Safety Lines - Minnesota Department of Labor and Industry

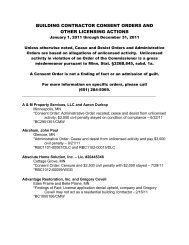

Safety Lines - Minnesota Department of Labor and Industry

Safety Lines - Minnesota Department of Labor and Industry

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The newsletter <strong>of</strong> <strong>Minnesota</strong> OSHA • October 2008 • Number 61<strong>Safety</strong> <strong>Lines</strong>Prepare now for familiar hazard: winter drivingBy Diane Amell, MNOSHA Training OfficerWith the first snowstorm each year, the local radio<strong>and</strong> TV reporters echo the well-known refrain:<strong>Minnesota</strong>ns seem to have forgotten how to drive inwinter conditions. This takes on additional meaningfor employers, because the number one cause <strong>of</strong>worker fatalities in <strong>Minnesota</strong> – <strong>and</strong> the rest <strong>of</strong> thecountry – continues to be traffic accidents.Federal OSHA <strong>and</strong> the National HighwayTransportation <strong>Safety</strong> Administration list three "Ps" <strong>of</strong> safe winter driving: prepare for the trip, protectyourself <strong>and</strong> prevent crashes on the road. To achieve these objectives, they <strong>of</strong>fer the following tips.Prepare• Maintain your car: check the battery, tire tread, antifreeze <strong>and</strong> windshield wipers; keep yourwindows clear; <strong>and</strong> put no-freeze fluid in the washer reservoir.• Pack your supplies: a flashlight, jumper cables, abrasive material (such as s<strong>and</strong>, kitty litter or evenspare floor mats), a shovel, a snow brush <strong>and</strong> ice scraper, warning devices (such as flares) <strong>and</strong>blankets. For long trips, add food, water, medication <strong>and</strong> a fully charged cell phone to your list.• If you're stopped, stuck or stalled: stay withyour car; don’t overexert yourself; put brightmarkers on the antenna or windows; shine thedome light; <strong>and</strong>, if you run your car, clear theexhaust pipe <strong>and</strong> run your car just enough tostay warm.• Plan your route: allow plenty <strong>of</strong> time (check theweather <strong>and</strong> leave early if necessary); befamiliar with the maps <strong>and</strong> directions; <strong>and</strong> letothers know your route <strong>and</strong> arrival time.• Practice <strong>and</strong> review cold weather driving skills:during daylight, maneuver slowly on ice or snow in an empty lot; steer into a skid; know whatyour brakes will do – stomp <strong>and</strong> hold down antilock brakes <strong>and</strong> pump non-antilock brakes;remember stopping distances are longer on water or ice; <strong>and</strong> remember not to idle for a long timewith the windows up or in an enclosed space.Familiar hazard, continues ...443 Lafayette Road N. • St. Paul, MN 55155 • (651) 284-5050 • 1-800-342-5354 • www.doli.state.mn.us/mnosha.html

Familiar hazard, continued ...Protect yourselfBuckle up. According to the <strong>Minnesota</strong> <strong>Department</strong> <strong>of</strong>Public <strong>Safety</strong>'s <strong>Minnesota</strong> Driver's Manual, <strong>of</strong> all thesafety equipment in your vehicle, the seat belt is mostlikely to save your life. In <strong>Minnesota</strong>, motor vehiclesmust be equipped with seat belts <strong>and</strong> the use <strong>of</strong> seatbelts is m<strong>and</strong>atory. Without a seat belt, your chances<strong>of</strong> being killed or injured in a crash are four timesgreater. It is possible to be killed in a crash whentraveling at speeds as low as 12 m.p.h.Prevent crashes• Monitor yourself: slow down <strong>and</strong> increase your following distance between the car ahead <strong>of</strong> you.• Expect the unexpected: keep your eyes open for pedestrians walking in the road.• Avoid fatigue: get plenty <strong>of</strong> rest before long trips; stop at least every three hours; <strong>and</strong> rotatedrivers if possible.Get more informationFor more tips about driving in the winter, visitwww.osha.gov/Publications/safeDriving.html. Otherwinter-related safety information from federal OSHAincludes:• Winter storms (an emergency preparedness <strong>and</strong>response safety <strong>and</strong> health guide):www.osha.gov/SLTC/emergencypreparedness/guides/winterstorms.html;• Cold stress (an emergency preparedness <strong>and</strong>response safety <strong>and</strong> health guide):www.osha.gov/SLTC/emergencypreparedness/guides/cold.html;• Fact Sheet No. OSHA 98-55 ProtectingWorkers in Cold Environments:www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=fact_sheets&p_id=186;<strong>and</strong>• Cold Stress QuickCard:www.osha.gov/Publications/osha3156.pdf– Also available in Spanish –www.osha.gov/Publications/osha3158.pdf.<strong>Safety</strong> <strong>Lines</strong>, October 2008 page 2 www.doli.state.mn.us/mnosha.html

