EZ ROLL GRAVEL PAVER Technical Specifications Guide

EZ ROLL GRAVEL PAVER Technical Specifications Guide

EZ ROLL GRAVEL PAVER Technical Specifications Guide

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TECHNICALSPECIFICATIONGUIDE<strong>EZ</strong> <strong>ROLL</strong> <strong>GRAVEL</strong> <strong>PAVER</strong>STECHNICAL SPECIFICATION GUIDEModel Numbers:GP4X150, GP4X150G, GP4X150T and GP4X150RNDS Customer Service851 N. Harvard Ave, Lindsay, CA 93247Phone: (800) 726-1994 • (559) 562-9888Fax: (800) 726-1998 • (559) 562-4488www.NDSPRO.com

TECHNICAL SPECIFICATION GUIDE<strong>EZ</strong> <strong>ROLL</strong> Gravel PaverSTABLE OF CONTENTSRecommended and Non-Recommended Uses......................................... 3Maintenance Tips and Warnings............................................................ 3Paver Installation <strong>Guide</strong>lines................................................................. 4Base Material DeterminationSite PreparationPaver Assembly & Installation (overview)Installation Tips & Techniques............................................................... 4-6Product <strong>Specifications</strong>.......................................................................... 7Staking Diagram................................................................................... 8GPStake <strong>Specifications</strong>......................................................................... 9Paver Design........................................................................................ 10Paver Mat Movement & SeparationNesting IntegrityCompressive StrengthProduct Features.................................................................................. 11Profile Levels........................................................................................ 12Depth of Base Course........................................................................... 12Typical Base Course Materials.............................................................. 12Material Composition............................................................................ 13-14Molding TechniqueTesting MethodsPermeability......................................................................................... 15Runoff % - 24 Hour Rainfall (Table 1)Water PenetrationGeneral Statement of FactProduct Testing Documentation............................................................ 162

<strong>EZ</strong> <strong>ROLL</strong> Gravel Pavers<strong>EZ</strong> Roll Gravel Pavers are a load transfer paving system designed to be placed directly on a clean stone orsandy gravel base (other base materials are acceptable, based on local conditions). <strong>EZ</strong> Roll Gravel Paversare designed to transfer vehicle load to the base material, allowing light to heavy vehicular traffic to travel overthe road without damage. The honeycomb cell paver design helps prevent particle migration and rutting thatwould deteriorate the gravel road. <strong>EZ</strong> Roll Gravel Pavers can be used for erosion control and help reduceor eliminate surface water runoff. The pavers are packaged in rolls that can be rolled out over the base material,allowing for easy installation and savings on labor costs. 40 stakes are supplied with every 600 sq ft roll.Recommended UsesLight to Moderate Traffic Loads, including:• Parking Lots• Service Roads• Jogging Tracks• Bike Trails• Roadway ShouldersHeavy Traffic Loads, including:• Fire lanes• Emergency vehicle access roads• Service vehicle utility roads• Truck maintenance and equipment yards• Construction entrance stabilizationNon-Load Applications:• Erosion control on slopes• Erosion control in swales• Residential Driveways• Golf Cart Paths• Overflow Parking Area• RV and Boat Access and Parking• Truck & Cart Wash-Down AreasTECHNICAL SPECIFICATION GUIDENon-Recommended Uses• Not recommended for traffic on slopes exceeding a 10% grade.• Not recommended for the playing surface of any sports field (e.g. baseball diamonds, football fields, etc.).• Not recommended to support tread-driven military vehicles.• Not recommended for light or heavy duty tread-driven construction equipment or bobcats.Maintenance Tips and Warnings1. When snow clearing equipment is used, skid shoes must be used or the snow plow must be raised aminimum of two inches above the paver surface. This will prevent the plow from digging into thegravel area and keep from disturbing the paver mat.2. Occasional surface grading may be required.3

