Prevention of fresh meat colour defects - Red Meat Innovation

Prevention of fresh meat colour defects - Red Meat Innovation

Prevention of fresh meat colour defects - Red Meat Innovation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

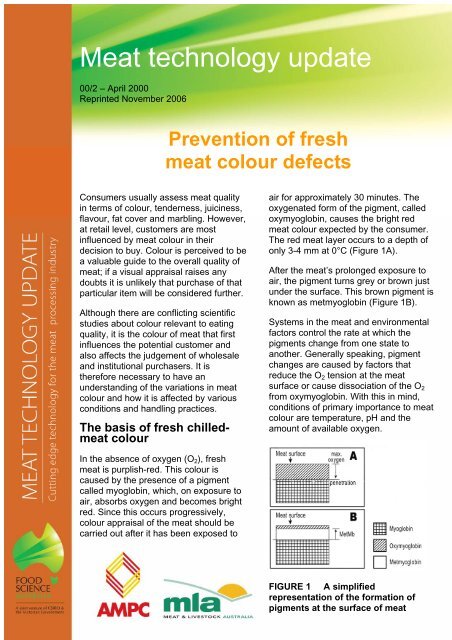

<strong>Meat</strong> technology update00/2 – April 2000Reprinted November 2006<strong>Prevention</strong> <strong>of</strong> <strong>fresh</strong><strong>meat</strong> <strong>colour</strong> <strong>defects</strong>Consumers usually assess <strong>meat</strong> qualityin terms <strong>of</strong> <strong>colour</strong>, tenderness, juiciness,flavour, fat cover and marbling. However,at retail level, customers are mostinfluenced by <strong>meat</strong> <strong>colour</strong> in theirdecision to buy. Colour is perceived to bea valuable guide to the overall quality <strong>of</strong><strong>meat</strong>; if a visual appraisal raises anydoubts it is unlikely that purchase <strong>of</strong> thatparticular item will be considered further.Although there are conflicting scientificstudies about <strong>colour</strong> relevant to eatingquality, it is the <strong>colour</strong> <strong>of</strong> <strong>meat</strong> that firstinfluences the potential customer andalso affects the judgement <strong>of</strong> wholesaleand institutional purchasers. It istherefore necessary to have anunderstanding <strong>of</strong> the variations in <strong>meat</strong><strong>colour</strong> and how it is affected by variousconditions and handling practices.The basis <strong>of</strong> <strong>fresh</strong> chilled<strong>meat</strong><strong>colour</strong>air for approximately 30 minutes. Theoxygenated form <strong>of</strong> the pigment, calledoxymyoglobin, causes the bright red<strong>meat</strong> <strong>colour</strong> expected by the consumer.The red <strong>meat</strong> layer occurs to a depth <strong>of</strong>only 3-4 mm at 0°C (Figure 1A).After the <strong>meat</strong>’s prolonged exposure toair, the pigment turns grey or brown justunder the surface. This brown pigment isknown as metmyoglobin (Figure 1B).Systems in the <strong>meat</strong> and environmentalfactors control the rate at which thepigments change from one state toanother. Generally speaking, pigmentchanges are caused by factors thatreduce the O 2 tension at the <strong>meat</strong>surface or cause dissociation <strong>of</strong> the O 2from oxymyoglobin. With this in mind,conditions <strong>of</strong> primary importance to <strong>meat</strong><strong>colour</strong> are temperature, pH and theamount <strong>of</strong> available oxygen.In the absence <strong>of</strong> oxygen (O 2 ), <strong>fresh</strong><strong>meat</strong> is purplish-red. This <strong>colour</strong> iscaused by the presence <strong>of</strong> a pigmentcalled myoglobin, which, on exposure toair, absorbs oxygen and becomes brightred. Since this occurs progressively,<strong>colour</strong> appraisal <strong>of</strong> the <strong>meat</strong> should becarried out after it has been exposed toFIGURE 1 A simplifiedrepresentation <strong>of</strong> the formation <strong>of</strong>pigments at the surface <strong>of</strong> <strong>meat</strong>

