Print Process Management System - BST Sayona Automations

Print Process Management System - BST Sayona Automations

Print Process Management System - BST Sayona Automations

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

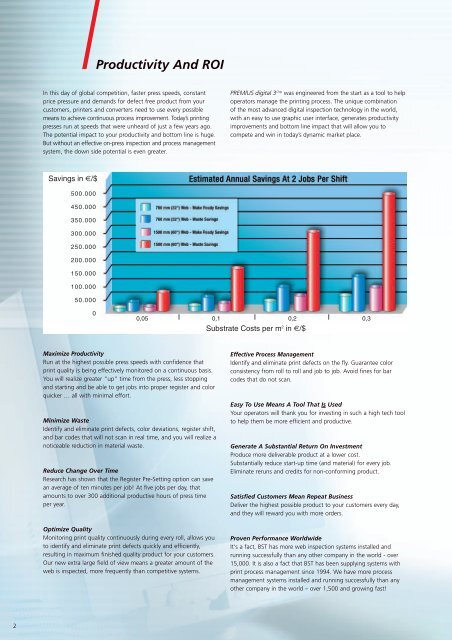

Productivity And ROIIn this day of global competition, faster press speeds, constantprice pressure and demands for defect free product from yourcustomers, printers and converters need to use every possiblemeans to achieve continuous process improvement. Today’s printingpresses run at speeds that were unheard of just a few years ago.The potential impact to your productivity and bottom line is huge.But without an effective on-press inspection and process managementsystem, the down side potential is even greater.PREMIUS digital 3 Chip was engineered from the start as a tool to helpoperators manage the printing process. The unique combinationof the most advanced digital inspection technology in the world,with an easy to use graphic user interface, generates productivityimprovements and bottom line impact that will allow you tocompete and win in today’s dynamic market place.Savings in €/$500.000450.000350.000300.000250.000200.000150.000100.00050.0000I I I0,05 0,1 0,2 0,3Substrate Costs per m 2 in €/$Maximize ProductivityRun at the highest possible press speeds with confidence thatprint quality is being effectively monitored on a continuous basis.You will realize greater “up” time from the press, less stoppingand starting and be able to get jobs into proper register and colorquicker … all with minimal effort.Minimize WasteIdentify and eliminate print defects, color deviations, register shift,and bar codes that will not scan in real time, and you will realize anoticeable reduction in material waste.Reduce Change Over TimeResearch has shown that the Register Pre-Setting option can savean average of ten minutes per job! At five jobs per day, thatamounts to over 300 additional productive hours of press timeper year.Optimize QualityMonitoring print quality continuously during every roll, allows youto identify and eliminate print defects quickly and efficiently,resulting in maximum finished quality product for your customers.Our new extra large field of view means a greater amount of theweb is inspected, more frequently than competitive systems.Effective <strong>Process</strong> <strong>Management</strong>Identify and eliminate print defects on the fly. Guarantee colorconsistency from roll to roll and job to job. Avoid fines for barcodes that do not scan.Easy To Use Means A Tool That Is UsedYour operators will thank you for investing in such a high tech toolto help them be more efficient and productive.Generate A Substantial Return On InvestmentProduce more deliverable product at a lower cost.Substantially reduce start-up time (and material) for every job.Eliminate reruns and credits for non-conforming product.Satisfied Customers Mean Repeat BusinessDeliver the highest possible product to your customers every day,and they will reward you with more orders.Proven Performance WorldwideIt‘s a fact, <strong>BST</strong> has more web inspection systems installed andrunning successfully than any other company in the world - over15,000. It is also a fact that <strong>BST</strong> has been supplying systems withprint process management since 1994. We have more processmanagement systems installed and running successfully than anyother company in the world – over 1,500 and growing fast!2