Installation<strong>EZ</strong> <strong>ROLL</strong> Gravel Pavers1. Installation of <strong>EZ</strong> Roll Gravel Pavers is generally done at the same time as other landscapeinstallation on the site, and after the completion of major area construction.2. Ensure that pavers are installed with the open cells facing up. Warranties are void for pavers installedface-down.3. Roll out the first section of <strong>EZ</strong> Roll Gravel Pavers either where there is an available straight border, orwhere there is the longest available single run.4. Roll out additional rolls of <strong>EZ</strong> Roll Gravel Pavers as needed to cover larger areas.5. Smaller areas can be filled in by attaching single sections of <strong>EZ</strong> Roll Gravel Pavers to the already laid outpaver mat. (These can be detached or cut from another roll).6. Be sure to leave the recommended 1” clearance between the paver mat and any (pre-installed)fixed objects or surface structures such as utility poles, valve boxes, drainage grates, curbs, walls,poured concrete, etc.7. The paver can be cut to fit any fixed object or surface structure using garden shears, a hand saw,PVC pipe cutter, utility cutter, or an appropriate power saw may also be used.8. Stake gravel pavers following the outer perimeter of the gravel area as specified in the staking diagram (thisguide is supplied with every roll of Gravel Paver and can be found on page 8 of this guide).Filling1. <strong>EZ</strong> Roll Gravel Pavers should be filled with gravel within 30 days of being installed.2. Fill should consist of clean, washed gravel that is uniform in size, (not graded) and sized between 3/16” and3/8”. Ensure stones are sharp and angular, not rounded. To maintain void spaces and porosity, avoid softstone materials that break apart easily.3. When planting trees near a gravel paver surface, it is advisable to install root barrier products around theroot balls of the trees to prevent shallow roots from interfering with surface integrity or the road base. NDSroot barrier products ((EP-1850 or EP-2450) are recommended.TECHNICAL SPECIFICATION GUIDE5

TECHNICAL SPECIFICATION GUIDE<strong>EZ</strong> <strong>ROLL</strong> <strong>GRAVEL</strong> Gravel <strong>PAVER</strong> PaverS<strong>EZ</strong> Roll Gravel Pavers should be installed on an engineer-specified road base.1. Cut the straps securing the <strong>EZ</strong> Roll tothe pallet, then cut off the zip ties.2. Roll out <strong>EZ</strong> Roll onto the engineeredroad base.3. <strong>EZ</strong> Roll may begin to slack as it unrolls. 4. Lift roll from both sides to tighten any slacking;set down and unroll again - this helps to preventbreakage.5. Unroll second <strong>EZ</strong> Roll adjacent to the first. 6. Align the two rolls together.7. <strong>EZ</strong> Roll can be trimmed using handpruners or a similar device.8. Apply stake as directed in staking instruction sheet,provided with each roll of Gravel Paver.Fill with gravel as specified. Leave at least one inch of clearance between <strong>EZ</strong> Roll Gravel Pavers and any hardscapes orfixed objects. Leave more clearance around sprinklers to allow for future maintenance.6

Product <strong>Specifications</strong>DescriptionMaterial & RecyclabilityDimensionsPanel DetailsPaver Top SurfaceAssembly MechanismPaver Bottom Open AreaPart Numbers and ColorsCompressive StrengthChemical ResistanceWeight Per UnitFabric<strong>EZ</strong> <strong>ROLL</strong> Gravel Pavers<strong>EZ</strong> Roll Gravel Paver is a high quality injection molded, plasticrolled gravel paver structure of linked and nested honeycomb cells.<strong>EZ</strong> Roll Gravel Pavers are molded from 100% recycled HDPE.Please recycle whenever possible.Each paver roll is 4 ft. wide and 150 ft. long.Each paver panel contains 72, 2¼-inch hexagonal cells in a nestedhoneycomb form, with integrated cross links that allow for easyrollout.The top surface of the hexagonal cell walls of <strong>EZ</strong> Roll GravelPavers are smooth and devoid of notches or grooves.12 lateral snap locks per panel. 40 stakes supplied with every 600 sq ftroll.The <strong>EZ</strong> Roll Gravel Paver structure has an over 80% fabric mesharea heat bonded to the bottom surface, equal to 478 square inchesper paver section.GP4X150 (black), GP4X150G (gray), GP4X150T (tan), andGP4X150R (brick red); all contain ultraviolet inhibitorsThe compressive strength of <strong>EZ</strong> Roll Gravel Pavers is 66,000 lbs.(psf) which is equal to 458 lbs. (psi), bare product (empty cells) 1 . Thisload capacity is in excess of H20 load requirements.<strong>EZ</strong> Roll Gravel Pavers have superior chemical resistance and aretotally inert.2.32 pounds per 24”x 24” panelNonwoven, spunbonded, continuous filament polypropylene isthermally bonded to the paver bottom surface. Fabric had thefollowing values, per ASTM standards: grab tensile = 110 (lbs),puncture = 30 (lbs), AOS = 50 (U.S. sieve no.), permeability = 0.05(cm/sec), water flow = 95 (gal/min/sf), UV stability = 70 (%).1 Independent laboratory tests conducted.TECHNICAL SPECIFICATION GUIDE7