attained; therefore, it is incorrectly assessedas dark cutting. Effective electricalstimulation will overcome this effect byaccelerating the rate <strong>of</strong> pH decline.Normal <strong>colour</strong> <strong>of</strong> vacuumpackagedand 100% CO 2flushed chilled <strong>meat</strong>The removal <strong>of</strong> oxygen during vacuumpacking leads to changes in the <strong>colour</strong> <strong>of</strong><strong>meat</strong>. Inside a vacuum package, residualoxygen is consumed and carbon dioxide(CO 2 ) is produced as a result <strong>of</strong> metabolismby the muscle tissue. The resultantatmosphere contains less than 0.5 per centoxygen, some 20-40 per cent CO 2 withnitrogen making up the remainder.The bright red (oxymyoglobin) <strong>colour</strong> <strong>of</strong> <strong>fresh</strong><strong>meat</strong> disappears in the vacuum pack and inthe CO 2 flushed pack as the pigment revertsto its purplish-red form. This is the normaland desirable <strong>colour</strong> <strong>of</strong> vacuum-packed<strong>meat</strong>. Within a short time <strong>of</strong> the pack beingopened the surface purple myoglobinchanges to bright red oxymyoglobin and the<strong>meat</strong> blooms to a bright red <strong>colour</strong>. Therelationship between pigments is shown inpunctures, or poor air evacuation at the time<strong>of</strong> packing and sealing, the <strong>meat</strong> will turnbrown during storage.The oxygen permeability <strong>of</strong> the films used forvacuum packing is also very important and isa matter to which the packer should payclose attention. To prevent oxygen fromgaining access to the <strong>meat</strong> surface, care isneeded to ensure that the appropriatedegree <strong>of</strong> impermeability is chosen. If thepermeability is a little too high, or if there arepinholes or poor seals, a small amount <strong>of</strong>oxygen will gain access to the <strong>meat</strong> surfaceand its concentration could very easily reachthe critical (low) level at which metmyoglobinformation is most rapid.It is difficult to evacuate all the air from avacuum pack but residual oxygen should beused up by respiration <strong>of</strong> the <strong>meat</strong> andmicrobial activity. The speed at which thisresidual oxygen is used up is dependent onthe age <strong>of</strong> the <strong>meat</strong> when packed. If the<strong>meat</strong> is not <strong>fresh</strong> (i.e. is older than 48 hourspost-slaughter) at the time <strong>of</strong> packing,insufficient <strong>meat</strong> respiration to consume theresidual oxygen can cause a problem.In addition, if there is residual oxygen in thepack due to any <strong>of</strong> these factors, thebrowning problem will be exacerbated byhigh temperatures.Figure 2.FIGURE 2 Some <strong>colour</strong> relationshipsfound in <strong>fresh</strong> and vacuum-packaged<strong>meat</strong>sBrowningBrowning <strong>of</strong> <strong>meat</strong> stored in a vacuumpackage indicates that there is too muchoxygen in the pack. This occurs fastest atmoderate (1%) level. If there are poor seals,Colour problems with beef stored in highconcentrations <strong>of</strong> carbon dioxide will notoccur provided oxygen is excluded from thepack. If only 0.5-1 per cent <strong>of</strong> oxygen ispresent, the rate <strong>of</strong> formation <strong>of</strong>metmyoglobin is higher than in air, andbrowning occurs more rapidly. In addition todis<strong>colour</strong>ation <strong>of</strong> the lean surface, problemswith the appearance <strong>of</strong> fat surfaces mayoccur (brown-grey dis<strong>colour</strong>ation). Withlamb, a brownish dis<strong>colour</strong>ation <strong>of</strong> the fellsurfaces may develop after several weeksstorage at 0°C if there is too much oxygenpresent and, if this occurs, the appearance isinferior to that <strong>of</strong> <strong>fresh</strong> primals.From a <strong>colour</strong> point <strong>of</strong> view the aim <strong>of</strong>vacuum or gas packing is to prevent theproduction <strong>of</strong> undesirable brownmetmyoglobin by reducing the concentration4

