2007-08

2007-08

2007-08

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

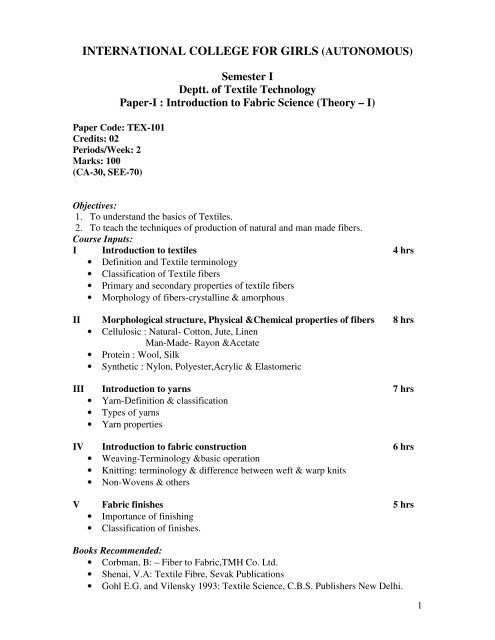

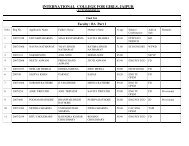

INTERNATIONAL COLLEGE FOR GIRLS (AUTONOMOUS)Paper Code: TEX-101Credits: 02Periods/Week: 2Marks: 100(CA-30, SEE-70)Semester IDeptt. of Textile TechnologyPaper-I : Introduction to Fabric Science (Theory – I)Objectives:1. To understand the basics of Textiles.2. To teach the techniques of production of natural and man made fibers.Course Inputs:I Introduction to textiles 4 hrs• Definition and Textile terminology• Classification of Textile fibers• Primary and secondary properties of textile fibers• Morphology of fibers-crystalline & amorphousII Morphological structure, Physical &Chemical properties of fibers 8 hrs• Cellulosic : Natural- Cotton, Jute, LinenMan-Made- Rayon &Acetate• Protein : Wool, Silk• Synthetic : Nylon, Polyester,Acrylic & ElastomericIII Introduction to yarns 7 hrs• Yarn-Definition & classification• Types of yarns• Yarn propertiesIV Introduction to fabric construction 6 hrs• Weaving-Terminology &basic operation• Knitting: terminology & difference between weft & warp knits• Non-Wovens & othersV Fabric finishes 5 hrs• Importance of finishing• Classification of finishes.Books Recommended:• Corbman, B: – Fiber to Fabric,TMH Co. Ltd.• Shenai, V.A: Textile Fibre, Sevak Publications• Gohl E.G. and Vilensky 1993: Textile Science, C.B.S. Publishers New Delhi.1

Paper Code: TEX -102Credits: 02Periods/Week: 2Marks: 100(CA-30, SEE-70)Textile TechnologyPaper-II : Introduction to Design (Theory – II)Objectives:1. To Create aesthetic sense through designingCourse Inputs:I Design 6 hrs• Structural : Woven & Knitted• Applied: Dyeing, Printing &embroideryIIBasics in design• Elements of Design• Principles of Design5 hrsIII Color perception and theories of color 5 hrsIV Color schemes 8 hrsV Introduction to motif, repeat & colour ways 6 hrsBooks Recommended:1. Gaur.J.,Textiles & Laundry, Research publications, New Delhi.2. Kadolph.J.S & Langford.L.A., Textiles,VIII ed.,1998,Prentice Hall, New Jersey.2

Paper Code: TEX -103Credits: 02Periods/Week: 3Marks: 100(CA-30, SEE-70)Textile TechnologyPaper-III : Textile Craft Lab (Practical –I)Objectives:1. To understand concept of design as related to textiles.2. To enhance awareness and appreciation of art and aesthetics through design.Course Input:• Preparation of various sample fromTie and Dye (10 Samples) using direct dyes• Identification of Fibers – Burning, Visual, Microscopic and Chemical• Collection of various types of yarns and fabrics• Experiment on thread count and balance of fabric25 hrs15 hrs05 hrs05 hrs3

