Publication 2 - Packaging for Mailing - Postal Explorer - USPS.com

Publication 2 - Packaging for Mailing - Postal Explorer - USPS.com

Publication 2 - Packaging for Mailing - Postal Explorer - USPS.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Packaging</strong> <strong>for</strong> <strong>Mailing</strong><strong>Publication</strong> 2 January 2002Transmittal LetterA. Explanation. This publication supplements the standards in Domestic Mail Manual (DMM)C010. It provides mailers and postal personnel with in<strong>for</strong>mation on how to properly packageitems <strong>for</strong> mailing. Proper packaging prior to mailing is necessary to prevent deterioration anddegradation of a mailpiece and its contents.B. Distribution and Requisition. Additional copies can be ordered as follows: Public. Call the Material Distribution Center (MDC) at 800-332-0317 (option 4).This publication is also available on the Internet at http://www.usps.<strong>com</strong> — click onInfo, then <strong>Postal</strong> Periodicals and <strong>Publication</strong>s, then <strong>Publication</strong>s (either PDFFormat or Text Format), and then Pub 2. <strong>Postal</strong> Service. Order by telephone, cc:Mail, or official mail as follows:— Touch Tone Order Entry: Call 800-332-0317, option 1, then option 2.— cc:Mail: Send an F3Fill-<strong>com</strong>pleted PS Form 7380, MDC Supply Requisition, bycc:Mail to MDC Customer Service at TOKS001L.— Official Mail: Send a <strong>com</strong>pleted PS Form 7380, MDC Supply Requisition, to thefollowing address:SUPPLY REQUISITIONS500 SW GARY ORMSBY DRTOPEKA KS 66624-9702This publication is also available on the corporate intranet at http://blue.usps.gov —click on In<strong>for</strong>mation, then Policies and Procedures, then Pubs, and then the title of thepublication.C. Comments and Questions. Direct <strong>com</strong>ments or questions concerning the content of thispublication to the following address:MANAGERMAIL PREPARATION AND STANDARDSUS POSTAL SERVICE1735 N LYNN ST RM 3025ARLINGTON VA 22209-6038D. Effective Date. This handbook is effective January 2002.Stephen M. KearneyVice PresidentPricing and Classification

ContentsContents1 <strong>Packaging</strong> Adequacy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1 Preparation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2 <strong>Packaging</strong> Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3 Load Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-3.1 Easy Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-3.2 Average Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-3.3 Difficult Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-4 Acceptability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31-4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31-4.2 Stationery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31-4.3 Liquids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31-4.4 Aerosols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41-4.5 High-Density Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41-5 Test Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41-6 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51-7 Mailability Determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51-8 Regulation Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 Containers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72-1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72-2 Bags, Bales, Bundles, Films, and Wraps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72-2.1 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72-2.2 Paper Bags and Wraps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72-2.3 Plastic Bags and Films . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-2.4 Cloth Bags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-2.5 Bales and Bundles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-3 Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-3.1 Use and Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-3.2 Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92-3.3 Making Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102-3.4 Banding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102-3.5 Outer Wrapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102-4 Cans and Drums . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112-5 Envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112-5.1 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112-5.2 Letter-Style Envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112-5.3 Other Envelope Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112-5.4 Odd-Shaped Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122-6 Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<strong>Publication</strong> 2, January 2002iii

Contents3 Cushioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133-1 Purpose and Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133-2 Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133-3 Fill Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133-4 Several and Fragile Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144 Closing, Sealing, and Rein<strong>for</strong>cing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154-1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154-2 Adhesives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154-2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154-2.2 Box Flaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154-3 Bandings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164-4 Staples and Steel Stitching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164-5 Tapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174-5.1 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174-5.2 Pressure-Sensitive Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174-5.3 Gummed Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185 Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195-1 Authorized Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195-1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195-1.2 Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195-1.3 Address Correction and Forwarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205-1.4 Class of Mail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205-1.5 Special Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205-1.6 Handling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215-2 Unauthorized Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215-2.1 Obsolete Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215-2.2 Erroneous Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215-2.3 Extraneous Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215-2.4 Other Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225-3 Marking Methods and Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225-3.1 Marking Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225-3.2 Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226 Bulk Mail Center Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236-1 About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236-2 Books . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236-2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236-2.2 Books up to 5 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246-2.3 Books From 5 to 10 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24iv <strong>Publication</strong> 2, January 2002

Contents6-2.4 Books From 10 to 25 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256-2.5 Books From 25 to 50 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256-2.6 Books From 50 to 70 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256-3 High-Density Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266-3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266-3.2 High-Density Items up to 20 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266-3.3 High-Density Items From 20 to 45 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276-3.4 High-Density Items From 45 to 70 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276-4 Soft Goods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286-4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286-4.2 Soft Goods up to 5 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286-4.3 Soft Goods From 5 to 10 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286-4.4 Soft Goods From 10 to 20 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296-4.5 Soft Goods From 20 to 45 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296-4.6 Soft Goods From 45 to 70 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296-5 Sound Recordings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306-5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306-5.2 Sound Recordings up to 10 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306-5.3 Sound Recordings From 10 to 20 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306-5.4 Sound Recordings From 20 to 40 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316-5.5 Sound Recordings From 40 to 70 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316-6 Magnetic Tapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316-6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316-6.2 Magnetic Tapes up to 5 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316-6.3 Magnetic Tapes From 5 to 10 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326-6.4 Magnetic Tapes From 10 to 20 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326-6.5 Magnetic Tapes From 20 to 40 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326-6.6 Magnetic Tapes From 40 to 70 Pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337 Hazardous Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357-1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357-1.1 Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357-1.2 Federal Laws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357-2 <strong>Mailing</strong> Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357-2.1 <strong>Postal</strong> Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357-2.2 Mailability Rulings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367-2.3 <strong>Packaging</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36<strong>Publication</strong> 2, January 2002v

AppendixesAppendixesA Package Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37B Rates and Classification Service Centers (RCSCs) . . . . . . . . . . . . . . . . . . . . 55vi <strong>Publication</strong> 2, January 2002

<strong>Packaging</strong> Adequacy1-21 <strong>Packaging</strong> Adequacy1-1 Preparation RequirementsThe in<strong>for</strong>mation in this publication is primarily <strong>for</strong> <strong>com</strong>panies and customerswho mail parcels and special items. For parcels to be accepted <strong>for</strong> mailing,they must be prepared according to the requirements and guidelines in thispublication. More detailed packaging and mailability requirements are inmodule C of the Domestic Mail Manual (DMM) and in the International MailManual (IMM). Requirements specific to each class of mail are covered inthose manuals.State and federal regulations also can affect the mailability of parcelscontaining certain items such as hazardous, biological, and restrictedmaterials. The <strong>Postal</strong> Service accepts properly prepared and marked parcels,but it reserves the right to refuse parcels that contain nonmailable items orthat seem improperly prepared.1-2 <strong>Packaging</strong> EvaluationItems sent through the mail must be packed in a way that prevents theirdeterioration or degradation. Large-volume mailers should test be<strong>for</strong>eshipping to determine their packaging’s effectiveness and the product’sdurability.Mailers can use the International Safe Transit Association (ISTA) TestProcedure 1A to evaluate their packaging (see Appendix A). Mailers can alsocontact the nearest postmaster, account representative, or business mailentry manager <strong>for</strong> a review of their packaging.<strong>Publication</strong> 2, January 20021

