Silbione® Liquid Silicone Rubbers for Healthcare

Silbione® Liquid Silicone Rubbers for Healthcare

Silbione® Liquid Silicone Rubbers for Healthcare

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

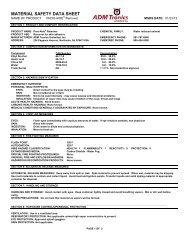

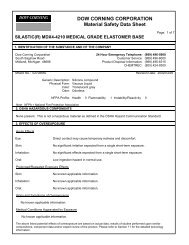

<strong>Healthcare</strong> August 2008Silbione ® <strong>Liquid</strong> <strong>Silicone</strong> <strong>Rubbers</strong> <strong>for</strong> <strong>Healthcare</strong>(4330, 4340, 4340 FC, 4340 SL, 4350, 4360, 60, 4370)<strong>Liquid</strong> <strong>Silicone</strong> RubberDescriptionSilbione ® <strong>Liquid</strong> <strong>Silicone</strong> <strong>Rubbers</strong> (LSRs) are two-component platinum-catalyzed siliconeelastomers designed <strong>for</strong> liquid injection molding healthcare and medical devices, includingapplications of less than 30 day implantation in the human body.Available in 30 to 70 durometer Shore A, Bluestar <strong>Silicone</strong>s’ Silbione ® LSRs offer thedistinctive advantages of easy processing and easy release combined with high per<strong>for</strong>mancephysical properties.FeaturesApplicationsInstructions<strong>for</strong> useCureDesigned specifically <strong>for</strong> healthcare applications, Silbione ® LSRs meet or exceed testingrequirements of United States Pharmacopoeia (USP) Class VI. Biocompatibility testingaddresses the categories of evaluation <strong>for</strong> cytotoxicity, skin sensitization and skin irritationspecified in ISO 10993 <strong>for</strong> device use of less than 30 days duration. See Table 2.• Easy processing• Excellent mold release <strong>for</strong> shorter cycle times• Superior clarity• High per<strong>for</strong>mance physicals – high tear and elongation• Rapid cure at elevated temperatures• Can be post-cured, but post cure is not necessary to achieve desired physicalsThe easy processing and high per<strong>for</strong>mance physical properties of the Silbione ® LSRs makethem suitable <strong>for</strong> a broad range of applications including:• Fabrication of healthcare and medical devices, including less than 30 day implantation• Skin contact parts like masks and goggles• Infant care products• Overmolding (Silbione ® LSR 60)Silbione ® LSRs are supplied as kit-matched products. Parts A and B components aredesigned to be mixed in equal parts using standard liquid injection molding processingequipment and techniques. Airless mixing, metering and dispensing equipment arerecommended.• Kit matching, accurate measuring and complete mixing are essential factors in obtainingconsistent results.Cure is initiated by heating the mixed elastomer. Cure is dependent upon molding temperatureand part size.Special care must be taken to assure clean molds and a clean work area with no organicrubbers used on the same processing equipment.Traces of <strong>for</strong>eign materials can poison the catalyst and inhibit the cure. All metering and mixingequipment should be thoroughly cleaned. Polymer systems, which contain traces of amines,sulfur, nitrogen oxide, organotin compounds and carbon monoxide can interfere with the cure ofthis product and should be avoided.1 - 4

