The effect of short fibre and neps on Murata vortex spinning

The effect of short fibre and neps on Murata vortex spinning

The effect of short fibre and neps on Murata vortex spinning

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

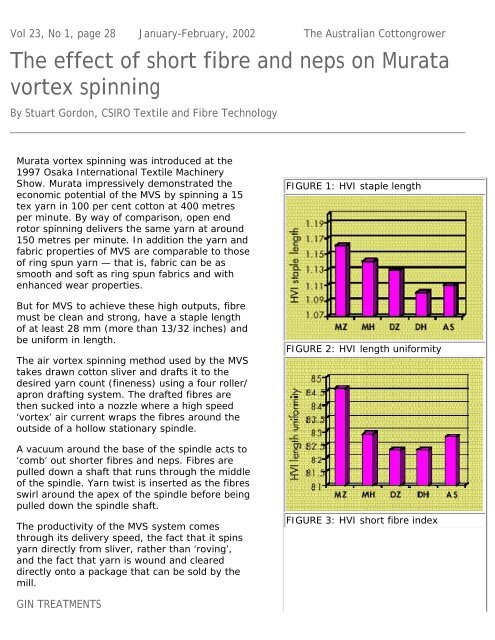

subjected to extended pilling tests to againhighlight the <str<strong>on</strong>g>effect</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> elevated <str<strong>on</strong>g>short</str<strong>on</strong>g> <str<strong>on</strong>g>fibre</str<strong>on</strong>g>.FIBRE QUALITY CHARACTERISTICSSince growing locati<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> c<strong>on</strong>diti<strong>on</strong>s includingharvesting were identical, the differences in <str<strong>on</strong>g>fibre</str<strong>on</strong>g>properties can be attributed to module storage<str<strong>on</strong>g>and</str<strong>on</strong>g> gin heat. As expected, micr<strong>on</strong>aire, <str<strong>on</strong>g>fibre</str<strong>on</strong>g>fineness <str<strong>on</strong>g>and</str<strong>on</strong>g> maturity were unaffected by the gintreatments. But length, strength, trash <str<strong>on</strong>g>and</str<strong>on</strong>g> nepcharacteristics were significantly affected by thecombinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> storage moisture <str<strong>on</strong>g>and</str<strong>on</strong>g> gin heatc<strong>on</strong>diti<strong>on</strong>s.FIGURE 6: MVS yarn tenacityFibre length characteristics<str<strong>on</strong>g>The</str<strong>on</strong>g>re were pr<strong>on</strong>ounced differences in staplelength, <str<strong>on</strong>g>short</str<strong>on</strong>g> <str<strong>on</strong>g>fibre</str<strong>on</strong>g> index <str<strong>on</strong>g>and</str<strong>on</strong>g> length uniformitybetween gin treatments (see Figures 1, 2 <str<strong>on</strong>g>and</str<strong>on</strong>g> 3).In general, seed cott<strong>on</strong> ginned with no heat inthe gin produced l<strong>on</strong>ger, more even cott<strong>on</strong>.Moist seed cott<strong>on</strong> ginned with no heat (MZ)produced the l<strong>on</strong>gest, most even cott<strong>on</strong> followedby dry seed cott<strong>on</strong> treated with zero heat (DZ).On the other h<str<strong>on</strong>g>and</str<strong>on</strong>g>, dry seed cott<strong>on</strong> treated withhigh heat (DH) <str<strong>on</strong>g>and</str<strong>on</strong>g> seed