Paper Code: TEX -201Credits: 02Periods/Week: 2Marks: 100(CA-30, SEE-70)Semester IITextile TechnologyPaper-I : Fabric Science(Theory – I)Objectives:1. To develop ability to create weaves.2. To enable students to understand and learn methods of developing fabric fromvarious fabric making techniques.Course Input:Unit I Yarn Making: Mechanical spinning• Chemical spinning: Dry, Wet, MeltUnit II• Yarn properties and their effect on fabrics• Yarn numbering system6 hrs6hrsUnit III5 hrs• Preparatory stages of weaving – winding, warping, drafting, drawing-in, tyeing in• Types of loom and their developments – Handloom, Powerlooms, Automaticloom, Shuttle less loom.Unit IV• Effects of color and design in weaving• Elements of woven design• Setting up of loom5 hrsUnit V8hrs• Construction of elementary weaves• Derivatives of Plain, Twill and satin/sateen weaves• Knitting – introduction, definition of knitting, difference of warp and weft-knits• Knitting machines• Non wovens- construction, properties & usageBooks Recommended:1. Grosicki, Z.J.: Watson’s Textile Design and Colour, Newness Butter Worth,London.2. Oelsner, G.H. A Handbook of Weaves: Dover Publishing Inc New York.3. Ajgaunkar, D.B: Knitting technology, Universal Publishing Comp., Mumbai.4. Gupta Sen: Weaving Calculation, D.B. Taraporawala Sons & Co. Private Ltd.,Bombay.5

Textile TechnologyPaper-II : Introduction to Dyeing & Finishing (Theory-II)Paper Code: TEX -202Credits: 02Periods/Week: 2Marks: 100(CA-30, SEE-70)Objectives:1. To understand basics of dyeing.2. To develop creative and technical skills through dyeing of fabric.Course Inputs:I Pre-treatments 6 hrs• Pretreatment of fabric before dyeing and printing cotton: scouring, bleaching,desizing, Wool: Scouring, Carbonising, Bleaching, Silk: Degumming, scouring &bleachingII Introduction to dyeing 6 hrs• Terminology and theory of dyeing• Classification of dyes• Clour fastness- wash, rub, light & perspiration.III Stages of dyeing 5 hrs• Fiber dyeing, yarn dyeing, fabric dyeing, garment dyeing – advantages anddisadvantages• Union and cross dyeing• Machines used in dyeing- fibers, yarns &fabric.IV Introduction to Finishing 7 hrs• Importance and Objectives of finishing• Classification of finishesV Functional finishes-Wrinkle resistant, water resistant, flame retardant, 7 hrssoil resistant, anti pilling & anti microbial.Mechanical finishes- Calendering, embossing, Napping, Shearing &FlockingBooks Recommended:1. Shenai, V.A. Technology of dyeing, Sevak Publications, Bombay2. Marsh J.T. Textile Science, B.I. Publications, Mumbai3. Marsh J.T., An Introduction to Textile Bleaching, B.I. Publications Mumbai4. Tortora, Phyllis G. Understanding Textile, McMillan Publishing & New York5. Gohl E.V. and Vilenskey L.D. Textile Science, C.B.S. Publishers New Delhi.6

Paper Code: TEX -203Credits: 02Periods/Week: 3Marks: 100(CA-30, SEE-70)Textile TechnologyPaper-III : Weaving Lab (Practical – I)Objectives:1. To understand the preparation of weaving.2. To develop ability to create weaves on looms.Course Inputs:1. Collection of of woven fabric samples and identification of weaves.10 hrs2. Fabric Analysis for design, repeat, draft and peg plan. 5 hrs3. Weaving – Setting of a simple loom and preparation of weaves on handloom10 hrs4. Preparation of Basic Weaves and their derivatives on loom. 20 hrs7

Paper Code: TEX -301Credits: 02Periods/Week: 2Marks: 100(CA-30, SEE-70)Semester IIITextile TechnologyPaper-I : Textile Traditions In India (Theory – I)Objectives:1. To acquaint the students with the country’s rich heritage.2. To study the important textile arts in their historical perspective, and impact ofmodernization and their contemporary status.Course Inputs:I Woven Textiles 8 hrs• Jamadani• Chanderi• Maheshwari• Brocades• BaluchariII Embroidered Textiles 6 hrs• Kashmir- kashida, kasuti• Phulkari• Kantha• ChikankariIII Printed Textiles 6 hrs• Bagh , Ajrak, Sanganeri• Madhubani• KalamkariIV Resist Dyed Textiles 4 hrs• Bhandej• Patola• IkatUnit V6 hrs• Applied Design and ornamentation: Embroidery, Dyeing, Painting and PrintingBooks Recommended:1. Donger Kery, R.S.: The Indian Saree, All India HandiCraft- Board, New Delhi.2. Brij Bhushan J: Costumes & Textiles of India, Taraporewalla Sons & Company,New Delhi.3. Akazi Roshan: Ancient Indian Costumes, New Delhi, Art Heritage9