<strong>of</strong> oxygen in the pack to below 0.2%. Toachieve this, the <strong>meat</strong> should be packed andsealed as quickly as possible after boning orcutting the carcase, provided that thecarcase deep muscle temperature isadequately reduced.This type <strong>of</strong> browning should not beconfused with cooked <strong>meat</strong> browning (greybrown),which can be caused by excessiveheat during shrinkage <strong>of</strong> the packaging film.Retail storage <strong>of</strong> chilled <strong>meat</strong> inair or in air-permeable filmBecause the bright red <strong>colour</strong> is enhancedby high concentrations <strong>of</strong> oxygen, mostdisplayed <strong>meat</strong> is either open to air or sealedin an oxygen-permeable wrap. The wrapallows passage <strong>of</strong> oxygen but preventsundesirable drying <strong>of</strong> the <strong>meat</strong> surface.<strong>Meat</strong> displayed in this fashion usuallybecomes dis<strong>colour</strong>ed owing to thedevelopment <strong>of</strong> brown <strong>colour</strong> (metmyoglobin)before bacteria have grown sufficiently tocause spoilage. Incorrect storage or handlingat any stage <strong>of</strong> the chain will reduce retailstorage life.The principal factor affecting the shelf life <strong>of</strong>wrapped <strong>meat</strong> on display is its temperature.This is mainly because the oxidation <strong>of</strong>myoglobin to metmyoglobin is extremelytemperature dependent. However, it is alsopartly because higher temperatures increasebacterial growth on the <strong>meat</strong>, and the resultis that bacterial metabolites contribute to theincreased oxidation rate.In order to obtain the longest possible shelflife for <strong>meat</strong> on display, the storagetemperature should be as close to 0°C aspossible. This will keep microbial growth to aminimum and prolong the retention <strong>of</strong> theattractive red <strong>meat</strong> <strong>colour</strong>. As it is impossibleto maintain a steady 0°C in open <strong>meat</strong>display cabinets, a realistic optimumtemperature range is 0-5°C.<strong>Meat</strong> should be cooled to below 5°C beforecutting and it should be cut immediately priorto display.Storage after ageingAfter three weeks ageing, aged <strong>meat</strong>exposed to air dis<strong>colour</strong>s in the retailsituation faster than <strong>fresh</strong> <strong>meat</strong> because <strong>of</strong> adiminished ability <strong>of</strong> any brown <strong>colour</strong> thathas formed to revert to the desired red<strong>colour</strong>. The longer <strong>meat</strong> is aged, the faster itwill dis<strong>colour</strong> after opening to air because theenzyme system becomes less effective withageing.Table 1 indicates the relative retail displaylife <strong>of</strong> consumer cuts <strong>of</strong> beef (stored at about5°C) in conventionally overwrapped andoxygen-enriched modified-atmosphere packs(as a function <strong>of</strong> the <strong>meat</strong> storage time in thevacuum pack at 0°C). The longer the period<strong>of</strong> storage in the vacuum pack the shorterthe display life <strong>of</strong> the consumer portions,because <strong>of</strong> the more rapid conversion <strong>of</strong>oxymyoglobin to the brown metmyoglobin.TABLE 1 The relative retail display life<strong>of</strong> consumer cuts <strong>of</strong> beef as a function<strong>of</strong>the time the <strong>meat</strong> was stored vacuumpackagedStorage time in thevacuum pack(weeks at 0°C)Retail display life(days)*Overwraped traysBeef and lamb stored in high levels <strong>of</strong> CO 2appear to retain their retail display life betterthan vacuum-packed lamb. Retail shelf life <strong>of</strong>product prepared from lamb primals orcarcases stored in a CO 2 atmosphere shouldbe three days after 12 weeks chilled storage.Summary0 2 4 6 83 3 2 2 1The delay <strong>of</strong> adverse <strong>colour</strong> changesinvolves efficient refrigeration during chilling,holding, transportation, storage, preparationand display; and proper hygiene, packagingand selection <strong>of</strong> <strong>meat</strong>. Attention to the aboveis necessary, but in particular, if <strong>fresh</strong> <strong>meat</strong> isto be maintained in good condition withminimum <strong>colour</strong> deterioration for anadequate commercial display period, the5

temperature <strong>of</strong> the <strong>meat</strong> must be keptclose to 0°C.Further Reading<strong>Meat</strong> Technology Update Newsletter99/6 ‘ Pre-slaughter aspects <strong>of</strong> beefeating quality’<strong>Meat</strong> Technology Update Newsletter99/4 ‘Post-slaughter aspects <strong>of</strong> beefeating quality’<strong>Meat</strong> Technology Update No. 97/3(AMT) ‘Lighting in <strong>Meat</strong> ProcessingAreas’CSIRO <strong>Meat</strong> Research Newsletter 93/5‘Displaying <strong>Meat</strong> for Maximum Return’Contact us for additional information<strong>Meat</strong> Industry Services is supported by the Australian <strong>Meat</strong> Processor Corporation (AMPC) and <strong>Meat</strong> & Livestock Australia (MLA).Brisbane: Sydney: Adelaide:Food Science Australia Bill Spooncer Chris SentancePO Box 3312 PO Box 181 PO Box 178Tingalpa DC QLD 4173 KURMOND NSW 2757 FLAGSTAFF HILL SA 5159Ian Eustace Neil McPhail Alison SmallT +61 7 3214 2117 T +61 7 3214 211 T +61 7 3214 2109 T +61 2 4567 7952 T +61 8 370 7466F +61 7 3214 2103 F +61 7 3214 2103 F +61 7 3214 2103 F +61 2 4567 8952 F +61 8 8370 7566M 0414 336 724 M 0414 336 907 M 0409 819 998 M 0414 648 387 M 0419 944 022