KURSUS JANGKA PENDEK DI ILP PERAI TAHUN 2013/2014

KURSUS JANGKA PENDEK DI ILP PERAI TAHUN 2013/2014

KURSUS JANGKA PENDEK DI ILP PERAI TAHUN 2013/2014

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

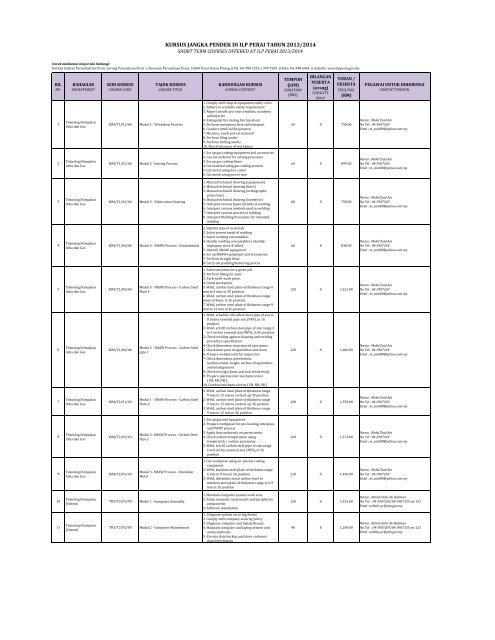

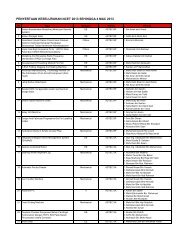

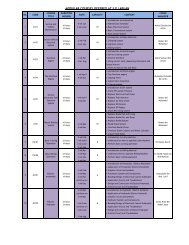

<strong>KURSUS</strong> <strong>JANGKA</strong> <strong>PENDEK</strong> <strong>DI</strong> <strong>ILP</strong> <strong>PERAI</strong> <strong>TAHUN</strong> <strong>2013</strong>/<strong>2014</strong>SHORT TERM COURSES OFFERED AT <strong>ILP</strong> <strong>PERAI</strong> <strong>2013</strong>/<strong>2014</strong>Untuk maklumat lanjut sila hubungi:Institut Latihan Perindustrian Perai, Lorong Perusahaan Perai 1, Kawasan Perusahaan Perai, 13600 Perai, Pulau Pinang || Tel: 04-390 7335 / 390 7269 || Faks: 04-398 6964 || website: www.ilpperai.gov.myBILNO12BAHAGIANDEPARTMENTTeknologi KimpalanArka dan GasTeknologi KimpalanArka dan GasKOD <strong>KURSUS</strong>COURSE CODEKIM/T1/01/06KIM/T1/02/06TAJUK <strong>KURSUS</strong>COURSE TITLEModul 1 - Workshop PracticeModul 2 - Cutting ProcessKANDUNGAN <strong>KURSUS</strong>COURSE CONTENT1. Comply with shop & equipment safety rules2. Adhere to worksite safety requirement3. Report unsafe acts and condition, accidentsand injuries4. Extinguish fire during fire break out5. Perform emergency first aid treatment6. Conduct Artificial Respiration7. Measure, mark and cut material8. Perform filing works9. Perform drilling works10. Check tolerance of workpiece1. Set up gas cutting equipment and accessories2. Lay out material for cutting processes3. Set up gas cutting flame4. Cut material using gas cutting process5. Cut metal using disc cutter6. Cut metal using power sawTEMPOH(JAM)DURATION(HRS)BILANGANPESERTA(orang)CAPACITY(pax)YURAN /PESERTAFEES/PAX(RM)60 8 758.0060 8 899.00PEGAWAI UNTUK <strong>DI</strong>HUBUNGICONTACT PERSONNama : Mohd Zaid AinNo Tel : 04-3907269Emel : m_zaid08@yahoo.com.myNama : Mohd Zaid AinNo Tel : 04-3907269Emel : m_zaid08@yahoo.com.my3Teknologi KimpalanArka dan GasKIM/T1/03/06Modul 3 - Fabrication Drawing1. Manual technical drawing (equipment)2. Manual technical drawing (lines)3. Manual technical drawing (orthographicprojection)4. Manual technical drawing (isometric)5. Interpret various types of joints in welding6. Interpret various symbols used in welding7. Interpret various process in welding8. Interpret Welding Procedure for intendedwelding60 8 758.00Nama : Mohd Zaid AinNo Tel : 04-3907269Emel : m_zaid08@yahoo.com.my4Teknologi KimpalanArka dan GasKIM/T1/04/06Modul 4 - SMAW Process - Fundamental1. Identify type of materials2. Select parent metal of welding3. Select welding consumables4. Handle welding consumables ( identify,segregate, store & bake)5. Identify SMAW equipment6. Set up SMAW equipment and accessories7. Perform straight bead8. Carry out padding/buttering proces60 8 838.00Nama : Mohd Zaid AinNo Tel : 04-3907269Emel : m_zaid08@yahoo.com.my5Teknologi KimpalanArka dan GasKIM/T1/05/06Modul 5 - SMAW Process - Carbon SteelPlate 11. Fabricate joints for a given