Paper Code: TEX -302Credits: 02Periods/Week: 2Marks: 100(CA-30, SEE-70)Textile TechnologyPaper-II: Dyeing Technology (Theory – II)Objective:1. To understand concept of design as related to fabric through dyeing.2. To enhance awareness and appreciation of art and aesthetics through dyeing.Unit IChemistry and application of synthetic dyes on various types of fabric• Direct, Reactive, Vat, Sulphur, Azo• Acid, Basic• DisperseUnit IIDyeing of fabric with natural dyesUnit IIIConcept of color measurement- reflection, absorption, lightness& darkness10 hrs5 hrs5 hrsUnit IV5 hrsRole and function of - Auxillaries, Exhausting agents, Wetting agents, Carriers, pHregulates used in dyeingUnit V Legal and Environmental concern• Laws and Regulations• Mandatory and voluntary labeling program• Environmental issues, Environmental laws and regulations• Environmental health and safety• Effluent treatments, selection of dyes and auxillary5 hrsBooks Recommended:1. Kadolph Sara J, Langford Anna L.: Textiles Upper saddle River, New Jersey2. Gulrajani M.L. and Gupta D: Natural dyes and their application to textiles, IITDelhi.3. Shenai V.A.: Chemistry of Dyes and Principles of Dyeing, Sevak PrakashanMumbai.10

Paper Code: TEX -303Credits: 02Periods/Week: 3Marks: 100(CA-30, SEE-70)Textile TechnologyPaper –III: Design Lab (Practical – I)Objectives:1. To create awareness with the textile traditions prevalent in India.2. To impart knowledge regarding the traditional textiles in India.Course Inputs:1. Catalogue of design2. Preparation of design sheet inspired from tradiotional Indian Textiles – abstract,geometrical, traditional & floral.3. Preparation of Indian Traditional Sari Design sheets 20 hrso Embroideryo Printingo Woveno Resist11

Paper Code: TEX -304Credits: 02Periods/Week: 3Marks: 100(CA-30, SEE-70)Textile TechnologyPaper-IV : Dyeing Lab (Practical – II)Objectives:1. To develop creative skills in designing through dyeing of fabric.Course Inputs:Practicals:• Dyeing of fabric samples with different classes of dyes• Dyeing of fabric samples with natural dyes• Preparation of fabric samples of batik on cotton & silk• Preparation of fabric samples of tie and dye on silk and wool15hrs10 hrs10hrs10 hrs12

Paper Code: TEX -401Credits: 02Periods/Week: 2Marks: 100(CA-30, SEE-70)Semester IVTextile TechnologyPaper-I : Advanced Fabric Science (Theory – I)Objectives:1. To develop ability to create fancy weaves.2. To enable students to understand and learn methods of developing advancefabrics using different fibers, yarns and fabric making techniques.Course Inputs:I Fancy Weaves 10 hrs• Introduction of fancy weaves• Construction of fancy weavesII Dobby and Jacquard 6 hrs• Dobby and Jacquard loom with their special features• Preparation of design for Jacquard loomIII Figuring 5 hrs• Principles of figuring Figuring with extra threads• Imitation of extra thread effectsIV Double Cloth 4 hrs• Basic double cloth construction• Stitched double cloth• Centre stitched double clothV Special Fabrics 5 hrs• Tapestry, Gauze, and leno structure, pile structure -warp and weft-pile fabricsBooks Recommended:1. Grosicki, Z.J.: Watson’s Textile Design and Colour, Newness Butter Worth,London.2. Oelsner, G.H. A Handbook of Weaves: Dover Publishing Inc New York.3. Joseph M: Essentials of textiles, Wonston Publication.13

Paper Code: TEX -402Credits: 02Periods/Week: 2Marks: 100(CA-30, SEE-70)Textile TechnologyPaper-II : Textile Printing (Theory – II)Objectives:1. To understand the basic of printing and finishing.2. To understand the concept of design as related to fabric.Course Inputs:I Preparation of various fabrics for printing 5 hrsII Printing 5 hrs• Styles of Printing – direct, discharge and resistIII Methods of Printing 10 hrs• Block, Screen, Stencil, Roller and Rotary• Advantages and disadvantages of various methods of printingIVAfter treatments of printed goods- ageing, steaming, raisins, fixing, curing andothers5 hrsV Printing of cellulosic fabrics, silk and polyester 5 hrsBooks Recommended:1. Storey, J: Manual of Textile Printing, Thames and Hudson Publication, London19922. Clarke, W. An Introduction to Textile Printing, Newnes – Butter Worth, Boston.3. Shenai V.A.: Technology of Printing, Sevak Publication, Mumba.4. Corbman, B: Fibre to Fabric, TMH Co. Ltd.14