1-3 <strong>Packaging</strong> Adequacy1-3 Load TypesIn the transportation industry, the term load is defined as a quantity ofmaterial assembled and packed as a shipping unit. Generally, packages areclassified into three load types based on the nature of the contents, how wellthe packaging protects it, and the strength of the mailing container.1-3.1 Easy LoadsEasy loads include moderate-density items that can<strong>com</strong>pletely fill the mailing container or be packed ininterior receptacles. Easy loads are not readily damagedby shock, <strong>com</strong>pression, or puncture during handling ormail processing. They do not shift or move within thecontainer, and they usually do not endanger otherparcels.1-3.2 Average LoadsAverage loads include moderately concentrated items that usually providepartial support to all surfaces of the mailing container. Often, the item can bedamaged if the package is <strong>com</strong>pressed.Average loads can be placed directly into acontainer or into separate interior containers.Nesting items within partitions or separate paperboardboxes can stabilize an average load and prevent damageto the container and the items.1-3.3 Difficult LoadsThe items in difficult loads usually need additional protection against shock,puncture, or distortion during handling or mailprocessing. Fragile objects, delicate instruments,high-density items, and small bulk items areconsidered difficult loads. Paper boxes, paperor plastic bags, or wraps of any kind cannotsupport difficult loads and are not acceptablecontainers <strong>for</strong> such items.2 <strong>Publication</strong> 2, January 2002

<strong>Packaging</strong> Adequacy1-4.3.11-4 Acceptability1-4.1 GeneralBesides load type, packaging acceptability is one of the principal standards ofmailability. A container must not be packed in a way that might cause or allowits contents to injure <strong>Postal</strong> Service employees or to damage other mail ormail processing equipment. Fragile items must be packed to withstand mailprocessing and transportation. Heavy items must be braced and cushioned toprevent damage to other mail.Items described in 1-4.2 through 1-4.5 often cause problems whenimproperly packaged. Requests <strong>for</strong> exceptions to the requirements in thissection must be made to a rates and classification service center (RCSC)(see Appendix B <strong>for</strong> addresses).1-4.2 StationeryStationery items often be<strong>com</strong>e loose during mail processing. Problems arecaused by unrestrained, concentrated, or shiftingcontents and by inadequate internal packaging,containers, closures, and rein<strong>for</strong>cements.Stationery items that are thicker than 1 inch orheavier than 1 pound may not be mailed in letter-style envelopes.These items must be unitized by tying or banding them or by partitioningtight containers to prevent shifting.1-4.3 Liquids1-4.3.1 ContainersLiquids can damage or destroy other mail and mail processingequipment. Generally, containers of liquid with only friction-topclosures (push-down type) are not acceptable. Screw-on caps,soldered tops, clips, or other means are necessary <strong>for</strong> secureclosing.Glass and other breakable containers holding more than4 fluid ounces must be cushioned with a material that canreadily absorb any leakage. These primary containers mustbe placed and packed inside sealed, leak-proof containers. If acontainer holds more than 32 fluid ounces, it is not acceptable <strong>for</strong> mailingunless cushioned as described above and packed within another sealed,leak-proof container such as a can or plastic bag. The outer mailing containermust be strong enough to protect the contents, must be marked “LIQUID,” andshould display orientation markings (i.e., up arrows) that indicate the uprightposition of the parcel.<strong>Publication</strong> 2, January 20023

1-4.3.2 <strong>Packaging</strong> Adequacy1-4.3.2 ExceptionsSteel pails and drums with carrying handles and positive closures (such aslocking rings or recessed spouts under screw-cap tops) are acceptable <strong>for</strong>mailing without additional packing. Requests <strong>for</strong> exceptions to theserequirements must be made to the nearest RCSC (see Appendix B <strong>for</strong>addresses).1-4.4 AerosolsAerosol containers with inadequate friction-capclosures or other nonpositive means toprevent accidental discharge of contents caninjure <strong>Postal</strong> Service employees or damageother mail and mail processing equipment.These containers must be constructed toprevent accidental discharge of their contents inthe mail.Recessed valves, screw-thread caps, tape closures, or other secure closurescan make such containers acceptable.1-4.5 High-Density LoadsHigh-density loads (such as tools and machine parts) canbe dangerous to <strong>Postal</strong> Service employees and to othermail and mail processing equipment. High-density loadsthat weigh between 15 and 35 pounds are machinableon <strong>Postal</strong> Service mail processing equipment if theloads are packaged so that they do not exert morethan 60 pounds of pressure per square foot (0.4167 poundper square inch) on the smallest side of the mailing container.1-5 Test Packages<strong>Packaging</strong> that does not meet the minimum requirements in this publicationmay be permitted under a “test” status. The manager at the originating bulkmail center (BMC) is authorized to approve this test status. Contact the localpostmaster <strong>for</strong> the address of the nearest BMC.If the BMC manager approves the test packaging and the packagingachieves acceptable per<strong>for</strong>mance levels, the mailer may continue using thepackaging. If the BMC manager disapproves test status, the mailer mayappeal this decision with an RCSC (see Appendix B <strong>for</strong> addresses).4 <strong>Publication</strong> 2, January 2002

<strong>Packaging</strong> Adequacy1-8If a mailer asks to use packaging that deviates significantly from postalrequirements, the manager of Mail Preparation and Standards at <strong>Postal</strong>Service Headquarters must be notified. If the deviation cannot be resolved bythe accepting postmaster, the BMC manager, or the business mail entrymanager, the mailer’s request is referred to the rates and classificationservice center.1-6 SafetyMailers should take appropriate precautions when packaging a parcel ofmailable items that have the potential to injure any person handling oropening the parcel. Because a small child might gain unauthorized access toa parcel, every potentially harmful item should be enclosed in a container thatis hard <strong>for</strong> a child to open.1-7 Mailability DeterminationIf a mailer is unsure about whether an item is mailable or its packaging isacceptable, the mailer should send a written request to the nearest businessmail entry unit (see DMM G042 <strong>for</strong> addresses). To ask <strong>for</strong> an exception to<strong>Postal</strong> Service packaging requirements, the mailer should submit a writtenrequest to an RCSC (see Appendix B <strong>for</strong> addresses). The request shouldfully describe the item and its packaging.1-8 Regulation Changes<strong>Postal</strong> regulations change from time to time. If there is conflicting in<strong>for</strong>mationbetween this publication and the DMM or IMM, then the DMM or IMM takesprecedence. Mailers may review copies of these documents at any postoffice, business mail entry unit, or postal business center. Both documentsare available to the public through a subscription service handled by the U.S.Government Printing Office, and current versions are accessible on the<strong>Postal</strong> Service’s “<strong>Postal</strong> <strong>Explorer</strong>” web page at http://pe.usps.gov.<strong>Publication</strong> 2, January 20025

<strong>Packaging</strong> AdequacyThis page intentionally left blank6 <strong>Publication</strong> 2, January 2002

Containers2-2.2.22 Containers2-1 GeneralSeveral types of containers are acceptable <strong>for</strong> mailing items if the containersand items are prepared within the standards of this publication. The principaltypes of mailing containers include the following:Bags, bales, bundles,films, and wraps.Boxes.Cans and drums.Envelopes.Tubes.2-2 Bags, Bales, Bundles, Films, and Wraps2-2.1 UseBags, bales, bundles, films, and wraps are acceptable <strong>for</strong> mailing certaineasy loads and average loads. The contents in these containers should be<strong>com</strong>pressed when possible. The <strong>Postal</strong> Service does not accept suchcontainers <strong>for</strong> the mailing of difficult loads.2-2.2 Paper Bags and Wraps2-2.2.1 Easy Load up to 5 PoundsA paper bag or paper wrap is acceptable. The paper must be of at least50-pound basis weight — the strength of a regular large grocery sack. Thecontents must be immune from impact or pressure damage. The <strong>com</strong>bining(layering) of several sheets that add up to or exceed a 50-pound basis weightis not acceptable.2-2.2.2 Easy or Average Load up to 20 PoundsA rein<strong>for</strong>ced bag or a bag of at least 70-pound basis weight is acceptable. Anonrein<strong>for</strong>ced loose-fill padded bag is not acceptable as an exterior containerunless the exterior layer is of at least 60-pound basis weight.<strong>Publication</strong> 2, January 20027