MNOSHA st<strong>and</strong>ards update, continues ...Other revisions proposedProposed addition <strong>of</strong> Minn. Rules 5205.0720, Thermoplastic piping (PVC Pipe) – This new rule wasdeveloped to protect employees from possible hazards when PVC piping is used to transportcompressed air.Proposed addition <strong>of</strong> <strong>Minnesota</strong> Rules 5205.1310 <strong>and</strong> 5207.1100, Elevating Work PlatformEquipment – These rules were developed to prevent potential injury by requiring fall protection toemployees while occupying a boom-supported elevating work platform or a personnel elevatingplatform supported by a rough terrain forklift truck.Status <strong>of</strong> changesThe proposed revisions were published in the State Register Sept. 2, followed by a 30-day commentperiod that ended Oct. 2. No comments were received. A notice adopting these amendments will bepublished in the State Register. Both the proposal notice <strong>and</strong> adoption notice (when available) can beaccessed at www.comm.media.state.mn.us/bookstore/state_register.asp.Copies <strong>of</strong> the proposal notice were sent to those on the <strong>Minnesota</strong> OSHA st<strong>and</strong>ards mailing list. To beadded to the mailing list for notification <strong>of</strong> future MNOSHA st<strong>and</strong>ard activity or other <strong>Department</strong> <strong>of</strong><strong>Labor</strong> <strong>and</strong> <strong>Industry</strong> rulemaking, visit www.doli.state.mn.us/docs/rules_reqnotices.doc.Saving lives without breaking the bankEditor's note: The following is an e-mail message, reprinted with the author's permission.This morning at 6:32 a.m., while walking downward on a 4/12 sheathed ro<strong>of</strong>, one <strong>of</strong> our workers stumbled <strong>and</strong> fellface fi rst toward the outside edge <strong>of</strong> the single-story ro<strong>of</strong> he was working on. From the momentum <strong>of</strong> his fall, helurched over the two-by-six guard at the edge <strong>of</strong> the ro<strong>of</strong> <strong>and</strong> continued over the edge.He was wearing a properly fi tting full-body harness connected to a DBI/SALA Ultra Lok SRL, which in turn wasconnected to a Super Anchor ARS 5K Surface Mounted/Fall Arrest Anchor. The SRL engaged causing him to bepulled backwards into an upright posture as he went over the edge <strong>of</strong> the ro<strong>of</strong>. The SRL cable impacted with thefascia <strong>and</strong> then the worker slid approximately four feet where he stopped over a window opening. At no time did theworker contact the ground!The worker was immediately rescued by his fellow coworkers <strong>and</strong> evaluated for injuries. The worker stated hethinks he may have hit the side <strong>of</strong> the sill with his ankle, because it ached a little. He said the pain was very mild<strong>and</strong> he could walk just fi ne. He said he felt no other injuries. The momentum, combined with the direction <strong>and</strong>angle the worker was falling, would likely have resulted in a serious or deadly accident had he not been usingConventional Fall Protection. He would have fallen head fi rst to the ground or he would have gone face fi rst into theblock wall only seven feet away from the ro<strong>of</strong> edge.The worker was issued a new harness <strong>and</strong> immediately returned to work. All equipment has been removed fromservice pending evaluation by a qualifi ed person.This is the third successful Conventional Fall Protection Systems outcome for LeBlanc Building Co., Inc.since implementation. We greatly appreciate the many trade partners who support us <strong>and</strong> our safety programunconditionally.From the author's second e-mail messageThe anchor point that his PFAS was connected to cost only $3.40; yes, that's right – less than $4.– Jeremy Bethancourt, <strong>Safety</strong> Director/Trainer, LeBlanc Building Co., Inc., Scottsdale, Ariz.<strong>Safety</strong> <strong>Lines</strong>, October 2008 page 4 www.doli.state.mn.us/mnosha.html

