BuehlerVanguard® 2000

BuehlerVanguard® 2000

BuehlerVanguard® 2000

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

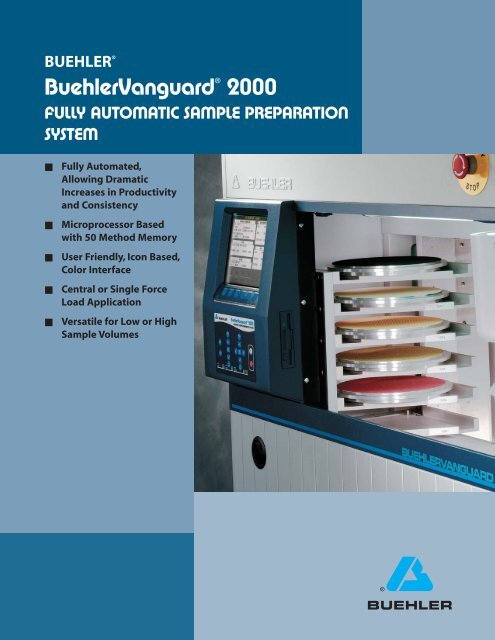

BUEHLER ®BuehlerVanguard ® <strong>2000</strong>FULLY AUTOMATIC SAMPLE PREPARATIONSYSTEM■■■■■Fully Automated,Allowing DramaticIncreases in Productivityand ConsistencyMicroprocessor Basedwith 50 Method MemoryUser Friendly, Icon Based,Color InterfaceCentral or Single ForceLoad ApplicationVersatile for Low or HighSample Volumes

Fully Automated PreparationIncreases Productivity andConsistencyThe <strong>BuehlerVanguard®</strong> <strong>2000</strong> is a FullyAutomatic Grinding-Polishing Systemdeveloped to free your personnelfrom the time consuming task ofsample preparation. Fully automatedmeans that samples can be preparedfrom start to finish without continuousoperator involvement. Just loadup to six samples at a time, select thepreparation method, and step away. Inas little as 15 to 20 minutes yoursamples will be finished; cleaned,dried, and ready for analysis. While theBuehlerVanguard <strong>2000</strong> preparessamples, the user is free to spend timeon critical applications such as analysisand report generation.With BuehlerVanguard <strong>2000</strong> you canincrease your lab’s volume without2sacrificing consistency or quality.BuehlerVanguard <strong>2000</strong> automaticallymonitors the critical operatingparameters for each batch, assuringconsistent results, operator tooperator, shift to shift, day in and dayout.Microprocessor Based with 50Method MemoryThe BuehlerVanguard <strong>2000</strong>’smicroprocessor based system allowsthe user to select from six preinstalledmethods or up to 44 individuallycreated preparation methods.Designed by Buehler’s expertlaboratory personnel, the sixpreinstalled methods enable lessexperienced metallographers toprepare a variety of materials quicklyand effectively.The user can easily create, retrieve,modify, and store up to 44 methods tomeet individual applicationrequirements. The same method usedtoday can be recalled day after day,operator after operator, to giveconsistent results sample aftersample.User Friendly, Icon DrivenInterfaceThe BuehlerVanguard’s user friendlyinterface makes operation simple. Allcontrols are located on one easy to usetouch panel. No keyboard or mouse isneeded. Simple icons guide the operatorthrough all program display screensenabling use by laboratory personnel ofall skill levels. Operation is furthersimplified by the use of full colordisplays, color graphics, and byhighlighting the windows or text to beedited.

User Friendly Control PanelTouch-pad controlsactivate correspondingscreen functionsSelects window to beedited on the screenSelects data toenter values incommand fieldsMain PowerEnters alphanumerictextThe key to the BuehlerVanguard<strong>2000</strong>’s ease of use is simplicity. Formost applications, the operator hasonly to press Power On, scroll tothe desired method, and press Runto begin preparing samples. Afterthe method is started, the roboticarm automatically loads one of sixselected platens onto thegrinding-polishing base. Next, theautomatic head places the sampleson the platen while providingsingle or central load application.As the samples are being prepared,the BuehlerVanguard <strong>2000</strong> countsdown the time remaining on agiven step and projects theestimated time to completion forthe entire process. Duringpreparation, the operator canpause, stop, or restart the system atanytime.A fully integrated dispensingsystem automatically dosesabrasive suspensions onto thegrinding/polishing surface. TheBuehlerVanguard <strong>2000</strong>’sdispensing system meters theabrasive suspensions dosing byfrequency and duration toeliminate waste, resulting inconsumable savings as comparedto manual abrasive application.The automatic head shuttles thesamples between steps to theultrasonic cleaning and dryingstation. Meanwhile, the robotic armautomatically returns the firstplaten to the storage rack andloads a second platen inpreparation for the next step.After the final polishing step, theBuehlerVanguard <strong>2000</strong> signals theoperator that the samples areready for analysis. The user can, bythe push of one button, repeat themethod or go back and select anew polishing method.BuehlerVanguard <strong>2000</strong> safetyfeatures include a transparentaccess portal with safety interlock,separate splash proof controlhousing, and an emergency stopswitch.Designed for international use, theBuehlerVanguard <strong>2000</strong> hasmultiple language capacity andEnglish or graphic display faciapanels.3