2-2.3 Containers2-2.3 Plastic Bags and Films2-2.3.1 Plastic BagsA plastic bag — polyethylene or equivalent — used as a mailing container <strong>for</strong>an easy load must be stretchable, must resist puncturing, must be relativelyleak-proof, and must have the following strength requirements: For up to 5 pounds, at least 2 mils thick. For up to 10 pounds, at least 4 mils thick.2-2.3.2 Plastic FilmsHeat-shrinkable plastic film — copolymer, irradiated polyethylene, or linearlow-density polyolefin — used to <strong>for</strong>m an outer mailing container must meetthe following requirements, based on load type and weight restriction: For an easy load of up to 5 pounds, at least 3/4 mil thick. For an average load of up to 5 pounds, at least 1-1/4 mils thick.2-2.4 Cloth BagsFor an easy load or an average load of up to 10 pounds, a cloth bag isacceptable if its seams are as strong as the basic material <strong>for</strong>ming the bag.2-2.5 Bales and BundlesIf it is within postal weight limits, a bale or bundle — a large bound orwrapped package of flat materials — is acceptable if it is adequately<strong>com</strong>pressed and rein<strong>for</strong>ced to contain the contents.2-3 Boxes2-3.1 Use and Type2-3.1.1 PaperboardA paperboard box (similar to a suit box) is acceptable only <strong>for</strong> easy andaverage loads of up to 10 pounds.2-3.1.2 Metal-Stayed PaperboardA metal-stayed or stapled paperboard box is acceptable only <strong>for</strong> easy andaverage loads of up to 20 pounds.8 <strong>Publication</strong> 2, January 2002

Containers2-3.22-3.1.3 Solid and CorrugatedFiberboardBox Manufacturer’scertificateA solid and corrugatedfiberboard box isacceptable <strong>for</strong> all loadtypes up to the weight andsize limits shown in Exhibit 2-3.1.3, unlessotherwise specified. The box grade(bursting strength) of a box is printedwithin the circular or rectangularboxmaker’s certificate (pictured here),which lists the box’s maximum size andgross weight limits <strong>for</strong> easy and averageloads. The first maximum limit reached <strong>for</strong>an item to be mailed, whether size or weight,governs the grade of box to be used.Exhibit 2-3.1.3Maximum Weight(Box + Contents, Pounds)Easy orAverage LoadDifficultLoadMaximum Size(Length + Girth,Inches)20 N/A 67 12540 20 100 17565 45 108 20070 65 108 275N/A 70 108 350Box Grade(Bursting Strength,Pounds per Square Inch)2-3.1.4 Wood, Metal, or PlasticA wood, metal, or plastic box is acceptable <strong>for</strong> all load types. The box’sacceptability depends on its construction, its ability to withstand shock andpressure, and its potential to damage other items.2-3.2 SizeA box used as a mailing container must be large enough to hold the itemsand any surrounding interior cushioning material. If the box is too large andthe items inside the box are inadequately blocked or cushioned, the itemsmight shift in transit. If the box is too small, the cushioning might beineffective protection. In either case, the box or items might get damagedduring handling and mail processing.<strong>Publication</strong> 2, January 20029

2-3.3 Containers2-3.3 Making BoxesIf a box of the size required <strong>for</strong> an item is unavailable, other boxes can beresized. Exhibit 2-3.3 shows how to cut a larger box down to the needed sizeand how to make an acceptable mailing container from two boxes of thesame general dimensions by removing their flaps.Exhibit 2-3.31. Mark new boxheight, flap length(side flaps abouthalf of box width).2. Split cornersto new height.Cut flaps.3. Fold new flaps.Discard excess oruse <strong>for</strong> internalcushioning.1. Start with two boxesof about the samedimensions.2. Cut the top orbottom offeach box.3. Use onebox asthebottomand slidethe otherover it asthe top.Tape theends andcornerssecurely.Note: All leftover external markings that do not correctly identify the contentsmust be fully obliterated.2-3.4 BandingA box containing a difficult load must berein<strong>for</strong>ced with banding (strapping). The box shouldbe banded about every 8 inches in two directionsaround the box. See 4-3 <strong>for</strong> more details on banding.2-3.5 Outer WrappingIf a box itself is adequate <strong>for</strong> mailing, wrapping paper should not be used tocover the box. If wrapping paper is necessary, paper as strong as a regularlarge grocery bag (60-pound basis weight) is re<strong>com</strong>mended. The appropriatetype of tape should be used to close and rein<strong>for</strong>ce the box. See 4-5 <strong>for</strong> moredetails on selecting and using tape <strong>for</strong> closing and rein<strong>for</strong>cing packages.10 <strong>Publication</strong> 2, January 2002

Containers2-5.32-4 Cans and DrumsA can or drum with positive closures (clips, solderedtops, screw-on caps) is acceptable <strong>for</strong> mailing certainitems such as liquids or powders. Generally, a can ordrum with only friction closures (push-down types) isnot acceptable. Protruding devices (such as lockingrings) must be shielded or covered with padding toprevent injury to <strong>Postal</strong> Service employees or damageto other mail or mail processing equipment.2-5 Envelopes2-5.1 UseEnvelopes are acceptable <strong>for</strong> mailing certain items that can reasonably beexpected to be processed and delivered without damage to the contents or toother mail or mail processing equipment.2-5.2 Letter-Style EnvelopesA letter-style envelope is any nongusseted envelope within the dimensionsshown in Exhibit 2-5.2. A letter envelope is acceptable <strong>for</strong> mailing nonrigidstationery and similar items weighing up to 1 pound and measuring up to1 inch thick.Exhibit 2-5.2Dimension Mimimum (in.) Maximum (in.)Length 5 11-1/2 (11.500)Height 3-1/2 (3.500) 6-1/8 (6.125)Thickness 0.007 0.2502-5.3 Other Envelope StylesFor an easy load of up to 5 pounds, an envelope that exceeds the letter-sizedimensions is acceptable <strong>for</strong> mailing. This large envelope should be madefrom paper of at least 28-pound basis weight or from material with a Mullenstrength greater than 90 pounds per square inch.An envelope designed as a photographic film mailer or a gusseted envelopeis also acceptable <strong>for</strong> mailing if it is made from envelope paper of at least24-pound basis weight.<strong>Publication</strong> 2, January 200211

2-5.4 Containers2-5.4 Odd-Shaped ItemsPens, bottle caps, and similar odd-shaped items are not acceptable in aletter-sized envelope mailed at the single-piece First-Class Mail rate. Theseitems can split or burst the envelope and injure <strong>Postal</strong> Service employees ordamage other mail and mail processing equipment.An envelope may be used to mail an odd-shapeditem at the bulk Standard Mail rate if the itemmeets the requirements <strong>for</strong> that mail class.The item should be wrapped with the othercontents of the envelope to streamline theshape of the envelope <strong>for</strong> automatedprocessing. The item’s package should beable to effectively hold it so that thecontents and the package will not bedamaged.2-6 TubesA fiberboard tube or similar long container is acceptable <strong>for</strong> mailing items ifthe tube length does not exceed 10 times the girth (the distance around thethickest part of the container). As a minimum, the strength of the tube endsmust equal the tube sidewall strength, unless the contents are lightweightrolled items such as maps or blueprints. In any case, the sidewall strengthmust equal the thickness of the fiberboard, as shown in Exhibit 2-6.Crimped or taped-end closures are not acceptable <strong>for</strong> mailing items otherthan lightweight rolled material. Tape must <strong>com</strong>pletely encircle the seams onfriction slide closures of mailing tubes.Exhibit 2-6Tube Length (in.)Sidewall Thickness (in.)Less than 18 1/16 (0.0625)18 to 32 3/32 (0.09375)More than 32 5/32 (0.15625)12 <strong>Publication</strong> 2, January 2002

