Technical Information - RO-FI Edelstahl

Technical Information - RO-FI Edelstahl

Technical Information - RO-FI Edelstahl

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

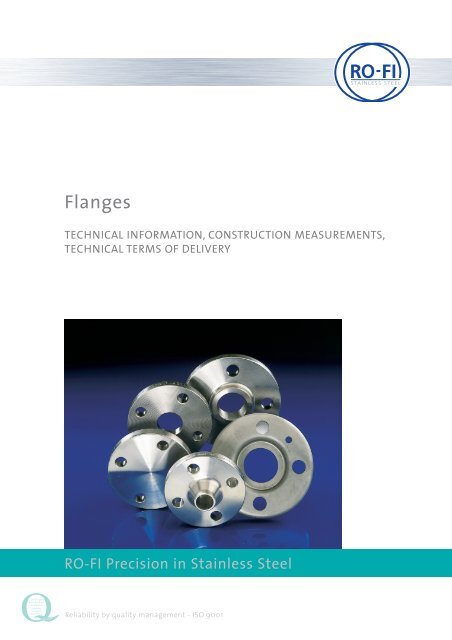

FlangesFlanges – spring and slot DIN 2512Nominal pressures (PN) 10 till 160 – construction dimensionsInsert ringfor flange connections slot against slotrotatedAppelation of a insert ring for slot flanges of a nominal width 65 of RSt 37-2:ring 65 DIN 2512 – Rst 37-2nominal widthnominal width11.2007_1.000www.rofi.deBracked nominal width if it’s possible*) just for flanges of the refregeration<strong>RO</strong>-<strong>FI</strong> Precision in Stainless Steel5/3

FlangesFlanges – nose flange and retrace flange DIN 2513Nominal pressure (PN) 10 till 40 – construction dimensionsThis norm consider in connection with the corresponding dimensions for flanges.male faced flangeForm V 13dimension in mmfemale faced flangeForm R 13b = bulking thickness accordingto the dimension standardnominalwidthmale facedfemale faced11.2007_1.0001) Retrace flanges could be, if desired from the orderer,marked with a channel at the circumferential outeredge.Flanges, overview see DIN 2500Flanges, forms of the seal face see DIN 2526Steel flanges, technical conditions of delivery see DIN 2519Flat seal ring for flanges with nose and retrace see DIN 2692Bracketed nominal width are to anoid, if it’s possible5/4<strong>RO</strong>-<strong>FI</strong> Precision in Stainless Steel

FlangesFlanges – nose flange with groove and retrace DIN 2514Nominal pressure (PN) 10 till 40 – construction dimensionsdimensions in mmThis norm consider in connection with the corresponding dimensions for flanges.The groove for round-seals can even be used for flat flanges or flanges with raised face.female facedForm R11.2007_1.000male facedrotatedwww.rofi.deForm Vdimensions at assemblingb = bulking thickness according to the dimension standard<strong>RO</strong>-<strong>FI</strong> Precision in Stainless Steel5/5

FlangesFlanges – nose flange with groove and retrace DIN 2514Nominal pressure (PN) 10 till 40 – construction dimensionsnominalwidthmale facedfemale facedSealingRing11.2007_1.000Bracketed nominal width are to anoid, if it’s possible5/6<strong>RO</strong>-<strong>FI</strong> Precision in Stainless Steel

FlangesSteel Flanges DIN 2519 – <strong>Technical</strong> conditions of delivery1 CoverageThis technical conditions of delivery have to use also ifThis technical conditions of delivery consider for all steelthe relevant dimension standards doesn´t refer to it; theyflanges which are made of the material named in chapterdoes n´t consider if in the dimension standards, other2 and produced by one of the processes in chapter 4.1.technical conditions of delivery are defined.They consider for example for:- Blind flanges according to DIN 25272 MaterialsThe flanges are made of materials which are defined in- Screwed flange according to DIN 2558, DIN 2561,the accordant dimension standard. If for special applicati-DIN 2565, DIN 2566, DIN 2567, DIN 2568 and DIN 2569ons, for example heat resisting, low-temperature, stain-- Flat flanges to soldering or welding according toless steels are necessary, than the choice of steel is in theDIN 2573 and DIN 2576case of the orderer.11.2007_1.000- Weld neck flanges according to DIN 2627 *), DIN 2628,DIN 2629, DIN 2630, DIN 2631, DIN 2632, DIN 2633, DIN2634, DIN 2635, DIN 2636, DIN 2637 and DIN 2638- Lose flanges for collar pipes according to DIN 2641and DIN 2642- Lose flanges with bunch according to DIN 2652,DIN 2653, DIN 2655 and DIN 2656- Lose flanges with butt-welded collar according toDIN 2667, DIN 2668 and DIN 2669- Lose flanges with butt-welded collar according toDIN 26733 Description of steelsFor all description are decisive:- for all general construction steels the shortnames accordingto DIN 17100- for all other steels, the in the accordant norms and specialprovisions, denoted shortnames4 Requirements4.1 Manufacturing processwww.rofi.deType of flangemanufacturing processmadebended andof forged compressed seamless welded ofplate rolled rolled sectionsflat oval flanges and ■ ■ ■ - -bund flangesflat flanges ■ ■ ■ - -flat bunches ■ ■ ■ ■ ■flanges with accretion - ■ ■ ■ ■weld not flanges - ■ ■ ■ ■and bunches<strong>RO</strong>-<strong>FI</strong> Precision in Stainless Steel5/7

