news & views - Australian Greens

news & views - Australian Greens

news & views - Australian Greens

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

In the early days of industrial paper making<br />

forests and fresh water were regarded<br />

as limitless resources. As the demand for<br />

paper and packaging products increased<br />

old growth forests were consumed at an<br />

alarming pace. Recycling (or more accurately<br />

downcycling) and plantation forests<br />

have made some impact but the demand<br />

continues to grow. Tragically, unique<br />

old growth rainforests are still being<br />

destroyed in Australia and elsewhere to<br />

produce woodchips that are pulped to<br />

produce often low value paper products.<br />

Pulp mills, with all the associated<br />

environmental problems, are being<br />

forced to close in developed countries<br />

such as Canada and are being moved<br />

to countries with lower environmental<br />

standards.<br />

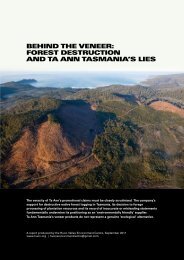

The ongoing conflict in Tasmania combines needless destruction<br />

of old growth forests and attempts to add some economic<br />

value to wood chipping by building a pulp mill. There are also<br />

current proposals to build pulp mills in Victoria and South<br />

Australia. All of these are seeking access to large volumes<br />

of fresh water, large amounts of cheap energy, licences to<br />

discharge large volumes of effluent and large direct or indirect<br />

Government subsidies.<br />

Meanwhile, a quiet revolution<br />

has been brewing in Adelaide.<br />

It has the potential to make the<br />

current paper and pulp industries<br />

as extinct as the dinosaurs.<br />

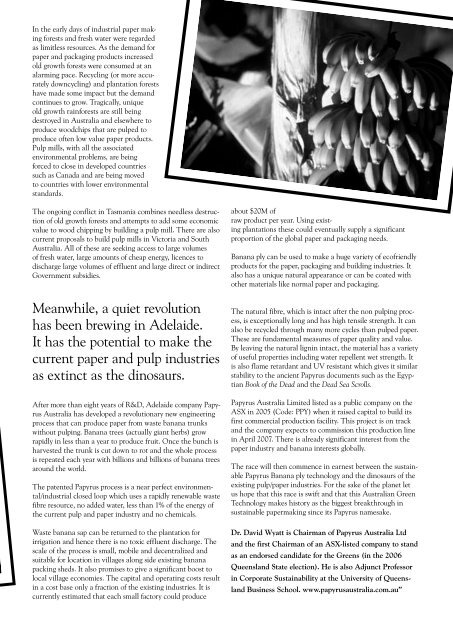

After more than eight years of R&D, Adelaide company Papyrus<br />

Australia has developed a revolutionary new engineering<br />

process that can produce paper from waste banana trunks<br />

without pulping. Banana trees (actually giant herbs) grow<br />

rapidly in less than a year to produce fruit. Once the bunch is<br />

harvested the trunk is cut down to rot and the whole process<br />

is repeated each year with billions and billions of banana trees<br />

around the world.<br />

The patented Papyrus process is a near perfect environmental/industrial<br />

closed loop which uses a rapidly renewable waste<br />

fibre resource, no added water, less than 1% of the energy of<br />

the current pulp and paper industry and no chemicals.<br />

Waste banana sap can be returned to the plantation for<br />

irrigation and hence there is no toxic effluent discharge. The<br />

scale of the process is small, mobile and decentralized and<br />

suitable for location in villages along side existing banana<br />

packing sheds. It also promises to give a significant boost to<br />

local village economies. The capital and operating costs result<br />

in a cost base only a fraction of the existing industries. It is<br />

currently estimated that each small factory could produce<br />

about $20M of<br />

raw product per year. Using existing<br />

plantations these could eventually supply a significant<br />

proportion of the global paper and packaging needs.<br />

Banana ply can be used to make a huge variety of ecofriendly<br />

products for the paper, packaging and building industries. It<br />

also has a unique natural appearance or can be coated with<br />

other materials like normal paper and packaging.<br />

The natural fibre, which is intact after the non pulping process,<br />

is exceptionally long and has high tensile strength. It can<br />

also be recycled through many more cycles than pulped paper.<br />

These are fundamental measures of paper quality and value.<br />

By leaving the natural lignin intact, the material has a variety<br />

of useful properties including water repellent wet strength. It<br />

is also flame retardant and UV resistant which gives it similar<br />

stability to the ancient Papyrus documents such as the Egyptian<br />

Book of the Dead and the Dead Sea Scrolls.<br />

Papyrus Australia Limited listed as a public company on the<br />

ASX in 2005 (Code: PPY) when it raised capital to build its<br />

first commercial production facility. This project is on track<br />

and the company expects to commission this production line<br />

in April 2007. There is already significant interest from the<br />

paper industry and banana interests globally.<br />

The race will then commence in earnest between the sustainable<br />

Papyrus Banana ply technology and the dinosaurs of the<br />

existing pulp/paper industries. For the sake of the planet let<br />

us hope that this race is swift and that this <strong>Australian</strong> Green<br />

Technology makes history as the biggest breakthrough in<br />

sustainable papermaking since its Papyrus namesake.<br />

Dr. David Wyatt is Chairman of Papyrus Australia Ltd<br />

and the first Chairman of an ASX-listed company to stand<br />

as an endorsed candidate for the <strong>Greens</strong> (in the 2006<br />

Queensland State election). He is also Adjunct Professor<br />

in Corporate Sustainability at the University of Queens-<br />

land Business School. www.papyrusaustralia.com.au”