BuehlerVanguard <strong>2000</strong> system gives the operator the choice of preparing samples using single or central force application. Single force application means as fewas one or as many as six samples can be prepared at a time. With single force application, individual samples can be removed, examined, then returned to the holderto continue preparation.The robotic arm moves the aluminum platens from the storage rack into the drive base. Abrasivesuspensions are dispensed from one of six self cleaning nozzles onto the preparation surface.The cleaning station offers a choice of ultrasonic ornon-ultrasonic cleaning and warm or cold airspecimen drying.The consumable storage area holds up to 6 bottles of abrasive and one bottle of UltraMet® SonicCleaning Solution. Buehler offers specially formulated abrasive suspensions for the BuehlerVanguard<strong>2000</strong> in addition to our standard line of grinding media, polishing cloths, and MetaDi® SupremeDiamond Suspensions. The easy to open front panel provides quick access to the storage area.A complete series of specimen holders accommodatesboth compression and cold mounted samples as wellas a range of unmounted specimens.4

The BuehlerVanguard <strong>2000</strong> makes it easy to program and run samplepreparation methods. The Main Menu displays a list of options andcommands to program, edit, or run a method. Press the key under thecorresponding command to activate a command.The BuehlerVanguard <strong>2000</strong> has six pre-programmed methods foralumina, aluminum alloys, carbon steels, copper/bronze alloys, stainlesssteels and titanium alloys. These methods can be used as programmedor edited and saved under a different method name.The Edit Method Mode allows changing method parameter values, suchas number of samples, force, platen identity and abrasives used andcleaning time.A service test can be performed to display the BuehlerVanguard <strong>2000</strong>system status.The Configuration Mode allows selection among a variety oflanguages. Select between English, German, French, Spanish, Chinese,Japanese or Korean languages.Select between metric or imperial units of measure in the ConfigurationMode.5

The Manual Mode - Platen Only screen enables Platen Speed and Fluidparameters to be entered before starting a method execution.The Manual Mode - Platen & Head screen enables Head, Polishing, Fluid andCarrier parameters to be entered at the start of the method execution.Technical DataOperation Modes• Fully automatic• Semi-automatic• ManualSingle and Central Mode SampleCapacity• Quantity 6 of 1″ or 25mm samples• Quantity 6 of 14″ or 30mmsamples• Quantity 3 of 12″ or 40mmsamplesSample Force• 1 to 20 lb. per sample• 4-89 N per sampleHead/Base Parameters• Base motor 1Hp (746 watts)• Wheel speed 20-350 rpm (in 10rpm increments)• Head motor 4 Hp (187 watts)• Head speed 30, 60, and 120 rpm• Head/base relative rotation:complementary or contraDispensing System• Automatic or touch panelcontrolled dispensing• 6 abrasive suspensions• 1 cleaning solution on/off• Water on/off• Self cleaning nozzlesCleaning and Drying Station• Ultrasonic cleaning• Cleaning time 0-5 minutes• Stainless steel wash tank• Cleaning solution dispensing• Warm or cold air drying• Air dry time 0-1 minutes• Final step air dry time 0-5 minutesMicroprocessor• Dual microprocessors• 32 MB Flash RAM Drive• 128 MB DDR RAM Memory• 400 MHz Speed• 16MB UMA Graphic DisplayMemory• 50 method memory up to 6 stepsper method (6 preinstalledmethods)Controls• User friendly icon driven• Fully integrated touch-pad control• 8.5″ (216mm) LCD color display• Multi-language user interface• English or graphic control faciapanel for easy world wideoperationConstruction• Tabletop system• Heavy duty, corrosion resistantaluminum constructionConstruction (cont.)• Corrosion and impact resistant ABScabinet• Quiet pneumatic operation• Lighted operating chamberSafety Features• Isolated splash proof controlcabinet• Transparent safety interlock accesspanel• Mushroom type emergency stopswitchPower:170-264V/50-60 Hz/1 phase, 20 ampsAir Requirments:95 psi (6.6 bars) filtered, regulatedcompressed airWater Requirements:a″ OD tube (9.5mm) supply, 15-85psi (1.0-5.9 bars) sourceWeight:350 lb. (159 kg)DimensionsW x D x H39.25″ x 23.65″ x 31.50″997mm x 601mm x 800mm6

