You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

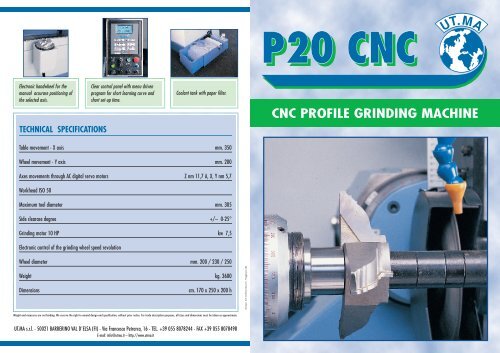

P20 <strong>CNC</strong>Electronic handwheel for themanual accurare positioning ofthe selected axis.TECHNICAL SPECIFICATIONSClear control panel with menu drivenprogram for short learning curve andshort set-up time.Coolant tank with paper filter.<strong>CNC</strong> <strong>PROFILE</strong> <strong>GRINDING</strong> <strong>MACHINE</strong>Table movement - X axis mm. 350Wheel movement - Y axis mm. 200Axes movements through AC digital servo motors Z nm 11,7 A, X, Y nm 5,7Workhead ISO 50Maximum tool diameter mm. 305Side clearace degree +/– 0-25°Grinding motor 10 HP kw 7,5Electronic control of the grinding wheel speed revolutionWheel diameter mm. 200 / 230 / 250Weight kg. 3600Dimensionscm. 170 x 250 x 200 hStampa: Arti Grafiche Nencini - Poggibonsi (Si)Weight and measures are not binding. We reserve the right to amend design and specification, without prior notice. For trade description purposes, all sizes and dimensions must be taken as approximate.UT.MA s.r.l. - 50021 BARBERINO VAL D'ELSA (FI) - Via Francesco Petrarca, 16 - TEL. +39 055 8078244 - FAX +39 055 8078498E-mail: info@utma.it – http://www.utma.it

P20 <strong>CNC</strong> <strong>PROFILE</strong> <strong>GRINDING</strong> <strong>MACHINE</strong>P20 <strong>CNC</strong> allows profiling of HM carbide and HSS cutting toolsincluding inserts/plates, carbide cutters, router bits and HSScorrugate back knives.The P20 <strong>CNC</strong> was designed for maximum flexibility and easeof operation. All MENU driven software allows operator toinput the requested values and create a program in minutesthat can be stored in the computer hard disk.Tool manufacturers will appreciate the speed and ease ofmaking one special profile tool or hundreds of the sameprofile. With the universal 50 internal taper in the A-axisworkhead, it is fast and simple to change from inserts torouter bits to cutters and back in a very few minutes.With the UTMA P20-<strong>CNC</strong>, the engineering and design conceptto work cost efficiently with single special tools or long runsof similar tools has been realized in a very dinamic andpractical way.<strong>CNC</strong> <strong>PROFILE</strong> GRINDER FOR CARBIDE AND HSS CUTTERS,INSERTS KNIVES AND ROUTER BITSThe P20-<strong>CNC</strong> allows the importing of DXF o HPGL drawings made on other CAD systems.The P20-<strong>CNC</strong> also is equipped as standard with a 2-D drawing program “PXCAD” whichallows the user to create a CAD drawing of a tool profile, or to finish drawing from anelectronic scan of a wood sample or a non-dimensioned line-drawing. Available on optionis a computer with industrial computer cabinet.Four <strong>CNC</strong> controlled axes - X, Y, A, ZAC digital servo motors on all <strong>CNC</strong> axesElectronic speed variator for grinding wheelSimple, fast teach-in tool positioningFast, simple programmingAccepts DXF CAD drawingsIncludes Windows based 2-D CAD systemOperator friendly CAD/CAM menuMicrometric Preset Stations for grinding wheel andcutting tool. External to the P20-<strong>CNC</strong>, theMicrometric preset Stations allow accurate checkingand control of wheel and tool specifications.