cott<strong>on</strong> stored underambient c<strong>on</strong>diti<strong>on</strong>s <str<strong>on</strong>g>and</str<strong>on</strong>g> treated to st<str<strong>on</strong>g>and</str<strong>on</strong>g>ard heat(AS) produced lint with reduced staple length<str<strong>on</strong>g>and</str<strong>on</strong>g> higher <str<strong>on</strong>g>short</str<strong>on</strong>g> <str<strong>on</strong>g>fibre</str<strong>on</strong>g> c<strong>on</strong>tents.FIGURE 7: MVS yarn imperfecti<strong>on</strong>s (Ne30/1 <strong>on</strong>ly)StrengthFibre strength is a fundamental <str<strong>on</strong>g>fibre</str<strong>on</strong>g> propertythat decides both yarn <str<strong>on</strong>g>and</str<strong>on</strong>g> fabric quality <str<strong>on</strong>g>and</str<strong>on</strong>g>processing efficiency. Fibre strength across alltreatments was generally very good (more than29 grams per tex) <str<strong>on</strong>g>and</str<strong>on</strong>g> in keeping with the grade<str<strong>on</strong>g>of</str<strong>on</strong>g> the cott<strong>on</strong> ginned. As expected, <str<strong>on</strong>g>fibre</str<strong>on</strong>g> strengthdid not vary greatly between gin treatments,although measurements were higher fortreatments stored under moist c<strong>on</strong>diti<strong>on</strong>s (MZ<str<strong>on</strong>g>and</str<strong>on</strong>g> MH).FIGURE 8: MVS yarn hairinessTrash <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>neps</str<strong>on</strong>g>Trash <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>fibre</str<strong>on</strong>g> entanglements, such as <str<strong>on</strong>g>neps</str<strong>on</strong>g>,disrupt the <strong>spinning</strong> processes <str<strong>on</strong>g>and</str<strong>on</strong>g> damage bothyarn <str<strong>on</strong>g>and</str<strong>on</strong>g> fabric appearance. <str<strong>on</strong>g>The</str<strong>on</strong>g>se c<strong>on</strong>taminantsmay be less <str<strong>on</strong>g>of</str<strong>on</strong>g> a problem in MVS <strong>spinning</strong>because <str<strong>on</strong>g>of</str<strong>on</strong>g> the sucti<strong>on</strong> around the MVSstati<strong>on</strong>ary spindle. As well as removing <str<strong>on</strong>g>short</str<strong>on</strong>g>er<str<strong>on</strong>g>fibre</str<strong>on</strong>g>s, the vacuum removes <str<strong>on</strong>g>neps</str<strong>on</strong>g> before they areFIGURE 9: Fibre lost during <strong>spinning</strong>

