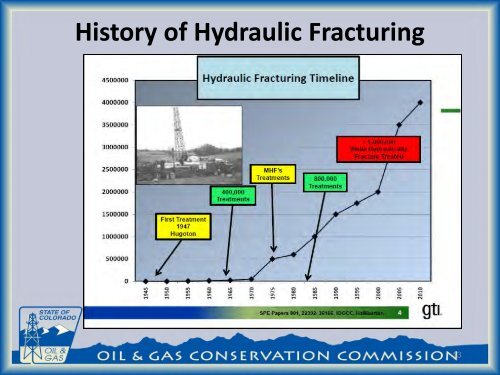

History of Hydraulic Fracturing

History of Hydraulic Fracturing

History of Hydraulic Fracturing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>History</strong> <strong>of</strong> <strong>Hydraulic</strong> <strong>Fracturing</strong>13

FRAC JOB – WELLSITEFRAC FLOW BACKTANKEARTH MOVERWATERTANKSACIDTRUCKSCOMMANDCENTER

Where do the fractures go?• They stay in the formation <strong>of</strong> interest.• Typical fracture:• “Half” Length: 300’ to 1500’.• Height: 20’ to 300’.• Width: 0.1” – 0.3”.• Energy Force: less than -1 on Richter Scale15

Where do the fluids go?• A portion will initially flowback prior to production. Flowbackis collected in the flowback tanks (or lined pits).• The rest will ultimately flowback as produced water from thewell. This will be collected in the production tanks (or linedpits).• Then it is reused at another site or disposed <strong>of</strong> into injectionwells or other E&P waste disposal facility. Same thing for theproduced water.• In La Plata County all flowback goes to tanks for ultimatedisposal into injection wells16

Typical Well Design17

Composition <strong>of</strong> Frac Fluid (XL Gel Frac)18

PROPPANT

WHAT ABOUT WATER?• <strong>Hydraulic</strong> fracturing accounts for about 1/10 <strong>of</strong>1% <strong>of</strong> Colorado’s annual water use.• The amount <strong>of</strong> water used for hydraulicfracturing is roughly comparable to the amount<strong>of</strong> water used in Colorado for snowmaking.• Operators can procure water from varioussources but must adhere to state water lawwhen obtaining and using it.

COGCC <strong>Hydraulic</strong> <strong>Fracturing</strong> Rules• Rule 205A - <strong>Hydraulic</strong> <strong>Fracturing</strong> Chemical Disclosure• 48 hour advance notice <strong>of</strong> treatment• Disclosure <strong>of</strong> chemicals used in fracture treatment.• Rule 317 - General Drilling Rules• Well casing and cementing requirement• Cement bond logs• Pressure test casing before treatment• Rule 341 – Bradenhead Monitoring During Well Stimulation Operations• Monitor well pressures during stimulation• Rules 903 & 904• Pit permitting, lining, monitoring, & secondary containment

Rule 205A – <strong>Hydraulic</strong> <strong>Fracturing</strong> ChemicalDisclosure• Must disclose chemicals used in frac jobs for alltreatments performed after April 1, 2012• Currently to be publically posted onwww.fracfocus.org• Trade secret claims must be certified on Form 41 –Claim <strong>of</strong> Entitlement – to the Director• Must also disclose the total volume <strong>of</strong> water used inthe treatment

Rule 317 - Drilling & Completion Methods toProtect Water Resources• Requires a casing & cementing program that protectsgroundwater• Surface casing must extend at least 50’ belowpotable aquifer base and be cemented to surface• In SJB wells, production casing is cemented tosurface• Downhole logs must be run to verify cement integrityand are evaluated by COGCC Engineering staff

Rule 341 - Bradenhead Monitoring• Requires continuous monitoring and recording <strong>of</strong>the bradenhead pressure during stimulationoperations.• If the bradenhead pressure increases more than 200psi during stimulation operations the operator willnotify the COGCC.• Required corrective action may include periodicmonitoring the bradenhead or sampling <strong>of</strong> nearbywater wells.