Cushioning3-33 Cushioning3-1 Purpose and MethodCushioning is important because, if there isenough cushioning material in a mailingcontainer, it absorbs and distributes<strong>for</strong>ces of shock, pressure, and vibration.Cushioning should keep an item fromtouching its mailing container andshould separate multiple items fromeach other. In other words, cushioneach item above, below, andon all sides.3-2 MaterialsExamples of cushioning include foamed plastics, rubberized hair, corrugatedfiberboard, and loose-fill material such as excelsior, polystyrene, andshredded newspapers.Combinations of several types of cushioning (such as corrugated fiberboardpads and less dense, loose-fill material) can be effective. Such <strong>com</strong>binationshelp dissipate shock and pressure by spreading these <strong>for</strong>ces over the surfaceof the items.3-3 Fill LevelThe inside of the mailingcontainer should beslightly overfilled withcushioning material tohold items in place andprevent their movementtoward an inside surfaceof the container or towardother items in the container.The container should not be distorted by overfilling.<strong>Publication</strong> 2, January 200213

3-4 Cushioning3-4 Several and Fragile ItemsWhen several items are packed together, they should be protected from oneanother and from external <strong>for</strong>ces.The illustration on this page shows some ways to cushion several fragileitems to be packaged together. The items can be individually wrapped inpaper or foam packing material and boxed separately. The boxes can be<strong>for</strong>tified by surrounding them with corrugated cardboard stiffeners. The boxescan then be placed in the external container and cushioned on all sides andon the top and bottom withstyrofoam particles or“peanuts.”Concentrated heavy itemsshould not be packed withfragile items unless they arecarefully separated. Heavyitems must be adequatelyblocked or stabilized.14 <strong>Publication</strong> 2, January 2002

Closing, Sealing, and Rein<strong>for</strong>cing4-2.24 Closing, Sealing, and Rein<strong>for</strong>cing4-1 GeneralClosing, sealing, and rein<strong>for</strong>cing are primary considerations in preparing theoutside of a parcel <strong>for</strong> mailing. The main materials <strong>for</strong> closing, sealing, andrein<strong>for</strong>cing mailing containers are adhesives, bandings (strappings), staplesand steel stitching, and tapes (gummed and pressure-sensitive). Frictionclosures, screw caps, and locking devices are used to close and seal cansand similar containers.4-2 Adhesives4-2.1 GeneralAdhesives include glue, paste, cement, mucilage, cold emulsion, and thermalplastic. An adhesive used to close a container is adequate if, when thecontainer is opened, at least a 50-percent fiber tear occurs on the surface towhich the adhesive is applied. An adhesive used on tapes or box flaps mustremain serviceable in temperatures from –20 to 160 Fahrenheit.4-2.2 Box FlapsFor box flaps, the adhesive shouldcover at least 50 percent of the boxflaps and be applied no more than1/4 inch from the box flap ends.Alternatively, four strips of hot-meltadhesive may be used on each part of thebox flap where the outer flap lies over theinner flap, but only if the strips have the following characteristics: Are 3/16 inch wide each (after <strong>com</strong>pression).Are no more than 1-1/2 inches apart (with the first strip no more than1/2 inch from the center seam).Extend to the full width of the inner flap (unless hot-melt adhesive isapplied to 25 percent of the area where the outer flap lies over the innerflap).<strong>Publication</strong> 2, January 200215

4-3 Closing, Sealing, and Rein<strong>for</strong>cing4-3 BandingsBandings (strappings) include both metallicand nonmetallic banding andpressure-sensitive filament tape.Flat steel banding should havesmooth or plastic-coated edges,and banding ends should becovered or protected. Twine orcord should not be used to closeand rein<strong>for</strong>ce a container; if used, itmust be of at least 20-pound tensile strengthand secured at an intersection at least onceon each side of the container.When a mailing container is closed and rein<strong>for</strong>ced with banding(strapping), at least one band must encircle the length and a secondband must encircle the girth. Loose strapping, especially metal, is notacceptable because it does not rein<strong>for</strong>ce the container and because itconstitutes a danger to <strong>Postal</strong> Service employees and mail processingequipment. The bands should be tight enough to depress the corners ofthe box.4-4 Staples and Steel StitchingStaples and steel stitching are acceptable <strong>for</strong> closing a mailing container ifthey are spaced <strong>for</strong> the load type as follows: For an easy load or an average load, not more than 5 inches apart. For a difficult load, not more than 2-1/2 inches apart.If distance is5 inches or more...Staples must not be more than 1-1/4 inches from the ends of the box ormailing container. If a box’s staple spacing does not meet theserequirements, the box should be banded to <strong>com</strong>pensate <strong>for</strong> the gap in thestaple closure, or a strip of 3-inch-wide rein<strong>for</strong>ced tape should be applied tothe box between the staples (as shown in the illustration).Envelopes, flat-size mailing containers, or cards that have partially openedstaples are not acceptable <strong>for</strong> mailing.16 <strong>Publication</strong> 2, January 2002

Closing, Sealing, and Rein<strong>for</strong>cing4-5.24-5 Tapes4-5.1 UseTapes are used to close, seal, and rein<strong>for</strong>ce mailing containers. Commonlyavailable tapes have pressure-sensitive adhesive or gummed adhesive, witheither rein<strong>for</strong>ced (filament) ornonrein<strong>for</strong>ced backings.However, certaintypes of tapes (suchas cellophane andmasking tapes) arenot strong enough <strong>for</strong>rein<strong>for</strong>cing.Rein<strong>for</strong>cementtape or bandingSealing andclosure tapeThe illustration at right shows howsealing tape can be <strong>com</strong>bined with banding or rein<strong>for</strong>cement tape toproduce an effective closure <strong>for</strong> boxes with flaps and <strong>for</strong> telescopingboxes.4-5.2 Pressure-Sensitive TapePressure-sensitive tape is acceptable <strong>for</strong> closing and rein<strong>for</strong>cing mailingcontainers. This type of tape is available with various cloth, paper, or plasticbackings, both plain and rein<strong>for</strong>ced. Except <strong>for</strong> pressure-sensitive filamenttape, tape used to close and rein<strong>for</strong>ce mailing containers may not be lessthan 2 inches wide. Nonrein<strong>for</strong>ced plastic tapes must be at least as strong inthe cross direction as in the machine (long) direction.Pressure-sensitivefilament tapeKraft paper tapeRein<strong>for</strong>ced kraftpaper tapePressure-sensitive tape works best when applied to clean surfaces attemperatures above freezing. In below-freezing temperatures, the tapeshould be rubbed down after it is applied.Cellophane and masking tapes may not be used to close or rein<strong>for</strong>cecontainers. These tapes may be used, however, on envelopes to augmentadhesive closures or on bags to cover staples.<strong>Publication</strong> 2, January 200217

4-5.3 Closing, Sealing, and Rein<strong>for</strong>cing4-5.3 Gummed TapeGummed tape is acceptable <strong>for</strong> closing and rein<strong>for</strong>cing mailing containers ifthe adhesive is adequately activated, usually with water. If the adhesive isimproperly activated or the fibrous material of the container absorbs thewater, the gummed tape cannot stick to the container.Gummed tape is applied correctlyif it remains attached to thecontainer during handling andtransportation and its removalcauses delamination or at leasta 50-percent fiber tear on thesurface to which the tape is applied.The tape should be kept away from freezingtemperatures <strong>for</strong> at least 1 hour be<strong>for</strong>e itsapplication. Even properly applied gummed tapetends to crack in extremely cold temperatures.At least 3-inchoverhangGummed paper tape is available in two types: Rein<strong>for</strong>ced Paper (Kraft). Rein<strong>for</strong>ced paper (kraft) tape is acceptable<strong>for</strong> closing and rein<strong>for</strong>cing irregular-shaped or soft-wrapped packages.A mailing container closed with rein<strong>for</strong>ced paper tape is more durablethan one closed with nonrein<strong>for</strong>ced paper tape. Nonrein<strong>for</strong>ced Paper (Kraft). Nonrein<strong>for</strong>ced paper (kraft) tape isacceptable <strong>for</strong> closing mailing containers if the tape is of at least60-pound basis weight. This tape is inadequate <strong>for</strong> rein<strong>for</strong>cement.When applied, the tape should extend at least 3 inches over theadjoining side of the container.18 <strong>Publication</strong> 2, January 2002