end uses.Two yarns counts were spun (Ne 30/1 <str<strong>on</strong>g>and</str<strong>on</strong>g> Ne40/1). <strong>Murata</strong> <strong>vortex</strong> <strong>spinning</strong> frames can spinyarn counts from carded sliver in the range fromNe 10/1 to Ne 50/1. Yarn was spun in sufficientquantities for thorough yarn <str<strong>on</strong>g>and</str<strong>on</strong>g> fabric testing<str<strong>on</strong>g>and</str<strong>on</strong>g> calculati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>spinning</strong> efficiencies <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>fibre</str<strong>on</strong>g>loss.Yarn tenacityYarn tenacity is determined by a combinati<strong>on</strong> by<str<strong>on</strong>g>fibre</str<strong>on</strong>g> fineness, <str<strong>on</strong>g>fibre</str<strong>on</strong>g> length <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>fibre</str<strong>on</strong>g> strength. As<str<strong>on</strong>g>fibre</str<strong>on</strong>g> fineness was c<strong>on</strong>stant in this trial, the yarntenacity results reflect the gin treatments <str<strong>on</strong>g>and</str<strong>on</strong>g>their <str<strong>on</strong>g>effect</str<strong>on</strong>g> up<strong>on</strong> <str<strong>on</strong>g>fibre</str<strong>on</strong>g> length <str<strong>on</strong>g>and</str<strong>on</strong>g> strength.<str<strong>on</strong>g>The</str<strong>on</strong>g> MZ treated cott<strong>on</strong> produced the highesttenacity yarn in both Ne 30/1 <str<strong>on</strong>g>and</str<strong>on</strong>g> Ne 40/1counts, while the AS <str<strong>on</strong>g>and</str<strong>on</strong>g> DH treated cott<strong>on</strong>produced the weakest yarns (Figure 6). Likewise,yarn el<strong>on</strong>gati<strong>on</strong> was better in the MZ treatedcott<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> worse in the drier, heat-treatedsamples.<str<strong>on</strong>g>The</str<strong>on</strong>g> overall tenacity <str<strong>on</strong>g>of</str<strong>on</strong>g> the MVS yarns was betterthan that <str<strong>on</strong>g>of</str<strong>on</strong>g> comparative open-end rotor yarnsbut weaker than that <str<strong>on</strong>g>of</str<strong>on</strong>g> ring spun yarns.Yarn evenness <str<strong>on</strong>g>and</str<strong>on</strong>g> imperfecti<strong>on</strong>s<str<strong>on</strong>g>The</str<strong>on</strong>g> evenness <str<strong>on</strong>g>of</str<strong>on</strong>g> yarn spun <strong>on</strong> all <str<strong>on</strong>g>short</str<strong>on</strong>g>-staple<strong>spinning</strong> systems is directly affected by <str<strong>on</strong>g>short</str<strong>on</strong>g><str<strong>on</strong>g>fibre</str<strong>on</strong>g> c<strong>on</strong>tent. Evenness results followed a similarpattern to tenacity results, in that evenness wasbetter in yarns spun from cott<strong>on</strong> treated to moiststorage or zero heat. This was evident in bothyarn counts <str<strong>on</strong>g>and</str<strong>on</strong>g> was also reflected in thick <str<strong>on</strong>g>and</str<strong>on</strong>g>thin place counts (see Figure 7).But nep counts did not follow this pattern. DZtreated cott<strong>on</strong> had the lowest number <str<strong>on</strong>g>of</str<strong>on</strong>g> yarn<str<strong>on</strong>g>neps</str<strong>on</strong>g> in both yarn counts but AS cott<strong>on</strong> producedmore <str<strong>on</strong>g>neps</str<strong>on</strong>g> in Ne 30/1 yarn <str<strong>on</strong>g>and</str<strong>on</strong>g> MZ producedmore <str<strong>on</strong>g>neps</str<strong>on</strong>g> in Ne 40/1 yarn. It is interesting t<strong>on</strong>ote that nep levels in both yarn counts were atleast 75 per cent better than yarn nep levels incarded ring spun yarns. Even yarns with thehighest yarn nep measurements (MZ <str<strong>on</strong>g>and</str<strong>on</strong>g> AS) fellwithin the lowest 25 per cent <str<strong>on</strong>g>of</str<strong>on</strong>g> all Uster Statisticentries for carded ring spun yarn <str<strong>on</strong>g>neps</str<strong>on</strong>g>.

