Nanalloy 395 N.indd - Castolin Eutectic

Nanalloy 395 N.indd - Castolin Eutectic

Nanalloy 395 N.indd - Castolin Eutectic

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

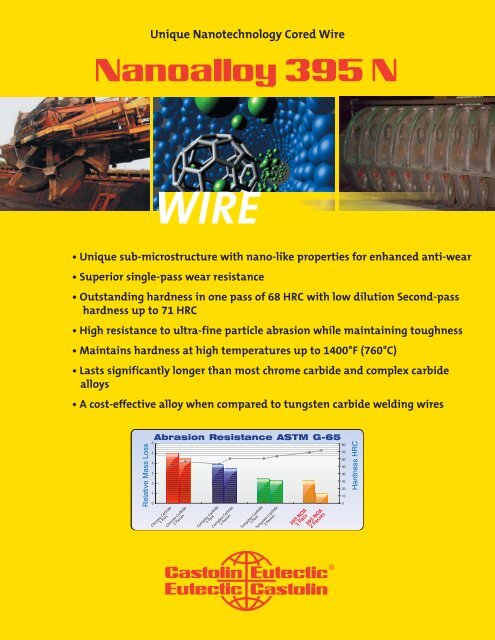

Unique Nanotechnology Cored WireNanoalloy <strong>395</strong> NWIRE• Unique sub-microstructure with nano-like properties for enhanced anti-wear• Superior single-pass wear resistance• Outstanding hardness in one pass of 68 HRC with low dilution Second-passhardness up to 71 HRC• High resistance to ultra-fine particle abrasion while maintaining toughness• Maintains hardness at high temperatures up to 1400°F (760°C)• Lasts significantly longer than most chrome carbide and complex carbidealloys• A cost-effective alloy when compared to tungsten carbide welding wiresRelative Mass LossAbrasion Resistance ASTM G-65Hardness HRC

DESCRIPTION:Nanoalloy <strong>395</strong> N is the newest development in cored wiretechnology. A new generation of wearfacing products basedon the science and engineering of ultra-fine, submicrongrain structures. Weld deposits have a high volume fractionof ultra-hard borocarbides distributed in a mesomorphous*iron-alloy matrix. A transformation phase relating to, orexisting in, a state of matter typically intermediate betweena liquid and a crystal phase i.e. not fully crystalline orfully amorphous.Nanoalloy <strong>395</strong> N weld deposits present a crystalline microstructurewith nano-size crystals and high hardness carbidesevenly spread throughout the matrix.The most important characteristic of <strong>395</strong> N is that it provideshigh hardness within a ductile matrix resistant tomoderate impact.TECHNICAL DATA:Operating Conditions:Current Type: ..............................................DCEP (+)Voltage: .........................................................25-34Amperage: ...................................................170-300Wire Stick-Out (MIG): ..............................1/2” - 3/4”Wire Stick-Out (Open Arc): ...................1” - 1 1/4”Typical Mechanical Values:Typical Hardness 1st Pass: ....................68-70 HRCTypical Hardness 2nd Pass: ...................69-71 HRCTemperature Limit ...................................1,400°F (760°C)Carbide Type: Complex borocarbide matrix of sub-micron,near-nano scale microstructureParameters:Position: Pull TechniqueShielding Gasses:a. Recommended gas mixture: 98% Ar + 2% O2b. Alternative gas mixture: 75%Ar + 25% CO290%Ar + 10%CO2Flow Rates: 30-35 SCFH (15-17 L/min.)Typical Coverage: 5.5lbs will cover 1 sq.ft. x 1/8” thickNote 1 - MIG or Open Arc: Nanoalloy <strong>395</strong> N wire works very well with or without shieldinggas. When using extended welding parameters the shielding gas helps reduceheat build up in the welding gun assembly.Availability:Package: 33 lb coils (15 kg)Wire Diameter: 0.045“ (1.2mm), 1/16“ (1.6mm)PROCEDURE AND TECHNIQUE:Power-Source Type: Nanoalloy <strong>395</strong> N is compatible withmost conventional constant voltage/constant potential(CC/CV) power sources, including programmable & pulsedarcunits. Note: Integrated wire feeders should be set upwith a 4-roll, knurled-drive wire system, and the gun cableliner, with either a Teflon® or polyamide liner to reduce wiredrag.Base Metal Preparation: Parts to be welded should be freeof oil or grease. For optimum results a light grind to removescale or other surface contamination, is advised. Alsoeliminate any previous weld metal and fatigued metal bymechanical means. Base material such as carbon steels,alloy steels, cast iron, and stainless steels can be weldedwith this product.Preheating Guide: The carbon and alloy content of thepart to be welded normally dictates preheating levels.The ease at which a part air-hardens (air-hardenability) isanother critical point along with considerations of workpiece size, thickness, and shape. Preheating according tocarbon contents of metal and thickness and configurationof the part to be welded. For a total carbon equivalent werecommend:• Up to 0.25%C: It is not necessary to preheat• From 0.25% to 0.45%C: Preheat to 200° - 400°F (100° - 200°C)• From 0.45% to 0.8%C: Preheat to 400° - 660°F (200° - 350°C)Buffer Layer Guide: To minimize any microfissuring tendencies,the use of an underlay is often a practical advantage.When welding manganese steel castings, or steelswith a high hardenability, TeroMatec 688OA or 690OA offeran ideal cushion layer to further optimize the wear resistanceof <strong>395</strong> N.Welding Technique: As indicated in the parameters, thereare certain advantages in using either a “push” or “pull”method during welding. For most downhand welding thepull method is suggested with the wire positioned at a 70°-80° angle. This will provide a clean, virtually spatter-free,high-crowned weld deposit. <strong>395</strong> N can be utilized as anopen arc wire requiring no shielding gas.Note - If a second pass is required it should follow while the weld metal is still hot.TYPICAL APPLICATIONS:• Bucket teeth • Extruders • Fans• Mixers • Bark crushers • Hammers• Scrapers • Knives • Central blades• Sinter crushers • Milling rolls• Milling liners • Conveyor screws• Coal crushers • Pipes and elbowsYOUR RESOURCE FOR PROTECTION, REPAIR AND JOINING SOLUTIONS<strong>Eutectic</strong> CorporationN94 W14355 Garwin Mace DriveMenomonee Falls, WI 53051 USAP 800-558-8524 • F 262-255-5542www.eutecticusa.com<strong>Eutectic</strong> Canada428, rue Aime VincentVaudreuil-Dorion, Quebec J7V 5V5Phone: (800) 361-9439Fax: (514) 695-8793www.eutectic-na.com<strong>Eutectic</strong> MexicoKM 36.5 AutopistaMexico-Quertaro54730 Cautitlan-IzcalliEstado de Mexico, MexicoPhone: 011 (52) 55-5872-1111e-mail: eutectic.mexico@eutectic.com.mxStatement of Liability: Due to variations inherent in specifi c applications, the technical information contained herein, including any information as to suggested product applications orresults, is presented without representation or warranty, expressed or implied. Without limitation, there are no warranties of merchantability or of fi tness for a particular purpose. Eachprocess and application must be fully evaluated by the user in all respects, including suitability, compliance with applicable law and non-infringement of the rights of others, and <strong>Eutectic</strong>Corporation and its affiliates shall have no liability in respect thereof.<strong>395</strong>N 08-17-10 © 2008, <strong>Eutectic</strong> Corporation, ® Reg. T.M., Printed in the U.S.A.