN EN 124/1229, grid size 260 x 800mm,design HÖLLKO 41071710Gully body made of steel S235 JR, hot-galvanisedwith lateral and/or vertical outlet ND 150with/without soak holes ø 30mmGrid made of cast ironSlot width 36mm – intake capacity 915cm²with hinge and friction lock (square, 16 mm made of stainless steel)Sludge trap made of steel sheet, hot-galvanised, volume 13.6LThe following designs are available upon request:- Different design heights- Drain nozzles ND 100/ND 125- Drain bodies and sludge traps made of stainless steelSECTION (lateral outlet longitudinal side)Installation notes:Install the bridge gully in a way thatthe grid is closed in driving direction.Remove the cover caps from the soak holesof the roadway and the front side.TOP VIEW (lateral outlet longitudinal side)DRIVING DIRECTION70FRICTION LOCK80010 SOAK HOLES260100HINGE159DRIVING DIRECTION70FRICTION LOCK800277244242321190220257268Different nozzle lengthsupon request159400SECTION (lateral outlet front side)TOP VIEW (lateral outlet front side)Different nozzle lengthsupon request50710015910 SOAK HOLES260HINGESECTION (vertical outlet)TOP VIEW (vertical outlet)DRIVING DIRECTION70220250FRICTION LOCK800340Different nozzle lengthsupon request159Gully for steel bridgesRated width Item no. Comment40010 SOAK HOLES260ND150 BA410-150-LS Lateral outlet (longitudinal side)ND150 BA410-150-SS Lateral outlet (front side)ND150 BA410-250 Vertical outletHINGESubject to technical changes - © with Höllko® 57

<strong>BRIDGE</strong> GULLY 450Product description/tender specificationCast-iron bridge gully for railway bridges with ballast bed,including ball grid with 6 soak apertures,design HÖLLKO 450Slot width 20mm – intake capacity 300cm²Threaded rod M 20 made of stainless steelNozzle connection ND 200 (and/or ND 150)Height of the drain bodies according to the tableSECTIONTOP VIEWGRIDFLANGE RINGBASE PARTTHREADED ROD M20(MADE OF STAINLESS STEEL)Ø580Ø450100design height H 50 3020SOAK SLOT BETWEENGRID AND FLANGE RINGSOAK SLOT BETWEENFLANGE RING AND SEALØ390Installation notes:Installation instructions for DB bridge gully no. 4501.) Base part (gully body)Position base part (gully body) onto form workThe insulating rim should be 10mm below the upper concrete edge2.) SealApply seal to insulating rim3.) Flange ring (attachment piece)Insert the flange ring4.) GridScrew in the threaded rod M 20 into the internal thread of the basepart (fixed hexagonal nut) and secure it with a lock nut.Position ball grid on threaded rod and tighten it with the inserted nut M 20by rotating the grid so that the seal of the roadway isclamped between flange ring and base part.5.) JointsSeal the joints according to the framework specification DB Netz,Deutsche Bahngruppe, drawing Framework specification M-ENT 1 - 804.9020Gully for ballast bed bridgesConcrete slab thickness Rated width Item no.Design height H (mm)250 ND 150 BA450DN150-H250250 ND 200 BA450DN200-H250300 ND 150 BA450DN150-H300300 ND 200 BA450DN200-H300350 ND 150 BA450DN150-H350350 ND 200 BA450DN200-H350400 ND 150 BA450DN150-H400400 ND 200 BA450DN200-H400Other design heights upon request58Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 1000Product description/tender specificationCast-iron bridge gully with lateral inletfor installation into the curbclass C 250, suitable for curb height 150mmdesign HÖLLKO 100071710with flange and soaking slotsIntake capacity 460cm²Vertical outlet ND 150 – standard length 500mmOther nozzle designs availableSuitable sludge traps and grid covers available upon requestLATERAL VIEW500400115165SECTION55 30 190 55255HINGESCREW CONNECTION M16159TOP VIEW500500330500SOAK SLOTDifferent nozzle lengthsupon request220330FRICTION LOCKGully for curbRated widthND150Item no.BA1000Subject to technical changes - © with Höllko® 59

<strong>BRIDGE</strong> GULLY 1001Product description/tender specificationCast-iron bridge gully with lateral inletfor installation into the curbclass C 250, suitable for curb height 200mmdesign HÖLLKO 100171710with flange and soaking slotsIntake capacity 500 cm²Vertical outlet ND 150 – standard length 500mmOther nozzle designs availableSuitable sludge traps and grid covers available upon requestLATERAL VIEW500400124205SECTION55 30 190 55500 295HINGESCREW CONNECTION M16SOAK SLOT159TOP 500 VIEW500330Different nozzle lengthsupon request220330FRICTION LOCKGully for curbRated widthND150Item no.BA100148 60Subject to technical changes - © with Höllko®