QAQAoshafrequently asked questionsanswersAs part <strong>of</strong> its continual effort to improve customer service <strong>and</strong> provide needed information to employers <strong>and</strong> employees,<strong>Minnesota</strong> OSHA (MNOSHA) answers the most frequently asked questions from the previous quarter.The proposed <strong>Minnesota</strong> Rules 5205.1310 <strong>and</strong> 5207.1100, Elevating Work PlatformEquipment, states that individuals st<strong>and</strong>ing on the specified elevating work platformsshall be protected from falling by the use <strong>of</strong> personal fall-arrest systems or positioningdevice systems (see MNOSHA st<strong>and</strong>ards update, page 3). Exactly how many fall-arrestsystems or positioning device systems are required to be used by each exposedemployee?In addition to any guardrails or sides the platform may have, an employee must wear either apersonal fall-arrest system (i.e., a body harness <strong>and</strong> lanyard or lifeline) that limits their freefall to no more than six feet, or a positioning device system, such as a body belt <strong>and</strong> lifeline,that limits their free fall to no more than two feet. The use <strong>of</strong> redundant systems is notrequired. See 1926.502(d) <strong>and</strong> (e) for further information about the other requirements forthese systems.It was so hot last night at work that I told my boss I was going to leave work for mypersonal safety. She said that if I did I was not to come back tomorrow, because Iwouldn't have a job. I thought that we could refuse to work if we felt it was unsafe.What does the law say?<strong>Minnesota</strong> Statutes §182.653, subd. 11, "Refusal to work under dangerous conditions," statesan employee can refuse to work only if they have "a reasonable belief" that conditions existthat "present an imminent danger <strong>of</strong> death or serious physical harm to the employee." Animminent danger is one in which a hazard could result in death or serious injury immediatelyor within a very short time. While heat-related illnesses can be serious, they do not rise to thelevel <strong>of</strong> an imminent danger. In addition, an employer may take corrective action to lessenthe risk to the employee, such as granting more frequent breaks, increasing the availability <strong>of</strong>drinking water, etc.QAIf the employee refuses to work <strong>and</strong> the employer <strong>of</strong>fers any alternative job, the employeemust perform the alternative job assignment.Last year, the principal stated an asbestos removal project was to be completed duringthe summer. When my kids went back to school, we found the building still torn apart. Idon't want my kids exposed to asbestos. What do I do?First, talk to the principal. It may be that the asbestos abatement is complete, but the finishingwork is not. The principal should be able to direct you to the person with the project<strong>Safety</strong> <strong>Lines</strong>, October 2008 page 5 www.doli.state.mn.us/mnosha.html