Marking5-1.25 Marking5-1 Authorized Markings5-1.1 GeneralThe DMM and the IMM provide in<strong>for</strong>mation on addressing standards andendorsements required <strong>for</strong> each class of mail and service. Special markingsare also required <strong>for</strong> certain restricted items. Contact a business mail entryunit <strong>for</strong> guidance (see DMM G042 <strong>for</strong> addresses).As a rule, the following markings are permitted on the outside of a mailingcontainer: Return and delivery addresses. Ancillary service endorsements <strong>for</strong> address correction, <strong>for</strong>warding, etc. Special service endorsements. Class of mail marking. Handling instructions.5-1.2 AddressEach package must show adelivery address on the mailingcontainer or on a label affixedto the container. In addition,a return address must beplaced in the upper left cornerof the container (or address label).The addresses should meet postal address<strong>for</strong>mat standards. <strong>Publication</strong> 28, <strong>Postal</strong> Addressing Standards, providesdetailed in<strong>for</strong>mation about address <strong>for</strong>mats and requirements.Inside the mailing container, the names and addresses of the sender andaddressee and a description of the enclosed items should be included. Thisprecaution can aid in the delivery of a parcel if the addresses on the outsideof the container be<strong>com</strong>e unreadable or the items be<strong>com</strong>e separated from thecontainer.<strong>Publication</strong> 2, January 200219

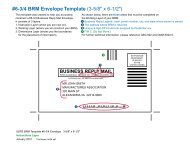

5-1.3 Marking5-1.3 Address Correction and ForwardingThe various ancilliary serviceendorsements <strong>for</strong> address correctionservice and the return and<strong>for</strong>warding of parcels are fullydescribed in DMM module F.These endorsements must beplaced below the return addressin the upper left corner or asallowed in DMM M012.5-1.4 Class of MailThe class of mail marking is required <strong>for</strong> allclasses of letters, parcels, and flat-size mailexcept First-Class Mail withpostage affixed (under13 ounces). Mailpiecesthat have Standard Mailor Package Servicespostage affixed but arenot marked as such areprocessed at the higher,First-Class Mail rate aspostage-due mail.The class marking must be placedin the area to the left of the postageand above the delivery address, asshown in the illustrations at right.5-1.5 Special ServicesAll markings <strong>for</strong> any special service requested must be placed above thedelivery address and to the right of the return address. Special servicesinclude the following: Certified mail. Collect on delivery (COD). Delivery confirmation. Insured mail. Registered mail. Restricted delivery. Return receipt. Return receipt <strong>for</strong> merchandise. Signature confirmation.20 <strong>Publication</strong> 2, January 2002

Marking5-2.35-1.6 Handling InstructionsApproved markings that give handlinginstructions based on the contents ofthe package are listed in Exhibit5-1.6, along with guidelines <strong>for</strong> usingthese markings. The markings must beplaced in the area below the postagebut above the addressee’s name.Exhibit 5-1.6MarkingFRAGILEPERISHABLEDO NOT BEND orDO NOT FOLDUseOnly on packages containing items that can break (such asglass and electrical appliances)Only on packages containing items that can degrade orde<strong>com</strong>pose rapidly (such as meat, produce, plants, andcertain chemical samples)Only on packages containing items protected withstiffeners5-2 Unauthorized Markings5-2.1 Obsolete MarkingsObsolete markings (from previous mailings or on reused boxes or containers)must be entirely removed or <strong>com</strong>pletely obliterated prior to mailing.5-2.2 Erroneous MarkingsContainers with improperly identified contents are not acceptable, as noted inthe following examples:A parcel marked “Bleach” that actually contains clothing is notacceptable.A parcel marked “ART SUPPLIES” that actually contains a flammableliquid is not acceptable, even if the liquid is technically an art supply likepaint thinner. The potential danger of the liquid’s flammability must beidentified through the proper external markings required by 49 CFR andDMM C023.5-2.3 Extraneous MarkingsExtraneous in<strong>for</strong>mation (such as order numbers) that can be confused withZIP Codes may not be printed immediately under the last line of the address.<strong>Publication</strong> 2, January 200221

5-2.4 Marking5-2.4 Other MarkingsIf other markings are used, such as advertising messages and <strong>com</strong>panylogos, they must be placed in areas that do not conflict with the essentialin<strong>for</strong>mation areas described in 5-1.5-3 Marking Methods and Surfaces5-3.1 Marking MethodsAny required address, marking, or endorsement placed on the outside of amailing container should be made with a waterproof material that cannot berubbed off or smeared. The lettering must be sharp and readable at adistance of 30 inches.5-3.2 SurfacesMarking methods and container surfaces must allow application and retentionof adhesive stamps, postage meter impressions, and postal endorsementsmade by hand stamp, ballpoint pen, or number 2 pencil. Address labels and,particularly, outside envelopes must be firmly sealed and attached tocontainers, with no more than 1/8-inch separation between the ends of theenvelope and the container.A container that does not meet these marking requirements and has causedprevious mail processing problems is not acceptable <strong>for</strong> mailing.22 <strong>Publication</strong> 2, January 2002

Bulk Mail Center Standards6-2.1.36 Bulk Mail Center Standards6-1 About This ChapterThe standards in this chapter apply to mailpieces of any class that areprocessed individually at a bulk mail center (BMC) in the bulk mail system.For alternatives to these standards, mailers should follow the procedures <strong>for</strong>testing packaging in 1-5.6-2 Books6-2.1 General6-2.1.1 Definition of BookFor packaging purposes only, a book is defined as a printed item with24 pages or more, fastened together along one edge between hardbackcovers, paperback covers, or self-covers. All catalogs and similar printedmaterial that meet this definition may be packaged as books.6-2.1.2 ContainersA fiberboard box of the right size and grade isgenerally the best type of container <strong>for</strong> mailingbooks. If a book is lighter than 1 pound andthinner than 1 inch, it may be mailed in aletter-style envelope. If the book is heavierthan 1 pound or thicker than 1 inch, theenvelope must be a stronger type, asdefined in 2-5.6-2.1.3 Causes of DamageA mailing of books or catalogs can be<strong>com</strong>edamaged principally <strong>for</strong> the following reasons: The outer container collapses or falls apartbecause the closure, rein<strong>for</strong>cement, or sizeand strength of the container are insufficient.<strong>Publication</strong> 2, January 200223