TECHNICAL SPECIFICATION GUIDE<strong>EZ</strong> <strong>ROLL</strong> <strong>GRAVEL</strong> <strong>PAVER</strong>Typical <strong>EZ</strong> Roll Gravel Paver StakingNOTES:1. Stakes to be inserted in molded stake location as shown above.2. The diagram above is designed for straight line runs. Miters, cuts and directional changes mayrequire additional stakes. Consult your local NDS Distributor, NDS Representative or contact NDS<strong>Technical</strong> Services at number listed below.3. Stake will be provided by NDS at a quantity of 40 per 4’ x 150’ roll. If additional stakes are requiredorder through your authorized NDS Representative using part # GPSTAKE.NDS Customer Service851 N. Harvard Ave, Lindsay, CA 93247Phone: (800) 726-1994 • (559) 562-9888Fax: (800) 726-1998 • (559) 562-4488www.NDSPRO.com8

TECHNICAL SPECIFICATION GUIDE<strong>EZ</strong> <strong>ROLL</strong> Gravel PaversPaver Design<strong>EZ</strong> Roll Gravel Pavers are configured in a nested honeycomb form with integrated cross links and are the onlygravel pavers on the market that combine the strength and stability benefits of a nested cell design with the easeof a roll out installation. Each paver panel is comprised of 72 - 2¼” hexagonal cells and forms a four-square-footflat block structure measuring approximately 24” x 24” x 1” deep. <strong>EZ</strong> Roll Gravel Pavers are designed to beplaced directly on a sandy gravel, clean stone or crushed run base material. The <strong>EZ</strong> Roll Gravel Pavers structureincludes a fabric covering on the bottom surface that allows water to drain freely into subgrade.Design Theory<strong>EZ</strong> Roll Gravel Pavers are engineered to withstand several types of forces that are capable of being applied intraffic situations, as well as pedestrian traffic applications.1. Paver Mat Movement & SeparationMajor forces that are applied during traffic include lateral pressure from turning, braking, andacceleration. These torsional forces must be addressed in key areas including paver matmovement and paver separation. The <strong>EZ</strong> Roll Gravel Pavers design incorporates three uniquefeatures that address these issues.- A lateral snap locks latching system to securely connect paver panels together and create anintegral paver mat. This latching system provides greater assurance against paver separation.- Thirty integrated cross links per panel provide stability for the cell row structure to withstandboth horizontal and lateral forces.- Steel Stakes (included) provide a quick and secure way to anchor together adjacent rolls of<strong>EZ</strong> Roll Gravel Pavers2. Nesting IntegrityLateral connectivity is critical; unlike a simple overlapping connection or post and eye connection, the heavyduty lateral snap locks latching system and connection clips prevent paver units from being pulled apart (ona flat plane). The lateral snap locks and connection clips securely fasten the entire mat into one continuoussection. This becomes extremely important in traffic load movement.3. Impact & Compressive Strength <strong>EZ</strong> Roll Gravel Pavers have been tested for compressive strength at 66,000 pounds per squarefoot (bare product), which means that <strong>EZ</strong> Roll Gravel Pavers are not relying on the fill material forload carrying capability. This load carrying capability is over double that of an H-20 loadspecification and will support any municipal fire truck with ease.Design Considerations• Keep the area free of sediment and erosion from adjacent areas• High traffic areas should have a slope of less than 5%• Light vehicular traffic, bicycles, and pedestrian areas can have a slope of up to 10%• Percolation rates of underlying soils should be greater than 0.63 cm of water per hour• Water table should be at least three feet below base course• Bedrock should not be closer than two feet below base course10

Product Features:<strong>EZ</strong> Roll Gravel Pavers are the latest and most advanced product of its type on the market. NDS has used itsyears of experience in the landscaping industry to create a product with all of the most desirable features wrappedup into a single product. <strong>EZ</strong> Roll Gravel Pavers have combined a series of 72 nested hexagonal cells per paverpanel connected with 30 integrated cross links and lateral snap locks. This unique combination makes a productwith the superior strength and durability of nested cells (like our popular Tufftrack® Grassroad Pavers®), andthanks to the addition of integrated cross links, it can be shipped in rolls. This means that <strong>EZ</strong> Roll GravelPavers can be installed by simply rolling out the product in the desired area, saving time and money.The design of the <strong>EZ</strong> Roll Gravel Pavers nested cells work together to support the load which makes for a muchmore stable paver mat than products using individual stand alone cells. The nested cell design is able to withstandnot only direct load but also lateral forces from braking, acceleration, and turning of vehicular traffic. The design ofthe <strong>EZ</strong> Roll Gravel Pavers is unique and able to support these forces while maintaining aesthetic appeal.Top view of cells<strong>EZ</strong> <strong>ROLL</strong> Gravel Pavers2¼” nestedhexagonal cellsTECHNICAL SPECIFICATION GUIDELateral snap locks11

