Manhattan Diamonds - Manhattan Corporation

Manhattan Diamonds - Manhattan Corporation

Manhattan Diamonds - Manhattan Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SA Mining November 2008 46<strong>Manhattan</strong><strong>Diamonds</strong>dazzles with exceptionalperformanceDespite unsettled markets and the tightening of the resources sector belt, <strong>Manhattan</strong><strong>Corporation</strong>’s diamond division, <strong>Manhattan</strong> <strong>Diamonds</strong> SA, continues to countermarket sentiment as it brings to account its fourth and fifth diamond operations. Fromhaving just one operational mine last year, to five this year, <strong>Manhattan</strong> <strong>Diamonds</strong> isnow targeting bringing online over ten mines by the end of 2013. Financial director,Theo Pouroullis, speaks about the diamond operations and the plans to extendproduction amid the current financial global crisis.The alluvial diamond mining arm of the group currentlyhas five operational diamond mines – Octo, Lycium, Simus,Varuno and the recently commissioned Clydesdale diamondmine - all located close to the Orange River in the NorthernCape.While the markets are in the grip of a re-alignment of value,<strong>Manhattan</strong> is using its equipment knowledge, experience andlatest technology to significantly reduce costs per tonne, and toreach its 12mtpa run of mine target by the end of H1 2009.Speaking of the diamond operations, Pouroullis explainsthat the <strong>Manhattan</strong> <strong>Diamonds</strong> group started to mine its firstdiamonds on the Orange River in August 2004. Only late inthe 2007 calendar year did it commence with the roll-out ofits additional mining operations.Its Varuno mine is steadily increasing its run of mine tonnageusing ‘its newly designed capacity concept’, which makes useof a number of initiatives focused on maximising quality productionand an optimal cost per tonne. Its innovations includean in-pit screening process - which effectively manages andreduces costs per tonne, as very little waste material needs tobe transported to the processing plants and re-transported tothe quarry; de–sanding, which reduces the waste-feed to rotarypan plants, and hence increases throughputs, and optimisedwaste material management, including direct loading of wasteinto trucks, eliminating the need for an additional front endloader cycle.The above initiatives including a centralised recovery, allowan enhanced cost per tonne for the operations, whichenables the business to continue to perform above averagein comparison to its peers in the industry.In the current economic climate, the focus on cost per tonneenhancements aims to ensure that <strong>Manhattan</strong> <strong>Diamonds</strong> becomesa world-class diamond mining business with a drive tobe the best cost per tonne performer in the industry.In the current market of softening diamond prices <strong>Manhattan</strong>takes the firm view that a maintained effort on the costs ofits operations will allow good margins to be maintained withsignificant upside in the future, as prices improve.The various mine sites are all managed centrally by infrastructurelinked to <strong>Manhattan</strong>’s head office in Johannesburg.<strong>Manhattan</strong> <strong>Corporation</strong> Mining Services, the equipment andservices arm of the group, and voted as one of SA’s Top 5mining service providers in 2008 by Topco Media, provides avariety of technical services and 24-hour backup support to theoperation. Through its 17-year track record of delivering bestcost per tonne solutions, its head office backbone is able toprovide a wide bouquet of technical support not easily availablein the Northern Cape or at remote mining operations.As fuel is a substantial portion of business cost for a surfacemining operation, data measured includes tonnes per litre ofdiesel, a measure <strong>Manhattan</strong> has managed to improve by over30% in the past six months. Other key variables include labourcost per tonne, machine utilisation per tonne and consumables/spares per tonne. These variables account for the majority ofthe operation’s monthly costs, and <strong>Manhattan</strong> focuses on theirtight control, targeting exceptional performance.The information is managed by a central database currentlybeing upgraded to an SQL platform, which allows easy integrationinto existing business systems. <strong>Manhattan</strong>’s servicearm intends to market this proprietary software to its miningclients along with equipment and technology offerings, aspart of its initiative to enhance the performance of its client’sbusiness.The Lycium operation has recently undergone a productioncapacity upgrade, which has enabled the mine to morethan double its installed capacity and throughput, as its trial47 SA Mining November 2008Lycium MineA view of the Octo Mine process plant

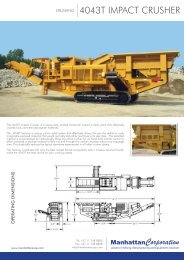

SA Mining November 2008 48mining programme was successfully carried out as part of itsexploration roll-out.Its FYI 2010 target is to be producing at over 18mtpa.<strong>Manhattan</strong> <strong>Diamonds</strong> would have in excess of a 20-year lifeof mine at this level, and this excludes its other Africa concessions,which are in the exploration phase.With mining contributing some 24% of the Northern CapeGross Domestic Profit (GDP), <strong>Manhattan</strong>’s contribution tothe area with one of the largest unemployment rates in SA issignificant, with the company employing over 900 personnelacross its diamond business, and directly and indirectly creatingover 3000 jobs amongst two local towns, which have a totalpopulation of just over 20 000.Over the next five years, <strong>Manhattan</strong> plans on growing itspersonnel base and is looking to employ over 3000 people,creating over 12 000 direct and indirect jobs. A number oflocal initiatives embarked on by its operational subsidiariesare already in progress including the development of localinfrastructure, construction of a bridge, roads and the developmentof a tarred landing strip all for use by the local community,other businesses and mining operations. These initiatives, inpartnership with government, local communities, and othercompanies are a few of <strong>Manhattan</strong>’s numerous projects whichcontribute to local communities and the regional economy ofthe Northern Cape.Developing sustainable relationships with landowners in theregion also forms part of the business strategy employed bySpyder screen machine inaction at Simus MineOcto Mine overview<strong>Manhattan</strong> to ensure successful partnerships and sustainablebusiness growth.<strong>Manhattan</strong> also has a programme to develop small-scaleminers and contract mining operations. <strong>Manhattan</strong>’s technicalknowledge on geological alluvial diamond modelling, besttechnical practice, cost management and other key elements,allows for knowledge transfer to smaller mining companies,thus assuring their success.While the markets remain volatile, Pouroullis anticipatesa relaxation in diamond prices over the short term, and advisesthat, to maintain mining sustainability: ‘It is important toenhance yield from your deposits and to drive down costssignificantly.’In addition, <strong>Manhattan</strong> <strong>Diamonds</strong> is investing heavily inacquiring the latest technology equipment, such as the Spyderscreen machines - the first three of which have been installedat the operations.In collaboration with the OEM, <strong>Manhattan</strong> has re-designedthe screen to incorporate a bottom deck high carbon de-sandingmesh to remove all sand in the mining quarry, reducingtramming loads and improving cost per ton efficiencies.The Spyder in-pit screens come with patented soft-start andsoft-stop technology where vibrating action is dampened, causingless stress to the screen frame and mechanical structuresextending component life.Meanwhile, <strong>Manhattan</strong> is looking to leverage off its miningservices arm which has an established presence in 28 countriesand 4 continents around the world, of which 15 are in Africa.The company is looking to extend its geographical productionfootprint and developing its exploration targets inthe medium term. ‘’We intend to have a producing Africanproject running within 24 months. The intent is that the rightcategory of diamonds would be brought back to SA for cuttingand polishing in our local factories, thereby creating employmentand developing the Africa brand of rough and polisheddiamonds.“Pouroullis concludes: “There is no reason why <strong>Manhattan</strong><strong>Diamonds</strong> cannot become the global leader in alluvial diamondmining, and deliver exceptional value to shareholders.” mA view of Clydesdale operationsVaruno Mine process plant