Key strategies central to overcoming poor API solubility - Almac

Key strategies central to overcoming poor API solubility - Almac

Key strategies central to overcoming poor API solubility - Almac

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

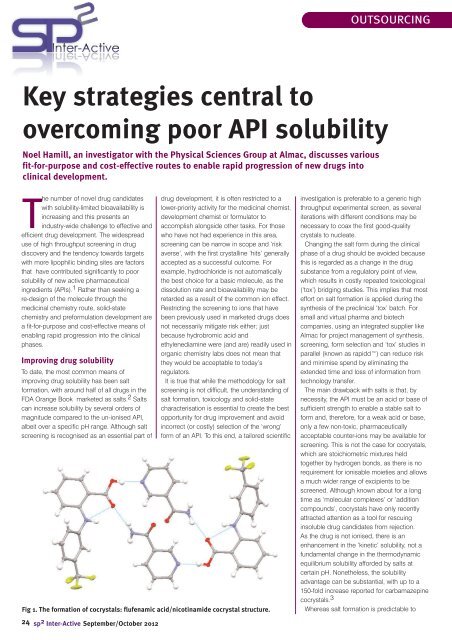

OUTSOURCING<strong>Key</strong> <strong>strategies</strong> <strong>central</strong> <strong>to</strong><strong>overcoming</strong> <strong>poor</strong> <strong>API</strong> <strong>solubility</strong>Noel Hamill, an investiga<strong>to</strong>r with the Physical Sciences Group at <strong>Almac</strong>, discusses variousfit-for-purpose and cost-effective routes <strong>to</strong> enable rapid progression of new drugs in<strong>to</strong>clinical development.The number of novel drug candidateswith <strong>solubility</strong>-limited bioavailability isincreasing and this presents anindustry-wide challenge <strong>to</strong> effective andefficient drug development. The widespreaduse of high throughput screening in drugdiscovery and the tendency <strong>to</strong>wards targetswith more lipophilic binding sites are fac<strong>to</strong>rsthat have contributed significantly <strong>to</strong> <strong>poor</strong><strong>solubility</strong> of new active pharmaceuticalingredients (<strong>API</strong>s). 1 Rather than seeking are-design of the molecule through themedicinal chemistry route, solid-statechemistry and preformulation development area fit-for-purpose and cost-effective means ofenabling rapid progression in<strong>to</strong> the clinicalphases.Improving drug <strong>solubility</strong>To date, the most common means ofimproving drug <strong>solubility</strong> has been saltformation, with around half of all drugs in theFDA Orange Book marketed as salts. 2 Saltscan increase <strong>solubility</strong> by several orders ofmagnitude compared <strong>to</strong> the un-ionised <strong>API</strong>,albeit over a specific pH range. Although saltscreening is recognised as an essential part of24sp 2 Inter-Active September/Oc<strong>to</strong>ber 2012drug development, it is often restricted <strong>to</strong> alower-priority activity for the medicinal chemist,development chemist or formula<strong>to</strong>r <strong>to</strong>accomplish alongside other tasks. For thosewho have not had experience in this area,screening can be narrow in scope and ‘riskaverse’, with the first crystalline ‘hits’ generallyaccepted as a successful outcome. Forexample, hydrochloride is not au<strong>to</strong>maticallythe best choice for a basic molecule, as thedissolution rate and bioavailability may beretarded as a result of the common ion effect.Restricting the screening <strong>to</strong> ions that havebeen previously used in marketed drugs doesnot necessarily mitigate risk either; justbecause hydrobromic acid andethylenediamine were (and are) readily used inorganic chemistry labs does not mean thatthey would be acceptable <strong>to</strong> <strong>to</strong>day’sregula<strong>to</strong>rs.It is true that while the methodology for saltscreening is not difficult, the understanding ofsalt formation, <strong>to</strong>xicology and solid-statecharacterisation is essential <strong>to</strong> create the bes<strong>to</strong>pportunity for drug improvement and avoidincorrect (or costly) selection of the ‘wrong’form of an <strong>API</strong>. To this end, a tailored scientificFig 1. The formation of cocrystals: flufenamic acid/nicotinamide cocrystal structure.investigation is preferable <strong>to</strong> a generic highthroughput experimental screen, as severaliterations with different conditions may benecessary <strong>to</strong> coax the first good-qualitycrystals <strong>to</strong> nucleate.Changing the salt form during the clinicalphase of a drug should be avoided becausethis is regarded as a change in the drugsubstance from a regula<strong>to</strong>ry point of view,which results in costly repeated <strong>to</strong>xicological(‘<strong>to</strong>x’) bridging studies. This implies that mosteffort on salt formation is applied during thesynthesis of the preclinical ‘<strong>to</strong>x’ batch. Forsmall and virtual pharma and biotechcompanies, using an integrated supplier like<strong>Almac</strong> for project management of synthesis,screening, form selection and ‘<strong>to</strong>x’ studies inparallel (known as rapidd) can reduce riskand minimise spend by eliminating theextended time and loss of information fromtechnology transfer.The main drawback with salts is that, bynecessity, the <strong>API</strong> must be an acid or base ofsufficient strength <strong>to</strong> enable a stable salt <strong>to</strong>form and, therefore, for a weak acid or base,only a few non-<strong>to</strong>xic, pharmaceuticallyacceptable counter-ions may be available forscreening. This is not the case for cocrystals,which are s<strong>to</strong>ichiometric mixtures held<strong>to</strong>gether by hydrogen bonds, as there is norequirement for ionisable moieties and allowsa much wider range of excipients <strong>to</strong> bescreened. Although known about for a longtime as ‘molecular complexes’ or ‘additioncompounds’, cocrystals have only recentlyattracted attention as a <strong>to</strong>ol for rescuinginsoluble drug candidates from rejection.As the drug is not ionised, there is anenhancement in the ‘kinetic’ <strong>solubility</strong>, not afundamental change in the thermodynamicequilibrium <strong>solubility</strong> afforded by salts atcertain pH. Nonetheless, the <strong>solubility</strong>advantage can be substantial, with up <strong>to</strong> a150-fold increase reported for carbamazepinecocrystals. 3Whereas salt formation is predictable <strong>to</strong>