job.2. Perform fitting for joint.3. Tack weld work piece.4. Grind work piece.5. Weld, carbon steel plate of thickness range 6mm to 9 mm, in 2F position.6. Weld, carbon steel plate of thickness range6mm to 9mm, in 1G position.7. Weld, carbon steel plate of thickness range 9mm to 12 mm in 2G position.120 8 1,521.00Nama : Mohd Zaid AinNo Tel : 04-3907269Emel : m_zaid08@yahoo.com.my6Teknologi KimpalanArka dan GasKIM/T1/06/06Modul 4 - SMAW Process - Carbon Steelpipe 11. Weld, schedule 40 carbon steel pipe of size 6-8 inches nominal pipe size (NPS), in 1Gposition2. Weld, sch 80 carbon steel pipe of size range 2to 4 inches nominal size (NPS), in 2G position3. Check welding against drawing and weldingprocedure specification4. Check dimension on prepared specimens5. Check inter pass irregularities and clean6. Prepare welded joint for inspection7. Check dimension, penetration,reinforcement, height, surface irregularitiesand misalignment8. Check test jigs (bend and nick break tests)9. Prepare specimen for mechanical test( FB, RB, NB ).10. Conduct mechanical tests ( FB, RB, NB )120 8 1,606.00Nama : Mohd Zaid AinNo Tel : 04-3907269Emel : m_zaid08@yahoo.com.my7Teknologi KimpalanArka dan GasKIM/T2/01/03Modul 1 - SMAW Process - Carbon SteelPlate 21. Weld, carbon steel plate of thickness range9 mm to 12 mm in vertical up 3F position2. Weld, carbon steel plate of thickness range9 mm to 12 mm in vertical up 3G position3. Weld, carbon steel plate of thickness range9 mm to 12 mm in 4G position120 8 1,559.00Nama : Mohd Zaid AinNo Tel : 04-3907269Emel : m_zaid08@yahoo.com.my8Teknologi KimpalanArka dan GasKIM/T2/02/03Modul 2- SMAW Process - Carbon SteelPipe 21. Set up gas and equipment2. Prepare workpiece for pre-heating, interpassand PWHT process3. Apply heat uniformly on parent meta4. Check surface temperature usingtemperstick / surface pyrometer5. Weld, sch 40 carbon steel pipe of size range6 to 8 inches nominal size (NPS), in 5Gposition120 8 1,574.00Nama : Mohd Zaid AinNo Tel : 04-3907269Emel : m_zaid08@yahoo.com.my9Teknologi KimpalanArka dan GasKIM/T2/03/03Modul 3- SMAW Process - DissimilarMetal1. Cut workpiece using air plasma cuttingequipment2. Weld, stainless steel plate of thickness range6 mm to 9 mm in 2G position3. Weld, dissimilar metal carbon steel tostainless steel plate of thickness range 6 to 9mm in 1G position120 8 1,496.00Nama : Mohd Zaid AinNo Tel : 04-3907269Emel : m_zaid08@yahoo.com.my10Teknologi Komputer(Sistem)TKS/T2/01/05Modul 1 - Computer Assembly1. Maintain computer system work area2. Setup computer system unit and peripheralscomponents3. Software installation120 8 1,525.00Nama : Atikah binti Ab RahmanNo Tel : 04-3907269/04-3907335 ext 123Emel : atikah_ar@jtm.gov.my11Teknologi Komputer(Sistem)TKS/T2/02/05Modul 2 - Computer Maintenance1. Diagnose system error log/beeps2. Comply with company security policy3. Diagnose computer and laptop threats4. Maintain computer and laptop system unitand peripherals5. Execute data backup and store customerdata/information90 8 1,189.00Nama : Atikah binti Ab RahmanNo Tel : 04-3907269/04-3907335 ext 123Emel : atikah_ar@jtm.gov.my