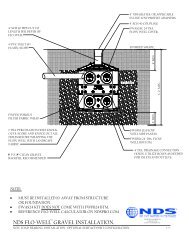

TECHNICAL SPECIFICATION GUIDE<strong>EZ</strong> <strong>ROLL</strong> Gravel PaverSProfile LevelsWhen using plastic gravel pavers in professional landscape applications involving fire lanes, utility roads, and overflowparking there are two profiles that address the gravel elevation adjustment to final grade and ultimately determine thefinished surface you can achieve: Top Profile and Recessed. The primary difference between the profiles is the gravelelevation or finished grade relative to the top surface of the gravel paving grid work.Low Maintenance:Fill with gravel to the top of the cells. Maintaining gravel completely within the cells will eliminate gravel migration.This low level of maintenance may show the top surface of the paver grid-work but will minimize gravel movementthroughout the gravel paver location.Aesthetic Appeal:Fill cells with gravel above the top surface of the cells from 0” to 2” above the top of the cells. Allowing gravel tosit atop of the cell grid-work will ensure that most of the grid-work is covered at all times. Occasionally the surfacemay need to be re-graded to remove surface rutts which have shifted the gravel paver surface. This re-grading wouldbe purely aesthetic and will not impact the structural compactness if the surface of the grid-work is left exposed.Depth of Base CourseTo calculate the depth and composition of material for the base course, consider:• Load bearing capacity of soil• Frost heave potential• Traffic load• Traffic frequency• Volume of water to be drained or storedTop ProfileTop Profile/RecessedGravel fill in andcovers over<strong>EZ</strong> Roll Gravel PaversMin. 4” base materialper engineer specs and localrequirementsSoil base, compacted perengineer specs and localrequirementsRecessed12

Typical Base Course MaterialsA mixture of stone and sand or a sandy gravel material allows for a free-draining structural base for use in lightto heavy load applications. A clean stone base contains most void space for storage of stormwater and minimizes oreliminates runoff. A clean stone base may be used for light to moderate load applications only.Material Composition<strong>EZ</strong> Roll Gravel Pavers are made from up to 100% recycled HDPE plastic. The nature of HDPE plastic isdurable, flexible, and ideally suited for outside exposure and longevity. Plastic polymers can show a decline inmechanical properties during service lifetime when they are exposed to sunlight. NDS uses UV inhibitors within theplastic in order to prevent a breakdown in the strength of the pavers over time due to environmental effects.As good corporate custodians of our environment, NDS uses quality reprocessed recycled materials in the manufactureof <strong>EZ</strong> Roll Gravel Pavers; they qualify to be used on projects requiring recycled construction materials.Molding TechniquePermeable BaseAASHTO #57 permeable subbase material defined as:Crushed Stone<strong>EZ</strong> <strong>ROLL</strong> Gravel PaversSieve Size Percent Passingmm in. #57 Typical37.5 1-1/2 100 10025 1 95-100 9719 3/4 7512.5 1/2 25-60 459.5 3/8 254.75 #4 0-10 52.36 #8 0-5 2Other permeable gradations include AASHTO #5, 6, 7, or sandy gravelmaterialA “Crusher Run” base material. 20%-40% sand may be mixed with the basematerial to ensure a porous base. Alternative products may be used basedon availability, such as sandy gravel.Ensure that the surface of the base course is smooth and compacted. Avoid the use of 100% crushed limestone. Lime absorbsmoisture and is capable of solidifying. Other materials may be used.<strong>EZ</strong> Roll Gravel Pavers are proudly manufactured in the U.S.A. in Lindsay, California. The pavers are injectionmoldedto an exact temperature range that will not damage the molecular chain of the polymer. The use of highquality reprocessed recycled resins and UV inhibitors coupled with computerized manufacturing technologiesguarantees that <strong>EZ</strong> Roll Gravel Pavers will preserve their strength over time. The geotextile material is heatbonded under a controlled temperature to ensure a 100% bond with the plastic paver units.TECHNICAL SPECIFICATION GUIDE13