6-2.2 Bulk Mail Center StandardsThe contents shift within the mailing container in transit becausebracing or internal packaging is inadequate.To prevent shifting of the contents or damage to the contents and mailingcontainer, empty spaces in a container holding books must be filled withcushioning material.6-2.2 Books up to 5 Pounds6-2.2.1 PackingA mailing of books weighing up to 5 pounds must be packed in a close-fittingpaperboard or fiberboard box, padded or rein<strong>for</strong>ced bag (with an exterior plyof at least 60-pound basis weight), or paper wraps (corrugated or of at least60-pound basis weight). The mailing container should be at least 1/4 inchthick. For a paperboard mailing container, the books inside should supportthe container and should fit snugly enough to restrict any lateral shift to nomore than 1/2 inch.For a mailing of paperback books weighing up to 3 pounds, shrinkwrap maybe used as the only packaging method. Shrinkwrap should have a coefficientof friction (ability to slide on a smooth, hard surface) between 0.025 and0.040 on metal surfaces at 20- to 25-degree elevations. Shrinkwrap is notacceptable as the only packaging method <strong>for</strong> hardback books thicker than1 inch or heavier than 1 pound.6-2.2.2 ClosingThe mailing container must be closed with multiple friction closures (theinsertion of more than one flap or tab), staples or steel stitching (<strong>com</strong>pletelyclinched to avoid injuries in handling), heat sealing, adhesive, tape, ornonmetallic banding. Shrinkwrap may be used on the exterior of an otherwiseproperly closed container.6-2.3 Books From 5 to 10 Pounds6-2.3.1 PackingA mailing of books weighing from 5 to10 pounds must be packed in at least a175-pound test fiberboard box (orequivalent). It is a good idea to use abuffer above and below the books toprotect them in case the box is openedwith a sharp instrument.6-2.3.2 ClosingThe mailing container must be closed with adhesive, rein<strong>for</strong>ced tape, or firmlyapplied nonmetallic banding. For nonmetallic banding to be acceptable, thebands must be tight enough to depress the edges of the container, as24 <strong>Publication</strong> 2, January 2002

Bulk Mail Center Standards6-2.6.1illustrated in 4-3. Rein<strong>for</strong>ced tape or nonmetallic banding is adequate both toclose and to rein<strong>for</strong>ce the container.6-2.4 Books From 10 to 25 Pounds6-2.4.1 PackingA mailing of books weighing from 10 to 25 pounds must be packed in at leasta 200-pound test fiberboard box (or equivalent).6-2.4.2 ClosingThe mailing container must be closed with adhesive, rein<strong>for</strong>ced paper tape,rein<strong>for</strong>ced plastic tape, pressure-sensitive filament tape, or firmly appliednonmetallic banding. For nonmetallic banding to be acceptable, the bandsmust be tight enough to depress the edges of the container.The container should be banded or rein<strong>for</strong>ced in the direction providing themost support. For this purpose, rein<strong>for</strong>ced paper tape, rein<strong>for</strong>ced plastic tape,pressure-sensitive filament tape, or firmly applied nonmetallic banding shouldbe used. Rein<strong>for</strong>ced tape or nonmetallic banding is adequate both to closeand to rein<strong>for</strong>ce the container.6-2.5 Books From 25 to 50 Pounds6-2.5.1 PackingA mailing of books weighing from 25 to 50 pounds must be packed asfollows: <strong>for</strong> hardback books, in at least a 275-pound test fiberboard box (orequivalent); <strong>for</strong> paperback books, in at least a 200-pound test fiberboard box(or equivalent).6-2.5.2 ClosingThe mailing container must be closed with adhesive, rein<strong>for</strong>ced paper tape,rein<strong>for</strong>ced plastic tape, pressure-sensitive filament tape, or firmly appliednonmetallic banding. For nonmetallic banding to be acceptable, the bandsmust be tight enough to depress the edges of the container.The container should be banded or rein<strong>for</strong>ced at two points to provide themost support. For this purpose, rein<strong>for</strong>ced paper tape, rein<strong>for</strong>ced plastic tape,pressure-sensitive filament tape, or firmly applied nonmetallic banding shouldbe used.6-2.6 Books From 50 to 70 Pounds6-2.6.1 PackingA mailing of books weighing from 50 to 70 pounds must be packed asfollows: <strong>for</strong> hardback books, in at least a 350-pound test fiberboard box (orequivalent); <strong>for</strong> paperback books, in at least a 275-pound test fiberboard box(or equivalent).<strong>Publication</strong> 2, January 200225

6-2.6.2 Bulk Mail Center Standards6-2.6.2 ClosingThe mailing container must be closed with adhesive, rein<strong>for</strong>ced paper tape,rein<strong>for</strong>ced plastic tape, pressure-sensitive filament tape, or firmly appliednonmetallic banding. For nonmetallic banding to be acceptable, the bandsmust be tight enough to depress the edges of the container.The container should be banded or rein<strong>for</strong>ced at two points to provide themost support. For this purpose, rein<strong>for</strong>ced paper tape, rein<strong>for</strong>ced plastic tape,pressure-sensitive filament tape, or firmly applied nonmetallic banding shouldbe used.6-3 High-Density Items6-3.1 GeneralHigh-density items are solid objects whose weightis <strong>com</strong>paratively high <strong>for</strong> their volume. Examplesinclude tools, hardware, machine and auto parts,and other metal or heavy items (but not books).A mailing of high-density items weighing between15 and 35 pounds is usually machinable on<strong>Postal</strong> Service mail processing equipment if thecontents exert no more than 60 pounds of pressure persquare foot (0.4167 pound per square inch) on thesmallest side of the container.A container packed with high-density items often be<strong>com</strong>es damaged <strong>for</strong> tworeasons:The blocking, bracing, or cushioning inside the container is inadequateto prevent shifting of the items.The container, the closure, or the rein<strong>for</strong>cement outside the container isinsufficient to withstand normal mail processing.6-3.2 High-Density Items up to 20 Pounds6-3.2.1 PackingA mailing of high-density items weighing up to 20 pounds must be packed inat least a 200-pound test fiberboard box or an equivalent wood, metal, orplastic container. A hard nonfiberboard container should be prepared so thatits coefficient of friction is similar to that of a domestic-class fiberboard box ofthe same size and weight.Internal blocking and bracing must be used as required (methods includeinterior containers, cut <strong>for</strong>ms, partitions, dunnage, and liners). The mailingcontainer must maintain its integrity without damage to its contents if droppedonce from a height of 3 feet on its smallest side onto a solid surface.26 <strong>Publication</strong> 2, January 2002

Bulk Mail Center Standards6-3.4.26-3.2.2 ClosingThe mailing container must be securely closed with staples, heat sealing,adhesive, or tape. A container without inner packing or a container with loosematerial should be rein<strong>for</strong>ced with rein<strong>for</strong>ced paper or plastic tape,pressure-sensitive filament tape, or firmly applied nonmetallic banding.6-3.3 High-Density Items From 20 to 45 Pounds6-3.3.1 PackingA mailing of high-density items weighing from 20 to 45 pounds must bepacked in at least a 200-pound test fiberboard box or an equivalent wood,metal, or plastic container. A hard nonfiberboard container must be preparedso that its coefficient of friction is similar to that of a domestic-class fiberboardbox of the same size and weight.Internal blocking and bracing must be used as required (methods includeinterior containers, cut <strong>for</strong>ms, partitions, dunnage, and liners). The mailingcontainer must maintain its integrity without damage to its contents if droppedonce from a height of 3 feet on its smallest side onto a solid surface.6-3.3.2 ClosingThe mailing container must be securely closed with staples, heat sealing,adhesive, or tape. A container without inner packing or a container with loosematerial should be rein<strong>for</strong>ced with pressure-sensitive filament tape or firmlyapplied nonmetallic banding.6-3.4 High-Density Items From 45 to 70 Pounds6-3.4.1 PackingA mailing of high-density items weighing from 45 to 70 pounds must bepacked in at least a 275-pound test fiberboard box or an equivalent wood,metal, or plastic container. A hard nonfiberboard container must be preparedso that its coefficient of friction is similar to that of a domestic-class fiberboardbox of the same size and weight.Internal blocking and bracing must be used as required (methods includeinterior containers, cut <strong>for</strong>ms, partitions, dunnage, and liners). The mailingcontainer must maintain its integrity without damage to its contents if droppedonce from a height of 3 feet on its smallest side onto a solid surface.6-3.4.2 ClosingThe mailing container must be securely closed with staples, heat sealing,adhesive, or tape. A container without inner packing or a container with loosematerial should be rein<strong>for</strong>ced with pressure-sensitive filament tape or tightnonmetallic banding.<strong>Publication</strong> 2, January 200227