FlangesSteel Flanges DIN 2519 – <strong>Technical</strong> conditions of delivery4.2 Condition of deliveryThe flanges have to be accord to the in the delivery denoteddimension standards ad-measurements, explanationsand materials. If there isn´t denoted a special accomplishmentconsider for the conditions of delivery the followingtable according to the choice of the manufacturer.4.3 Kind of surfaceAll surfaces have to be in a top condition which does n´taffected the application of the flanges. The nut bearingfaces have to be parallel to the seal face. Machined surfaceshave to accord to the according to DIN 3141 (pre-standard),edition march 1960ox, line 1. Seal surfaces shoutnot be finer as 40 μm depth of roughness.outer edgecenter hole seal face screw holesnut bearingfaceunmachinedwith windingorblankedordrilleddrilledunmachinedorblankedordrilled11.2007_1.000drilledororblankedordrilleddrilledbrunchescrudeorflangesbrunchesandflangesbrunchesflangesblankedordrilledbrunchesflangesbrunchesflangesbrunchesflangesdrilledbrunchesorflangesbrunchesorflangesbrunchesflangesblankedordrilled1)At the application of extension bolts according to DIN 2510 the orderer have toinstruct that the accomplishment of the nut-bearing face with the letter codes in the DIN-appellation is arranged before the short mark.5/8<strong>RO</strong>-<strong>FI</strong> Precision in Stainless Steel

FlangesSteel Flanges DIN 2519 – <strong>Technical</strong> conditions of delivery4.4 Acceptable dimension meanderingsdimensiondimensional rangeaccomplishmentmachinedunmachinedexternaldiameteroveroverovertototocentre holeoverovertototoexcept flangeboth surfacesflangeone surfacesovertoflange thicknessovertooverto11.2007_1.000flange heightmg thickness 3)diameter ofthe sealbolt circlediameteroveroveroveroveroveroverovertototototototoAt keyed gaskets the concentrically have to be warranted for bolt circle and centre hole.The acceptable dimensional deviation for the diameter of the centre hole, the hole centredistance and the diameter of the screw hole will be bordered by the play between studboltand the diameter of the screw hole.www.rofi.de5 InspectionsAt the delivery with approval the flanges will be checkedby batches. For this you have to organise the flanges bysteel grade and , if it´s possible, by dimensions, and toarrange them in batches of 100 articles. The remainingquantity can be disturb equally in the specific batches.The quantities and the remaining quantities between 51and 100 flanges and the delivery of 50 flanges and lessconsider as one closed batch. The inspection scope of theorder have to arrange between orderer and manufacturer.The assays have to arrange in the manufacturing plant.About the assays will be certificate a test report accordingto DIN 50049, edition April 1960, chapter 2, or a certificateaccording to chapter 3.6 Identification markAll standardised flanges have to be marked as following:- manufacturer´s sign- nominal width/external diameter of the tube- nominal pressure- material association mark DIN7 ComplaintExternal and internal faults just may be complained ifthey prejudice more than irrelevant the reasonable convertingand application of the steel garde and the form ofmanufacture.The orderer have to afford an opportunity to the supplierto satisfy about the authority of the complaint, if it´s possibleby present the reference sample of the complainedflange.<strong>RO</strong>-<strong>FI</strong> Precision in Stainless Steel5/9

FlangesFlanges DIN 2526 – forms of the seal facesArea of applicationThis norm contains an compendium about the appellationand short marks the of the detailed types of gaskets requiredforms of the seal faces.Flanges without sealing stripFlanges with sealing stripForm ASeal face without accountForm BSealing strip Rz=160 (not finer than 40 μm), rotatedForm CSealing stripe Rz=160 (not finer than 40 μm), rotatedForm DSealing strip Rz=40, rotatedForm ESealing stripe Rz=16 , rotatedFlanges with keyed sealing stripeForm Fspring according to 2512Form V 14male faced according to DIN 251411.2007_1.000Form Nnotch according to DIN 2512Form R 14female faced according to DIN 2514Form V 13male faced according to DIN 2513Form Mslant for membrane-welded gasket according toDIN 2695Form R 13female faced according to DIN 2513Form Lgroove for lenticular gasket according to 26965/10<strong>RO</strong>-<strong>FI</strong> Precision in Stainless Steel

STAINLESS STEELwww.rofi.deSTAINLESS STEELwww.rofi.deSouthKarl-Arnold-Straße 7D-73230 Kirchheim/TeckTel. +49 (0) 70 21 94 35-0Fax +49 (0) 70 21 5 60 31kirchheim@rofi.deNorth South ExportMittelgönrather Karl-Arnold-Straße Straße 7 15D-42655 D-73230 Solingen Kirchheim/TeckTel. +49 (0) 2701212 94 3235-054-0Fax +49 (0) 2701212 5326054-1131solingen@rofi.dekirchheim@rofi.deMiddle North ExportOstendstraße Mittelgönrather 3 Straße 15D-63110 D-42655 Rodgau-NiederrodenSolingenTel. +49 (0) 61 2 12062 2328554-079-30Fax +49 (0) 61 2 12062 232254-1108rodgau@rofi.desolingen@rofi.deEast MiddleReuterstraße Ostendstraße 23D-99867 D-63110 Gotha Rodgau-NiederrodenTel. +49 (0) 36 61 21 06 72 33 85 97-0 79-30Fax +49 (0) 36 61 21 06 72 33 22 97-10 08gotha@rofi.derodgau@rofi.de<strong>RO</strong>-<strong>FI</strong> Precision in Stainless SteelZuverlässigkeitdurch QualitätsmanagementReliabilityby qualitymanagementReliability by quality management - ISO 9001EastReuterstraße 2D-99867 GothaTel. +49 (0) 36 21 7 33 97-0Fax +49 (0) 36 21 7 33 97-10gotha@rofi.de