management plan. Under the federal Asbestos Hazard Emergency Response Act (AHERA),every school district <strong>and</strong> private school is required to designate someone to oversee allasbestos-related activities in the district or school. This person should be able to answerquestions regarding the project as well.The <strong>Minnesota</strong> <strong>Department</strong> <strong>of</strong> Health (MDH) Asbestos Abatement Unit can be a source <strong>of</strong>information about a specific project. It can provide a parent with the identity <strong>of</strong> the licensedabatement contractor, the contractor's compliance record, the project permit number <strong>and</strong>other information, such as the project dates <strong>and</strong> the contractor's work shifts. The unit will alsobe able to tell the parent whether MDH has conducted an inspection <strong>of</strong> the project. Contactthe Asbestos Abatement Unit at (651) 201-4620 <strong>and</strong> ask to speak with the asbestos inspectoron duty. The MDH Web site also has a wealth <strong>of</strong> general information about this subject –www.health.state.mn.us/divs/eh/asbestos.Ask MNOSHADo you have a question for <strong>Minnesota</strong> OSHA? To get an answer, call (651) 284-5050 or sendan e-mail message to osha.compliance@state.mn.us. We may feature your question here.Injury <strong>and</strong> illness survey gearing up for new yearBy Brian Zaidman, Policy Development, Research <strong>and</strong> StatisticsAs 2008 draws to a close, the <strong>Minnesota</strong> <strong>Department</strong> <strong>of</strong> <strong>Labor</strong> <strong>and</strong><strong>Industry</strong> (DLI) will start work on the next round <strong>of</strong> the Bureau <strong>of</strong> <strong>Labor</strong>Statistics annual Survey <strong>of</strong> Occupational Injuries <strong>and</strong> Illnesses (SOII).The SOII is a m<strong>and</strong>atory survey; employers that receive a notifi cation <strong>of</strong>participation are required by federal law to respond. Each year,approximately 5,000 <strong>Minnesota</strong> employers participate in the SOII.Employers that are participating in the survey <strong>of</strong> 2008 injuries <strong>and</strong>illnesses will receive their survey notices during the fi rst few weeks <strong>of</strong>January 2009. The 2008 survey is the fi rst year the SOII will be collectedprimarily via the Internet. This will improve the effi ciency <strong>of</strong> the SOII <strong>and</strong>reduce mailing costs. Employers’ timely response to the survey is greatly appreciated <strong>and</strong> helps keep the surveycosts low.Employers that have been selected to participate in the survey <strong>of</strong> 2009 injuries <strong>and</strong> illnesses will receivenotifi cation <strong>of</strong> their participation in the second half <strong>of</strong> December 2008. Employers receiving notifi cations need tokeep OSHA log data during 2009 <strong>and</strong> will complete the survey response in 2010.It is very important for each company to review the OSHA recordkeeping requirements to make sure injuries <strong>and</strong>illnesses are correctly recorded. Staff members who are responsible for keeping the OSHA log should haverecordkeeping training. The OSHA recordkeeping requirements are online at www.doli.state.mn.us/recordkeeping.html.Links to the Recordkeeping 101 <strong>and</strong> 201 series that appeared in <strong>Safety</strong> <strong>Lines</strong> are also available on that Web page.Employers with questions about the SOII may call the DLI Policy Development, Research <strong>and</strong> Statistics unit at(651) 284-5428.The 2007 summary results, showing the incidence rates by industry, are scheduled for release Oct. 23; the case<strong>and</strong> demographic details <strong>of</strong> the cases with days away from work are scheduled for release Nov. 20. Visit the DLIWeb site at www.doli.state.mn.us/dlistats.html to view the 2007 <strong>Minnesota</strong> tables on or after those dates.<strong>Safety</strong> <strong>Lines</strong>, October 2008 page 6 www.doli.state.mn.us/mnosha.html

