Nitrox workshop dings - Divers Alert Network

Nitrox workshop dings - Divers Alert Network

Nitrox workshop dings - Divers Alert Network

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

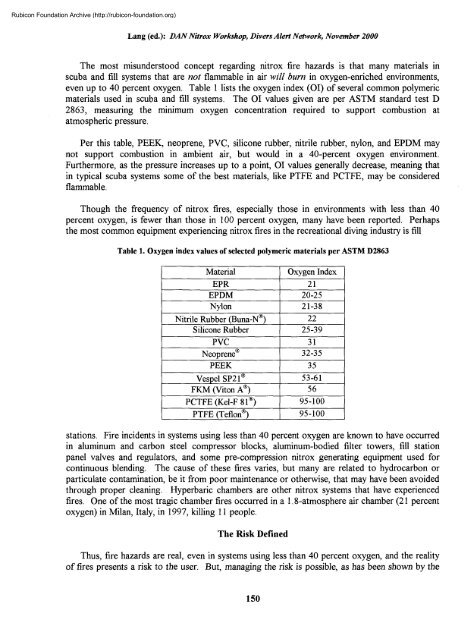

Rubicon Foundation Archive (http://rubicon-foundation.org)Lang (ed.).' DAN <strong>Nitrox</strong> Workshop, <strong>Divers</strong> <strong>Alert</strong> <strong>Network</strong>, November 2000The most misunderstood concept regarding nitrox fire hazards is that many materials inscuba and fill systems that are not flammable in air will burn in oxygen-enriched environments,even up to 40 percent oxygen. Table 1 lists the oxygen index (01) of several common polymericmaterials used in scuba and fill systems. The 01 values given are per ASTM standard test D2863, measuring the minimum oxygen concentration required to support combustion atatmospheric pressure.Per this table, PEEK, neoprene, PVC, silicone rubber, nitrile rubber, nylon, and EPDM maynot support combustion in ambient air, but would in a 40-percent oxygen environment.Furthermore, as the pressure increases up to a point, 01 values generally decrease, meaning thatin typical scuba systems some of the best materials, like PTFE and PCTFE, may be consideredflammable.Though the frequency of nitrox fires, especially those in environments with less than 40percent oxygen, is fewer than those in 100 percent oxygen, many have been reported. Perhapsthe most common equipment experiencing nitrox fires in the recreational diving industry is fillTable 1. Oxygen index values of selected polymeric materials per ASTM D2863MaterialEPREPDMNylonNitrile Rubber (Buna-N®)Silicone RubberPVCNeoprene®PEEKVespel SP21®FKM (Viton A®)PCTFE (Kel-F 81®)PTFE (Teflon®)Oxygen Index2120-2521-382225-393132-353553-615695-10095-100stations. Fire incidents in systems using less than 40 percent oxygen are known to have occurredin aluminum and carbon steel compressor blocks, aluminum-bodied filter towers, fill stationpanel valves and regulators, and some pre-compression nitrox generating equipment used forcontinuous blending. The cause of these fires varies, but many are related to hydrocarbon orparticulate contamination, be it from poor maintenance or otherwise, that may have been avoidedthrough proper cleaning. Hyperbaric chambers are other nitrox systems that have experiencedfires. One of the most tragic chamber fires occurred in a 1.8-atmosphere air chamber (21 percentoxygen) in Milan, Italy, in 1997, killing 11 people.The Risk DefinedThus, fire hazards are real, even in systems using less than 40 percent oxygen, and the realityof fires presents a risk to the user. But, managing the risk is possible, as has been shown by the150