Leaf Chain

Leaf Chain

Leaf Chain

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

U.S. TSUBAKI LEAF CHAINA - DRIVE CHAINS<strong>Leaf</strong> <strong>Chain</strong><strong>Leaf</strong> chains generally have greater tensile strength thanroller chains, and run over sheaves rather than sprockets.They are most often used as counterweight chains formachine tools, elevator and oven doors, fork lift truck masts,spinning frames and similar lifting or balancing applications.BL series can, in most instances, replace the older AL series<strong>Leaf</strong> chains; consult U.S. Tsubaki for interchangeinformation.These chains are supplied with male or female terminationsto allow addition of various clevises as desired.A-63

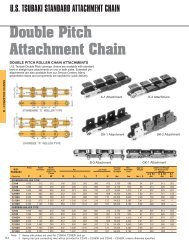

AL SeriesNew applications should use BL serieschain. AL series was removed from theA.N.S.I. B29.8 <strong>Leaf</strong> chain standard in 1975.A - DRIVE CHAINSU.S.TSUBAKIPitch Lacing Min. Hole Approx.Tensile Pin Link Plate Dia. WeightStrength (min.) lbs./ft.lbs.<strong>Chain</strong> No. P D L T H SAL422.5002x2 3,700 .156 .331 .060 .409AL444.5004x4 7,500 .156 .585 .060 .409AL466.5006x6 11,200 .156 .839 .060 .409AL522.6252x2 6,200 .200 .427 .080 .512AL544.6254x4 12,300 .200 .762 .080 .512AL566.6256x6 18,500 .200 1.094 .080 .512AL622.7502x2 8,600 .234 .498 .094 .614AL644.7504x4 17,200 .234 .888 .094 .614AL666.7506x6 25,800 .234 1.278 .094 .614AL8221.0002x2 14,600 .311 .644 .125 .819AL8441.0004x4 29,100 .311 1.173 .125 .819AL8661.0006x6 43,600 .311 1.701 .125 .819AL1022 1.2502x2 22,000 .373 .789 .156 1.024AL1044 1.2504x4 44,000 .373 1.445 .156 1.024AL1066 1.2506x6 66,000 .373 2.098 .156 1.024AL1222 1.5002x2 31,700 .437 .953 .187 1.228AL1244 1.5004x4 63,400 .437 1.732 .187 1.228AL1266 1.5006x6 95,000 .437 2.514 .187 1.228AL1444 1.7504x4 83,600 .500 2.020 .219 1.433AL1466 1.7506x6 125,400 .500 2.935 .219 1.433AL1644 2.0004x4 105,800 .562 2.285 .250 1.638AL1666 2.0006x6 158,000 .562 3.325 .250 1.638.1578.1578.1578.2019.2019.2019.2362.2362.2362.3138.3138.3138.3768.3768.3768.4386.4386.4386.5016.5016.5638.5638.25.50.74.42.821.21.581.151.701.012.002.971.803.565.312.394.757.076.9510.188.7013.00U.S.TSUBAKINon-Standard <strong>Chain</strong>Pitch Lacing Min. Hole Approx.Tensile Pin Link Plate Dia. WeightStrength (min.) lbs./ft.lbs.<strong>Chain</strong> No. P D L T H SBL532 (6H-5) .6253x2 7,000 .187 .583 .094 .590 .189NOTE: BL532 is available only as a replacement chain and should not be specified for new applications or designs..79A-64