<strong>Minnesota</strong>'s newest MNSHARP worksitesWorkplace safety <strong>and</strong> healthrepresentatives from the <strong>Minnesota</strong><strong>Department</strong> <strong>of</strong> <strong>Labor</strong> <strong>and</strong> <strong>Industry</strong>recently recognized five companies fortheir achievement as <strong>Minnesota</strong> <strong>Safety</strong><strong>and</strong> Health Achievement RecognitionProgram (MNSHARP) worksites.MNSHARP is a <strong>Minnesota</strong> OSHAprogram that recognizes companieswhere managers <strong>and</strong> employeeswork together to develop safety <strong>and</strong>health programs that go beyond basiccompliance with all applicable OSHAst<strong>and</strong>ards <strong>and</strong> result in immediate <strong>and</strong>long-term prevention <strong>of</strong> job-relatedinjuries <strong>and</strong> illnesses.Siewert Cabinet & Fixture Manufacturing, Inc.BASF Polyurethane Foam Enterprises, LLCTapemarkSiewert Cabinet & Fixture Manufacturing,Inc., Minneapolis, was recognizedJuly 11. Siewert Cabinet began as aresidential kitchen cabinet supplierin 1965. Since then, it has grown toa full-service commercial supplier <strong>of</strong>architectural millwork, casework <strong>and</strong>design services.“Together, we willensure more employeescome home safe <strong>and</strong>healthy at the end<strong>of</strong> the workday.”– Steve Sviggum, Commissioner<strong>Department</strong> <strong>of</strong> <strong>Labor</strong> <strong>and</strong> <strong>Industry</strong>BASF Polyurethane Foam Enterprises,LLC, Plymouth, Minn., was recognizedJuly 15. BASF <strong>of</strong>fers a wide range<strong>of</strong> polyurethane foam products tocontractors, consultants, architects<strong>and</strong> owners in the residential,institutional, commercial <strong>and</strong> industrialmarket sectors.Tapemark, West St. Paul, Minn.,was recognized July 24. Tapemarkis a specialty contract manufacturerwhose integrated convertingcapabilities include coating, printing,die cutting <strong>and</strong> packaging <strong>of</strong> complexcomponents <strong>and</strong> products for thepharmaceutical, medical device <strong>and</strong>consumer products markets.MNSHARP sites, continues ...<strong>Safety</strong> <strong>Lines</strong>, October 2008 page 7 www.doli.state.mn.us/mnosha.html

<strong>Minnesota</strong>'s newest MNSHARP worksites, continued ...Anderson Dahlen, Inc., Ramsey, Minn., was recognizedSept. 24. The company provides world-class custommetal fabrication for the food, dairy, pharmaceutical,chemical processing <strong>and</strong> architectural markets. It alsoprovides the engineered solutions <strong>and</strong> complete fi eldinstallation needed to solve processing concerns in thesemarkets.Anderson Dahlen, Inc.D.J. Kranz Co., Inc., Minneapolis, was recognizedSept. 18 as a MNSHARP Construction worksite at theMaple Grove Hospital. The company <strong>of</strong>fers constructionservices for a variety <strong>of</strong> projects, ranging from hospitals<strong>and</strong> medical facilities to automotive dealerships, churches<strong>and</strong> manufacturing facilities.The Maple Grove Hospital opens December 2009 <strong>and</strong> isa partnership between North Memorial <strong>and</strong> Fairview. It willcontain 90 beds (all private patient rooms) <strong>and</strong> providea variety <strong>of</strong> services to the growing population in thenorthwest metro area.D.J. Kranz Co., Inc.MNSHARP Construction is a separate branch <strong>of</strong> theprogram recognizing major-construction companieswith safety <strong>and</strong> health programs that go beyond basiccompliance with all applicable OSHA st<strong>and</strong>ards. Onlycontstruction projects at least 18 months in duration areaeligible for participation. D.J. Kranz is one <strong>of</strong> three currentcertifi ed MNSHARP Construction worksites in <strong>Minnesota</strong>.Visit www.doli.state.mn.us/mnsharp.html to learn more.I-35W safety <strong>and</strong> health audits continue under the bridge<strong>Minnesota</strong> OSHA (MNOSHA) will maintain its compliance assistance audits at the I-35W bridge project until there are no moresignifi cant serious hazards. The opening <strong>of</strong> the bridge Sept. 18 ended the work on the bridge deck, but work remains under thebridge, which includes completion <strong>of</strong> the observation deck, roads, pathways <strong>and</strong> painting. Currently, MNOSHA anticipates themajority <strong>of</strong> significant hazards will be eliminated by mid-October. At that time, Mn/DOT safety <strong>and</strong> MNOSHA will simultaneouslyconclude participation in the partnership they have formed since the bridge collapse in August 2007.<strong>Safety</strong> <strong>Lines</strong>, October 2008 page 8 www.doli.state.mn.us/mnosha.html