Paper Code: TEX -403Credits: 02Periods/Week: 3Marks: 100(CA-30, SEE-70)Textile TechnologyPaper-III : Weaving Lab (Practical – I)Objectives:1. To create fancy weaves on handloom.2. To provide in-depth knowledge of advance fabric construction.Course Inputs:• Collection of samples of woven fabrics, identification of fancy weaves by visualexamination using magnifying glass.10 hrs• Sample preparation of fancy weaves on looms.20 hrs• Preparation of Card for Jacquard loom.5 hrs• Fabric Analysis for design, repeat, draft, peg plan and other details. 5 hrs• Creating designs for stripes, checks, towels.5 hrs15

Paper Code: TEX -404Credits: 02Periods/Week: 3Marks: 100(CA-30, SEE-70)Textile TechnologyPaper-IV : Printing Lab (Practical – II)Objectives:1. To understand the techniques involved in printing technology.Course Inputs:1. Preparation of Fabric for Printing – different fibre groups with different dyes,different styles of Printing.15 hrs2. Printing with Blocks and screens on cotton and silk in different styles withdifferent dye classes.30 hrsa. Direct style c. Discharge styleb. Azoic style d. Resist style16

Paper Code: TEX -501Credits: 02Periods/Week: 2Marks: 100(CA-30, SEE-70)Semester VTextile TechnologyPaper-I : CAD in textiles (Theory I)Objectives:1. To develop creativity in designing textile.2. To understand the role of computers in textile designing.3. To enable students to acquaint the CAD based application in Textiles Industries.Course Inputs:I Microsoft Windows 6 hrs• Introduction to Microsoft Window, its use and importance and comparison withDOS application, types of icon, parts of windows.• Knowledge creating new folders, concept of paths and saving of file.II Computer Aided Designing 5 hrs• Introduction to computer Aided Design Fundamentals of CAD design process.• Application of computer data base, Benefits of CAD.III Colour Mode 7 hrs• Working on colour mode, different background technically of scanning andworking with presentation.• Working with geometrical motif and learning the details of weavers print andembroidery representation.IV Presentation Style 6 hrs• Working on various filters and rendering fabrics in vogue.Learning presentationstyle.• Flat pattern and three dimensional pattern. Anatomy for designers. Basictechniques in master pattern.V CorelDraw & Photoshop 6 hrs• Introduction to CorelDraw, its importance and use. Export and Import files.Creating various pattern, design in CorelDraw.• Introduction to Photoshop, its use and importance. Understanding all effects onphotos.Books Recommended:1. Chase R.W: Cad for fashion, PHI2. Gray S:CAD/CAM in Clothing and Textiles, Grover Publication.3. Winfred, A: CAD in clothing and Textiles (2d Ed.)17

Textile TechnologyPaper-II: Apparel Industry & Garment Finishing (Theory II)Paper Code: TEX -502Credits: 02Periods/Week: 2Marks: 100(CA-30, SEE-70)Objectives:1. Gain knowledge of apparel production in various stages of manufacture.2. Know the techniques of process evaluation to improvise production.I Apparel Industry 5 hrs• Introduction to apparel industry their requirement in Indian Context.II Clothing Science 6 hrs• Factors involved in the study of clothing science.• Functional description of clothing, physical properties of clothing.• Clothing material in relation to the protective performance of garments.III Garment Processing 5 hrs• Processing of denim garments, biopolishing, stone washing.• Processing of knitwear garments, dyeing, durable press finish, printing ofgarments.• Printing of Garments, limitation of garment processing.IV Garments Dyeing machines 6 hrs• Paddle dyeing machine rotary drum and high temperature circular liquor dyeingmachines.V Quality Control in Garments 8 hrs• Introduction to quality control, definition of Quality, Importance of qualityassurance, fabric inspection, IPQC, AQL, MIL Standards and Final inspection.• Concepts of TQM, tools used for quality assurance.• Care labels, International care labelling system, Japan/Canada/British care,labeling systems. Eco labels.Books Recommended:1. Mehta P.V. (2001): Quality control in Apparel Industry, Nift Pub. New Delhi2. Bheda R. (2003): ‘Managing Productivity in the Apparel Industry, CBSPublication, New Delhi3. Harford C & Lathom B (1994), The Technology of Clothing Manufacture’Oxford Publication. USA18