TECHNICAL SPECIFICATION GUIDE<strong>EZ</strong> <strong>ROLL</strong> Gravel PaversTesting Methods<strong>EZ</strong> Roll Gravel Pavers undergo a battery of tests with each production run, as is the process with all of theproducts manufactured by NDS. Manufacturing tests are conducted within the manufacturing cycle to assure aquality-finished product.Compression tests are used to determine the yield and ultimate load strength of a given paver. Smith-EmeryLaboratories, Inc. in Los Angeles, California performed the stress load testing on <strong>EZ</strong> Roll Gravel Paversusing the following procedure: Each sample paver was individually placed flat on the steel base of the load testingmachine. A load was then applied to the top surface of the paver, through a 12” x 12” steel plate until failure. Theultimate compressive strength of the <strong>EZ</strong> Roll Gravel Pavers was 66,000 pounds per square foot (bare product).This is over double that of an H-20 load specification. (See testing and documentation data on the following pages.)PermeabilityIn comparing concrete or asphalt paving with the use of <strong>EZ</strong> Roll Gravel Pavers, there are several factors toconsider. <strong>EZ</strong> Roll Gravel Pavers provide a lower runoff coefficient, a prolonged time of concentration, a muchhigher rate of percolation, and a cleaner runoff of storm water than concrete or asphalt.As a general rule, using <strong>EZ</strong> Roll Gravel Pavers over an aggregate rock and sand base with a gravel fill willpromote a situation unlikely to generate surface runoff in an average rainstorm. We define an average storm as onedelivering less than six inches of rain in a 24-hour period.When <strong>EZ</strong> Roll Gravel Pavers are installed over clay soils(CN78), water absorption will vary slightly depending uponthe depth of the base course because of internal water storagecapacity of the base. <strong>EZ</strong> Roll Gravel Pavers provide apermeable area of approximately 80% per square foot of surfacearea. As per <strong>Technical</strong> Release #55, US Dept of Agriculture,Soil and Conservation Service, the evaluation of storm watermanagement objective is done by the following method.Calculate the existing (pre-construction) runoff volumes andtime of concentration factors. Next calculate area and runoffvolumes, which will be generated by new hard surface areas.Runoff reduction can be calculated and compared when usingTable 1 which lists runoff percentages from various soils basedon “meadow” type cover and a 24 hour rainfall.Water PenetrationAs a general reference on base preparation, the main purposeof the base is to obtain 95% compaction while still allowingthe water to percolate through the entire paved area.Runoff % - 24 Hr RainfallSand to Clay SoilsInches CN30 CN58 CN71 CN781.0 0.0 0.0 0.01 0.061.2 0.0 0.0 0.03 0.101.4 0.0 0.0 0.05 0.141.6 0.0 0.0 0.08 0.181.8 0.0 0.01 0.11 0.212.0 0.0 0.02 0.13 0.242.5 0.0 0.05 0.20 0.323.0 0.0 0.09 0.25 0.384.0 0.0 0.17 0.35 0.475.0 0.0 0.23 0.42 0.546.0 0.01 0.29 0.48 0.607.0 0.03 0.34 0.53 0.648.0 0.05 0.39 0.57 0.679.0 0.08 0.43 0.61 0.7010.0 0.10 0.46 0.64 0.7311.0 0.12 0.49 0.66 0.7512.0 0.15 0.52 0.68 0.76Table 1: <strong>Technical</strong> Release #55, US Dept of AgricultureSoil and Conservation Service tableGeneral Statement about Gravel PaversA gravel paving structure such as the <strong>EZ</strong> Roll Gravel Paver or any other gravel paving structure, whether it isconstructed of plastic or concrete, is only as good as the base foundation upon which it is installed. This is the primaryfactor that must be considered beyond design.14

15TECHNICAL SPECIFICATION GUIDE

TECHNICAL SPECIFICATION GUIDE<strong>EZ</strong> <strong>ROLL</strong> <strong>GRAVEL</strong> <strong>PAVER</strong>S16

<strong>EZ</strong> <strong>ROLL</strong> Gravel PaversTECHNICAL SPECIFICATION GUIDE17

TECHNICAL SPECIFICATION GUIDE6.2010NDS Customer Service851 N. Harvard Ave, Lindsay, CA 93247Phone: (800) 726-1994 • (559) 562-9888Fax: (800) 726-1998 • (559) 562-4488www.NDSPRO.com