August 2008Silbione ® <strong>Liquid</strong> <strong>Silicone</strong> <strong>Rubbers</strong> <strong>for</strong> <strong>Healthcare</strong>(4330, 4340, 4340 FC, 4340 SL, 4350, 4360, 60, 4370)LimitationStorage andshelf lifeSafetyPackagingBluestar <strong>Silicone</strong>s supports the sales of these products to customers involved in manufacturingand assembling approved medical devices <strong>for</strong> less than 30 day implantation. The purchaserhas the sole responsibility to select a particular Bluestar <strong>Silicone</strong>s product and determine itsapplication suitability. The purchaser also has the sole responsibility to comply with allapplicable statutory, regulatory and industry requirements and standards <strong>for</strong> compatibility,extractability, testing, safety, efficacy and labeling.Silbione ® LSRs, when stored in original unopened packaging, at a temperature of 24°C (77°F),may be stored <strong>for</strong> 12 months from the date of manufacture. Beyond this date, Bluestar<strong>Silicone</strong>s no longer guarantees that the product meets the sales specifications.Please read the container labels <strong>for</strong> Silbione ® LSRs or consult the Material Safety Data Sheet(MSDS) be<strong>for</strong>e handling <strong>for</strong> safe use, physical and health hazard in<strong>for</strong>mation. The MSDS is notincluded with the product packaging, but can be obtained by contacting Bluestar <strong>Silicone</strong>s at866-474-6342 or consult your Bluestar <strong>Silicone</strong>s representative.Silbione ® LSRs are supplied in 36 kg (79.4 lb.) pail or 400 kg (881.8 lb.) drum kits. EUROPE NORTH AMERICA LATIN AMERICA ASIA PACIFICBluestar <strong>Silicone</strong>s France21 Avenue Georges PompidouF69486 Lyon Cedex 03FRANCETel. (33) 4 72 13 19 00Fax (33) 4 72 13 19 88Bluestar <strong>Silicone</strong>s USATwo Tower Center BoulevardSuite 1601East Brunswick, NJ 08816-1100United StatesTel. (1) 732 227 2060Fax (1) 732 249 7000Bluestar <strong>Silicone</strong>s Brazil Ltda.Av. Maria Coelho Aguiar, 215Bloco G -1º Andar05804-902 - São Paulo - SP -BrazilTel. (55) 11 3747 7887Fax (55) 11 3741 7718Bluestar <strong>Silicone</strong>s Hong KongTrading Co. Ltd.Unit C, 18/F Manulife Tower169 Electric RoadNorth Point-Hong KongTel. (852) 3106 8200Fax (852) 2979 0241Warning to the usersThe in<strong>for</strong>mation contained in this document is given in good faith based on our current knowledge. It is only an indication and is in no way binding, particularly as regardsinfringement of or prejudice to third party rights through the use of our products. BLUESTAR SILICONES guarantees that its products comply with its sales specifications.This in<strong>for</strong>mation must on no account be used as a substitute <strong>for</strong> necessary prior tests which alone can ensure that a product is suitable <strong>for</strong> given use. Users are responsible<strong>for</strong> ensuring compliance with local legislation and <strong>for</strong> obtaining the necessary certifications and authorizations. Users are requested to check that they are in possession ofthe latest version of this document and BLUESTAR SILICONES is at their disposal to supply any additional in<strong>for</strong>mation.Silbione ® is a registered Trademark of BLUESTAR SILICONES2 - 4