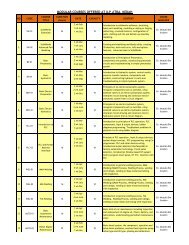

BILNOBAHAGIANDEPARTMENTKOD <strong>KURSUS</strong>COURSE CODETAJUK <strong>KURSUS</strong>COURSE TITLEKANDUNGAN <strong>KURSUS</strong>COURSE CONTENTTEMPOH(JAM)DURATION(HRS)BILANGANPESERTA(orang)CAPACITY(pax)YURAN /PESERTAFEES/PAX(RM)PEGAWAI UNTUK <strong>DI</strong>HUBUNGICONTACT PERSON12Teknologi Komputer(Sistem)TKS/T2/03/05Modul 3 - Computer Troubleshooting1. Inspect internal and external computer andlaptop power supply devices2. Check computer and laptop system3. Replace computer and laptop faultycomponent60 8 872.00Nama : Atikah binti Ab RahmanNo Tel : 04-3907269/04-3907335 ext 123Emel : atikah_ar@jtm.gov.my1314Teknologi Komputer(Sistem)Teknologi Komputer(Sistem)TKS/T2/04/05TKS/T2/05/05Modul 4 - ComputerUpgradingModul 5 - Basic Networking15 Teknologi Automotif AUTO/T1/01/06 Modul 1 - Petrol Fuel System16 Teknologi Automotif AUTO/T1/01/07Modul 2 - Electrical & Electronic System117 Teknologi Automotif AUTO/T1/01/08 Modul 3 - Brake System1. Upgrade computer and laptop system unitcomponents2. Check computer and laptop system software3. Update computer and laptop software1. Set up computer network cable2. Design computer network environment3. Set up client network operating system1. Carry out fuel tank replacement2. Carry out electrical fuel pump replacement3. Determine vehicle fuel system function4. Replace mechanical fuel pump1. Rectify engine ignition system2. Rectify engine starting system3. Rectify vehicle charging system4. Rectify vehicle lighting system5. Rectify vehicle headlamp alignment6. Rectify windshield wiper system1. Replace vehicle brake pads2. Replace vehicle brake disc3. Replace brake drum4. Replace brake lining5. Rectify parking brake6. Rectify brake master pump7. Rectify brake calliper8. Rectify brake wheel cylinder9. Replace front wheel bearing10. Replace rear wheel bearing11. Carry out Brake Booster Replacement1. Carry out vehicle inspection18 Teknologi Automotif AUTO/T1/01/09 Modul 4 - Vehicle Periodical Maintenance 2. Carry out engine lubrication service3. Carry out vehicle schedule maintenance60 8 872.0060 8 919.0060 8 905.0060 8 855.0060 8 938.0030 8 615.00Nama : Atikah binti Ab RahmanNo Tel : 04-3907269/04-3907335 ext 123Emel : atikah_ar@jtm.gov.myNama : Atikah binti Ab RahmanNo Tel : 04-3907269/04-3907335 ext 123Emel : atikah_ar@jtm.gov.myNama : Zaidi bin Abd RahmanNo Tel : 04-3907269/04-3907335 ext 117Emel : zaidi.rahman@jtm.gov.myNama : Zaidi bin Abd RahmanNo Tel : 04-3907269/04-3907335 ext 117Emel : zaidi.rahman@jtm.gov.myNama : Zaidi bin Abd RahmanNo Tel : 04-3907269/04-3907335 ext 117Emel : zaidi.rahman@jtm.gov.myNama : Zaidi bin Abd RahmanNo Tel : 04-3907269/04-3907335 ext 117Emel : zaidi.rahman@jtm.gov.my19 Teknologi Automotif AUTO/T1/01/10 Modul 5 - Workshop Practice1. Carry out workshop safety practices2. Carry out bench fitting activities3. Carry out workshop tools maintenance4. Carry out basic welding activities5. Carry out workshop equipment management120 8 1,619.00Nama : Zaidi bin Abd RahmanNo Tel : 04-3907269/04-3907335 ext 117Emel : zaidi.rahman@jtm.gov.my20 Teknologi Automotif AUTO/T1/01/11 Modul 6 - Transmission System 121 Teknologi Automotif AUTO/T1/01/12 Modul 1 - Engine Maintenance1. Replace vehicle clutch cable2. Rectify hydraulic clutch system3. Rectify vehicle clutch assembly4. Rectify drive shaft assembly5. Rectify propeller shaft