Training seminars:Preventingcombustible-dustexplosionWorkplace <strong>Safety</strong> Consultation<strong>Department</strong> <strong>of</strong><strong>Labor</strong><strong>and</strong><strong>Industry</strong><strong>Minnesota</strong> OSHA Compliance <strong>and</strong> Workplace <strong>Safety</strong>Consultation, in partnership with BS&B <strong>Safety</strong>Systems, present two half-day seminars aimed ateliminating combustible-dust explosions <strong>and</strong> helpingemployers comply with the recently issued <strong>Minnesota</strong>OSHA combustible-dust national emphasis program,CPL-03-00-008.The presentation explains key steps in effective dustexplosion risk-management, from the assessment<strong>of</strong> risk to the implementation <strong>of</strong> practical solutionscompliant with OSHA requirements <strong>and</strong> National FireProtection Association (NFPA) industry st<strong>and</strong>ards.Guidance for plant owners, operators <strong>and</strong> designers <strong>of</strong>process equipment will be provided. Participants willlearn how <strong>Minnesota</strong> OSHA Compliance investigatorstest for <strong>and</strong> identify hazardous qualities <strong>of</strong> dust. Anoverview <strong>of</strong> proper electrical <strong>and</strong> other equipment forareas with combustible dust will also be included.Dates <strong>and</strong> locationsOct. 22Nov. 19Cloquet, Minn.Cloquet Forestry Center175 University RoadSt. Cloud, Minn.Holiday Inn Hotel75 37th Ave. S.oshaDEPARTMENT OF LABOR AND INDUSTRYThe cost <strong>of</strong> each half-day seminar is $25.Pre-registration <strong>and</strong> payment by mail is required.For complete information <strong>and</strong> a registration form, visitwww.doli.state.mn.us/osheven.html or call MNOSHAWorkplace <strong>Safety</strong> Consultation at (651) 284-5060,toll-free at 1-800-657-3776.<strong>Safety</strong> <strong>Lines</strong>, October 2008 page 9 www.doli.state.mn.us/mnosha.html

MINNESOTASAFETYHAZARDALERTMobile shelving systems<strong>Minnesota</strong> <strong>Department</strong> <strong>of</strong> <strong>Labor</strong> <strong>and</strong> <strong>Industry</strong>Occupational <strong>Safety</strong> <strong>and</strong> Health Division443 Lafayette Road N.St. Paul, MN 551551-877-470-6742InitiativeIn 2007, the <strong>Minnesota</strong> Occupational <strong>Safety</strong> <strong>and</strong>Health Division (MNOSHA) investigated a fatalaccident due to the improper use <strong>of</strong> a mobileshelving system. This hazard alert is in response tothat investigation, as well as to anecdotal evidenceregarding the use <strong>of</strong> this type <strong>of</strong> equipment.These devices are <strong>of</strong>ten found where there isa need for a large amount <strong>of</strong> fi le storage, i.e.,hospitals, libraries, schools, etc. The systems <strong>of</strong>tenconsist <strong>of</strong> several large shelves that can exp<strong>and</strong><strong>and</strong> collapse to allow a larger amount <strong>of</strong> storage ina smaller space than conventional storage.The purpose <strong>of</strong> this <strong>Minnesota</strong> OSHA <strong>Safety</strong> HazardAlert is to heighten public awareness <strong>of</strong> the properuse <strong>of</strong> this equipment <strong>and</strong> the safety devices usedto prevent the units from closing unintentionally.Description <strong>of</strong> the hazardFactors that can lead to failure:• overriding safety systems through the use <strong>of</strong>the battery pack;• resetting the mobile unit while an aisle is inuse;• limited safety devices that will still allow thecarriages to move even though a person is inthe aisle; <strong>and</strong>• use <strong>of</strong> the equipment by someone other thana trained/competent person.Controlling <strong>and</strong> eliminating the hazardOne key method to preventing mobile shelvingsystem accidents is to have the proper safetydevices installed when the system is fi rst put in. Aphotoelectric eye that runs the length <strong>of</strong> the aisle<strong>and</strong> will stop the equipment when interrupted is notsuffi cient to protect people <strong>and</strong> objects, becauseit may still allow the carriage to move while theaisle is occupied. The aisle needs to be protectedto the point that the equipment will not operatewhile an obstruction is in the aisle. This can bedone using a photoelectric eye that detects whena person or object is present in an open aisle <strong>and</strong>automatically locks out carriage movement. If theaisle is accessed while the carriage is closing, aphotoelectric beam must also be able to detectentry <strong>and</strong> reverse movement.A battery pack that accompanies the equipmentis only to be used in cases where the power hasgone out <strong>and</strong> fi les still need to be accessed. Properemployee training regarding the limitations <strong>of</strong> thebattery pack must be instituted. <strong>Safety</strong> devicesmay be deactivated while the battery pack is in use;thus, special training must take place to ensureemployees are familiar with its use <strong>and</strong> limitations.Employees may not enter into an aisle while thepack is being used. Also, the battery pack switchmust be guarded against unintended activation.Training regarding general use <strong>of</strong> the equipment isalso necessary, including procedures for when anaisle is already in use.Be sure to consult the operator's manual beforeuse <strong>and</strong> for additional guidance.For more informationEmployers <strong>and</strong> employees with questions orconcerns can consult the federal OSHA Web siteat www.osha.gov or contact MNOSHA Complianceat (651) 284-5050 or toll-free at 1-877-470-6742.For more information about requirements <strong>and</strong>recommendations, refer to 29 CFR 1926.212 <strong>and</strong><strong>Minnesota</strong> Rules 5205.0710 <strong>and</strong> 5205.0880.The principal contributor to this <strong>Minnesota</strong> OSHA <strong>Safety</strong> Hazard Alert was Dustin Privette, a senior safety investigatorwith the MNOSHA Mankato Area Offi ce.<strong>Safety</strong> <strong>Lines</strong>, October 2008 page 10 www.doli.state.mn.us/mnosha.html