Paper Code: TEX -503Credits: 02Periods/Week: 3Marks: 100(CA-30, SEE-70)Textile TechnologyPaper-III: CAD Lab (Practical I)Objectives:1. Gain knowledge of Computer Applications in Textile Designing.Course Inputs:I Photoshop 15 hrso Understanding its importance and use.o Altering existing drawingo Storing and Printing of drawingo Colour schemeso Effects on photos.II Corel Draw 10 hrso Introduction to CorelDraw, understanding its basic fundamentals, drawingand creating patterns, filling texture form. Arranging the design inCorelDraw, and the print, texture, checks, flower and using the coral drawtools.III Designing Software 10 hrso Practice on Dobby and Jacquard based weavy design softwareo Preparation of draft, design and Peg plan for various type of design.IV Printing Software 10 hrso Practice on Printing Software, Colour Separation, Screen Preparation, Useof Scanner.19

Paper Code: TEX -601Credits: 02Periods/Week: 2Marks: 100(CA-30, SEE-70)Semester VITextile TechnologyPaper-I CAM in Textiles(Theory I)Objectives:1. To develop creativity in designing textile.2. To understand the role of computers in textile designing.3. To enable students to acquaint the CAM based application in TextilesIndustries.Course Inputs:Unit I• Creation of a new pattern from a specs sheet. Digitizing of basic pattern.6 hrsUnit II6 hrs• Marker functions, Making markers interactively, Making markers automatically.Unit III• Plotters and their functions.6 hrsUnit IV6 hrs• Business relationship skill techniques and strategies to deal with designers,exporters, buyers, suppliers, superiors and your assistants.Unit V• Role of Internet in business development.6hrsBooks Recommended:1. Gray S: CAD/CAM in clothing and textile, Grover Publishing2. Winfred, A: CAD in clothing and Textiles (2d Ed.)21

Paper Code: TEX -602Credits: 02Periods/Week: 2Marks: 100(CA-30, SEE-70)Textile TechnologyPaper- II : Pollution Control andProcess House Management (Theory II)Objectives:1. To aware the students to the environmental concerns related to textile.2. To gain the knowledge related to textile hazards and process house management.Course Inputs:I Textile Hazards 7 hrs• Hazards in man made fibre production and wet processing.• Toxicity of dyes. Intermediates, auxiliaries, finishing chemicals etc.• Textile effluent and their characterization, measurement of effluent strength.Methods of treatment, disposal and recycling of effluents.II Environment Legislation & Balancing 6 hrs• Environment legislation in India and other countries with respect to dyes andother chemicals.• Balancing of machinery, spacing, material handling. Handling of chemicals,processed goods, storing of goods for subsequent operations for final product.III Various Systems 6 hrs• Management Information System (MIS).• Ventilation and lighting systems.• Causes of fire, fire fighting and fire prevention. Causes of accidents in process.Houses, safety devices, methods for minimizing accidents.IV Costing Systems 6 hrs• Costing as an aid to management, elements of costing, control of materials, storesand labour cost.• Classification and distribution of overheads, depreciation and different system ofproviding depreciation. Determination of cost per meter of processed goods.V Process House Management 5 hrs• Duties and responsibilities of process house staff. Administration in processhouse, wages system.• Process control in process houses.Books Recommended:1. Traversy, W.J: Methods for chemical analysis of Water and Waste Water.2. Maiti S.K.: Handbook of methods in Environmental Science, S.K. Publication.3. Irra S: Textile Waster Water Treatment – by coagulation Process, C.B.S.Publishers.22

Textile TechnologyPapar-III : InternshipPaper Code: TEX -603Credits: 02Marks: 100Objectives:1. Acquire the practical knowledge regarding the working procedure and theproduction of textiles at industrial level.2. To study the current market trends of textiles at commercial level.3. To get acquaint with the basic concepts related to Textile Industry.In the end of V Semester, students will undergo internship training in a textile designingunit, textile dyeing and printing unit etc. So that they get to understand the existingworking practices, conditions and acquire an indepth technical know how since ‘Seeing isbelieving and doing is understanding’, the practical experience in different units of textileindustry is of great relevance and significance.Internship Training (IT)Purpose Duration PlaceInternship 3 week Industrial UnitEvaluation: The students shall prepare a project during “Internship Training” along withreport of training – The training institution (Industrial Unit) shall give a certificateregarding successful training. Then 3 members team from the department shall conduct avice-voce and evaluate the reports. The students will be given marks out of 100, whichwill be converted to credits as per the programme.23

Textile TechnologyPaper-IV: CAM LabPaper Code: TEX -604Credits: 02Periods/Week: 3Marks: 100(CA-30, SEE-70)Objectives:1. To enable the students to understand the importance of CAM in textiles.Course Inputs:• Basic pattern digitizing• Creating new patterns• Pattern modification and grading• Making marker automatically.15 hrs10 hrs10 hrs10 hrs24