assembly6. Rectify drive shaft assembly7. Service gear shift linkages1. Determine engine condition2. Carry out engine top overhaul3. Carry out engine overhaul60 8 930.00120 8 1,691.00Nama : Zaidi bin Abd RahmanNo Tel : 04-3907269/04-3907335 ext 117Emel : zaidi.rahman@jtm.gov.myNama : Zaidi bin Abd RahmanNo Tel : 04-3907269/04-3907335 ext 117Emel : zaidi.rahman@jtm.gov.my22 Teknologi Automotif AUTO/T1/01/13 Modul 2 - Diesel Fuel System 11. Carry out diesel fuel injectors servicing2. Carry out diesel fuel injection pump timing3. Determine diesel fuel system function4. Rectify diesel pre heating system60 8 952.00Nama : Zaidi bin Abd RahmanNo Tel : 04-3907269/04-3907335 ext 117Emel : zaidi.rahman@jtm.gov.my23 Teknologi Automotif AUTO/T1/01/14 Modul 3 - Steering System1. Rectify steering tie-rod end2. Rectify steering rack dust cover3. Carry out manual steering rectification work4. Carry out power steering rectification work5. Carry out tyre changing6. Carry out vehicle wheel balancing7. Carry out vehicle wheel alignment8. Carry out power steering functionality test60 8 1,024.00Nama : Zaidi bin Abd RahmanNo Tel : 04-3907269/04-3907335 ext 117Emel : zaidi.rahman@jtm.gov.my24 Teknologi Automotif AUTO/T1/01/15 Modul 4 - Air-Conditioning System1. Replace air-conditioning belt and tensionerassembly2. Replace air-conditioning evaporator air filter3. Recover and recycle air-conditioningrefrigerant4. Carry out air-conditioning receiver drierreplacement5. Carry out air-conditioning expansion valvereplacement6. Carry out air-conditioning system flushing60 8 999.00Nama : Zaidi bin Abd RahmanNo Tel : 04-3907269/04-3907335 ext 117Emel : zaidi.rahman@jtm.gov.my25 Teknologi Automotif AUTO/T1/01/16 Modul 5 - Transmission System 21. Carry out front wheel driveshaft rectificationwork2. Carry out manual transaxle overhaul3. Carry out manual transmission overhaul4. Carry out rear wheel driveshaft rectificationwork5. Carry out rear axle overhaul60 8 958.00Nama : Zaidi bin Abd RahmanNo Tel : 04-3907269/04-3907335 ext 117Emel : zaidi.rahman@jtm.gov.my26 Teknologi Automotif AUTO/T1/01/17 Modul 6 - Suspension System272829Pusat Sumber danMultimediaPusat Sumber danMultimediaPusat Sumber danMultimedia1. Replace vehicle suspension bushes2. Replace front shock absorbers3. Replace rear shock absorbers4. Replace vehicle leaf springs assembly5. Carry out Macpherson strut assemblyreplacement6. Carry out suspension ball joint replacement7. Carry out suspension bushes replacement8. Carry out control arm replacement60 8 1,036.00PSM - 001 Microsoft Word 2007 Basic Microsoft Word 2007 8 8 102.00PSM - 002 Microsoft Excel 2007 Basic Microsoft Excel 2007 8 8 102.00PSM - 003 Microsoft Power Point 2007 Basic Microsoft Power Point 2007 8 8 102.00Nama : Zaidi bin Abd RahmanNo Tel : 04-3907269/04-3907335 ext 117Emel : zaidi.rahman@jtm.gov.myNama : Aimi Ruzaini binti AhmadNo Tel : 04-3907269/04-3907335 ext 120Emel : aimiruzaini@jtm.gov.myNama : Aimi Ruzaini binti AhmadNo Tel : 04-3907269/04-3907335 ext 120Emel : aimiruzaini@jtm.gov.myNama : Aimi Ruzaini binti AhmadNo Tel : 04-3907269/04-3907335 ext 120Emel : aimiruzaini@jtm.gov.my30Pusat Sumber danMultimediaPSM - 004 Microsoft Office 20101. Difference between Microsoft Office 2010 &20072. New Function in Microsoft Office 201016 8 190.00Nama : Aimi Ruzaini binti AhmadNo Tel : 04-3907269/04-3907335 ext 120Emel : aimiruzaini@jtm.gov.my