6-4 Bulk Mail Center Standards6-4 Soft Goods6-4.1 GeneralSoft goods include textile items like clothing; sheets, blankets, pillows, andpillow cases; draperies; and cloth and fabric. Containers <strong>for</strong> these items canbe badly damaged if they are inadequately closed or cannot withstandpuncture, friction, or <strong>com</strong>pression during normal handling.6-4.2 Soft Goods up to 5 Pounds6-4.2.1 PackingA mailing of soft goods weighing up to 5 pounds should be packed in a clothbag, a paper bag, paper wraps (with an exterior ply of atleast 50-pound basis weight), a plastic bag (atleast 2-mil-thick polyethylene or equivalent),or a paperboard or fiberboard box. If abox is used, it must be filled to capacity.If a paper bag, plastic bag, or paper wraps areused, the container should be vented so it will not burst if <strong>com</strong>pressed quickly.6-4.2.2 ClosingA bag should be closed with heat sealing, adhesive, sewing, tape, or<strong>com</strong>pletely clinched staples. Improperly clinched staples must be removed toprevent injury to <strong>Postal</strong> Service employees or damage to other mail or mailprocessing equipment.A box should be closed with staples, adhesive, heat sealing, nonmetallicbanding, or tape. Paper or plastic tape should be applied along all box flapsand closure seams. Although shrinkwrap is not acceptable as the only meansof packaging, it may be used on the exterior of an otherwise properly closedbox. When a box weighs less than 5 pounds (or its density is less than 4 poundsper cubic foot), it should be rein<strong>for</strong>ced in at least two of the longest directions.6-4.3 Soft Goods From 5 to 10 Pounds6-4.3.1 PackingA mailing of soft goods weighing from 5 to 10 pounds should be packed in acloth bag, a paper bag, a filament-rein<strong>for</strong>ced paper bag, a fiberboard box,paper wraps (with an exterior ply of at least 70-pound basis weight), or aplastic bag (at least 4-mil-thick polyethylene or equivalent).6-4.3.2 ClosingA bag should be closed with heat sealing, adhesive, sewing, tape, or<strong>com</strong>pletely clinched staples. Improperly clinched staples must be removed to28 <strong>Publication</strong> 2, January 2002

Bulk Mail Center Standards6-4.6.1prevent injury to <strong>Postal</strong> Service employees or damage to other mail or mailprocessing equipment.A box should be closed withstaples, adhesive, heat sealing,nonmetallic banding, or tape.Paper or plastic tape should beapplied along all box flaps and closureseams. Although shrink-wrap is notacceptable as the only means of packaging,it may be used on the exterior of an otherwiseproperly closed box. Rein<strong>for</strong>ced tape is adequateboth to close and rein<strong>for</strong>ce the container.6-4.4 Soft Goods From 10 to 20 Pounds6-4.4.1 PackingA mailing of soft goods weighing from 10 to 20 pounds should be packed in apaper bag, paper wraps (with an exterior ply of at least 70-pound basisweight), a rein<strong>for</strong>ced paper or cloth bag, or a 175-pound test fiberboard (orstronger) box.6-4.4.2 ClosingThe mailing container should be closed with staples, adhesive, rein<strong>for</strong>cedpaper tape, or equally strong plastic tape. The container should be optimallyrein<strong>for</strong>ced with pressure-sensitive filament tape or tight nonmetallic banding.Rein<strong>for</strong>ced tape is adequate both to close and rein<strong>for</strong>ce the container.6-4.5 Soft Goods From 20 to 45 Pounds6-4.5.1 PackingA mailing of soft goods weighing from 20 to 45 pounds should be packed in apaper bag, paper wraps (with an exterior ply of at least 70-pound basisweight), a rein<strong>for</strong>ced paper or cloth bag, or a 200-pound test fiberboard (orstronger) box.6-4.5.2 ClosingThe mailing container should be closed with staples, adhesive, rein<strong>for</strong>cedpaper tape, or equally strong plastic tape. The container should be rein<strong>for</strong>cedwith rein<strong>for</strong>ced paper or plastic tape, pressure-sensitive filament tape, or tightnonmetallic banding.6-4.6 Soft Goods From 45 to 70 Pounds6-4.6.1 PackingA mailing of soft goods weighing from 45 to 70 pounds should be packed in apaper bag, paper wraps (with an exterior ply of at least 70-pound basis<strong>Publication</strong> 2, January 200229

6-4.6.2 Bulk Mail Center Standardsweight), a rein<strong>for</strong>ced paper or cloth bag, or a 275-pound test fiberboard (orstronger) box.6-4.6.2 ClosingThe mailing container should be closed with staples, adhesive, rein<strong>for</strong>cedpaper tape, or equally strong plastic tape. The container should be rein<strong>for</strong>cedwith rein<strong>for</strong>ced paper or plastic tape, pressure-sensitive filament tape, or tightnonmetallic banding.6-5 Sound Recordings6-5.1 GeneralSound recordings, <strong>for</strong> the purpose of packaging only, are plastic,nonbreakable disc-type records (normally 33-1/3, 45, or 78 RPM) or <strong>com</strong>pactdisks normally used with home and auto sound-reproducing equipment. Formagnetic tapes and cassette tapes, see 6-6.6-5.2 Sound Recordings up to 10 Pounds6-5.2.1 PackingA mailing of sound recordings (in paper sleeves, paperboard, or chipboardshells) weighing up to 10 pounds must be packed in at least one other shell(paperboard, chipboard, or plastic) in an outer corrugated fiberboardcontainer.6-5.2.2 ClosingThe outer mailing container must be securely closed with adhesive, kraftpaper tape, equivalent plastic tape, or staples.6-5.3 Sound Recordings From 10 to 20 Pounds6-5.3.1 PackingA mailing of sound recordings (in paper sleeves, paperboard, or chipboardshells) weighing from 10 to 20 pounds must be packed in at least one othershell (paperboard, chipboard, or plastic) in an outer corrugated fiberboardcontainer.6-5.3.2 ClosingThe outer mailing container must be securely closed with adhesive, kraftpaper tape, equivalent plastic tape, or staples. It should then be rein<strong>for</strong>ced inat least one direction with rein<strong>for</strong>ced paper tape, rein<strong>for</strong>ced plastic tape,pressure-sensitive filament tape, or firmly applied nonmetallic banding.Rein<strong>for</strong>ced tape is adequate both to close and rein<strong>for</strong>ce the outer container.30 <strong>Publication</strong> 2, January 2002

Bulk Mail Center Standards6-6.2.16-5.4 Sound Recordings From 20 to 40 Pounds6-5.4.1 PackingA mailing of sound recordings (in paper sleeves, paperboard, or chipboardshells) weighing from 20 to 40 pounds must be packed in at least one othershell (paperboard, chipboard, or plastic) in at least a 175-pound testfiberboard outer box (or equivalent).6-5.4.2 ClosingThe outer mailing container must be securely closed with adhesive, kraftpaper tape, equivalent plastic tape, or staples. It should also be rein<strong>for</strong>ced attwo points with pressure-sensitive filament tape or firmly applied nonmetallicbanding. Rein<strong>for</strong>ced tape is adequate both to close and rein<strong>for</strong>ce the outercontainer.6-5.5 Sound Recordings From 40 to 70 Pounds6-5.5.1 PackingA mailing of sound recordings (in paper sleeves, paperboard, or chipboardshells) weighing from 40 to 65 pounds must be packed in at least one othershell (paperboard, chipboard, or plastic) in at least a 200-pound testfiberboard outer box (or equivalent). A mailing weighing from 65 to 70 poundsmust be packed in multiple shells in at least a 275-pound test fiberboard box(or equivalent).6-5.5.2 ClosingThe outer mailing container must be securely closed with adhesive, kraftpaper tape, equivalent plastic tape, or staples. In addition, the outer containermust be rein<strong>for</strong>ced at about 8-inch intervals on all sides around the container.Rein<strong>for</strong>ced tape is adequate both to close and rein<strong>for</strong>ce the outer container.6-6 Magnetic Tapes6-6.1 GeneralMagnetic tapes, cassette tapes, and cartridges present special problemswhen their mailing containers (especially <strong>for</strong> small quantities) orrein<strong>for</strong>cement (<strong>for</strong> large quantities) are inadequate.6-6.2 Magnetic Tapes up to 5 Pounds6-6.2.1 PackingFor a single tape, the tape must be packed in a plastic film wrap of at least0.75 mil, in a cushioned bag, or in a cushioned paper bag of at least<strong>Publication</strong> 2, January 200231