Yarn hairinessYarn hairiness is significantly affected by <str<strong>on</strong>g>short</str<strong>on</strong>g><str<strong>on</strong>g>fibre</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> the trial results follow a similar patternto the yarn tenacity <str<strong>on</strong>g>and</str<strong>on</strong>g> evenness results. BothMZ <str<strong>on</strong>g>and</str<strong>on</strong>g> DZ treated cott<strong>on</strong>, which had relativelylow levels <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>short</str<strong>on</strong>g> <str<strong>on</strong>g>fibre</str<strong>on</strong>g>, had the lowest hairinessvalues in both yarn counts, while AS <str<strong>on</strong>g>and</str<strong>on</strong>g> MHcott<strong>on</strong> produced the highest hairiness values inboth yarn counts (see Figure 8).Fibre lossFibre loss at the MVS twist z<strong>on</strong>e due to thevacuum around the base <str<strong>on</strong>g>of</str<strong>on</strong>g> the stati<strong>on</strong>aryspindle will be an important issue in themarketability <str<strong>on</strong>g>of</str<strong>on</strong>g> Australian cott<strong>on</strong> to MVS<strong>spinning</strong> mills. Fibre losses, expressed as apercentage <str<strong>on</strong>g>of</str<strong>on</strong>g> the total input weight, weresignificant <str<strong>on</strong>g>and</str<strong>on</strong>g> greater for the cott<strong>on</strong>s exposed todry storage <str<strong>on</strong>g>and</str<strong>on</strong>g> excessive heat during ginning.Figure 9 illustrates the <str<strong>on</strong>g>fibre</str<strong>on</strong>g> loss for each yarncount due to each gin treatment. As expected,MZ cott<strong>on</strong>s lost less <str<strong>on</strong>g>fibre</str<strong>on</strong>g> while cott<strong>on</strong>s subject toharsher treatments — for example AS <str<strong>on</strong>g>and</str<strong>on</strong>g> DHcott<strong>on</strong> — lost more <str<strong>on</strong>g>fibre</str<strong>on</strong>g>. Different nozzlegeometry <str<strong>on</strong>g>and</str<strong>on</strong>g> pressures can be used to reducethese figures although alterati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> such<strong>spinning</strong> parameters may cause significantchanges in yarn properties.Spinning breaksSpin breaks are defined as the number <str<strong>on</strong>g>of</str<strong>on</strong>g> breaksper hour per <strong>spinning</strong> frame. Sixty breaks perhour is c<strong>on</strong>sidered the cut <str<strong>on</strong>g>of</str<strong>on</strong>g>f if a <strong>spinning</strong>efficiency <str<strong>on</strong>g>of</str<strong>on</strong>g> above 90 per cent is to be achieved.Spinning breaks for Ne 30/1 yarn were similarfor all gin treatments. <str<strong>on</strong>g>The</str<strong>on</strong>g> high end-break ratewith the DZ treatment was attributed to thec<strong>on</strong>diti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the sliver (see Figure 10).Spinning breaks increased when the yarnbecame finer with all Ne 40/1 yarn exceeding 60breaks per hour per machine. But the MZtreatment had the lowest number <str<strong>on</strong>g>of</str<strong>on</strong>g> end breaks(64) while the DH treatment had the highest(96). <str<strong>on</strong>g>The</str<strong>on</strong>g> high number <str<strong>on</strong>g>of</str<strong>on</strong>g> breaks is evidence thatNe 40/1 may <str<strong>on</strong>g>effect</str<strong>on</strong>g>ively be the spin limit forcarded Australian cott<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> that to efficientlyspin finer counts, combing may be required.