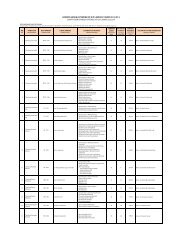

BILNO3132333435BAHAGIANDEPARTMENTPusat Sumber danMultimediaPusat Sumber danMultimediaPusat Sumber danMultimediaPusat Sumber danMultimediaPusat Sumber danMultimediaKOD <strong>KURSUS</strong>COURSE CODETAJUK <strong>KURSUS</strong>COURSE TITLEKANDUNGAN <strong>KURSUS</strong>COURSE CONTENTTEMPOH(JAM)DURATION(HRS)BILANGANPESERTA(orang)CAPACITY(pax)YURAN /PESERTAFEES/PAX(RM)PSM - 005 Adobe Photoshop - Basic Tools, effect, blending and text 16 8 315.00PSM - 006 Digital Photography - Basic Shutter, aperture, ISO, white balance, framing 16 8 315.00PSM - 007 Digital Video - Basic Video camera works and shooting technique 16 8 315.00PSM - 008 Adobe Premier - Baisc Video editing, tools, rendering, transition 16 8 315.00PSM - 009 Adobe Flash - Basic Tools, transition, movement, animation 16 8 315.00PEGAWAI UNTUK <strong>DI</strong>HUBUNGICONTACT PERSONNama : Aimi Ruzaini binti AhmadNo Tel : 04-3907269/04-3907335 ext 120Emel : aimiruzaini@jtm.gov.myNama : Aimi Ruzaini binti AhmadNo Tel : 04-3907269/04-3907335 ext 120Emel : aimiruzaini@jtm.gov.myNama : Aimi Ruzaini binti AhmadNo Tel : 04-3907269/04-3907335 ext 120Emel : aimiruzaini@jtm.gov.myNama : Aimi Ruzaini binti AhmadNo Tel : 04-3907269/04-3907335 ext 120Emel : aimiruzaini@jtm.gov.myNama : Aimi Ruzaini binti AhmadNo Tel : 04-3907269/04-3907335 ext 120Emel : aimiruzaini@jtm.gov.my