FICHA TÃCNICA Durastar DS 1010 - Activas

FICHA TÃCNICA Durastar DS 1010 - Activas

FICHA TÃCNICA Durastar DS 1010 - Activas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

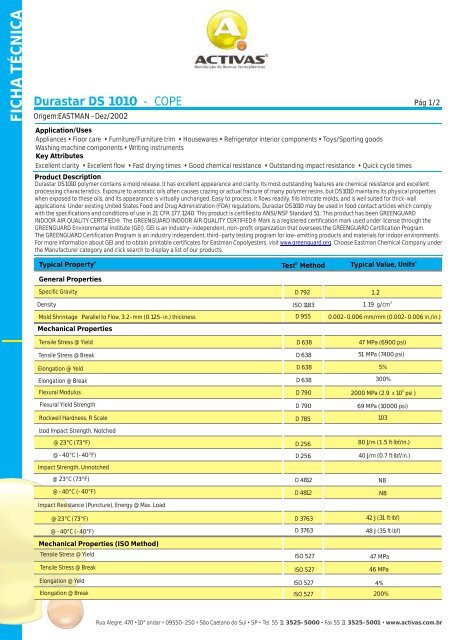

<strong>FICHA</strong> TÉCNICA<strong>Durastar</strong> <strong>DS</strong> <strong>1010</strong> - COPEOrigem:EASTMAN -Dez/2002Pág 1/2Application/UsesAppliances • Floor care • Furniture/Furniture trim • Housewares • Refrigerator interior components • Toys/Sporting goodsWashing machine components • Writing instrumentsKey AttributesExcellent clarity • Excellent flow • Fast drying times • Good chemical resistance • Outstanding impact resistance • Quick cycle timesProduct Description<strong>Durastar</strong> <strong>DS</strong><strong>1010</strong> polymer contains a mold release. It has excellent appearance and clarity. Its most outstanding features are chemical resistance and excellentprocessing characteristics. Exposure to aromatic oils often causes crazing or actual fracture of many polymer resins, but <strong>DS</strong><strong>1010</strong> maintains its physical propertieswhen exposed to these oils, and its appearance is virtually unchanged. Easy to process, it flows readily, fills intricate molds, and is well suited for thick-wallapplications. Under existing United States Food and Drug Administration (FDA) regulations, <strong>Durastar</strong> <strong>DS</strong><strong>1010</strong> may be used in food contact articles which complywith the specifications and conditions of use in 21 CFR 177.1240. This product is certified to ANSI/NSF Standard 51. This product has been GREENGUARDINDOOR AIR QUALITY CERTIFIED®. The GREENGUARD INDOOR AIR QUALITY CERTIFIED® Mark is a registered certification mark used under license through theGREENGUARD Environmental Institute (GEI). GEI is an industry-independent, non-profit organization that oversees the GREENGUARD Certification Program.The GREENGUARD Certification Program is an industry independent, third-party testing program for low-emitting products and materials for indoor environments.For more information about GEI and to obtain printable certificates for Eastman Copolyesters, visit www.greenguard.org. Choose Eastman Chemical Company underthe Manufacturer category and click search to display a list of our products.aTypical PropertybTest MethodcTypical Value, UnitsGeneral PropertiesSpecific GravityDensityMold Shrinkage Parallel to Flow, 3.2-mm (0.125-in.) thicknessMechanical PropertiesTensile Stress @ YieldTensile Stress @ BreakD 792ISO 1183D 955D 638D 6381.231.19 g/cm0.002-0.006 mm/mm (0.002-0.006 in./in.)47 MPa (6900 psi)51 MPa (7400 psi)Elongation @ YeldElongation @ BreakFlexural ModulusFlexural Yield StrengthRockwell Hardness, R ScaleD 638 5%D 638D 790D 790D 785300%52000 MPa (2.9 x 10 psi )69 MPa (10000 psi)103Izod Impact Strength, Notched@ 23°C (73°F)@ -40°C (-40°F)Impact Strength, Unnotched@ 23°C (73°F)@ -40°C (-40°F)Impact Resistance (Puncture), Energy @ Max. LoadD 256D 256D 4812D 481280 J/m (1.5 ft·lbf/in.)40 J/m (0.7 ft·lbf/in.)NBNB@ 23°C (73°F)@ -40°C (-40°F)Mechanical Properties (ISO Method)Tensile Stress @ YieldTensile Stress @ BreakElongation @ YeldElongation @ BreakD 376342 J (31 ft·lbf)D 376348 J (35 ft·lbf)ISO 52747 MPaISO 52746 MPaISO 5274%ISO 527 200%Rua Alegre, 470 •10° andar • 09550-250 • São Caetano do Sul • SP • Tel. 55 11 3525-5000 • Fax 55 11 3525-5001 • www.activas.com.br

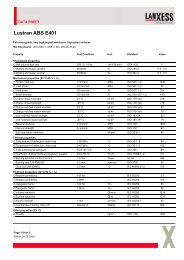

<strong>FICHA</strong> TÉCNICA<strong>Durastar</strong> <strong>DS</strong> <strong>1010</strong> - COPEOrigem:EASTMAN -Dez/2002Pág 2/2Mechanical Properties (ISO Method)Tensile ModulusFlexural ModulusFlexural Yield StrengthIzod Impact Strength, NotchedHazeRegular TransmittanceTotal TransmittanceDrying TemperatureDrying TimeP rocessing Melt TemperatureMold TemperatureComments@ 23°C@ -40°CImpact Resistance (Puncture), Energy @ Max. Load@ 23°C@ -40°CThermal PropertiesDeflection Temperature@ 0.455 MPa (66 psi)@ 1.82 MPa (264 psi)UL Flammability Classificationd3.0 mm specimenThermal Properties (ISO Method)Deflection Temperature@ 0.455 MPa (66 psi)@ 1.82 MPa (264 psi)Optical PropertiesTypical Processing Conditionsa Unless noted otherwise, all tests are run at 23°C (73°F) and 50% relative humidity.b Unless noted otherwise, the test method is ASTM.c Units are in SI or US customary units.d For color ATISO 527ISO 178ISO 178ISO 180ISO 180ISO 6603-2ISO 6603-2D 648D 648UL 94ISO 75ISO 75D 1003D 1003D 10031800 MPa1850 MPa65 MPa27.8 kJ/m24.8 kJ/m58.7 J52.6 J75°C (167°F)65°C (149°F)94V-272°C66°C0.3%89%91%71°C (160°F)3-4 hrs232-277°C (450-530°F)16-38°C (60-100°F)Properties reported here are typical of average lots. Eastman makes no representation that the material in any particular shipment will conform exactly to the values given.Eastman and its marketing affiliates shall not be responsible for the use of this information, or of any product, method, or apparatus mentioned, and you must make your own determination of its suitabilityand completeness for your own use, for the protection of the environment, and for the health and safety of your employees and purchasers of your products. No warranty is made of the merchantability offitness of any product, and nothing herein waives any of the Seller's conditions of sale.Esta ficha é cópia da ficha do fabricante, fornecida de boa fé pela <strong>Activas</strong>, somente como informação. A mesma está sujeita a alterações pelo fabricante sem prévio aviso.Na aquisição do produto, acompanha o laudo/lote atualizado. www.activas.com.brEmissão: Fevereiro/2010Rua Alegre, 470 •10° andar • 09550-250 • São Caetano do Sul • SP • Tel. 55 11 3525-5000 • Fax 55 11 3525-5001 • www.activas.com.br