Specifications63-<strong>2000</strong> BuehlerVanguard <strong>2000</strong> Fully Automatic Preparation System tabletop unit with microprocessorbased operation, six 8″ (203mm) aluminum platens. Complete with operating instructions. Specimen holderssupplied separately. For 170-264V/50-60 Hz/1 phase operation.Accessories63-1001 Aluminum Platen, for BuehlerVanguard <strong>2000</strong>, 8″ (203mm).48-8282 TechMet® Table, for BuehlerVanguard <strong>2000</strong>, 36″ H x 54″ W x 30″ D (915mm x 1372mm x 762mm).Single Force AccessoriesSingle force holders come standard with drive adapters. The single force holders also include one set of appropriatelysized retaining rings.ComponentPart NumberSpecimen Holder, Single Force six 1″ mounts 63-1002Specimen Holder, Single Force six 14″ mounts 63-1003Specimen Holder, Single Force three 12″ mounts 63-1004Specimen Holder, Single Force six 25mm mounts 63-1005Specimen Holder, Single Force six 30mm mounts 63-1006Specimen Holder, Single Force three 40mm mounts 63-1007Retaining Ring Replacements, Single Force six 1″ and 25mm mounts 63-1022Retaining Ring Replacements, Single Force six 14″ and 30mm mounts 63-1023Retaining Ring Replacements, Single Force three 12″ and 40mm mounts 63-1024Central Force AccessoriesCentral force holders require the purchase of drive adapters.Specimen Holder, Central Force six 1″ or 25mm mounts 60-2482Specimen Holder, Central Force six 14″ mounts 60-2483Specimen Holder, Central Force three 12″ mounts 60-2485Specimen Holder, Central Force six 30mm mounts 60-2486Specimen Holder, Central Force three 40mm mounts 60-2487Drive Adapter for Central Force Specimen Holders 60-2499Specimen Loading Plate, for Central Force Specimen Holders 60-2425ConsumablesApex® Diamond Grinding Discs, Color, PSA Backed, 8″ (203mm)Micron Color Quantity Part Number75 Red 1 41-350855 Purple 1 41-360835 Yellow 1 41-370815 White 1 41-38088 Blue 1 41-39087

Consumables (Cont.)BuehlerVanguard <strong>2000</strong>’s proprietary slurries and suspensions are specially formulated for use with Buehler’s dispensingsystems to maximize performance and are conveniently sized to fit the BuehlerVanguard <strong>2000</strong>’s consumable storagearea.MetaDi® Supreme Polycrystalline Diamond Suspensions, 32 oz. (.95l)Diamond Size Color Type Part Number1 micron Blue Water Based 40-6630-0323 micron Green Water Based 40-6631-0326 micron Yellow Water Based 40-6632-0329 micron Deep Red Water Based 40-6633-03215 micron Brown Water Based 40-6634-032Final Polishing Suspensions and <strong>BuehlerVanguard®</strong> <strong>2000</strong> ConsumablesDescription Microns Part NumberMasterPrep® Suspension, 6 oz. 0.05 63-6377-006MicroPolish® Alumina, #1, 6 oz. 5.0 63-6351-006MicroPolish® Alumina, #1C, 6 oz. 1.0 63-6354-006MicroPolish® Alumina, #2A, 6 oz. 0.3 63-6352-006MicroPolish® Alumina, #3B, 6 oz. 0.05 63-6353-006Cleaning SolutionDescriptionPart NumberUltraMet® 2 Sonic Cleaning Solution, 6 oz. 63-6000-006UltraMet® 2 Sonic Cleaning Solution, 32 oz. 75-6000-032The BuehlerVanguard Fully Automatic Preparation System is also compatible with Buehler’s standard grinding media, polishing cloths, and MetaDi® Diamond Suspensions.For a complete consumable listing, please refer to the Quality At Work - Consumables Buyers Guide.Buehler continuously makes product improvements; therefore, technical specifications are subject to change without notice.© 2008 BUEHLER LTD. Printed in U.S.A. PDF0208 FN01323 *For metallurgical equipment produced by BUEHLER LTD. USABUEHLER LTD. – Worldwide Headquarters41 Waukegan Road • P.O. Box 1Lake Bluff, Illinois 60044-1699 USATel: 847/295-6500 • Fax: 847/295-7979Sales: 1/800/BUEHLER • 1/800/283-4537Web Site: http://www.buehler.comEmail: info@buehler.comBUEHLER GMBH - European and MESA HeadquartersIn der Steele 2 • 40599 DüsseldorfPostfach 16 03 55 • 40566 DüsseldorfTelefon: (49) 211 974100 • Telefax: (49) 211 9741079Web Site: http://www.buehler-met.deEmail: info@buehler-met.deBUEHLER FRANCETéléphone: 0800 89 73 71Télécopie: 0800 88 05 27Web Site: http://www.buehler.frEmail: info@buehler.frBUEHLER UNITED KINGDOMTelephone: 0800 707 6273Fax: 0800 707 6274Web Site: http://www.buehler.co.ukEmail: sales@buehler.co.ukBUEHLER CANADA10 Carlow Court, Unit #2Whitby, Ontario L1N 9T7Telephone: (905) 430-4684 • Fax: (905) 430-4647Sales Telephone: 1-800-268-3593Email: info@buehler.caBUEHLER ASIA5/F Vogue Centre696 Castle Peak RoadLai Chi Kok, KowloonHong Kong, SAR, ChinaTelephone: (852) 2307 0909Fax: (852) 2307 0233