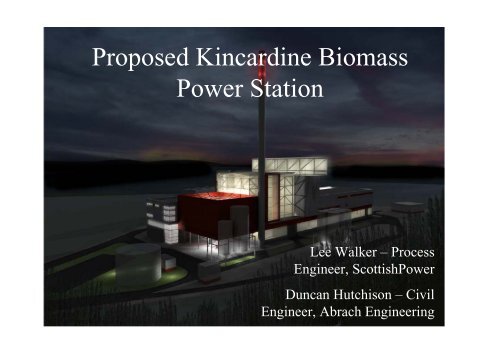

Proposed Kincardine Biomass Power Station presentation

Proposed Kincardine Biomass Power Station presentation

Proposed Kincardine Biomass Power Station presentation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Project Development• Pressure to cease WDF co-firing at Longannet as soon aspracticable led to the start of the Civil Enabling Works(CEW) to maintain programme ahead of project reviewbeing completed• CEW began in Sept 2008, at a cost of circa £3M• Development of <strong>Power</strong> <strong>Station</strong> passed to CommercialDevelopment’s Construction team at Longannet• Re-tendering process (on a multi-contract basis)commenced with a variety of Boiler, Steam Turbine andFuel Handling Equipment manufacturers & suppliers

<strong>Biomass</strong> CEW• Historical use of the Site – a MunitionsStore was constructed on the site in early1939, which spanned across the LongannetCoal Plant and the <strong>Biomass</strong> site.• Munitions surveys undertaken for previousGI, needed to be completed early in theCivil Enabling Works.

<strong>Kincardine</strong> Munitions StoreCEW Upfill

Munitions Store / CEW LayoutFoundations ofpreviously demolishedbunkerConcrete Roadsuncovered duringCEWConcrete Road inscope3 Bunkers inscope

CEW Overview• Demolition of existing structures• Installation of band drains to promotesettlement• Placing of Pulverised Fuel Ash/FurnaceBottom Ash upfill (circa 173k tonnes)• Construction of Site Access Road

CEW Band Drains• Installation of band drainsto promote consolidationof ‘toothpaste-like’sediments and to speed upsettlement• Geotextile material boundto plastic corrugatedsection

• Placement/reuse of ashfrom Longannet. Use ofinternal site roads only.• Initial design requiredPFA. Availability ofmaterial was low, due toLongannet operations.• Testing undertaken toconfirm the feasibility ofusing FBA, containingWDF, as this could not beused in concrete productmanufacture.CEW Ash Upfill

Future Legislative Activites• Existing PPC Permit for Longannet covers the<strong>Biomass</strong> site.• PPC Permits are applicable to Process Plant.• Scottish<strong>Power</strong> intend to amend the LongannetPPC to remove Construction site from the Permit.• If this is not done, then noise limits etc from thePPC Permit will be enforced on the Constructionsite.• New permit required for <strong>Kincardine</strong> BPS prior tocommissioning.

WDF Fuel Supplies• WDF – circa 50kTesourced from SMWat Daldowie(Glasgow)• WDF granulesproduced by dryingsewage sludge in apurpose built plant(from 3% to 90% drysolids)£1

WDF Fuel Supplies• Drying plant operated under PPC Permit to monitorand control emissions to air, land, water• Plant also accepts sewagecake from outwithcatchment• Low moisture contentrequired for co-firing• Large rotary drum dryersused to give uniformproduct sizeFilter PressesCentrifuges&WDF Dryers

WDF Fuel Supplies• WDF composition is monitored against an agreedfuel specification to maintain emission limits postcombustion• WDF has health and safety issues which must bemanaged through design:– Dust exposure, dust explosion, fire etc.• WDF transported to new biomass plant inenclosed road tankers, as at present for Longannet.

Waste Wood Fuel Supplies• Waste Wood – only certain types (subset of WRAPcategories / German Ordinance categories)• Acceptable waste wood will include :– Telegraph poles– Sleepers– Demolition wood, MDF, chipboard, offcuts etc.– Pallets– Green forestry residues• Delivered to site pre-crushed via aggregating suppliers or asbulk timber direct from source• Can’t accept waste wood if it has a halogen content greaterthan 1% by mass

Wood Fuel ProcessingEddy Current SeparatorsSlow Speed CrusherCrane GrabMagnetic SeparatorsHand Sorting CabinBunker2 x TravellingCraneBoilerFeedChuteHigh Speed CrushersUnder/Oversize screen

Wood Fuel Processing

Boiler• 80MWt Fluidised Bed boiler raising steamACC

Steam/Water Cycle• STG Gross Output 25.5MWe• Rankine cycle – 32% gross efficiency• Impulse type condensing extraction typeturbine• Inlet steam conditions 490 o C and 83Bar(a)• Air Cooled Condenser• 3 stages of feedwater heating to improveefficiency

Steam/Water Cycle

Flue Gas Treatment• Combustion will produce Bottoms and Fly ash• Electrostatic Precipitator for clean ash capture• Sodium Bicarbonate addition to capture SO x• Activated Carbon added to capture heavy metals• Additional bag filter to capture FGT Residues andmeet Waste Incineration Directive dust emissionlimits• Continuous Emission Monitoring System (CEMS)used to measure emissions from stack

<strong>Proposed</strong> Contract Strategy• Engineering Procurement and Construction(EPC) contract with sister company (IEC)• EPC Turnkey solution reduces SP risk• Project cost +£100M• 4 large pre-agreed contracts (Boiler/FGT,Steam Turbine and Generator, WoodHandling and WDF Handling)• 30 – 40 smaller contracts.

Scottish<strong>Power</strong>’s Role• Monitoring of progress, performance andpayments of EPC Contractor• Review of EPC sub-contractors and workscopes• CDM Co-ordinator Role (sub-contracted to 3 rdParty)• Quality and Environmental Monitoring -including auditing• Health and Safety Monitoring (MethodStatements, Risk Assessments, Statistics etc)• Permitting (PPC, CAR, Planning etc.)• Liaison with Local Authority and Stakeholders

Scottish<strong>Power</strong>’s Role• On-site Engineering team to monitor design,construction, commissioning and testing:– Design Reviews– Hazard Reviews– Constructability Reviews– RAM Studies– FMECA Studies– Factory Acceptance Tests/Site Acceptance Tests– Witnessing of performance and acceptancetesting

Potential CHP Addition• Currently looking for heat loads (steam/hot water)• Potential usage on-site to replace fossil fuel• STG fitted with CHP extraction port, however CHP willnot be considered until a heat customer is identified• Increases overall plant efficiency• Electrical efficiency reduced• Hopefully considered Good Quality CHP by Government(CHPQA application pending)• Electricity qualifies for additional renewable energybenefits (2 ROCs/MWh)

Questions