6-6.2.2 Bulk Mail Center Standards60-pound basis weight. Multiple tapes up to 5 pounds must be packed in anouter container of fiberboard or chipboard at least 22 mils thick.6-6.2.2 ClosingThe outer mailing container must be securely closed with tape, heat sealing,adhesive, <strong>com</strong>pletely clinched staples, or a multiple friction closure (two ormore flaps or tabs). Paper tape must be of at least 60-pound basis weightkraft. Shrinkwrap may be used on the outside of an otherwise properly closedbox. Rein<strong>for</strong>ced tape is adequate both to close and rein<strong>for</strong>ce the outercontainer.6-6.3 Magnetic Tapes From 5 to 10 Pounds6-6.3.1 PackingA mailing of tapes weighing from 5 to 10 pounds must be packed in an outercontainer of fiberboard or chipboard at least 22 mils thick. Tapes should bepacked in multiple shells <strong>for</strong> additional protection.6-6.3.2 ClosingThe outer mailing container must be securely closed with tape, adhesive, or<strong>com</strong>pletely clinched staples. Paper tape must be of at least 60-pound basisweight kraft. An otherwise properly closed box may be shrinkwrapped.Rein<strong>for</strong>ced tape is adequate both to close and rein<strong>for</strong>ce the outer container.Tapes should be packed in multiple shells <strong>for</strong> additional protection.6-6.4 Magnetic Tapes From 10 to 20 Pounds6-6.4.1 PackingA mailing of tapes weighing from 10 to 20 pounds must be packed in an outercontainer of fiberboard or chipboard at least 22 mils thick.6-6.4.2 ClosingThe outer mailing container must be securely closed with tape, adhesive, or<strong>com</strong>pletely clinched staples. Paper tape must be of at least 60-pound basisweight kraft. The container should be rein<strong>for</strong>ced in a direction that providesthe most support with rein<strong>for</strong>ced paper or plastic tape, pressure-sensitivefilament tape, or tight nonmetallic banding. Rein<strong>for</strong>ced tape is adequate bothto close and rein<strong>for</strong>ce the box. An otherwise properly closed box may beshrinkwrapped.6-6.5 Magnetic Tapes From 20 to 40 Pounds6-6.5.1 PackingA mailing of tapes weighing from 20 to 40 pounds must be packed in at leasta 175-pound test fiberboard box (or equivalent). Tapes should be packed inmultiple shells <strong>for</strong> additional protection.32 <strong>Publication</strong> 2, January 2002

Bulk Mail Center Standards6-6.6.26-6.5.2 ClosingThe outer mailing container must be securely closed with tape, adhesive, or<strong>com</strong>pletely clinched staples. Paper tape must be of at least 60-pound basisweight kraft. The container must be rein<strong>for</strong>ced at two points with rein<strong>for</strong>cedpaper or plastic tape, pressure-sensitive filament tape, or tight nonmetallicbanding. An otherwise properly closed box may be shrinkwrapped.6-6.6 Magnetic Tapes From 40 to 70 Pounds6-6.6.1 PackingA mailing of tapes weighing from 40 to 65 pounds must be packed in at leasta 200-pound test fiberboard box (or equivalent). A mailing weighing from65 to 70 pounds must be packed in at least a 275-pound test fiberboardbox (or equivalent). Multiple shells should be used <strong>for</strong> greater protection.6-6.6.2 ClosingThe outer mailing container must be securely closed with tape, adhesive, or<strong>com</strong>pletely clinched staples. Paper tape must be of at least 60-pound basisweight kraft. An otherwise properly closed box may be shrinkwrapped. Thecontainer must be rein<strong>for</strong>ced at two points with rein<strong>for</strong>ced paper or plastictape, pressure-sensitive filament tape, or tight nonmetallic banding.<strong>Publication</strong> 2, January 200233

Bulk Mail Center StandardsThis page intentionally left blank34 <strong>Publication</strong> 2, January 2002

Hazardous Materials7-2.17 Hazardous Materials7-1 General7-1.1 DefinitionA hazardous material (referred to as a “dangerous good” in international<strong>com</strong>merce) is any article or substance having a clear potential <strong>for</strong> causingharm to the mail or to persons or property involved in moving the mail.7-1.2 Federal LawsThe Department of Transportation (DOT) regulates all surface and aircarriage of hazardous materials within the United States via any meansof transportation. DOT regulations on hazardous materials are codified inTitle 49, Code of Federal Regulations (49 CFR), parts 100–185.Mailers are reminded that it is a federal crime, punishable by fines andimprisonment, to place in the mails any “natural or artificial articles,<strong>com</strong>positions, or material which may kill or injure another, or injure the mailsor other property ....” (18 U.S.C. 1716(a)). This statute allows the <strong>Postal</strong>Service to permit the mailing of some injurious articles under regulationsprescribing conditions of preparation and packaging (18 U.S.C. 1716(b)).For more specific in<strong>for</strong>mation, see DMM C020 and C023 and <strong>Publication</strong> 52,Hazardous, Restricted, and Perishable Mail.7-2 <strong>Mailing</strong> Conditions7-2.1 <strong>Postal</strong> RegulationsThe <strong>Postal</strong> Service accepts <strong>for</strong> mailing a very small number of certainpotentially hazardous materials that are not outwardly or of their own <strong>for</strong>cedangerous or injurious to life, health, or property. Generally, this is limited toORM-D materials that are hazardous materials presenting the lowest level ofrisk during transportation. The conditions of preparation and packaging underwhich such materials are accepted are explained in the DMM and in<strong>Publication</strong> 52. Conditions applicable to mailings of hazardous materials to<strong>for</strong>eign addresses are explained in the IMM.<strong>Publication</strong> 2, January 200235

7-2.2 Hazardous Materials7-2.2 Mailability Rulings<strong>Postal</strong> standards <strong>for</strong> hazardous materials closely adhere to 49 CFR and veryoften include additional restrictions and prohibitions. Generally, theacceptability of chemicals and other types of hazardous materials <strong>for</strong> mailingdepends on container fluid/vapor capacities, the ability of the <strong>com</strong>pletepackage to contain the product, and the method of absorbing and containingthe product in case the primary container accidentally leaks. To determinemailability of a specific product, a mailer must submit a material safety datasheet (MSDS) and the following in<strong>for</strong>mation to the RCSC serving the mailer’slocation:Name of material, hazard class, and assigned UN or NA identificationnumber.Chemical <strong>com</strong>position by percentage of ingredient.Flashpoint.Toxic properties.7-2.3 <strong>Packaging</strong>Effect of material when it is inhaled or swallowed or when it <strong>com</strong>es incontact with eyes or skin.Special precautions necessary to permit handling without harm to<strong>USPS</strong> employees or damage to property or other mail.Explanation of warning labels and shipping papers required by state orfederal regulations.Proposed packaging method, including addressing and requiredmarkings.To be acceptable <strong>for</strong> mailing, hazardous materials must be packaged asrequired by DMM C023 and <strong>Publication</strong> 52.36 <strong>Publication</strong> 2, January 2002