OUTSOURCINGsome extent from pKa data, cocrystals arenot. Formation can be inferred from knownfunctional group interactions, such as Etter’srules, 4 but these predictions are onlysuccessful in an estimated 30 per cent ofcases. 5 Even when observed, the propertiesof the resulting cocrystal can elude prediction.For example, in our recent study on fivestructurally related non-steroidal antiinflamma<strong>to</strong>rydrugs (NSAIDs), 6 four formedcocrystals with nicotinamide (example inFigure 1), but the <strong>solubility</strong> and stability of theresulting cocrystals were remarkably different.As with salts, the challenge is not so much infinding cocrystals, but development of anoperable scale-up method. Control of purityand particle size usually requires a solutionbasedmethod, for which knowledge ofternary phase diagrams and in situcrystallisation development <strong>to</strong>ols, such asFBRM and PVM (Fig 2) become invaluable inthis regard.Although most commonly employed formodifying aqueous <strong>solubility</strong>, salts andcocrystals modify a range of other properties,such as hygroscopicity, chemical stability,dissolution rate, crystallinity and physicalstability, making them an attractive means ofgenerating intellectual property.Amorphous phasesIt is worth noting that the level of <strong>solubility</strong>enhancement through the use of crystallinesalt and cocrystal forms may not be sufficientfor large insoluble and/or lipophilic (alsoknown as ‘brick dust’ and ‘grease ball’)molecules. In such cases, amorphous phasesmay be more advantageous. The <strong>solubility</strong>enhancement possible with amorphousmaterial has been reported as 10 <strong>to</strong> morethan 1000 times greater than crystalline formsin some cases, 7 with 2- <strong>to</strong> 10-fold increasesmuch more common in practice. However, asthey are inherently more chemically andphysically unstable than crystalline forms,amorphous formulations require increasedinvestment <strong>to</strong> develop and stabilise. As aresult of this need for stabilisation withexcipients, amorphous dispersions aretraditionally the reserve of formulationspecialists in late-phase development.However, this huge <strong>solubility</strong> enhancementcan also be used <strong>to</strong> great benefit duringpreclinical studies. Due <strong>to</strong> the improvementsin targeted drug therapies, it is becomingincreasingly difficult <strong>to</strong> demonstrate a <strong>to</strong>xiceffect during ascending-dose animal studies.This requires higher dosing and bioavailabilityquickly becomes <strong>solubility</strong>-limited due <strong>to</strong> theincreasingly lipophilic character of newchemical entities. In many cases for salts,cocrystals and amorphous formulations, the<strong>solubility</strong> enhancement is short-lived ‘kinetic’<strong>solubility</strong>, before a more stable, less solubleform precipitates in vivo. The challenge <strong>to</strong>formula<strong>to</strong>rs is <strong>to</strong> sustain the enhancementlong enough <strong>to</strong> maximise bioavailability.Screening platform for amorphoussolid dispersions<strong>Almac</strong> have developed a screening platformfor amorphous solid dispersions, formufastTMSD, which assesses the interaction ofstabilising polymer and <strong>API</strong> in the solutionstate. Stronger interactions have been linkedwith stability in the solid dispersion, 8 andprecipitation inhibition. 