FABRIC QUALITYNe 30/1 yarn from each gin treatment wasknitted into single jersey fabric. <str<strong>on</strong>g>The</str<strong>on</strong>g>se sampleswere then subject to a pilling resistance test.MVS fabrics are generally highly resistant toabrasive damage <str<strong>on</strong>g>and</str<strong>on</strong>g> pill formati<strong>on</strong>, <str<strong>on</strong>g>and</str<strong>on</strong>g>c<strong>on</strong>sequently retain a fresh appearance evenafter many launderings.All fabrics in this trial were rated as having no orlittle pilling.CONCLUSIONSTreatment <str<strong>on</strong>g>of</str<strong>on</strong>g> seed cott<strong>on</strong> before <str<strong>on</strong>g>and</str<strong>on</strong>g> duringginning, especially with respect to <str<strong>on</strong>g>fibre</str<strong>on</strong>g> moisture<str<strong>on</strong>g>and</str<strong>on</strong>g> drying temperatures, has significant <str<strong>on</strong>g>effect</str<strong>on</strong>g>s<strong>on</strong> <str<strong>on</strong>g>fibre</str<strong>on</strong>g> quality. Dry seed cott<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> hot air inthe gin lead to high <str<strong>on</strong>g>short</str<strong>on</strong>g> <str<strong>on</strong>g>fibre</str<strong>on</strong>g> c<strong>on</strong>tent, <str<strong>on</strong>g>short</str<strong>on</strong>g>erstaple length, increased <str<strong>on</strong>g>neps</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> reducedstrength. <str<strong>on</strong>g>The</str<strong>on</strong>g>se properties have adverse <str<strong>on</strong>g>effect</str<strong>on</strong>g>s<strong>on</strong> both the quality <str<strong>on</strong>g>of</str<strong>on</strong>g> spun yarn <str<strong>on</strong>g>and</str<strong>on</strong>g> theefficiency with which the yarn can be spun.With MVS yarn, higher <str<strong>on</strong>g>short</str<strong>on</strong>g> <str<strong>on</strong>g>fibre</str<strong>on</strong>g> c<strong>on</strong>tents leadto greater <str<strong>on</strong>g>fibre</str<strong>on</strong>g> loss around the MVS twist z<strong>on</strong>e,which translates directly into lost producti<strong>on</strong> forthe <strong>spinning</strong> mill.High <str<strong>on</strong>g>short</str<strong>on</strong>g> <str<strong>on</strong>g>fibre</str<strong>on</strong>g> also c<strong>on</strong>tributes to poorer yarntenacity, poorer yarn evenness, higher levels <str<strong>on</strong>g>of</str<strong>on</strong>g>imperfecti<strong>on</strong>s, higher yarn hairiness <str<strong>on</strong>g>and</str<strong>on</strong>g> lower<strong>spinning</strong> efficiency. C<strong>on</strong>versely, elevated neplevels in <str<strong>on</strong>g>fibre</str<strong>on</strong>g> did not translate into higher yarnimperfecti<strong>on</strong>s, because <str<strong>on</strong>g>neps</str<strong>on</strong>g> are removed at thetwist inserti<strong>on</strong> point during MVS <strong>spinning</strong>.In terms <str<strong>on</strong>g>of</str<strong>on</strong>g> grade <str<strong>on</strong>g>and</str<strong>on</strong>g> trash c<strong>on</strong>tent, the cott<strong>on</strong>investigated in this study would normally bedescribed as a high quality growth. But for MVS(<str<strong>on</strong>g>and</str<strong>on</strong>g> ring) spinners the c<strong>on</strong>trol cott<strong>on</strong> (AS) could<strong>on</strong>ly be described as being <str<strong>on</strong>g>of</str<strong>on</strong>g> reas<strong>on</strong>able quality.<str<strong>on</strong>g>The</str<strong>on</strong>g> AS treated cott<strong>on</strong> performed worst in almostall yarn quality indicators.MVS spinners require better lengthcharacteristics to achieve the desired quality intheir yarns. <str<strong>on</strong>g>The</str<strong>on</strong>g> results from this study showthat cott<strong>on</strong> treated with more moisture <str<strong>on</strong>g>and</str<strong>on</strong>g> lessheat in the gin performed better <strong>on</strong> MVS interms <str<strong>on</strong>g>of</str<strong>on</strong>g> yarn quality, <strong>spinning</strong> efficiency <str<strong>on</strong>g>and</str<strong>on</strong>g>raw material cost savings.

This study was funded by the CRDC <str<strong>on</strong>g>and</str<strong>on</strong>g> CSIRO Textile <str<strong>on</strong>g>and</str<strong>on</strong>g>Fibre Technology. Assistance was received from: <str<strong>on</strong>g>The</str<strong>on</strong>g>NCEA, Queensl<str<strong>on</strong>g>and</str<strong>on</strong>g> Cott<strong>on</strong> (Dalby Gin), Rocklea SpinningMills, Muratec Ltd, Trützschler GmbH & Co. KG <str<strong>on</strong>g>and</str<strong>on</strong>g>Schlafhorst GmbH.