MagicWave 4000 / 5000 TransTig 4000 / 5000 - Ambitex

MagicWave 4000 / 5000 TransTig 4000 / 5000 - Ambitex

MagicWave 4000 / 5000 TransTig 4000 / 5000 - Ambitex

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

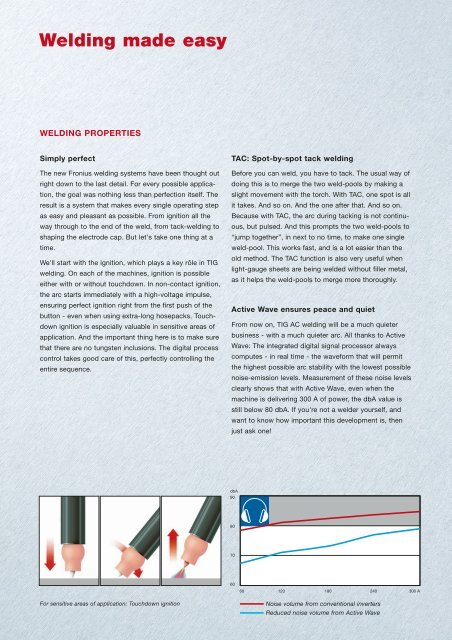

Welding made easyWELDING PROPERTIESSimply perfectThe new Fronius welding systems have been thought outright down to the last detail. For every possible application,the goal was nothing less than perfection itself. Theresult is a system that makes every single operating stepas easy and pleasant as possible. From ignition all theway through to the end of the weld, from tack-welding toshaping the electrode cap. But let's take one thing at atime.We'll start with the ignition, which plays a key rôle in TIGwelding. On each of the machines, ignition is possibleeither with or without touchdown. In non-contact ignition,the arc starts immediately with a high-voltage impulse,ensuring perfect ignition right from the first push of thebutton - even when using extra-long hosepacks. Touchdownignition is especially valuable in sensitive areas ofapplication. And the important thing here is to make surethat there are no tungsten inclusions. The digital processcontrol takes good care of this, perfectly controlling theentire sequence.TAC: Spot-by-spot tack weldingBefore you can weld, you have to tack. The usual way ofdoing this is to merge the two weld-pools by making aslight movement with the torch. With TAC, one spot is allit takes. And so on. And the one after that. And so on.Because with TAC, the arc during tacking is not continuous,but pulsed. And this prompts the two weld-pools to“jump together”, in next to no time, to make one singleweld-pool. This works fast, and is a lot easier than theold method. The TAC function is also very useful whenlight-gauge sheets are being welded without filler metal,as it helps the weld-pools to merge more thoroughly.Active Wave ensures peace and quietFrom now on, TIG AC welding will be a much quieterbusiness - with a much quieter arc. All thanks to ActiveWave: The integrated digital signal processor alwayscomputes - in real time - the waveform that will permitthe highest possible arc stability with the lowest possiblenoise-emission levels. Measurement of these noise levelsclearly shows that with Active Wave, even when themachine is delivering 300 A of power, the dbA value isstill below 80 dbA. If you're not a welder yourself, andwant to know how important this development is, thenjust ask one!dbA9080706060 120 180 240 300 AFor sensitive areas of application: Touchdown ignitionNoise volume from conventional invertersReduced noise volume from Active Wave