August 2008Silbione ® <strong>Liquid</strong> <strong>Silicone</strong> <strong>Rubbers</strong> <strong>for</strong> <strong>Healthcare</strong>(4330, 4340, 4340 FC, 4340 SL, 4350, 4360, 60, 4370)Table 1: TYPICAL PROPERTIESAs SuppliedCTMLSR4330LSR4340(1) Slab 6” x 6” x 0.07”Please note: The typical properties listed in this bulletin are not intended <strong>for</strong> use in preparing specifications <strong>for</strong> any particular application of Silbione ® silicone materials.Please contact our Technical Service Department <strong>for</strong> assistance in writing specifications.LSR4340 FCLSR4340 SLAppearance TP 038 clear clear clear opaque clear clear clear clearViscosityShear rate 1/sec, Pa.s 550 1,800 1,800 1,800 2000 2000Shear rate 10/sec, Pa.s 270 650 650 650 700 700Extrusion Rate, g/min TP 001 105 90 90 100 80 75 100 70Specific Gravity, g/cm TP 013 1.11 1.12 1.12 1.10 1.12 1.13 1.13 1.14Press Cured (1) 5 min.,177 ° C2 - 4ASTMLSR4330LSR4340LSR4340 FCLSR4340 SLHardness, Shore AD 2240 30 40 40 34 50 60 59 68Tensile Strength, psi (N/mm 2 )D 412 1,400 (9.7) 1230 (8.5) 1230 (8.5) 942 (6.5) 1,225 (8.4) 1,300 (9.0) 1380 (9.5) 1300 (9.0)Compression Set D395B 35 35 35 35 50Elongation,% D 412 790 615 615 580 570 480 415 450Tear Strength, Ppi (N/mm) D 624, Die B 195 (34) 250 (43) 250 (43) 237 (40) 265 (45) 250 (43) 190 (33) 240 (41)Modulus,100%, psi (N/mm2) D 412 190 200 200 200 (1.4) 350 425 360 (2.5) 530Resiliency, % D 2632 62 62 62 56 63 63 63Post Cured (1) 4 hrs.,200°CASTMLSR4330LSR4340LSR4340 FCLSR4340 SLHardness, Shore A 31 40 40 50 61 70Tensile Strength,psi (N/mm 2 )D 2240 1,350 (9.3) 1250 (8.6) 1250 (8.6) 1,275 (8.8) 1,250 (8.6) 1200 (8.3)Compression Set D395B 10 10 10 12 25Elongation,% D 412 750 605 605 530 430 400Tear Strength, Ppi (N/mm) D 624, Die B 205(36) 285 (50) 285 (50) 290 (51) 235 (41) 200 (35.1)Modulus,100%, psi (N/mm 2 )D 412 200 (1.4) 200 (1.4) 200 (1.4) 340 (2.3) 400 (2.8) 580 (4.0)Resiliency, % D 2632 60 52 52 57 60 60LSR4350LSR4350LSR4350LSR4360LSR4360LSR4360LSR60LSR60LSR60LSR4370LSR4370LSR43703 - 4

August 2008Silbione ® <strong>Liquid</strong> <strong>Silicone</strong> <strong>Rubbers</strong> <strong>for</strong> <strong>Healthcare</strong>(4330, 4340, 4340 FC, 4340 SL, 4350, 4360, 60, 4370)Table 2: BIOCOMPATIBILITY DATALSR4330Biocompatibility Tests (1)(2)LSR LSR LSR4340 4340 FC 4340 SL (3)LSR4350LSR4360Cytotoxicity ● ● ● ○ ● ● ● ●Skin Sensitization ● ● ○ ○ ○ ○ ● ●Intracutaneous Toxicity ● ● ○ ○ ● ○ ● ●Systemic Toxicity ● ● ○ ○ ● ○ ● ●Mutagenicity ● ● ○ ○ ● ○ ● ●Hemolysis ● ○Mucosal IrritationPyrogenicity ● ○ ●7-Day Implant ● ● ○28-Day Implant ● ○ ○90-Day Implant ●USP Class VI ● ● ○ ○ ● ○ MAF ●FDA Master File (MAF) ●LSR60LSR4370LSR4330LSR4340Extraction Tests (2)LSR4340 FCLSR4340 SL (3)LSR4350FDA 21 CFR 177.2600 ● ○ ● ○FDA 7117.11 Nitrosamines ● ○ ●LSR4360LSR60LSR4370See note(4)○● = Indicates test per<strong>for</strong>med on the material, successfully passed○ = Indicates test not per<strong>for</strong>med on the material, however, it is substantially equivalent to another tested Bluestar <strong>Silicone</strong>s LSR(1) - The biocompatibility testing listed addresses the categories of evaluation specified in ISO 10993 <strong>for</strong> device use of less than 30 days duration.(2) - Tests conducted on final product (A+B)(3) - Equivalent to LSR 4340 with a healthcare grade self lubricating additive(4) - Supported by testing meeting European Pharmacopoeia section 3.1.9 hexane extraction4 - 4