<strong>BRIDGE</strong> GULLY 1002Product description/tender specificationCast-iron bridge gully with lateral inletfor installation into the curbclass C 250, suitable for curb height 250mmdesign HÖLLKO 100271710with flange and soaking slotsIntake capacity 800cm²Vertical outlet ND 150 – standard length 500mmOther nozzle designs availableSuitable sludge traps and grid covers available upon requestLATERAL VIEW500400202256SECTION55 30 190 55345HINGESCREW CONNECTION M16159TOP VIEW500500330500SOAK SLOTDifferent nozzle lengthsupon request220330Gully for curbRated widthND150Item no.BA1002FRICTION LOCKSubject to technical changes - © with Höllko® 49 61

SPACE FOR NOTES62Subject to technical changes - © with Höllko®

TOP PARTS AND<strong>RECONSTRUCTION</strong> <strong>ATTACHMENTS</strong>TOP PARTS AND<strong>RECONSTRUCTION</strong> <strong>ATTACHMENTS</strong>Subject to technical changes - © with Höllko® 63

TOP PART 1020Product description/tender specificationCast-iron top part suitable for installedbase parts according to the former specification drawing WAS 3class D 400 according to DIN EN 124/1229, grid size 300 x 400mm,design HÖLLKO 102071710Top part height- and angle-adjustable by means of base platesSlot width 30mm – intake capacity 530cm² (standard)Slot width 16mm – intake capacity 430cm²Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)suitable sludge traps available upon requestSECTIONTOP VIEW SW30FRICTION LOCK128HINGEDRIVING DIRECTION430330330Top part made of cast ironDesign height (mm) Adjustment range (mm) Item no. SW 30 Item no. SW 1660 60 - 105 (standard) BAOT1020-SW30-H060 BAOT1020-SW16-H060100 100 - 145 BAOT1020-SW30-H100 BAOT1020-SW16-H100120 120 - 165 BAOT1020-SW30-H120 BAOT1020-SW16-H120140 140 - 185 BAOT1020-SW30-H140 BAOT1020-SW16-H140Base plates made of stainless steel A2Design height (mm)Item no.5 ULP5MM-A210 ULP10MM-A264Subject to technical changes - © with Höllko®

TOP PART 1030Product description/tender specificationCast-iron top part suitable for installedbase parts according to the former specification drawing WAS 3(703 series)class D 400 according to DIN EN 124/1229, grid size 300 x 500mm,design HÖLLKO 103071710Top part height- and angle-adjustable by means of base platesSlot width 30mm – intake capacity 700cm² (standard)Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)suitable sludge traps available upon requestSECTIONTOP VIEW SW30FRICTION LOCK330128HINGEDRIVING DIRECTION530330Top part made of cast ironDesign height (mm) Adjustment range (mm) Item no. SW 3060 60 - 105 (standard) BAOT1030-SW30-H060100 100 - 145 BAOT1030-SW30-H100140 140 - 185 BAOT1030-SW30-H140180 180 - 225 BAOT1030-SW30-H180Base plates made of stainless steel A2Design height (mm)Item no.5 ULP5MM-A210 ULP10MM-A2Subject to technical changes - © with Höllko® 65

TOP PART 1040Product description/tender specificationCast-iron top part suitable for installedbase parts according to the former specification drawing WAS 3(503 series)class D 400 according to DIN EN 124/1229, grid size 500 x 500mm,design HÖLLKO 104071710Top part height- and angle-adjustable by means of base platesSlot width 30mm – intake capacity 1300cm² (standard)Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)suitable sludge traps available upon requestSECTIONTOP VIEW SW30FRICTION LOCK502128HINGEDRIVING DIRECTION496502Top part made of cast ironDesign height (mm) Adjustment range (mm) Item no. SW 3065 65 - 105 BAOT1040-SW30Base plates made of stainless steel A2Design height (mm)Item no.5 ULP5MM-A210 ULP10MM-A266Subject to technical changes - © with Höllko®

TOP PART 1050Product description/tender specificationCast-iron top part for bridge reconstructionsuitable for the Streicher systemclass D 400 according to DIN EN 124/1229, grid size 300 x 400mm,design HÖLLKO 105071710Top part height- and angle-adjustable by means of threaded pins M 16Slot width 30mm – intake capacity 480cm²Top part (frame and grid) with dampening insert,with hinge and friction lock (square, 14mm made of stainless steel)suitable sludge traps available upon requestSECTIONTOP VIEW SW30FRICTION LOCK235 x 33555105HINGEDRIVING DIRECTION405510330Top part made of cast ironDesign height (mm) Adjustment range (mm) Item no. SW 3055 55 - 105 BAOT1050-SW30-H05595 95 - 145 BAOT1050-SW30-H095Subject to technical changes - © with Höllko® 67