EZ ROLL GRAVEL PAVER Technical Specifications Guide

EZ ROLL GRAVEL PAVER Technical Specifications Guide

EZ ROLL GRAVEL PAVER Technical Specifications Guide

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

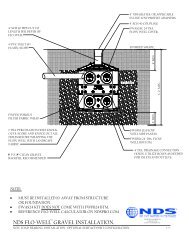

Installation<strong>EZ</strong> <strong>ROLL</strong> Gravel Pavers1. Installation of <strong>EZ</strong> Roll Gravel Pavers is generally done at the same time as other landscapeinstallation on the site, and after the completion of major area construction.2. Ensure that pavers are installed with the open cells facing up. Warranties are void for pavers installedface-down.3. Roll out the first section of <strong>EZ</strong> Roll Gravel Pavers either where there is an available straight border, orwhere there is the longest available single run.4. Roll out additional rolls of <strong>EZ</strong> Roll Gravel Pavers as needed to cover larger areas.5. Smaller areas can be filled in by attaching single sections of <strong>EZ</strong> Roll Gravel Pavers to the already laid outpaver mat. (These can be detached or cut from another roll).6. Be sure to leave the recommended 1” clearance between the paver mat and any (pre-installed)fixed objects or surface structures such as utility poles, valve boxes, drainage grates, curbs, walls,poured concrete, etc.7. The paver can be cut to fit any fixed object or surface structure using garden shears, a hand saw,PVC pipe cutter, utility cutter, or an appropriate power saw may also be used.8. Stake gravel pavers following the outer perimeter of the gravel area as specified in the staking diagram (thisguide is supplied with every roll of Gravel Paver and can be found on page 8 of this guide).Filling1. <strong>EZ</strong> Roll Gravel Pavers should be filled with gravel within 30 days of being installed.2. Fill should consist of clean, washed gravel that is uniform in size, (not graded) and sized between 3/16” and3/8”. Ensure stones are sharp and angular, not rounded. To maintain void spaces and porosity, avoid softstone materials that break apart easily.3. When planting trees near a gravel paver surface, it is advisable to install root barrier products around theroot balls of the trees to prevent shallow roots from interfering with surface integrity or the road base. NDSroot barrier products ((EP-1850 or EP-2450) are recommended.TECHNICAL SPECIFICATION GUIDE5