9 Variations on thisplatform have also been successfullyemployed for screening excipients for oraland intravenous formulations, formufastPO & IV, <strong>to</strong> provide a scientific rationalapproach <strong>to</strong> early-phase formulationdevelopment. The his<strong>to</strong>rical approach wasstepwise, with simple formulationsincrementally changed until a ‘hit’ wasachieved, much in the same way as with saltscreening, as discussed earlier. Thismethodology is more likely <strong>to</strong> miss the bestpossible formulation and does not generatethe deep understanding that can streamlinelater-phase (clinical) formulation development,leading <strong>to</strong> calls for a more systematicapproach. 10The formufast oral and IV screens are arapid, low-cost means of systematicallyassessing many excipients, as combinationsin different proportions or by varying the orderof addition. From these small-scale tests, arational design for preclinical formulation canbe identified from kinetic <strong>solubility</strong> andprecipitation inhibition in aqueous media orlipidic vehicles.Of course, there are always difficult <strong>API</strong>s thatmay not form stable amorphous dispersions,or where enhancement from salts/cocrystalsis still inadequate. Since <strong>poor</strong> <strong>solubility</strong> alsoimparts a <strong>poor</strong> dissolution rate, this impliesthat the bioavailability of some <strong>API</strong>s isreduced merely because they are notdissolving fast enough in vivo. The simplestway <strong>to</strong> increase the rate is by increasingsurface area through particle size reduction.The micronisation of drugs is nowcommonplace, with jet milling and spraydrying routinely carried out at manufacturerssuch as <strong>Almac</strong>. Micronisation increasesdissolution rate but tends not <strong>to</strong> influence theequilibrium <strong>solubility</strong> of a drug, 11 except bydisordering the crystallinity of the particlesurface. Since surfaces have a higher freeenergy (and higher <strong>solubility</strong>) compared <strong>to</strong> thebulk, particles have <strong>to</strong> be sub-micron in sizebefore this phenomenon can be exploited.This has led <strong>to</strong> the rise of nanosuspensionsFig 2: In situ PVM (particle vision &measurement) image of a crystal suspension.for drug delivery in the past two decades. 12These sub-micron colloidal dispersions ofdrug particles are stabilised by surfactantsand enable increased bioavailability, such asthe 16-fold increase reported for Danazol. 13Some preparation techniques remain underpatent protection, such is the level ofcommercial interest. However, researchsamples can be successfully scaled downand tested,14 prior <strong>to</strong> committing <strong>to</strong> thesetechnologies at full scale.In summaryAs an integrated service provider, <strong>Almac</strong> canemploy the full arsenal of <strong>solubility</strong>enhancement <strong>to</strong>ols and brings a wealth ofexperience in synthetic chemistry, solid-stateservices and formulation <strong>to</strong> provide clientswith workable cost-effective solutions, andallow the best candidates <strong>to</strong> progress in<strong>to</strong> theclinical phase rapidly and with minimal spend.<strong>Almac</strong>’s Physical Sciences group offers thecomplete range of screening, development,analytical and legal support services relating<strong>to</strong> solid forms in drug substance and drugproduct, uniting the company’s expertise inprocess chemistry, operations and formulation<strong>to</strong> provide an integrated, synergistic solution<strong>to</strong> our clients’ needs.For further information andreferences contact the author:Dr Noel HamillInvestiga<strong>to</strong>r - Physical Sciences<strong>API</strong> Services & Chemical Development<strong>Almac</strong>20 Seagoe Industrial EstateCraigavon BT63 5QD, United KingdomTel: +44 28 3833 2200Fax: +44 28 3833 2299Email: pharmaservices@almacgroup.comWeb: www.almacgroup.comSeptember/Oc<strong>to</strong>ber 2012 sp 2 Inter-Active25