U.S. TSUBAKI LEAF CHAINA-65A - DRIVE CHAINSBL SeriesPitch Lacing Min. ANSI Hole Approx.Tensile Min. Pin Link Plate Dia. WeightStrength Tensile (min.) lbs./ft.lbs.Strength<strong>Chain</strong> No.Plbs.D L T H S.46.56.76.861.111.32.72.851.141.271.611.881.131.371.902.142.693.181.742.152.983.394.255.072.533.154.405.036.247.503.254.396.116.988.079.804.916.097.618.7112.1015.136.618.1711.3912.7516.1919.31.2019.2019.2019.2019.2019.2019.2362.2362.2362.2362.2362.2362.3138.3138.3138.3138.3138.3138.3768.3768.3768.3768.3768.3768.4386.4386.4386.4386.4386.4386.5016.5016.5016.5016.5016.5016.5638.5638.5638.5638.5638.5638.6886.6886.6886.6886.6886.6886.472.472.472.472.472.472.591.591.591.591.591.591.713.713.713.713.713.713.949.949.949.949.949.9491.1851.1851.1851.1851.1851.1851.4251.4251.4251.4251.4251.4251.6611.6611.6611.6611.6611.6611.8981.8981.8981.8981.8981.898.080.080.080.080.080.080.094.094.094.094.094.094.125.125.125.125.125.125.156.156.156.156.156.156.187.187.187.187.187.187.219.219.219.219.219.219.250.250.250.250.250.250.281.281.281.281.281.281.427.510.677.764.9291.094.498.594.791.8881.0831.278.645.7781.0411.1731.4371.701.794.9531.2811.4531.7722.098.9441.1381.5301.7082.1142.5141.1041.3351.7912.0202.4782.9361.2451.5042.0242.2852.8053.3251.4011.7032.2992.5933.1913.785.200.200.200.200.200.200.234.234.234.234.234.234.312.312.312.312.312.312.375.375.375.375.375.375.437.437.437.437.437.437.500.500.500.500.500.500.562.562.562.562.562.562.687.687.687.687.687.6875,0005,0007,50010,00010,00015,0007,5007,50011,00015,00015,00022,50011,00011,00017,00022,00022,00033,00019,00019,00029,00038,00038,00057,00026,00026,00041,00052,00052,00078,00034,00034,00055,00068,00068,000102,00043,00043,00071,00086,00086,000130,00065,00065,00099,000130,000130,000195,03097,50097,500146,000195,000195,000292,5005,3005,3007,90010,60010,60015,6008,8008,80013,20017,60017,60026,40014,30014,30021,50028,50028,50043,00023,10023,10034,80046,20046,20069,50031,70031,70048,50063,40063,40095,20041,80041,80067,20083,60083,600125,60052,90052,90087,000105,800105,800158,70079,30079,300124,500158,600158,600238,300119,000119,000178,800238,500238,500357,8002x22x33x44x44x66x62x22x33x44x44x66x62x22x33x44x44x66x62x22x33x44x44x66x62x22x33x44x44x66x62x22x33x44x44x66x62x22x33x44x44x66x62x22x33x44x44x66x62x22x33x44x44x66x6.500.500.500.500.500.500.625.625.625.625.625.625.750.750.750.750.750.7501.0001.0001.0001.0001.0001.0001.2501.2501.2501.2501.2501.2501.5001.5001.5001.5001.5001.5001.7501.7501.7501.7501.7501.7502.0002.0002.0002.0002.0002.0002.5002.5002.5002.5002.5002.500BL422BL423BL434BL444BL446BL466BL522BL523BL534BL544BL546BL566BL622BL623BL634BL644BL646BL666BL822BL823BL834BL844BL846BL866BL1022BL1023BL1034BL1044BL1046BL1066BL1222BL1223BL1234BL1244BL1246BL1266BL1422BL1423BL1434BL1444BL1446BL1466BL1622BL1623BL1634BL1644BL1646BL1666BL2022BL2023BL2034BL2044BL2046BL2066CONSULT U.S. TSUBAKI ENGINEERINGU.S.TSUBAKI

U.S. TSUBAKI LEAF CHAINA - DRIVE CHAINSTYPICAL APPLICATIONS[A][B]For counterweights of heavy machine tools — planers,multi-spindle drills, etc.For increasing the travel distance on hydraulic lifts.[C][D]For suspension of a counterweight for the arm of drillsor similar machine tool elements.For transmitting reciprocating motion or lift.A-67

A - DRIVE CHAINSGENERAL CAUTIONS1. Use lengths of factory assembled chain. Do not build lengths from individual components.2. Do not attempt to rework damaged chains by replacing only the components obviouslyfaulty. The entire chain may be compromised and should be discarded.3. Never electroplate assembled <strong>Leaf</strong> chain or its components. Plating could result in failurefrom hydrogen embrittlement.4. Welding should not be performed on any chain or component. Welding spatter should neverbe allowed to come in contact with chain or components.5. <strong>Leaf</strong> chains are manufactured exclusively from heat treated steels and, therefore, must notbe annealed. If heating a chain with a cutting torch is absolutely necessary for removal, thechain should not be reused.6. Joining chains together should only be done by the chain manufacturer.7. The Minimum Ultimate Strength of a chain means the minimum load at which it will breakwhen subjected to a destructive tensile test. It does not mean working load.8. <strong>Chain</strong>s from different manufacturers should not be used in the same application.A-68