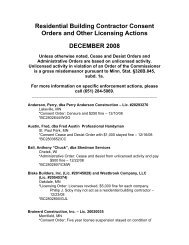

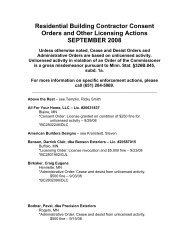

<strong>Minnesota</strong>'s newest MNSTAR worksiteLockheed MartinAbove left: Steve Sviggum, <strong>Minnesota</strong> <strong>Department</strong> <strong>of</strong> <strong>Labor</strong> <strong>and</strong> <strong>Industry</strong> commissioner, congratulatesthe Lockheed Martin staff for its "total commitment to safety <strong>and</strong> health," at its Oct. 1, 2008, fl ag-raisingevent in Eagan, Minn. Above right: <strong>Safety</strong> <strong>and</strong> health committee members from Lockheed Martincelebrate their facility’s achievement as a <strong>Minnesota</strong> STAR (MNSTAR) worksite. Lockheed Martin is aglobal security company that is principally engaged in the research, design, development, manufacture,integration <strong>and</strong> sustainment <strong>of</strong> advanced technology systems, products <strong>and</strong> services.CareeropportunitiesThe <strong>Minnesota</strong> Occupational <strong>Safety</strong> <strong>and</strong> Health (MNOSHA)program, administered by the <strong>Minnesota</strong> <strong>Department</strong> <strong>of</strong> <strong>Labor</strong><strong>and</strong> <strong>Industry</strong>, was established by the <strong>Minnesota</strong> Legislature in1973.Working for MNOSHA can be a very rewarding job. <strong>Minnesota</strong>’seconomy has a great variety <strong>of</strong> industries <strong>and</strong> its businessleaders are <strong>of</strong>ten at the forefront <strong>of</strong> new technology. Keepingup with new developments is challenging <strong>and</strong> exciting. AndMNOSHA investigators are one <strong>of</strong> the very few individuals withthe authority to affect improvements in working conditionsfor all <strong>Minnesota</strong>ns.www.doli.state.mn.us/mnosha.htmlIf you wish to speak to someone about jobs with <strong>Minnesota</strong>OSHA, contact a MNOSHA supervisor at:• (651) 284-5050; or• toll-free at 1-877-470-6742.oshaDEPARTMENT OF LABORAND INDUSTRY<strong>Safety</strong> <strong>Lines</strong>, October 2008 page 11 www.doli.state.mn.us/mnosha.html